Pipe compound optical fiber cable processing technique

A composite optical cable and processing technology, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of many construction personnel, difficult organization, and large investment in equipment, and achieve the effect of simple and reasonable process, good product quality and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

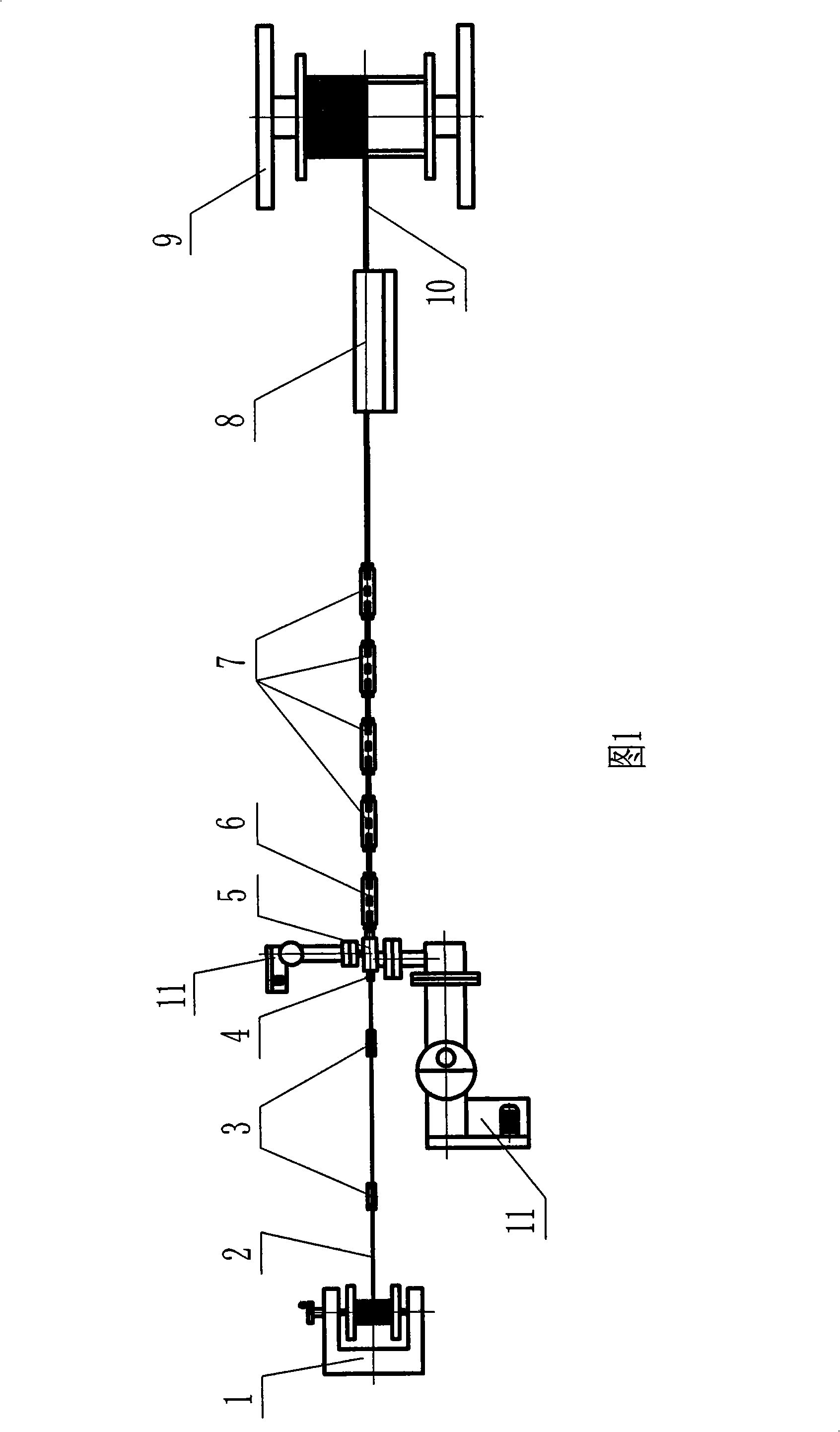

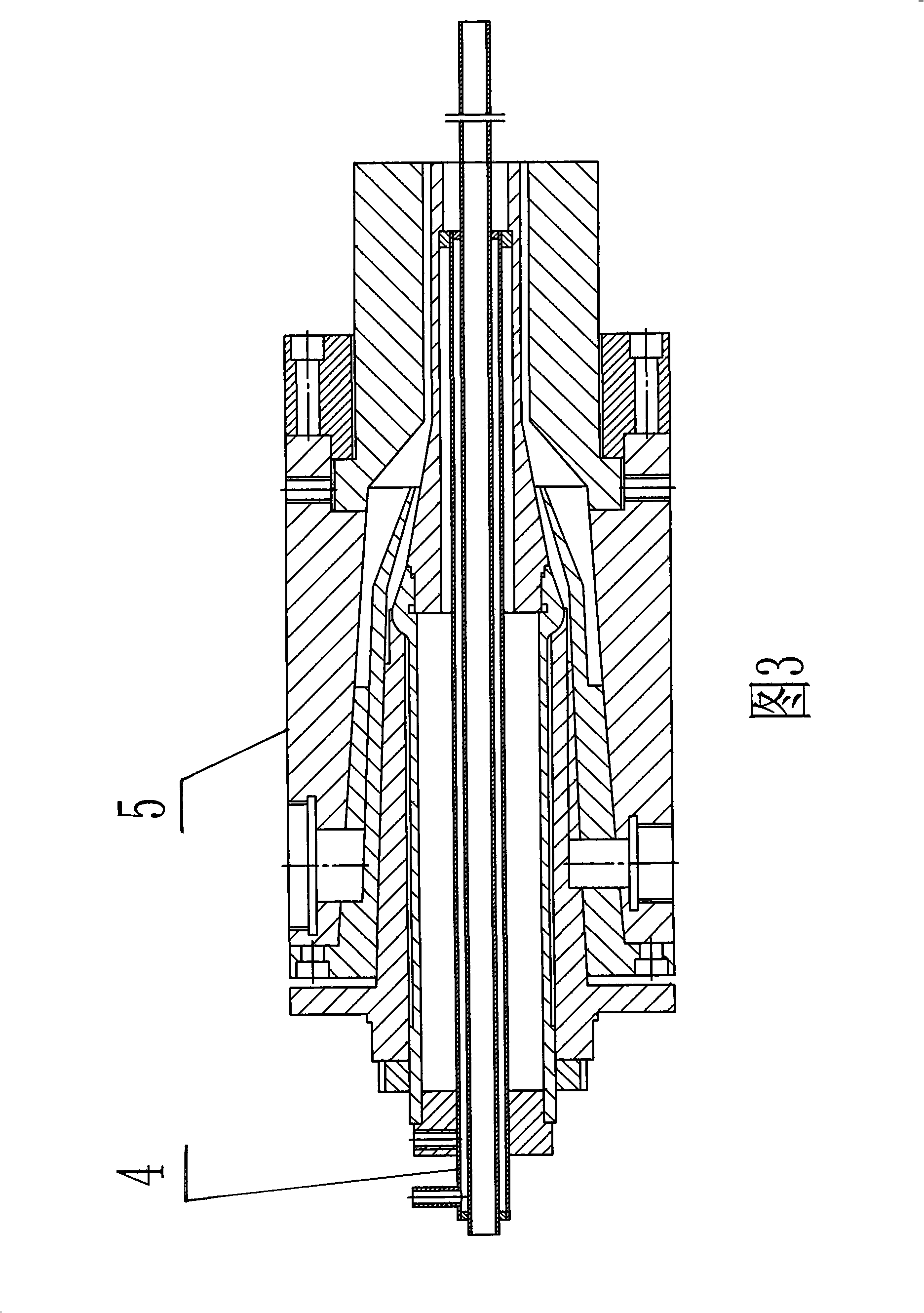

[0019] Below in conjunction with accompanying drawing, the present invention is further described as follows:

[0020] The invention provides an optical cable synchronously composited into the pipeline when the pipeline is produced, and the optical cable and the pipeline of the finished pipeline composite optical cable are in a loose state without bonding phenomenon. And the length of the product can be made into more than 4 kilometers per plate, the processing efficiency is high, the equipment structure is simple, and the processed product has a beautiful appearance. The specific processing steps are as follows:

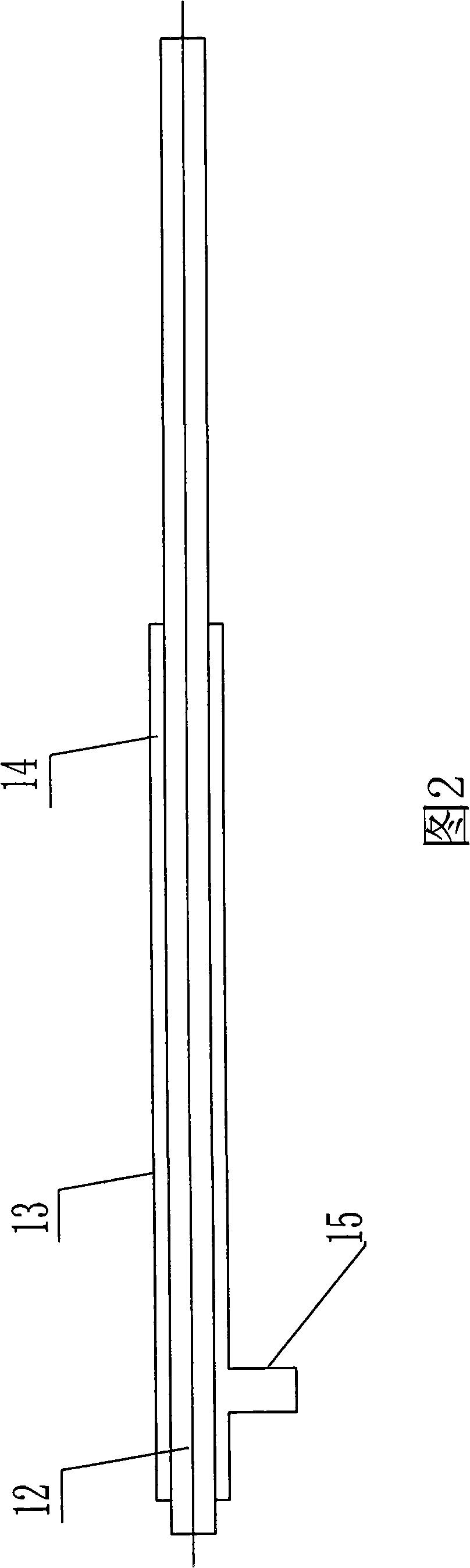

[0021] The first step: preparatory work, wind the optical cable 2 to be pipe-combined into the drum of the optical cable pay-off frame 1, and inject the cooling medium 14 into the inner layer conduit 4 with cooling through the connection port 15. And inject cooling water in the cooling device 7 to cool the optical cable 2 during production, prevent the optical cable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com