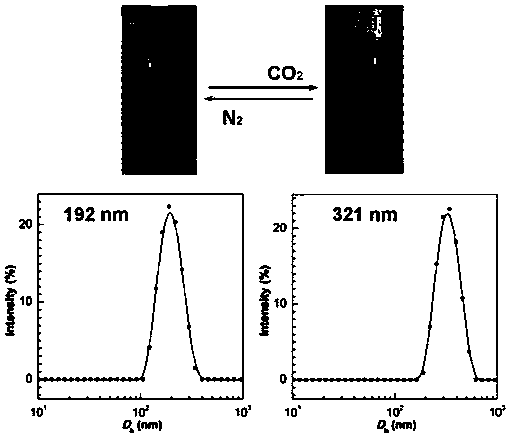

CO2 response polymer hollow microsphere and preparation method thereof

A technology of hollow microspheres and polymers, applied in the field of CO2-responsive microspheres and their preparation, can solve the problems of weakening stimulus response sensitivity, performance switchable attenuation, difficulty in removing stimulus residues, etc., achieve high yield and facilitate large-scale production , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

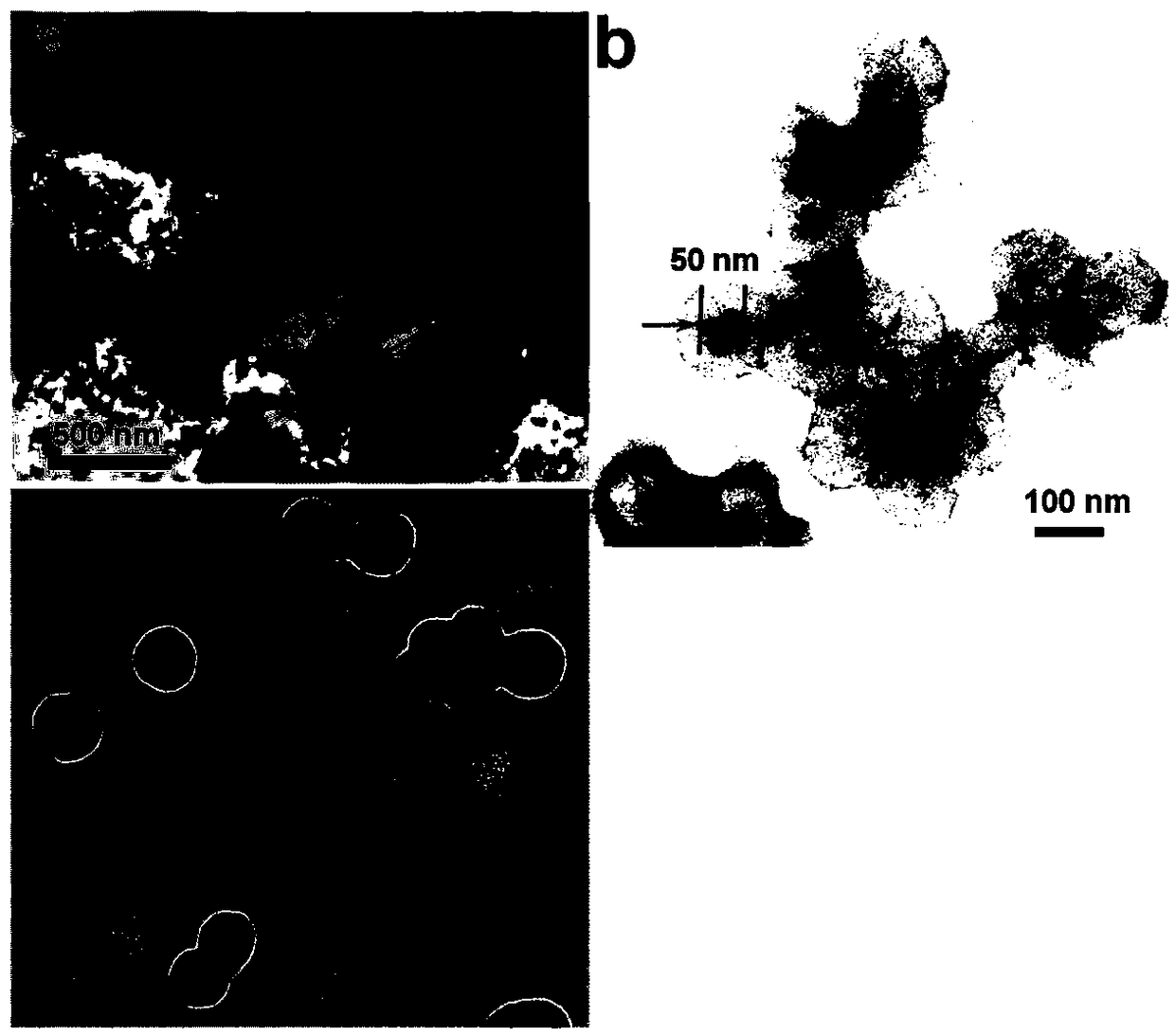

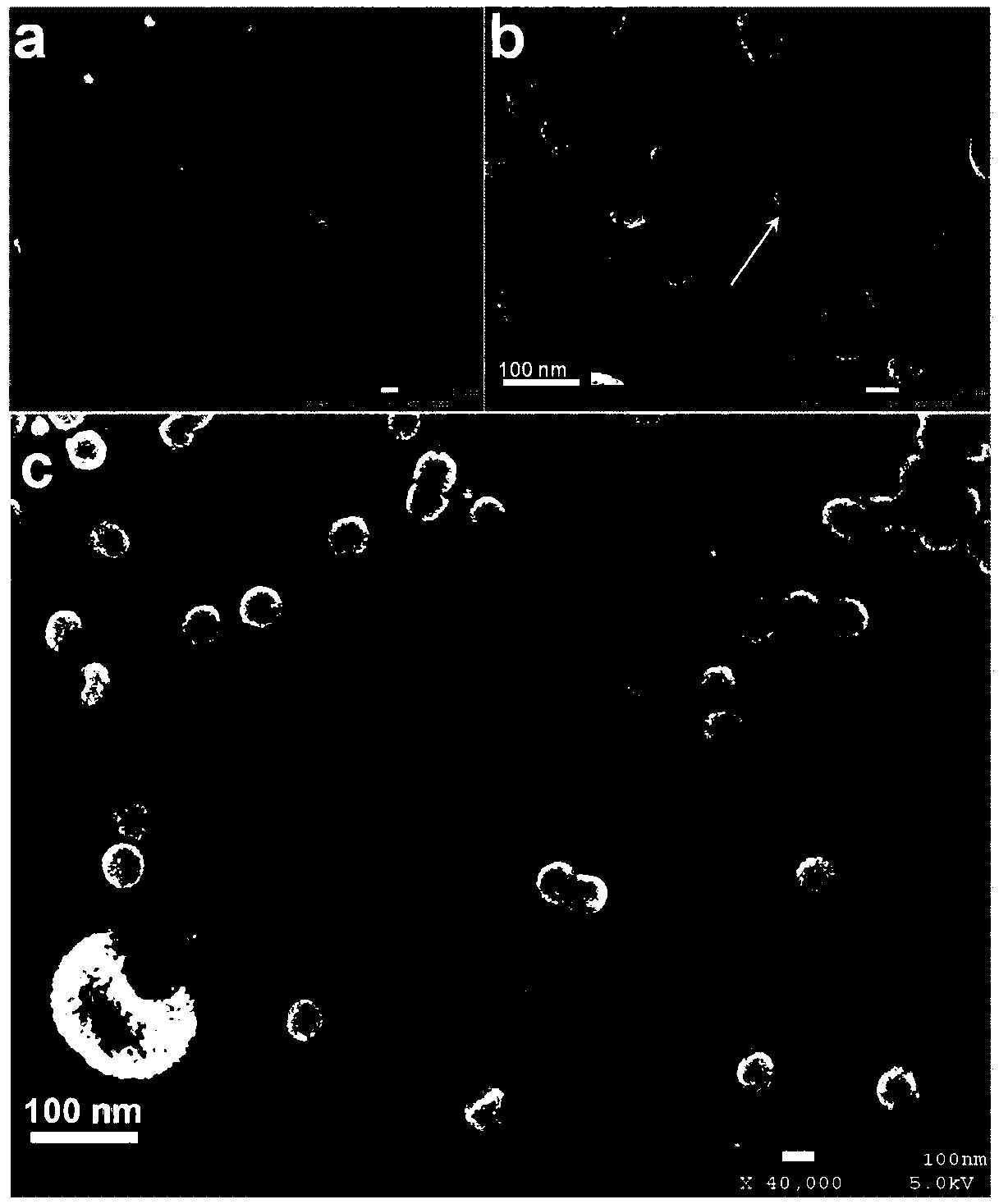

Method used

Image

Examples

Embodiment 1

[0038] (1) First transfer 2.95g of styrene (St) monomer to the dropping funnel, then dissolve 0.07g of APS in deionized water to obtain an initiator solution, and continuously pass nitrogen gas into the solution for 0.5h to remove oxygen at room temperature. 0.08 g of emulsifier SDS was dissolved in 105 g of pure water to obtain an emulsifier solution. in N 2 Under the condition of protection and 70°C, the styrene monomer and the initiator solution were simultaneously added dropwise to the emulsifier solution, and stirred for 7 hours. After the reaction, the slag was removed by filtration to obtain the seed microsphere emulsion.

[0039] (2) Stir 5.03g monomer dimethylaminoethyl methacrylate (DEAEMA) and 0.16g crosslinking agent divinylbenzene (DVB) evenly and record it as mixed monomer. 0.04g ACVA was stirred and mixed with deionized water to prepare the initiator solution. in N 2 Protect and drop the mixed monomer and initiator solution into the seed emulsion obtained in ...

Embodiment 2

[0042] (1) Transfer 2.96g of styrene (St) monomer to the dropping funnel, dissolve 0.07g of APS in deionized water to obtain an initiator solution, and continuously pass nitrogen gas into the solution for 0.5h to remove oxygen at room temperature. 0.10 g of emulsifier SDS was dissolved in 105 g of pure water to obtain an emulsifier solution. in N 2 The styrene monomer and the initiator solution were simultaneously added dropwise into the emulsifier solution under the condition of protection and 70° C., and stirred for 7 hours. After the reaction, the slag was removed by filtration to obtain the seed microsphere emulsion.

[0043] (2) Stir 5.02g monomer dimethylaminoethyl methacrylate (DEAEMA), 0.50g styrene (St) and 0.21g cross-linking agent divinylbenzene (DVB) and record it as a mixed monomer; 0.10g Stirring and mixing of APS and deionized water is recorded as the initiator solution; 2 Protect and drop the mixed monomer and initiator solution into the seed emulsion obtaine...

Embodiment 3

[0046] (1) Transfer 2.99 g of styrene (St) monomer to the dropping funnel, dissolve 0.07 g of APS in deionized water to obtain an initiator solution, and continuously pass nitrogen gas into the solution for 0.5 h to remove oxygen at room temperature. 0.10 g of emulsifier SDS was dissolved in 100 g of pure water to obtain an emulsifier solution. in N 2 The styrene monomer and the initiator solution were simultaneously added dropwise into the emulsifier solution under the condition of protection and 70° C., and stirred for 7 hours. After the reaction, the slag was removed by filtration to obtain the seed microsphere emulsion.

[0047] (2) Stir 5.04g monomer dimethylaminoethyl methacrylate (DEAEMA), 0.60g styrene (St) and 0.46g cross-linking agent divinylbenzene (DVB) evenly and record it as mixed monomer, 0.10g APS was stirred and mixed with deionized water and recorded as initiator solution. in N 2 Protect and drop the mixed monomer and initiator solution into the seed emuls...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com