A method for producing spherical zinc powder using hot-dip galvanizing slag

A hot-dip galvanizing slag, spherical technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of high oxidation degree of zinc powder, large one-time investment, different particle sizes, etc., to improve the fineness of zinc powder, Good effect, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

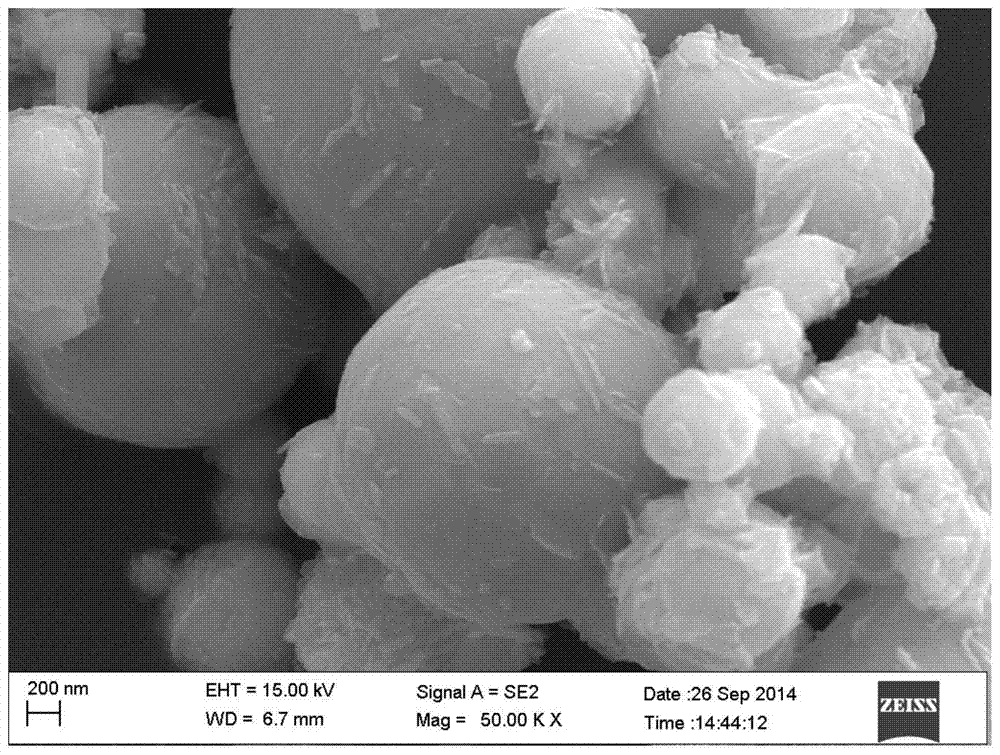

Examples

Embodiment 1

[0032] The method for utilizing hot-dip galvanizing slag to produce spherical zinc powder comprises the following steps:

[0033] Step 1, Ingredients:

[0034] The main components of hot-dip galvanizing slag are shown in Table 1. After coarse crushing and screening with a diameter of less than or equal to 3cm, weigh 100g;

[0035] The main chemical composition of table 1 embodiment 1 hot-dip galvanizing slag

[0036] Element

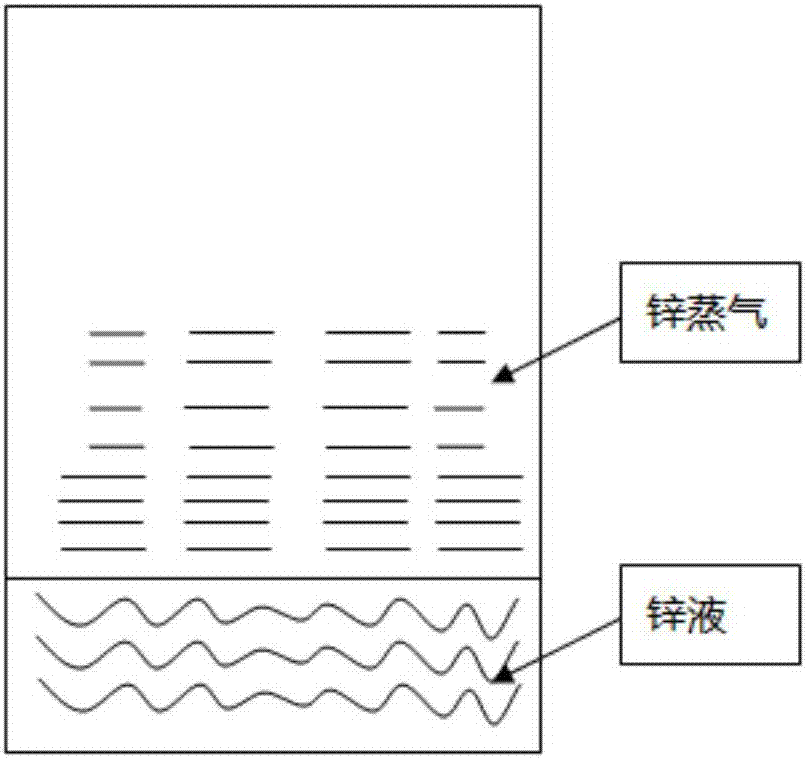

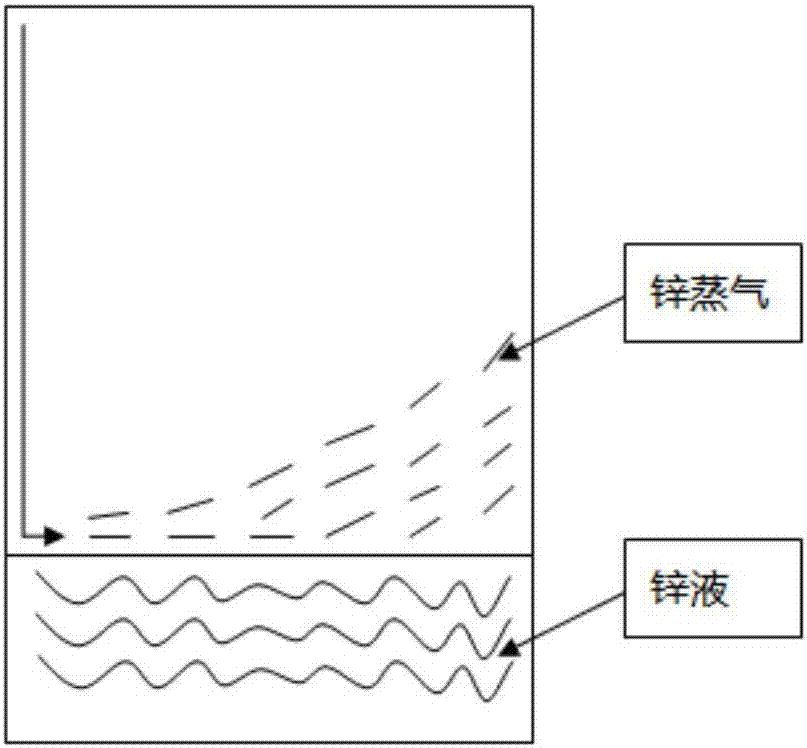

[0037] Step 2, jet smelting evaporation:

[0038] Put the material into the crucible and place it at the bottom of the sealed heat-resistant reaction device. The blowing pipe is fed with high-purity argon gas. The gas flow rate is 5L / min. After heating to 500°C for 10 minutes, the temperature is raised to 1000°C, and the gas flow rate becomes 15L. / min, stop heating after all the Zn in the material evaporates, and the residue stays in the crucible to cool naturally, wherein, the distance between the spray pipe and the surface of the liquid ma...

Embodiment 2

[0047] The method for utilizing hot-dip galvanizing slag to produce spherical zinc powder comprises the following steps:

[0048] Step 1, Ingredients:

[0049] The main components of hot-dip galvanizing slag are shown in Table 3. After coarse crushing and screening with a diameter of less than or equal to 3cm, weigh 100g;

[0050] The main chemical composition of table 3 embodiment 2 hot-dip galvanizing slag

[0051] Element

Zn

Fe

Al

Pb

Mass percentage, %

95.66

1.61

2.43

0.001

[0052] Step 2, jet smelting evaporation:

[0053] Put the material into the crucible and place it at the bottom of the sealed heat-resistant reaction device. Nitrogen gas is introduced into the blowing pipe, and the gas flow rate is 8L / min. After heating to 550°C for 10 minutes, the temperature is raised to 975°C, and the gas flow rate becomes 11L / min. Stop heating after all the Zn in the material evaporates, and the residue is left in the crucible to ...

Embodiment 3

[0071] The method for utilizing hot-dip galvanizing slag to produce spherical zinc powder comprises the following steps:

[0072] Step 1, Ingredients:

[0073] The main components of hot-dip galvanizing slag are shown in Table 7. After coarse crushing and screening with a diameter of less than or equal to 3cm, weigh 100g;

[0074] The main chemical composition of table 7 embodiment 3 hot-dip galvanizing slag

[0075] Element

Zn

Fe

Al

Pb

Mass percentage, %

94.86

1.87

2.76

0.001

[0076] Step 2, jet smelting evaporation:

[0077] Put the material into the crucible and place it at the bottom of the sealed heat-resistant reaction device. The blowing pipe is fed with high-purity argon gas. The gas flow rate is 5L / min. After heating to 600°C for 10 minutes, the temperature is raised to 1000°C, and the gas flow rate becomes 13L. / min, stop heating after all the Zn in the material evaporates, and the residue stays in the crucible to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com