Method for preparing organic nanometer rubber particle enhanced epoxy resin self-repairing microcapsule

A technology of self-healing microcapsules and epoxy resin, which is applied in the direction of microcapsule preparation and microsphere preparation, can solve problems such as poor repeatability, unstable performance, and difficulty in controlling rubber particle size, and achieve low cost, stable properties, and reduced Effect of cure shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Preparation of composite epoxy resin: 20 g of butyl glycidyl ether 501 resin (purchased from Shanghai Resin Factory) and 80 g of E-51 epoxy resin were stirred evenly, and the bubbles generated by stirring were removed by vacuuming.

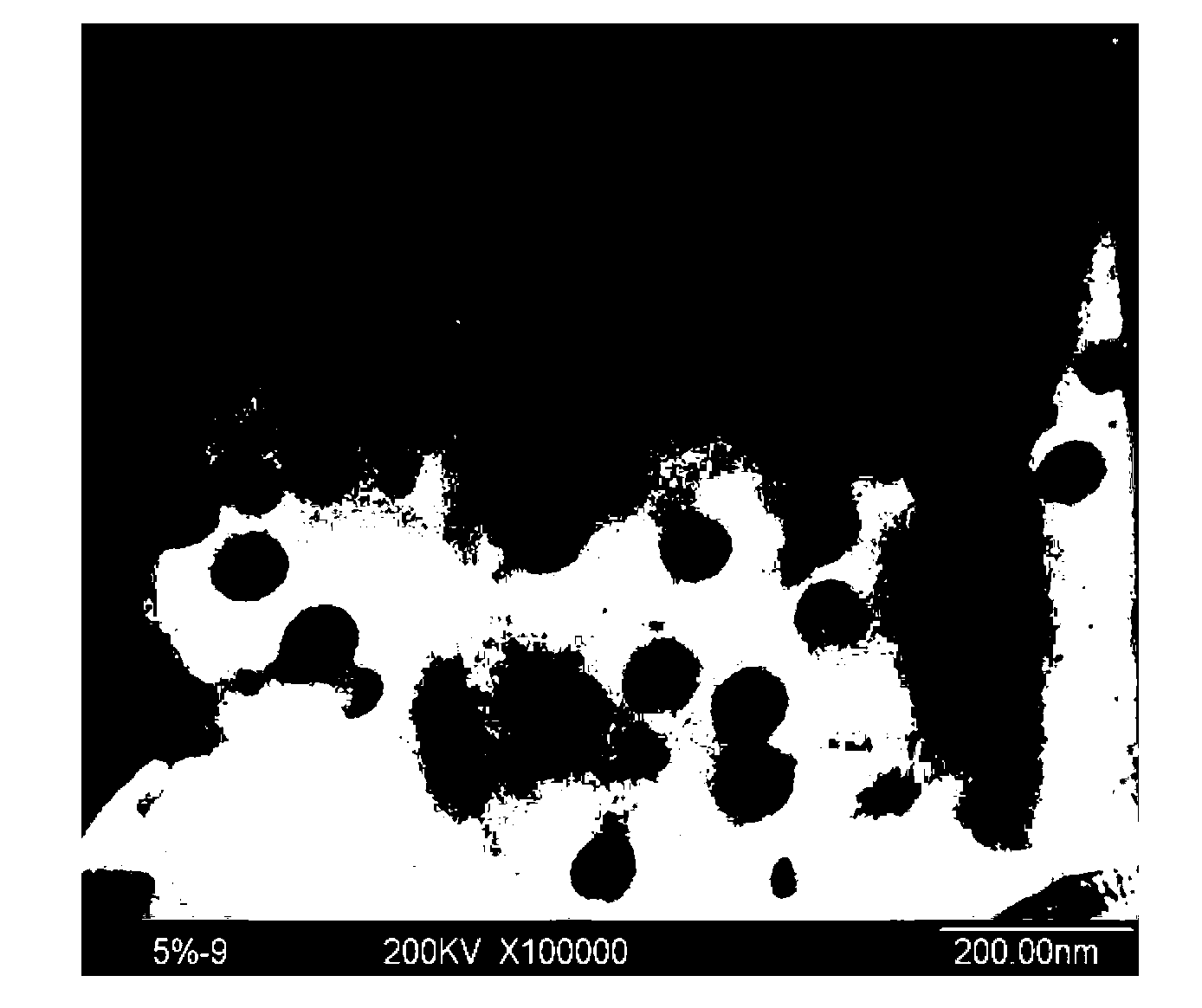

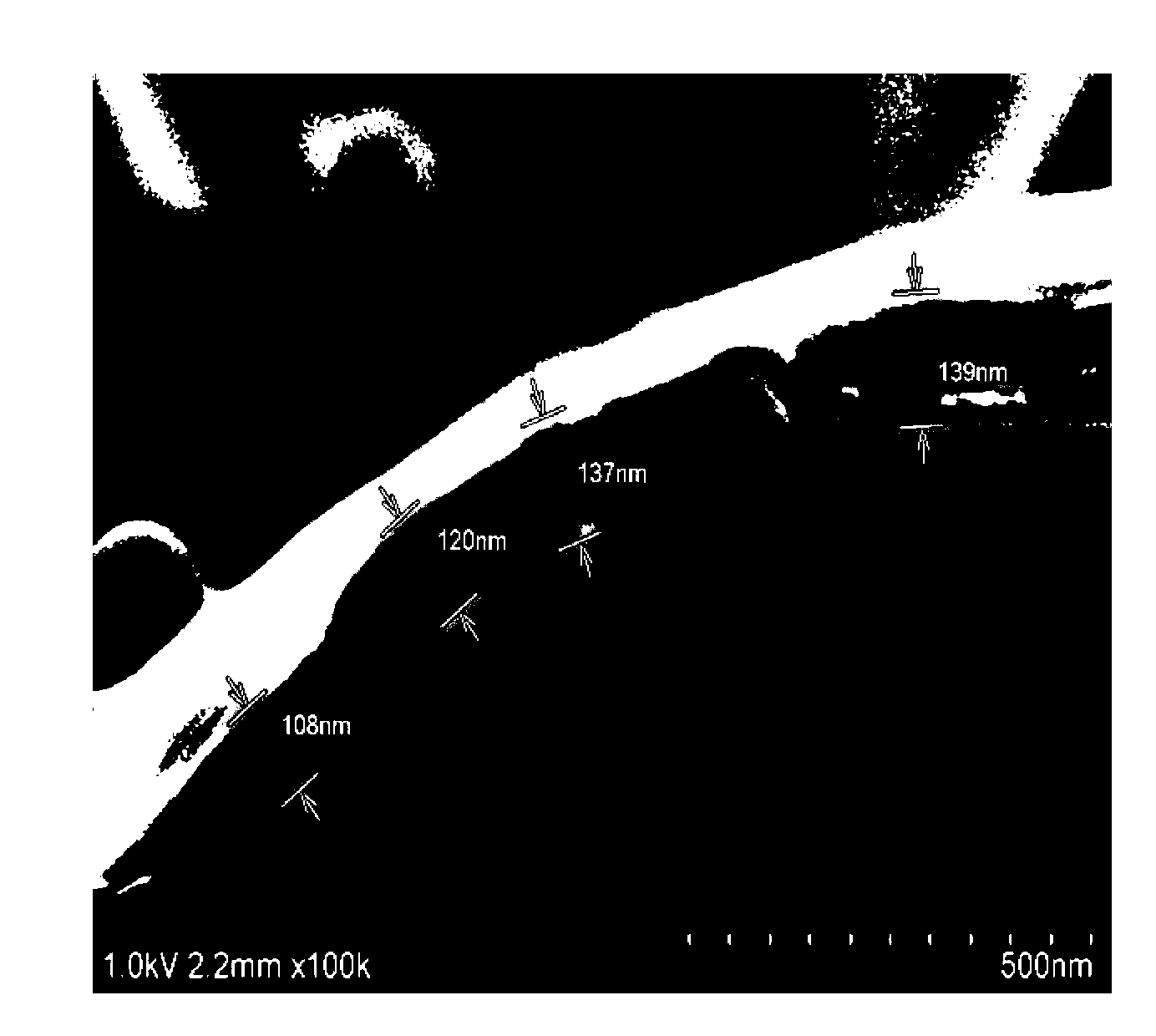

[0027] 2) Preparation of nano-phase reinforced epoxy resin: disperse carboxylated nitrile rubber VP-501 powder (purchased from Beijing Petrochemical Research Institute) of 50-100nm in 85g composite epoxy resin with a particle diameter of 15g, stir evenly, and then Scrape the obtained mixture onto the feeding roller of the three-roll mill with a copper scraper, adjust the speed ratio between the front roller, middle roller and rear roller to 1:3:9, and grind the mixture three times in sequence , the first grinding roll spacing is 10 μm, the roll speed of the front roll is 200r / min; the ground mixture is left to stand for three days, and then the second grinding is carried out, the roll spacing is 5 μm, and the roll speed of the front roll ...

Embodiment 2

[0031] 1) Preparation of composite epoxy resin: 20 g of chlorobenzene (purchased from Xilong Chemical Factory, Shantou City, Guangdong Province) and 100 g of E-51 epoxy resin were stirred evenly, and the bubbles generated by stirring were removed by vacuuming.

[0032] 2) Disperse 20g of carboxylated nitrile rubber VP-501 powder (purchased from Beijing Petrochemical Research Institute) with a particle size of 50-100nm into the above-mentioned composite epoxy resin, stir evenly, and then use a copper scraper to obtain the mixture Scrape the plate onto the feed roller of the three-roll mill, adjust the speed ratio between the front roller, middle roller and rear roller to 1:3:9, grind the mixture three times in sequence, and the distance between the rollers for the first grinding is 10 μm, the roll speed of the front roller is 200r / min; the ground mixture is left to stand for three days, and then the second grinding is carried out, the distance between the rolls is 5 μm, the roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com