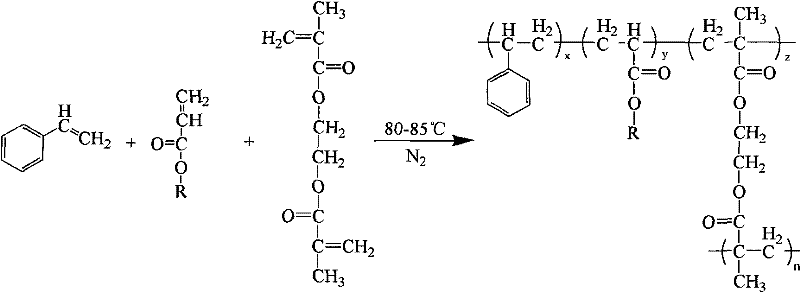

Preparation method of macroporous long alkyl side chain acrylic acid ester-styrene-ethylene dimethacrylate crosslinking copolymerization microballoon

A technology of ethylene glycol dimethacrylate and acrylate, which is applied in the field of macroporous cross-linked copolymer microspheres and their preparation, can solve the problems of complex effects of influencing factors and unreported problems, and achieve low production cost and spherical shape. The effect of good temperature and easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 3.75g of lauryl acrylate, 3.75g of styrene, 7.5g of ethylene glycol dimethacrylate, and 15g of n-octanol, and mix them evenly. Dissolve 0.15g of benzoyl peroxide in the above mixture to form an oil phase. Add 695% polyvinyl alcohol aqueous solution to 2% NaCl aqueous solution to prepare the aqueous phase required for the reaction. Using the suspension polymerization method, first add the water phase solution into a 1000mL four-port reactor equipped with a condenser, an electric stirrer and a heating device, and pass in nitrogen gas, then add the oil phase solution after 30 minutes, and stir at a speed of 300r / min. Heating to 85°C, constant temperature reaction for 10 hours to obtain a bead copolymer, the product was filtered and washed with deionized water at 60-70°C, then extracted with acetone for 24 hours, and finally dried in a vacuum oven at 60°C to constant weight. The total hole area of the product is 148.84m 2 / g, the total pore volume is 1.15mL / g, the ...

Embodiment 2

[0020] Weigh 4.5g of lauryl acrylate, 4.5g of styrene, 9g of ethylene glycol dimethacrylate, and 12g of n-octanol, and mix them evenly. Dissolve 0.15g of benzoyl peroxide in the above mixture to form an oil phase. Add 6 g of 5% polyvinyl alcohol aqueous solution to 2% NaCl aqueous solution to prepare the aqueous phase required for the reaction. Using the suspension polymerization method, first add the water phase solution into a 1000mL four-port reactor equipped with a condenser, an electric stirrer and a heating device, and feed nitrogen, then add the oil phase solution after 30 minutes, and stir at a speed of 300r / min. Heating to 85°C, constant temperature reaction for 10 hours to obtain a bead copolymer, the product was filtered and washed with deionized water at 60-70°C, then extracted with acetone for 24 hours, and finally dried in a vacuum oven at 60°C to constant weight. The total hole area of the product is 127.75m 2 / g, the total pore volume is 0.704mL / g, the poros...

Embodiment 3

[0022] Weigh 3.75g of tetradecyl acrylate, 3.75g of styrene, 7.5g of ethylene glycol dimethacrylate, and 12g of liquid paraffin, mix well, and dissolve 0.15g of benzoyl peroxide in the above mixture to form an oil phase. Add 6 g of 5% polyvinyl alcohol aqueous solution to 2% NaCl aqueous solution to prepare the aqueous phase required for the reaction. Using the suspension polymerization method, first add the water phase solution into a 1000mL four-port reactor equipped with a condenser, an electric stirrer and a heating device, and pass in nitrogen gas, then add the oil phase solution after 30 minutes, and stir at a speed of 300r / min. Heating to 85°C, constant temperature reaction for 10 hours to obtain a bead copolymer, the product was filtered and washed with deionized water at 60-70°C, then extracted with acetone for 24 hours, and finally dried in a vacuum oven at 60°C to constant weight. The total hole area of the product is 33m 2 / g, the total pore volume is 1.65mL / g, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com