Construction method for fast breaking pile head of cast-in-place pile

A construction method and cast-in-place pile technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of bending and damage of steel bars, low work efficiency, affecting construction quality and progress, etc., to achieve convenient construction and installation, and improve construction efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] A construction method for quickly removing the head of a cast-in-situ pile, comprising the following steps:

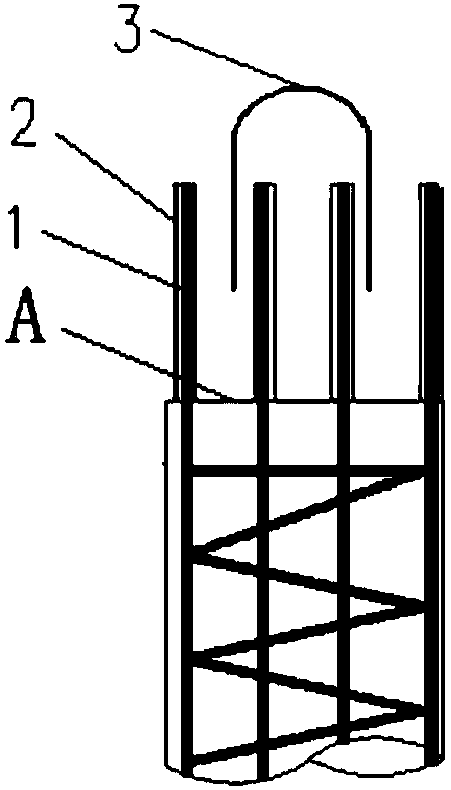

[0022] (1) if figure 1 As shown, when the reinforcement cage is processed and manufactured, the main reinforcement 1 above the pile top elevation is not bent, and the parallel state is kept; each main reinforcement is placed at the pile top elevation ( figure 1 The upper part of the middle horizontal line A) is inserted into the casing 2, and the casing is made of soft plastic pipe, and the upper and lower ends of the casing are wound and tightened with iron wires. The function is to prevent the pile head reinforcement from sticking to the poured concrete knot; the inner diameter of the casing is 3-5mm thicker than the steel bar;

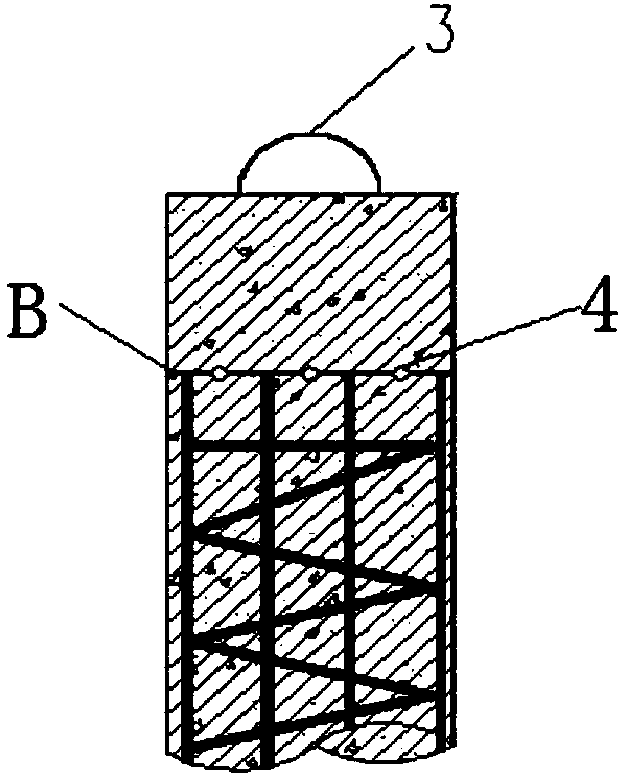

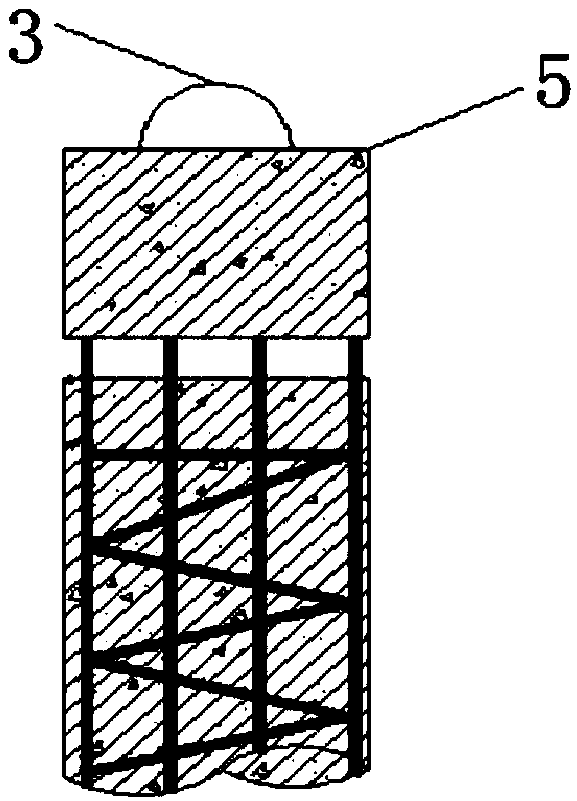

[0023] (2) Carry out pile foundation concrete pouring until it exceeds the design elevation of the pile top; figure 1 , figure 2 As shown, when pouring to the pile top elevation, the reinforcement ring 3 that meets the overall hoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com