Preparation method of spherical silver powder for photovoltaic positive silver electrode

A silver powder and photovoltaic technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of reduced sintering activity of silver particles, difficulty in forming silver-silicon contacts, and increased electrode wire resistance, etc., to achieve stable electrical performance, high tap density, High dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A kind of spherical silver powder (100g), its production process is as follows:

[0027] 1. Preparation of silver-containing mixed solution: take 150 grams of methylcellulose, add appropriate amount of water, and dissolve it completely; weigh 158 grams of silver nitrate and add 200 ml of water, dissolve it completely, and use ammonia water to prepare the silver nitrate solution into silver ammonia solution. Mix the above two solutions, add water to make up to 5L.

[0028] 2. Weigh 200 grams of organic reducing agent ascorbic acid, add 2 L of water to dissolve, and set aside.

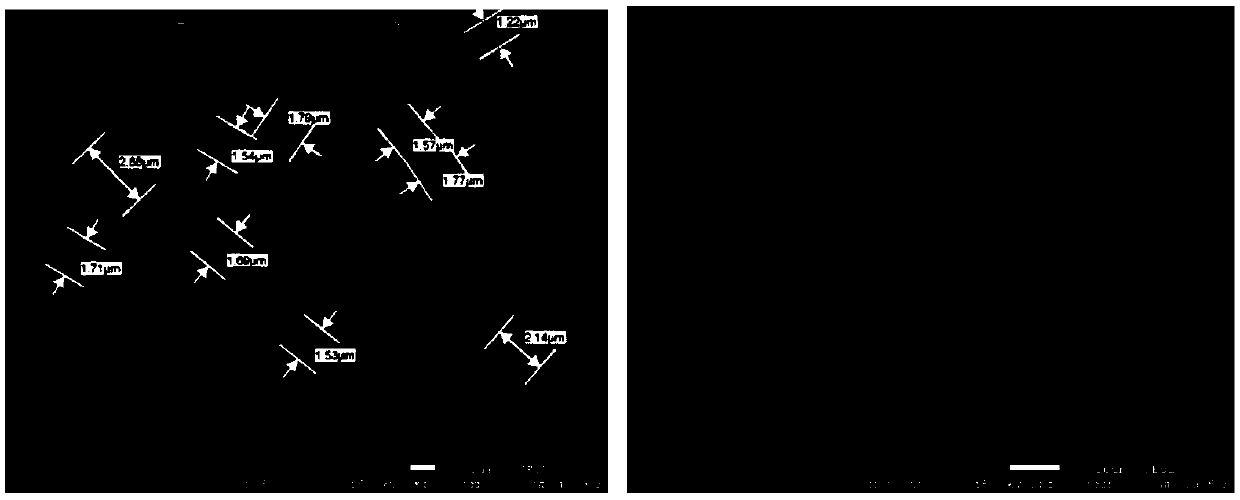

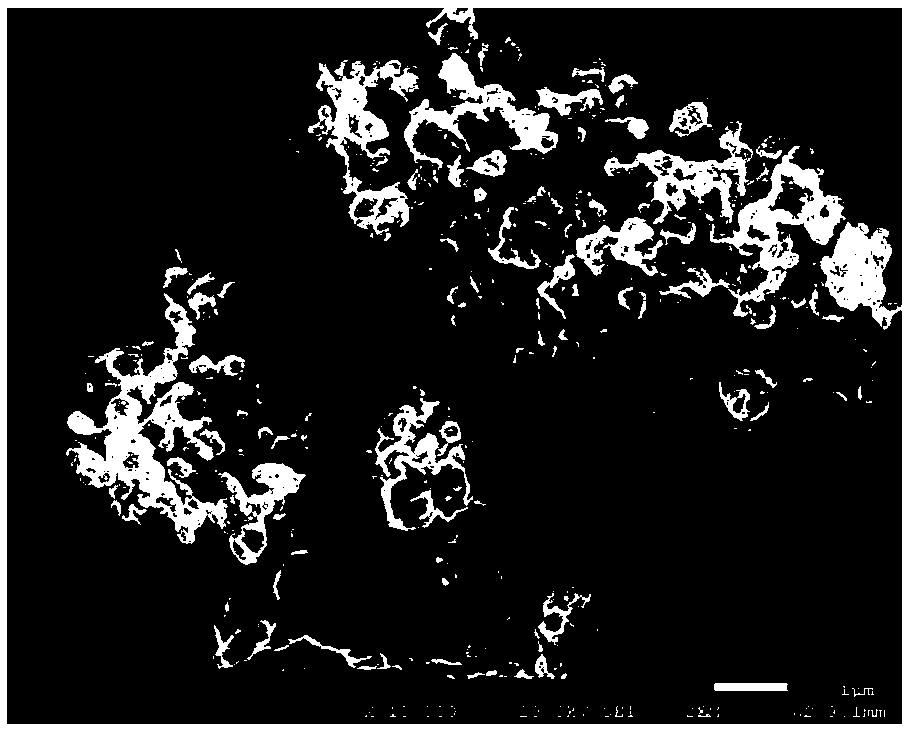

[0029] 3. Reduction: Place the silver-containing mixed solution in an ultrasonic water bath, control the temperature of the heating solution within the range of 40-60°C, pour the reducing agent solution into the silver-containing mixed solution at one time to reduce Ag+, and wait until the upper mixed solution becomes clear , Ag+ reduction is complete, and spherical silver powder is prepared.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com