Ta-contained 3D printing cobalt chromium molybdenum alloy powder for dental department and preparation method thereof

A cobalt-chromium-molybdenum alloy, 3D printing technology, applied in the field of dental restoration, can solve the problems of reduced oxygen content and poor gold-ceramic bonding performance, and achieves the effect of reducing oxygen content, improving gold-ceramic bonding performance, and good purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this example, the chemical composition of the 3D printing cobalt-chromium-molybdenum alloy powder containing Ta for dental use and the weight percentages of each element are: Cr 26.0%, Mo 10.0%, Si 2.0%, Mn 1.5%, W 5.0%, Nb 1.0% , Ta 2.0%, the balance is Co. The processing steps of the preparation method are as follows:

[0054] (1) Master alloy smelting

[0055] According to the above chemical composition, the ingredients are added, and the raw materials are added to the vacuum induction furnace to be smelted into a cobalt-chromium-molybdenum master alloy liquid containing Ta. The vacuum degree in the furnace during the refining period should be higher than 1.0×10 -2 Pa, then pouring the Ta-containing cobalt-chromium-molybdenum master alloy liquid into a strip-shaped Ta-containing cobalt-chromium-molybdenum master alloy ingot of 20mm × 20mm × 100mm;

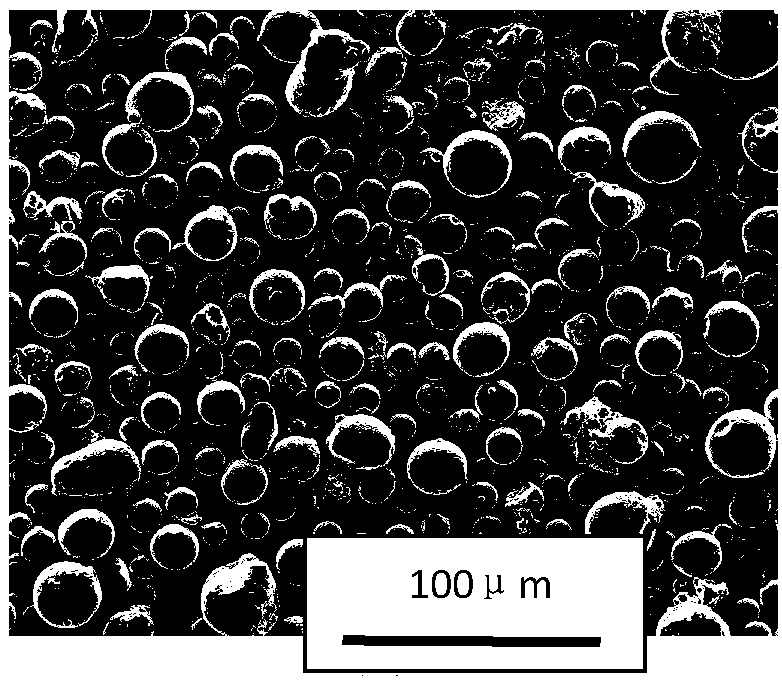

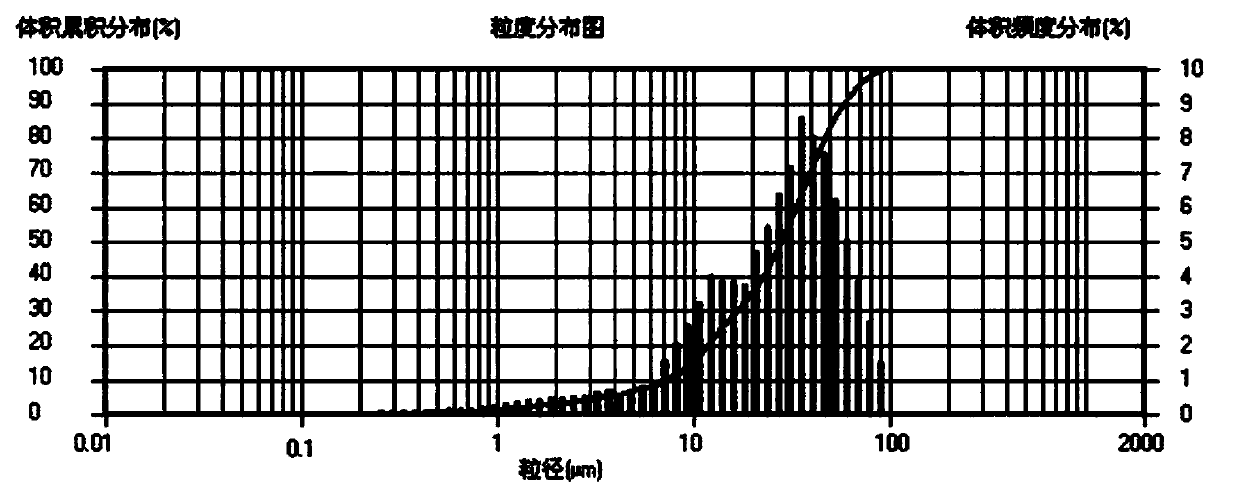

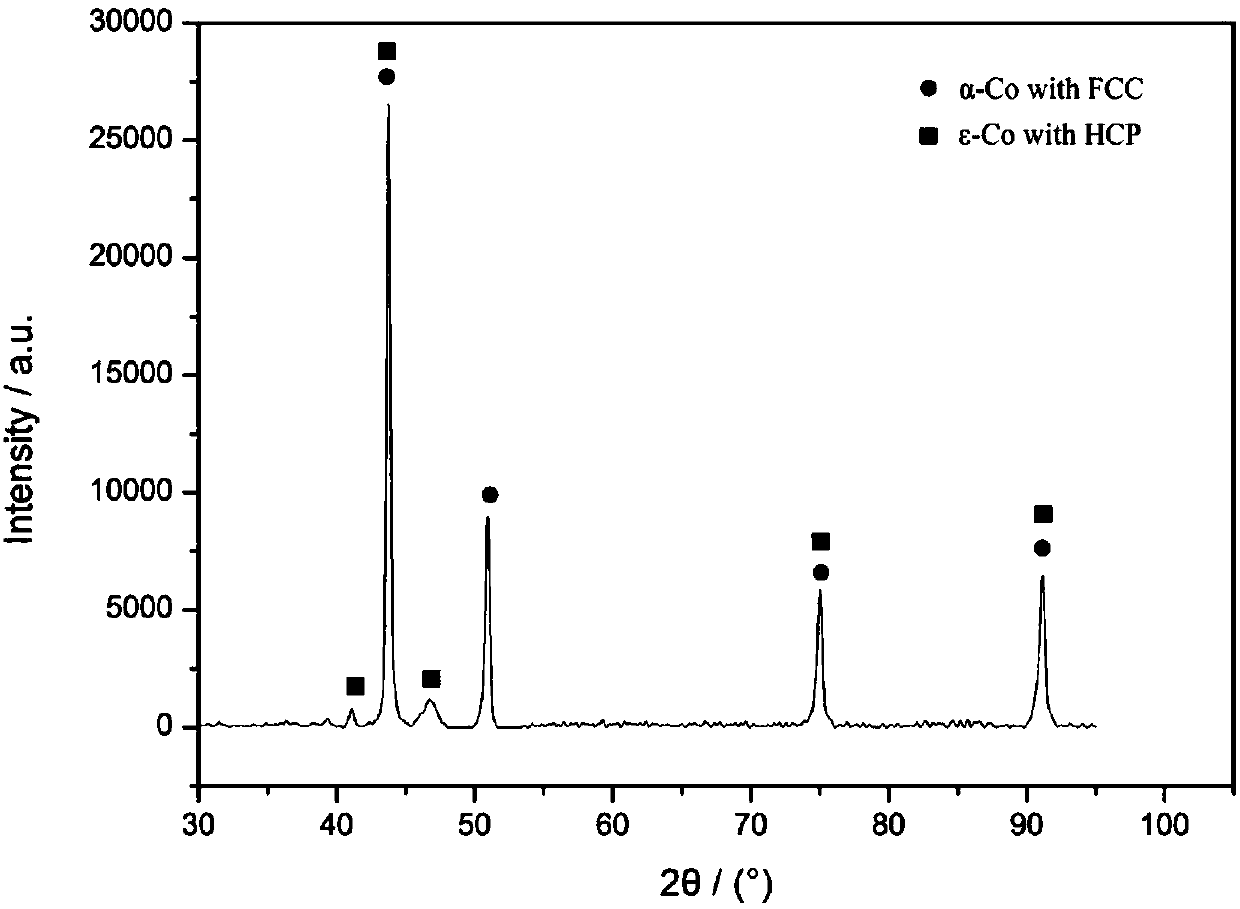

[0056] (2) Atomized powder making

[0057] The Ta-containing cobalt-chromium-molybdenum master alloy ingot obtain...

Embodiment 2

[0062] In this example, the chemical composition and the weight percentage of each element of the 3D printing cobalt-chromium-molybdenum alloy powder containing Ta for dental use are: Cr 30.0%, Mo 8.0%, Si 2.0%, W 3.0%, Nb 1.0%, Ta 0.5% , and the balance is Co. The processing steps of the preparation method are as follows:

[0063] (1) Master alloy smelting

[0064] According to the above chemical composition, the ingredients are added, and the raw materials are added to the vacuum induction furnace to be smelted into a cobalt-chromium-molybdenum master alloy liquid containing Ta. The vacuum degree in the furnace during the refining period should be higher than 1.0×10 -2 Pa, then pouring the Ta-containing cobalt-chromium-molybdenum master alloy liquid into a strip-shaped Ta-containing cobalt-chromium-molybdenum master alloy ingot of 20mm × 20mm × 100mm;

[0065] (2) Atomized powder making

[0066] The Ta-containing cobalt-chromium-molybdenum master alloy ingot obtained in s...

Embodiment 3

[0071]In this example, the chemical composition and the weight percentage of each element of the 3D printing cobalt-chromium-molybdenum alloy powder containing Ta for dental use are: Cr 27.0%, Mo 10.0%, Mn 1.0%, W 8.0%, Nb 0.5%, Ta 5.0% , and the balance is Co. The processing steps of the preparation method are as follows:

[0072] (1) Master alloy smelting

[0073] According to the above chemical composition, the ingredients are added, and the raw materials are added to the vacuum induction furnace to be smelted into a cobalt-chromium-molybdenum master alloy liquid containing Ta. The vacuum degree in the furnace during the refining period should be higher than 1.0×10 -2 Pa, then pouring the Ta-containing cobalt-chromium-molybdenum master alloy liquid into a strip-shaped Ta-containing cobalt-chromium-molybdenum master alloy ingot of 20mm × 20mm × 100mm;

[0074] (2) Atomized powder making

[0075] The Ta-containing cobalt-chromium-molybdenum master alloy ingot obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com