Patents

Literature

48 results about "Cobalt-Chromium-Molybdenum Alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioactivity artificial joint material and preparation method thereof

InactiveCN1557503AImprove biological activityGood osteogenic effectJoint implantsCoatingsPhosphateCeramic coating

The present invention is one kind of artificial joint material with surface porous Ca-P bioactive ceramic coating layer and bone morphogenetic protein and its preparation process. The artificial joint material consists of metal substrate, one layer of double-layered porous Ca-P bioactive ceramic coating layer on the surface of the metal substrate, and bone morphogenetic protein covering the bioactive ceramic coating layer. The porous bioactive Ca-P ceramic coating layer comprises the non-crystal calcium phosphate base layer contacting with the metal substrate in 1-10 micron thickness and the crystalline bone-like apatite surface layer in 10-100 micron thickness. The preparation process includes machining artificial joint with titanium alloy, stainless steel or CO-Cr-Mo alloy; surface activating the artificial joint, two-step bionic deposition; and soaking the artificial joint inside mixed solution comprising bone morphogenetic protein and buffering phosphate solution.

Owner:SOUTHEAST UNIV +1

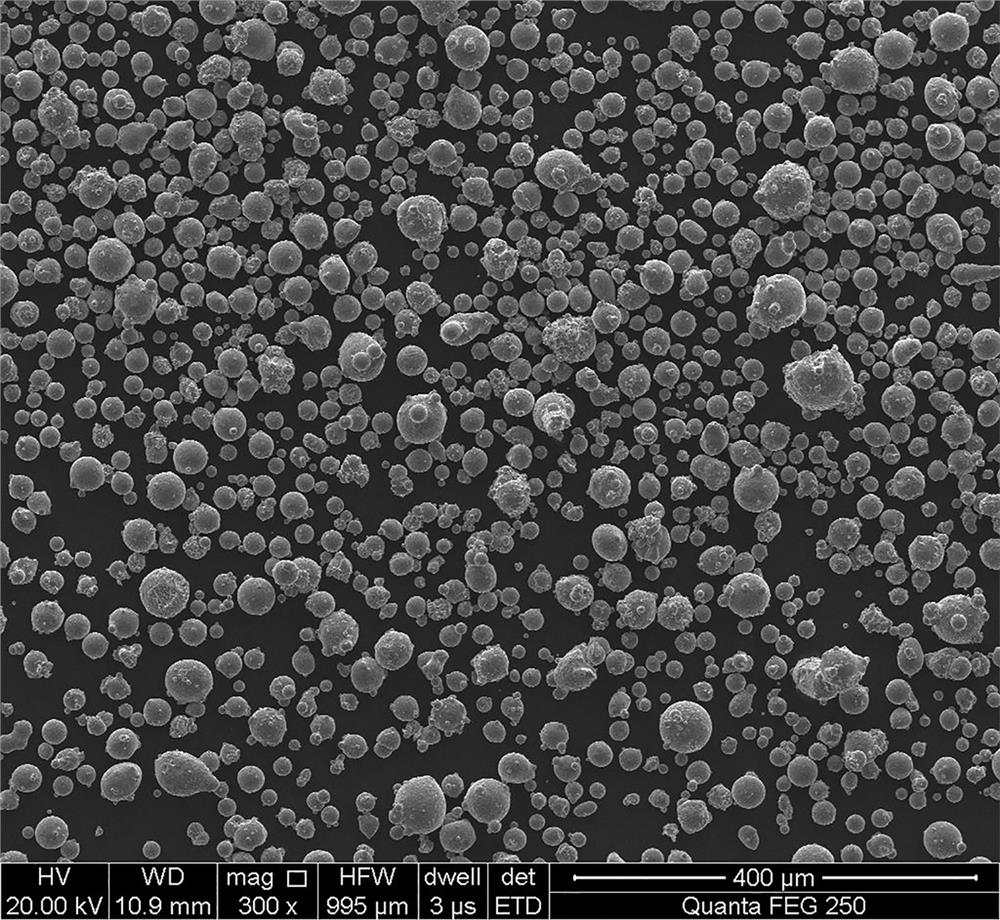

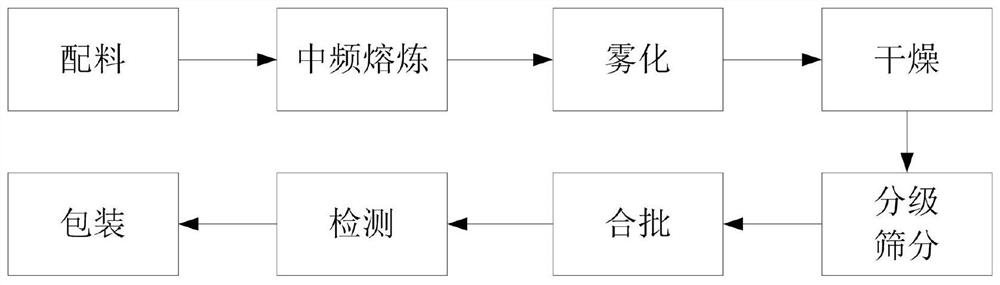

Ta-contained 3D printing cobalt chromium molybdenum alloy powder for dental department and preparation method thereof

ActiveCN107598151ASolve the broken porcelainSolve the problem of porcelain peelingAdditive manufacturing apparatusChemical compositionBond properties

The invention provides Ta-contained 3D printing cobalt chromium molybdenum alloy powder for the dental department and a preparation method thereof. The chemical components of the alloy power comprise,by weight, 26.0%-30.0% of Cr, 8.0%-10.0% of Mo, 0.5%-5.0% of Ta, 3.0%-8.0% of W and the balance Co. The preparation method of the Ta-contained 3D printing cobalt chromium molybdenum alloy powder comprises the three steps of mother alloy smelting, powder atomization, powder screening and drying treatment. According to the alloy powder, the particle size, the sphericility degree and the mechanicalproperty are ensured, and meanwhile, the gold-procelain bonding property, the thermal stability and the flowability are improved while the oxygen content is reduced, the problems of porcelain crackingand porcelain spalling of a cobalt chromium molybdenum alloy are effectively solved, and obtaining of dental rebuilt parts with the high quality is facilitated.

Owner:CHENGDU KENINGDA MATERIALS

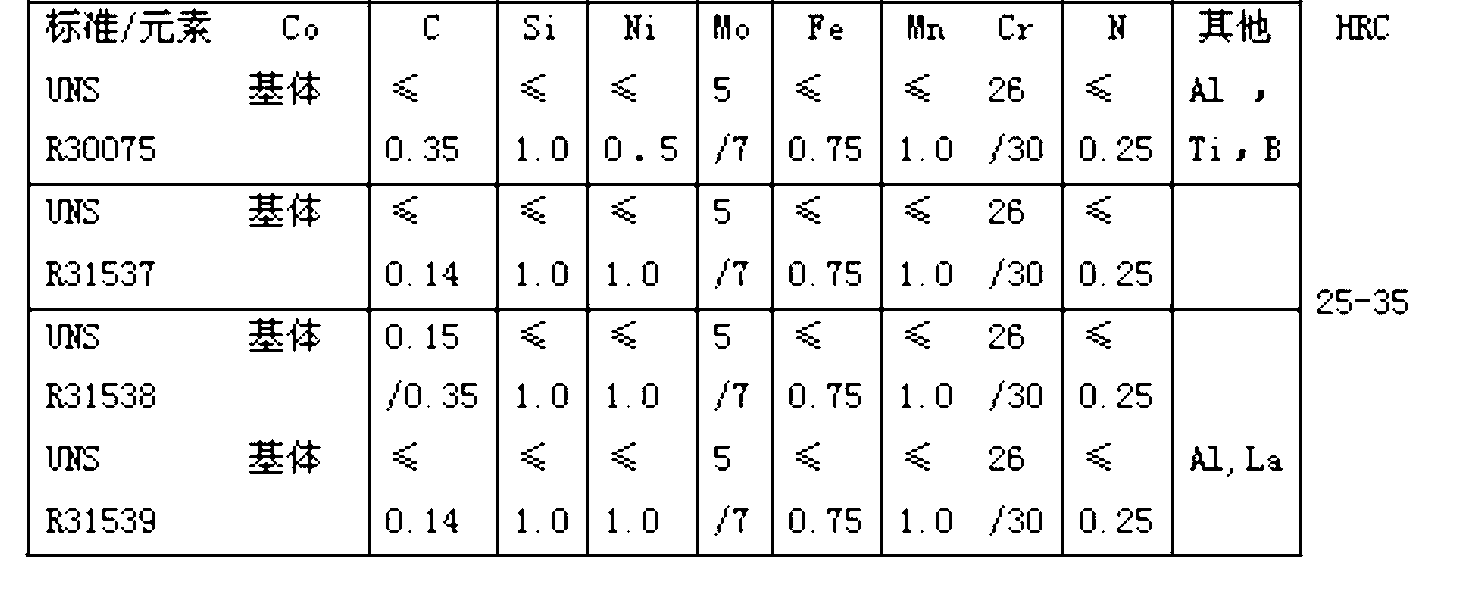

Co-Cr-Mo alloy with high wear resistance

The invention relates to a Co-Cr-Mo alloy with high wear resistance, which belongs to the technical field of high temperature alloy. The Co-Cr-Mo alloy comprises, by weight, 24 to 35% of Cr, 5 to 20% of Mo, 0.35 to 2.5% of C, 0 to 4% of Ni, 0 to 4% of Fe, 0 to 2% of Si and 0 to 2% of Mn, with the balance being Co and other avoidable impurity elements and technical elements. The invention has the following advantages: the Co-Cr-Mo alloy overcomes the problem that conventional Co-Cr-Mo alloy has insufficient wear resistance, and production modes like casting, forging and powder metallurgy can be used for production of the Co-Cr-Mo alloy; the Co-Cr-Mo alloy can meet individual need or simultaneous need for high temperature resistance, corrosion resistance and wear resistance in the zinc industry and the like with a severe industrial environment, satisfies requirements for scratch resistance, brightness and whiteness on products like finger rings, bracelets and watchcases in the ornament industry, is applicable to production of electroplating sputtering target materials for formation of compact, high-wear resistance, white and bright surface layers through physical vapor deposition and meet higher demands by people for color, luster and visual impression of the appearance of ornaments.

Owner:BEIJING MELTOP METAL

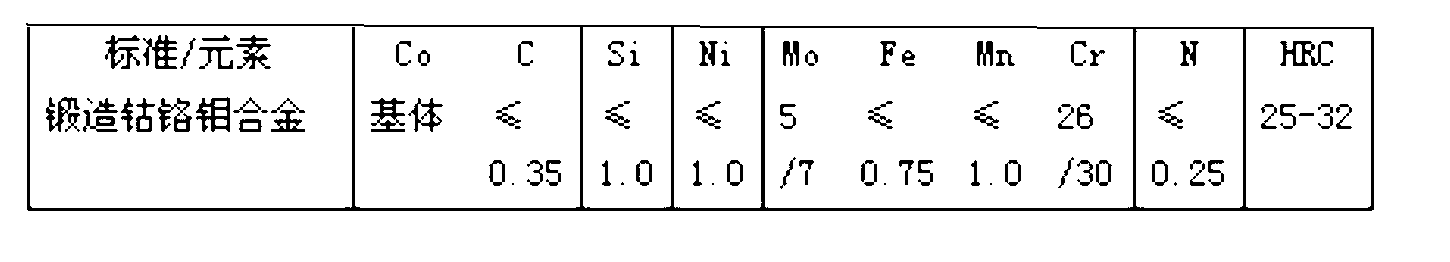

Method for preparing medical spherical Co-Cr-Mo alloy particles

Owner:BAOJI FEILI NONFERROUS METAL MATERIALS

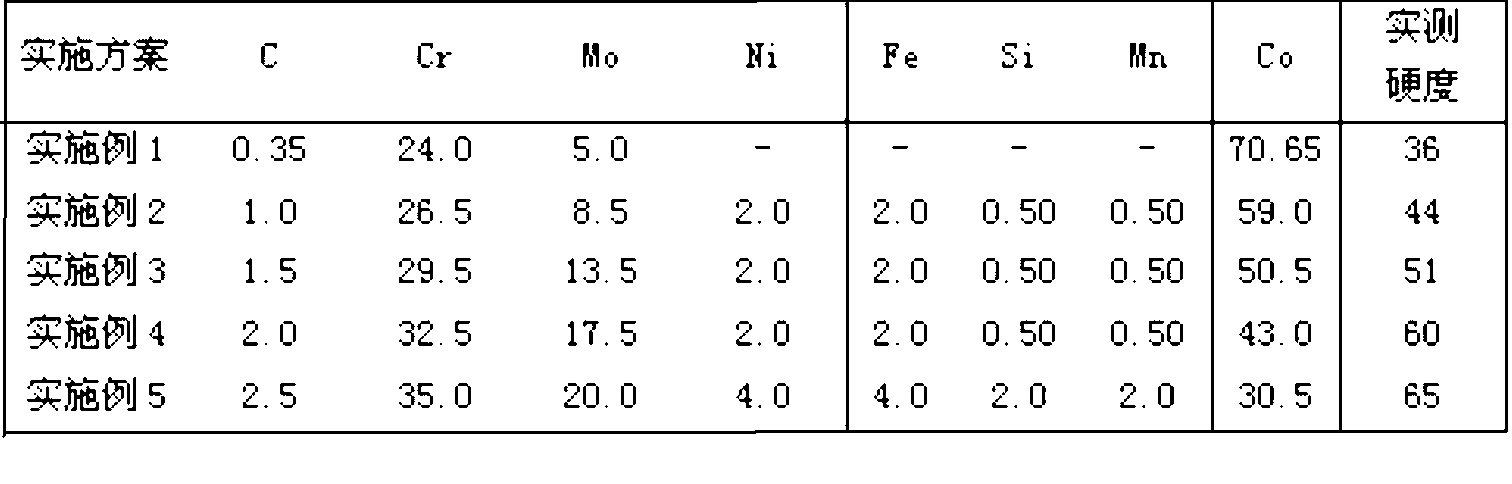

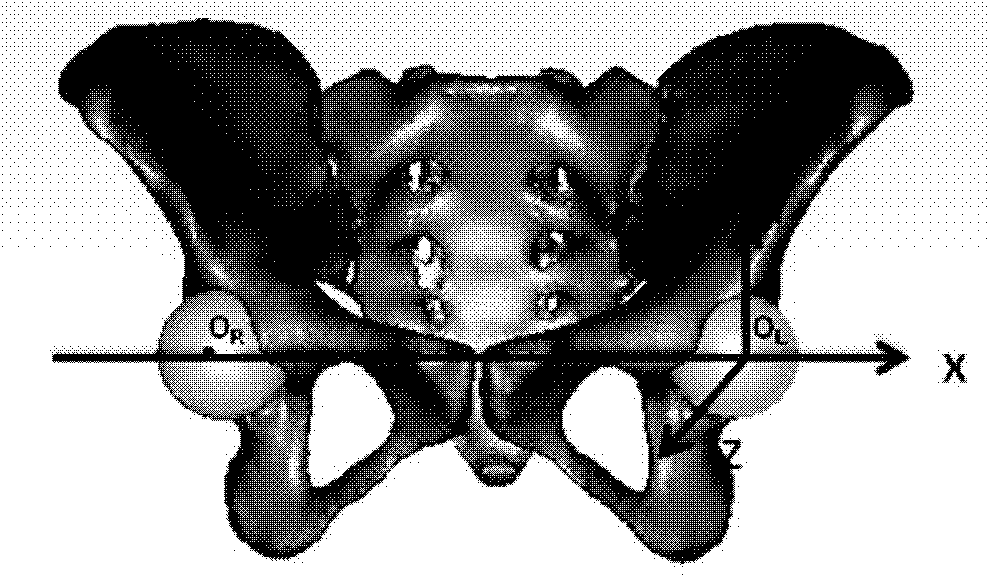

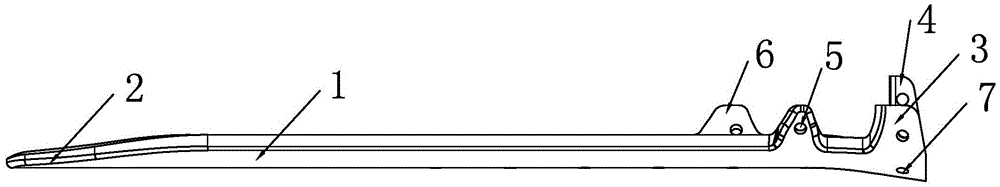

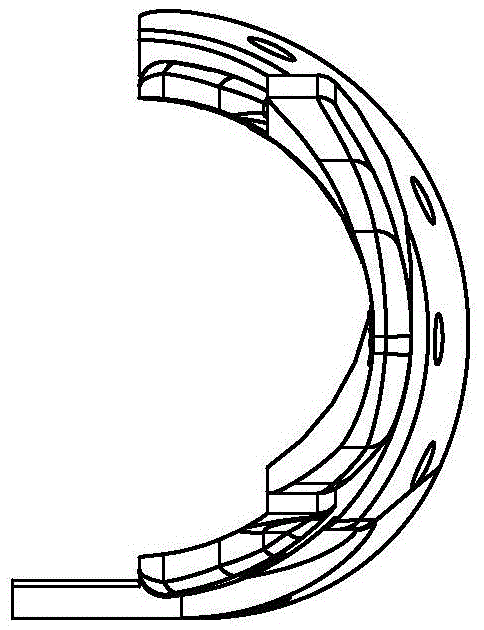

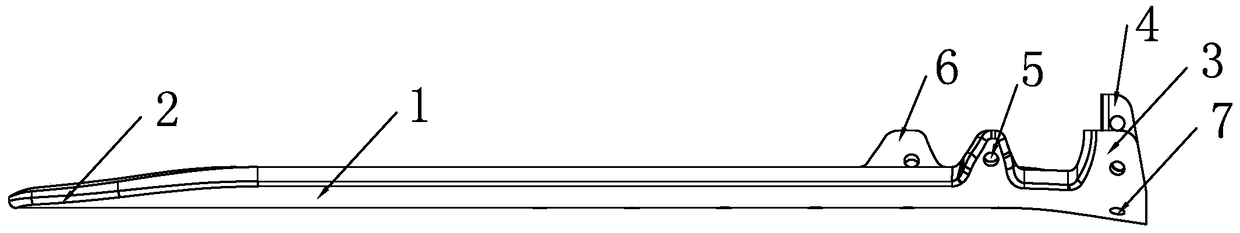

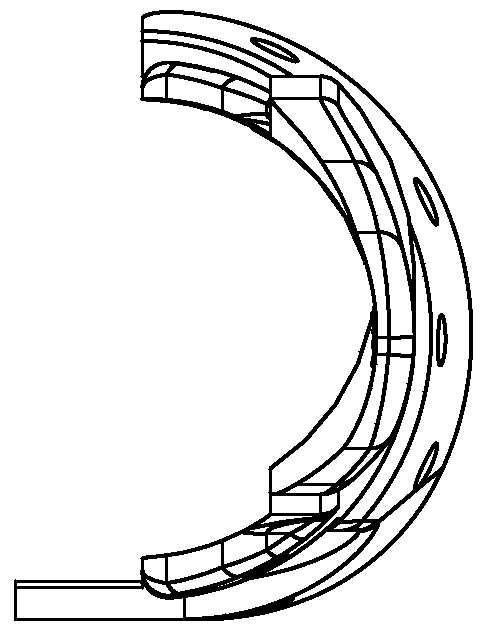

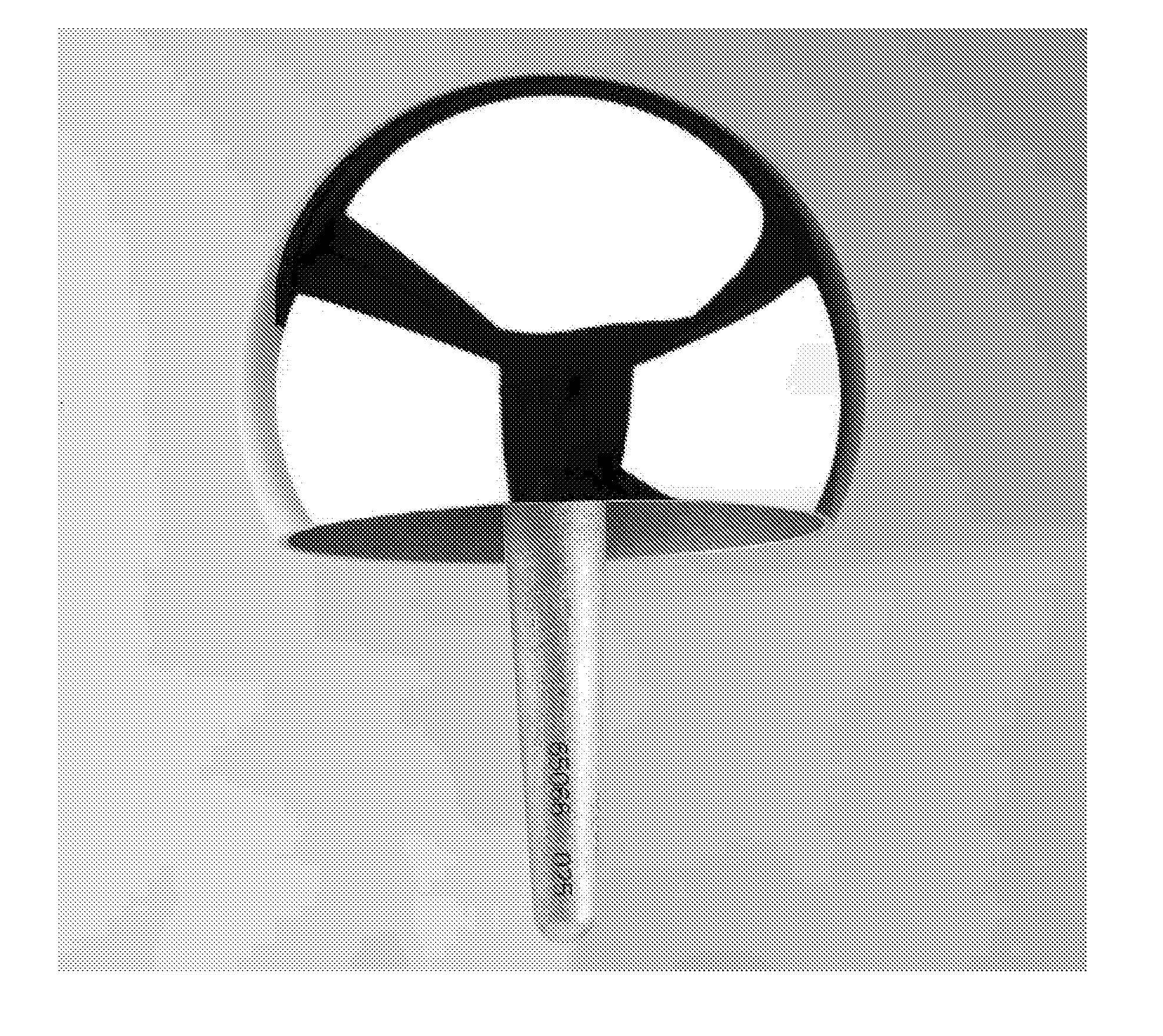

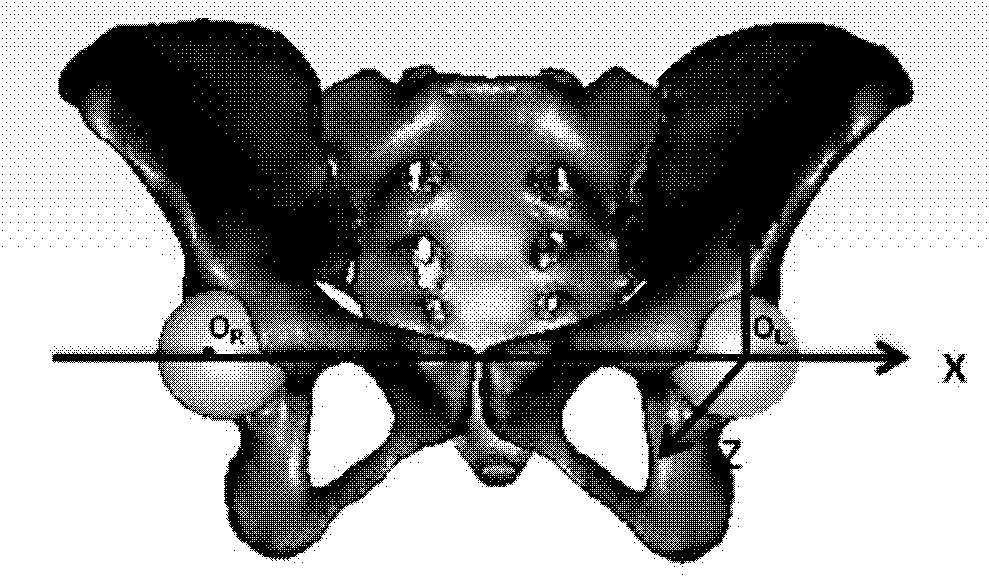

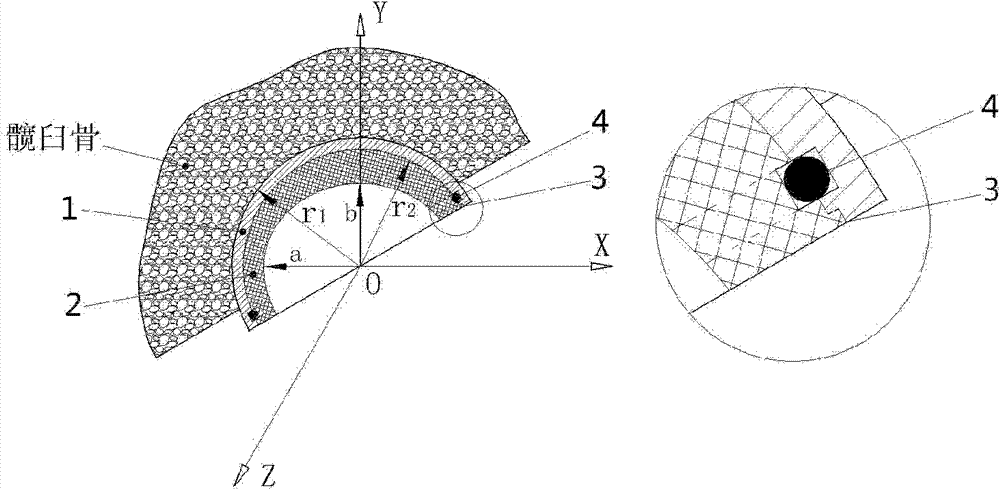

Acetabular prosthesis of artificial hip joint with rotational ellipsoid joint interface

ActiveCN102125472AImprove joint interface stress concentration phenomenonMeet personalized treatment needsJoint implantsAcetabular cupsStress concentrationCobalt

The invention belongs to the technical field of medical devices and discloses an acetabular prosthesis of an artificial hip joint with a rotational ellipsoid joint interface, which comprises an acetabular outer cup made of a cobalt / chrome / molybdenum alloy and an acetabular liner made of polyethylene. The liner of the acetabular prosthesis comprises a spherical outer surface and a rotational ellipsoid inner surface, wherein the radius of the spherical outer surface, i.e. the outside diameter of the liner, is equal to the subtraction of the thickness of the acetabular outer cup from the radius of the acetabular prosthesis outer cup; the length of the major axis of the rotational ellipsoid inner surface is equal to the subtraction of the thickness of the liner from the outside diameter of the liner; and the length of the minor axis of the rotational ellipsoid inner surface is equal to the multiplication of the length of the major axis by 0.98. A positioning groove and a clamping ring arearranged between the liner and the outer cup to achieve the effect of fixation. According to the shapes of acetabular fossa of different patients, the acetabular prostheses of different specifications are designed and manufactured so as to solve the problem of stress concentration on the joint interface of the spherical artificial hip joint in the prior art and meet the needs for individual treatment of different patients. Therefore, the acetabular prosthesis provided by the invention is truly put into effect in clinics.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

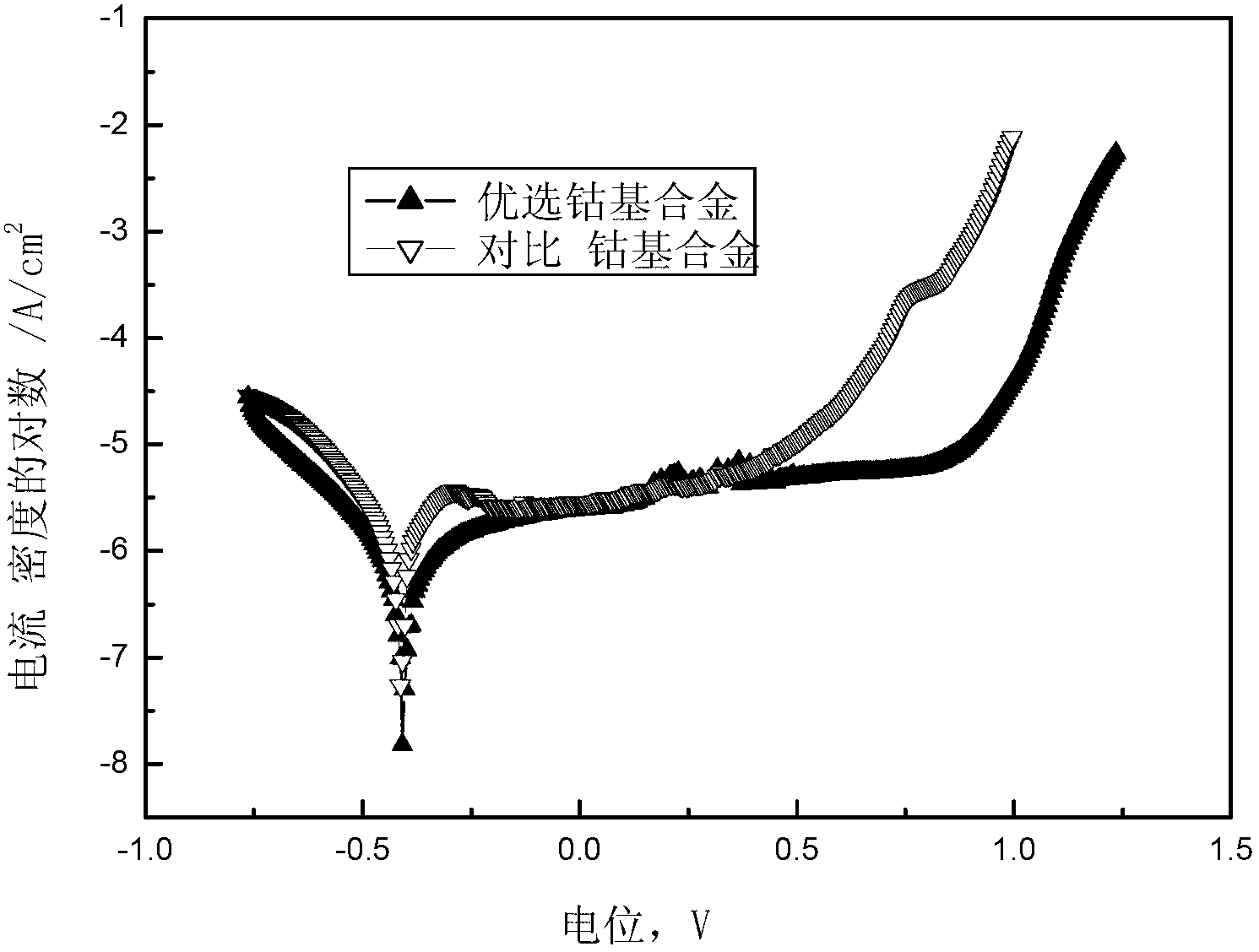

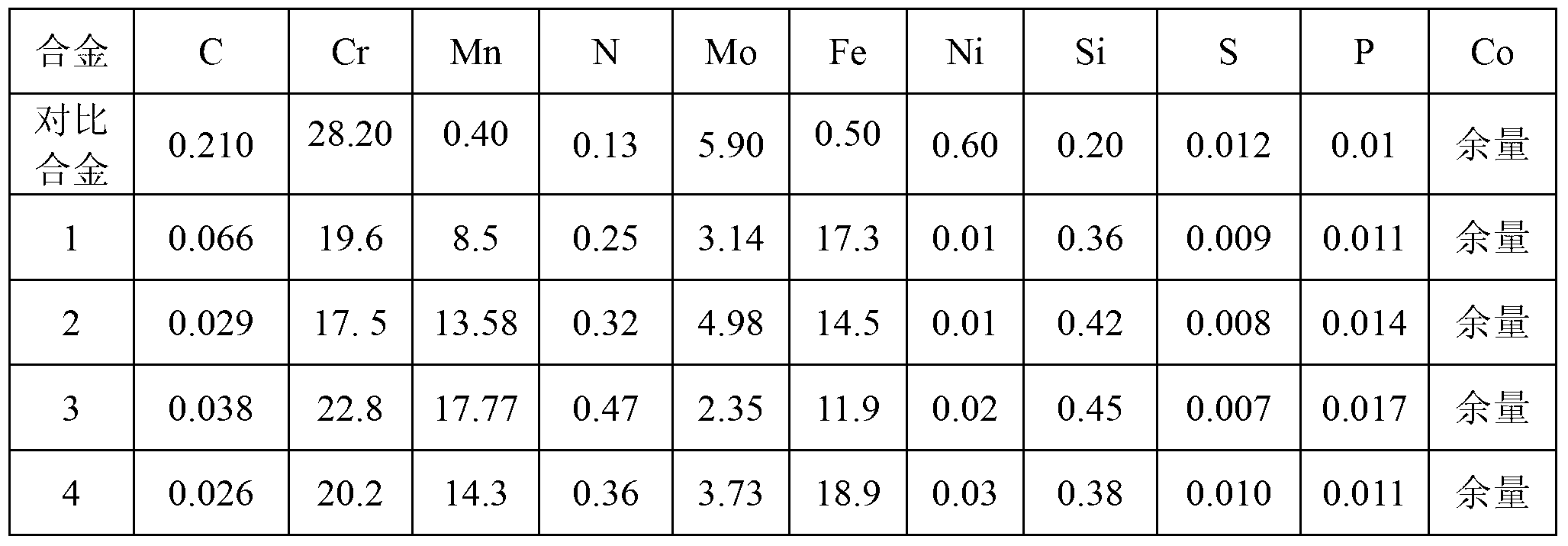

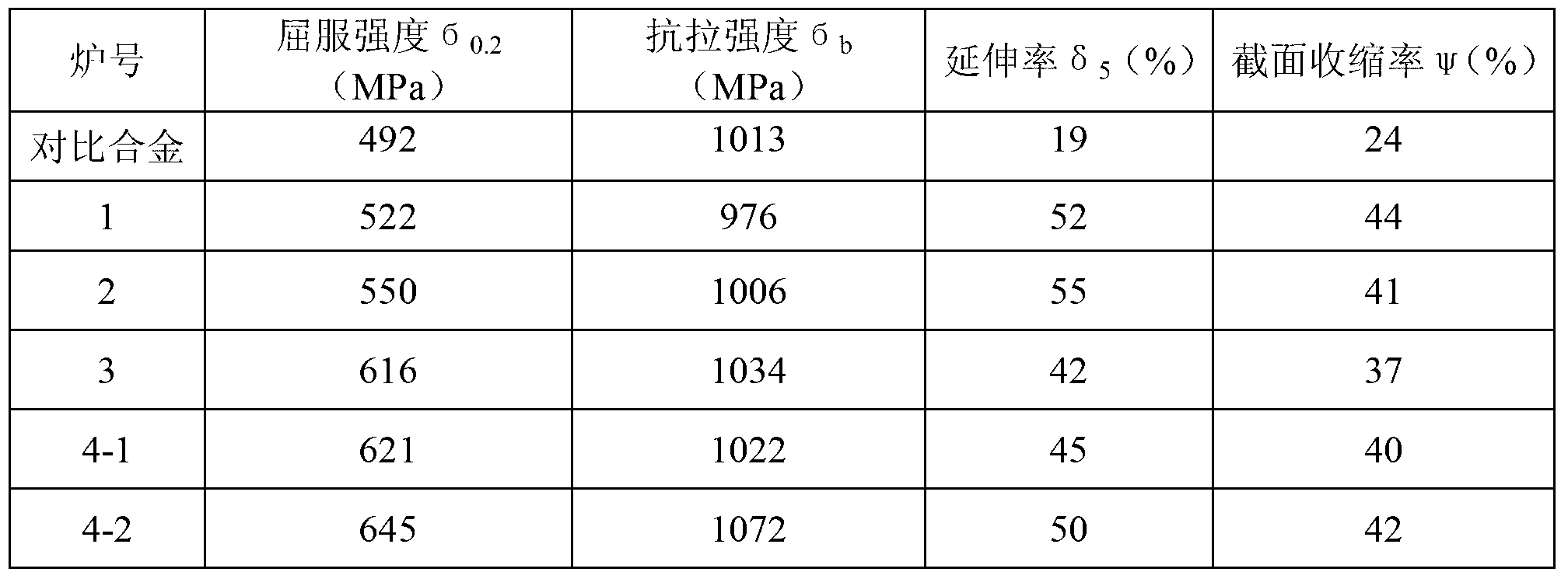

Novel cobalt-base alloy for surgical implant and application thereof

ActiveCN103215475AImprove mechanical propertiesImprove corrosion resistanceProsthesisChemical compositionNitrogen

The invention discloses a novel forgeable cobalt-base alloy for surgical implant and application through which the content of cobalt and chromium is reduced on the basis of the Co-Cr-Mo alloy and the mechanical property and corrosion-resistant property are optimized by adding a proper amount of iron and manganese elements and by adding the nitrogen element. The novel forgeable cobalt-base alloy is characterized by comprising the following chemical components by weight: less than or equal to 0.08 percent of C, 16-24 percent of Cr, 10-20 percent of Fe, 5-20 percent of Mn, 2-6 percent of Mo, 0.2-0.6 percent of N, less than or equal to 0.1 percent of Ni, less than or equal to 0.5 percent of Si, less than or equal to 0.01 percent of S, less than or equal to 0.02 percent of P and the balance of Co. The alloy has excellent mechanical property and corrosion-resistant property, can be used for avoiding the nickel damage and reducing the cost of the alloy, has excellent toughness combination and cold and hot working performance and has important social and economic significance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for smelting nitrogenous Co-Cr-Mo alloy for surgical implanting through electroslag remelting furnace

The invention belongs to the field of metallurgy and relates to a method for smelting nitrogenous Co-Cr-Mo alloy for surgical implanting through an electroslag remelting furnace. The method comprises the following steps: I, preparing an electrode and slag charge, welding a Co-Cr-Mo alloy stun rod and an artificial electrode together, and using a slag charge feeder to add the slag charge to be remelted; II, closing the furnace and filling nitrogen continuously for 2 minutes and then stopping nitrogen supply, and starting a cooling circulation system; III, arcing and slugging, and adopting a power, current, voltage and slag resistance comprehensive control method; IV, after slag charge adding, supplying nitrogen continuously; V, after the finish of an arcing period, starting a melting period, adopting a melting speed and slag swing control method, and stabilizing the melting speed to be 5kg / min; VI, adopting a stepped power reduction method during a hot top sealing process; and VII, cooling and demoulding inside the furnace. The Co-Cr-Mo alloy remelted by adopting the method is excellent in ESR ingot segregation control, N element is evenly distributed, the burning loss is less than 5 percent, the content of sulphur is lower than 10 ppm, and the ingot surface is free from the defect of slag troughs.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

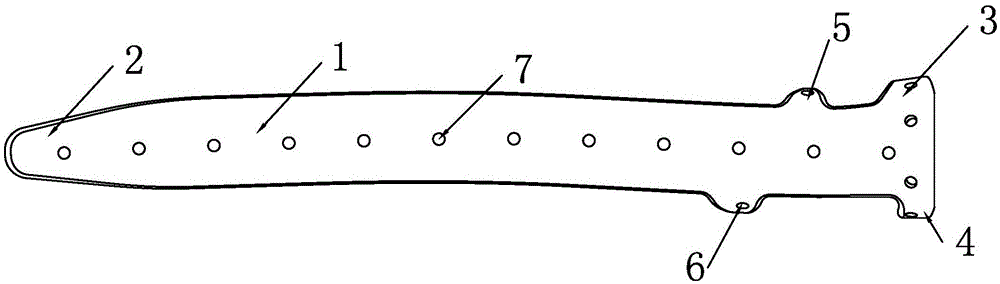

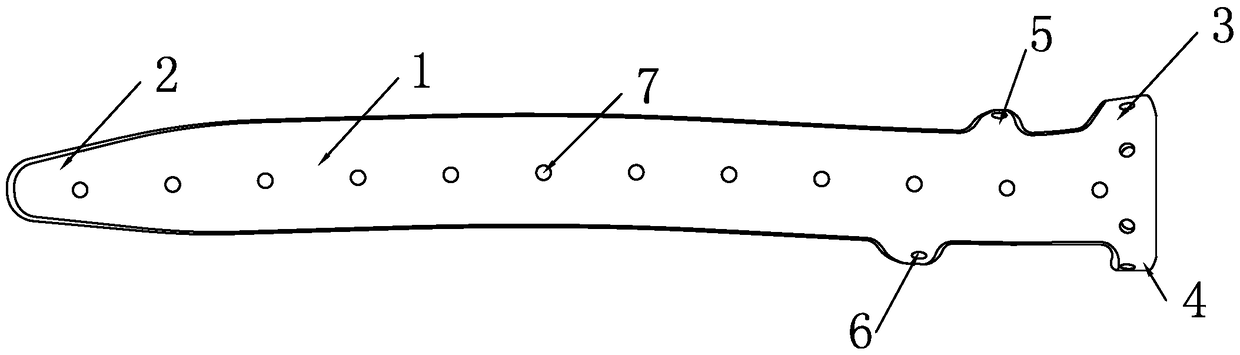

Periprosthetic femoral fracture revision locking steel plate

InactiveCN105640635ANo need to increase the widthStrong bending resistanceBone platesStress concentrationVitallium

The invention relates to a periprosthetic femoral fracture revision locking steel plate. The periprosthetic femoral fracture revision locking steel plate is provided with a U-type body with the shape matched with that of the thighbone. The body can be made of titanium alloy or vitallium. A first contracting part is arranged at the bottom end of the body. Each of the two sides of the body extends to form two wings, and the wings comprise the first wing, the second wing, the third wing and the fourth wing. The body and the wings are provided with a plurality of nail holes. The near end of a fracture can be fixed at multiple angles, the width of the steel plate does not need to be increased, and the screw bonding force, and the bending resisting force and rotating resisting capacity of the steel plate are all higher than those of any former fixing material. By means of locking design, blood supply damage caused by the fact that a steel plate is too closely attached to the bone face and the periosteum and soft tissue are excessively stripped can be avoided. The force arm of the steel plate is long, and by means of dispersed fixing, steel plate breakage caused by stress concentration or bone ununion caused by stress shielding can be avoided. The minimally invasive percutaneous steel plate internal fixing technology is used in cooperation, and therefore soft tissue injuries can be further reduced.

Owner:黑龙江高德医疗科技有限责任公司

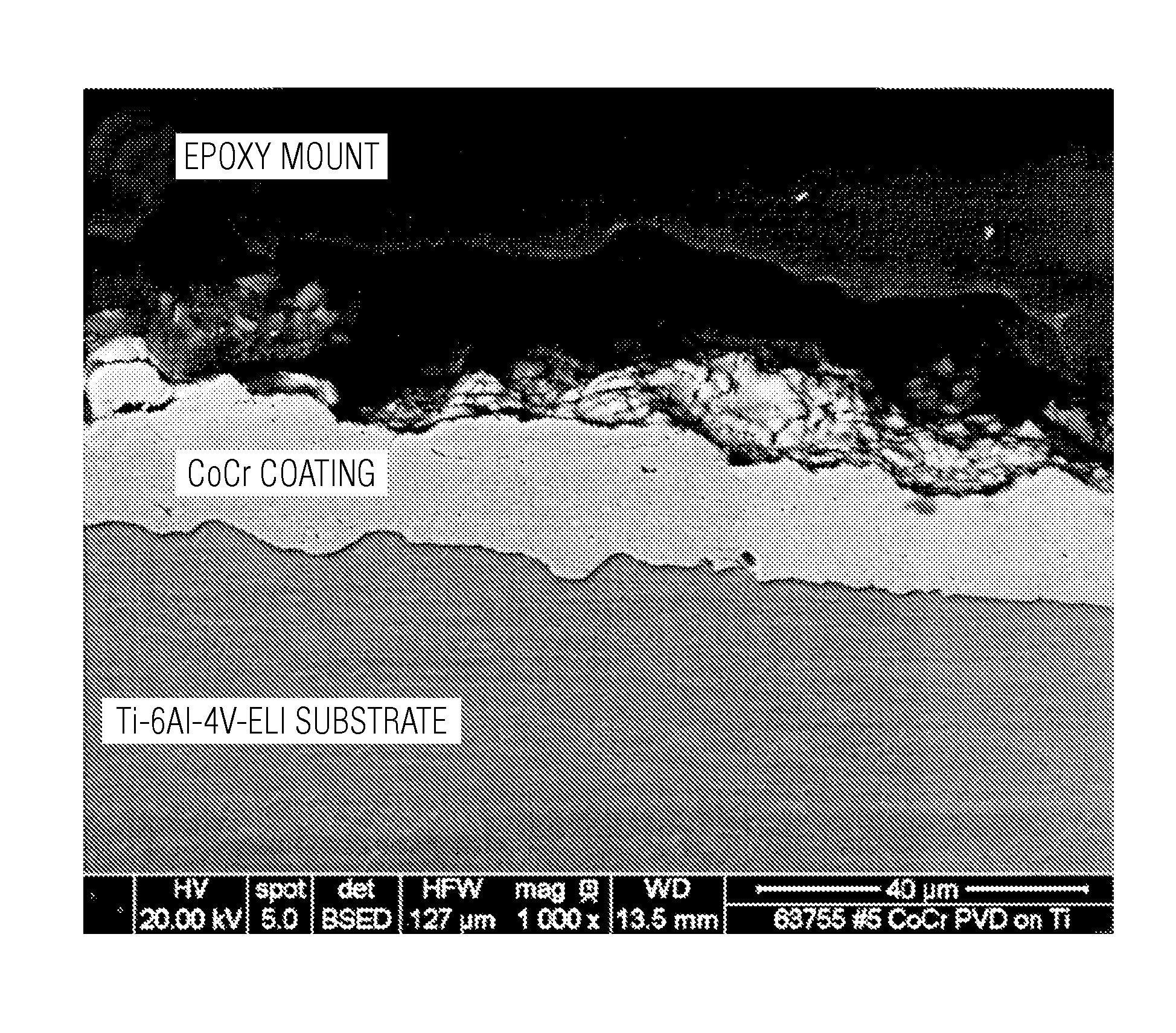

Cobalt chrome coated titanium implant

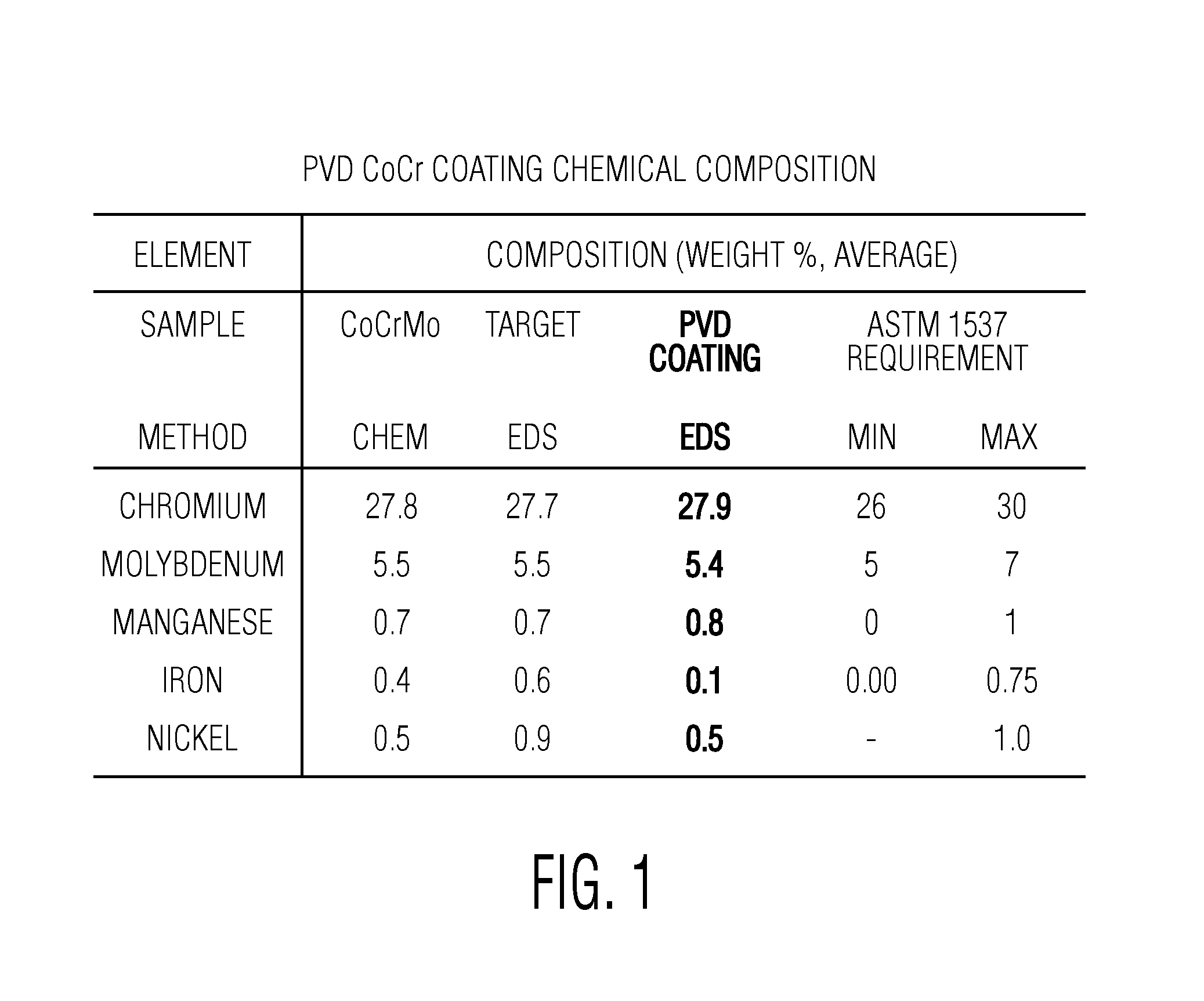

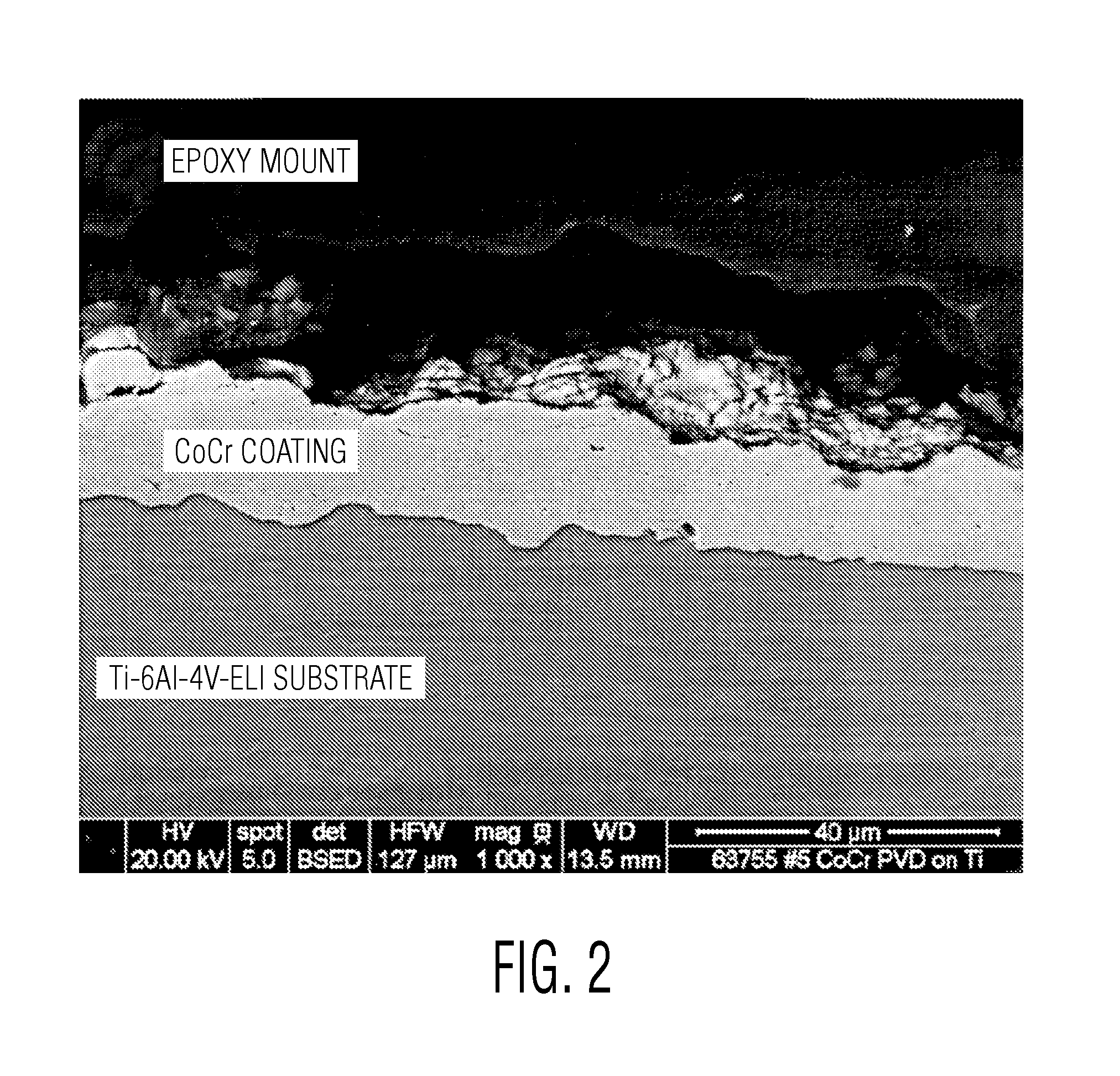

ActiveUS9370605B2Third body wear resistanceHigh hardnessVacuum evaporation coatingSputtering coatingCobalt-chromeProsthetic joint component

Owner:HOWMEDICA OSTEONICS CORP

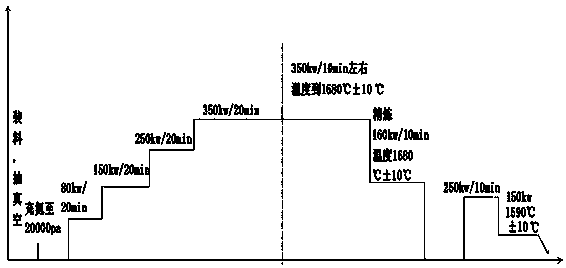

Nitriding CoCrMo alloy and smelting process thereof

The invention relates to the field of alloy smelting, and discloses a nitriding CoCrMo alloy and a smelting process thereof. The CoCrMo alloy mainly comprises following components including, by weightpercent, 0.25 to 0.31% of C, 27 to 30% of Cr, 5.0 to 7.0% of Mo, 0.75 to 0.92% of Si, 0.3 to 0.4% of Mn, 0.18 to 0.25% of N, and 64.12 to 66.51% of Co. According to the smelting process, vacuum is pumped in a vacuum furnace, and then nitrogen is inflated. Compared with the prior art, high-temperature gas nitriding smelting is adopted, medical CoCrMo alloy is subjected to high-temperature nitriding treatment, the content of austenite in a base body is increased, the microhardness is improved, the brine corrosion resistance is improved, the wear resistance is improved, alloy hardness and surface roughness after ionic nitriding are increased, the microhardness is obviously improved, and the anti-wear property is obviously improved.

Owner:江苏奇纳新材料科技有限公司

Cobalt-chromium-molybdenum alloy artificial joint implant material and preparation method thereof

The invention discloses a cobalt-chromium-molybdenum alloy artificial joint implant material, which comprises the following components in percentage by weight: 0.4 to 0.65% of C, 25 to 27% of Cr, 9 to10% of Mo, 0.7 to 0.85% of Al, 0.35 to 0.65% of Fe, 0.4 to 0.7% of Mn, 0.6 to 0.85% of Si, 0.5 to 0.75% of Nb, and the balance being Co. The prepared cobalt-chromium-molybdenum alloy artificial jointimplant material has the advantages of high hardness, good toughness, and good plasticity, has a higher compression strength, tensile strength, and anti-fatigue property, compared with a conventionalartificial joint implant material, and is suitable for preparing artificial joints, which have a long service life and are resistant to fracture and stress fatigue.

Owner:PEKING UNION MEDICAL COLLEGE HOSPITAL CHINESE ACAD OF MEDICAL SCI

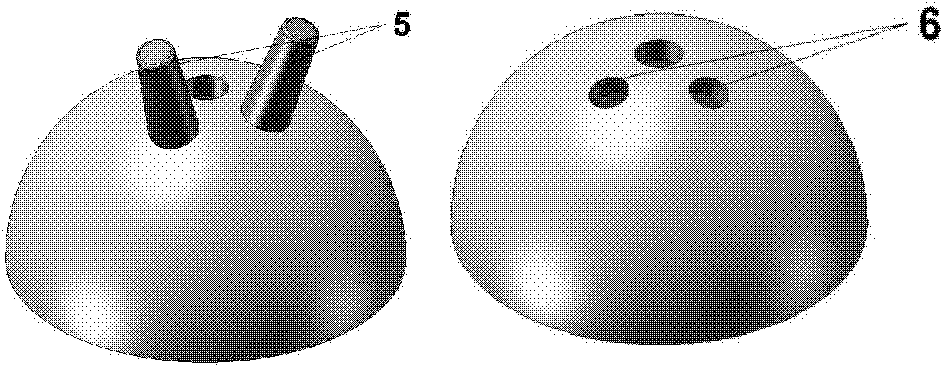

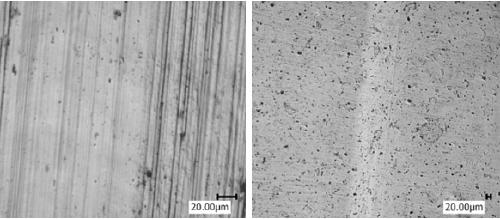

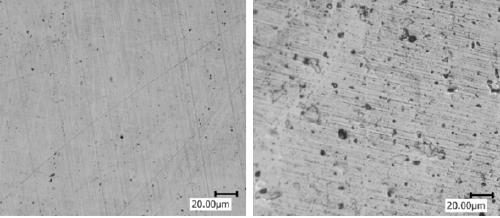

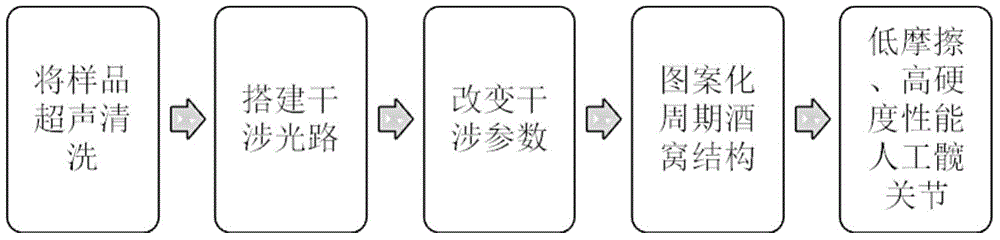

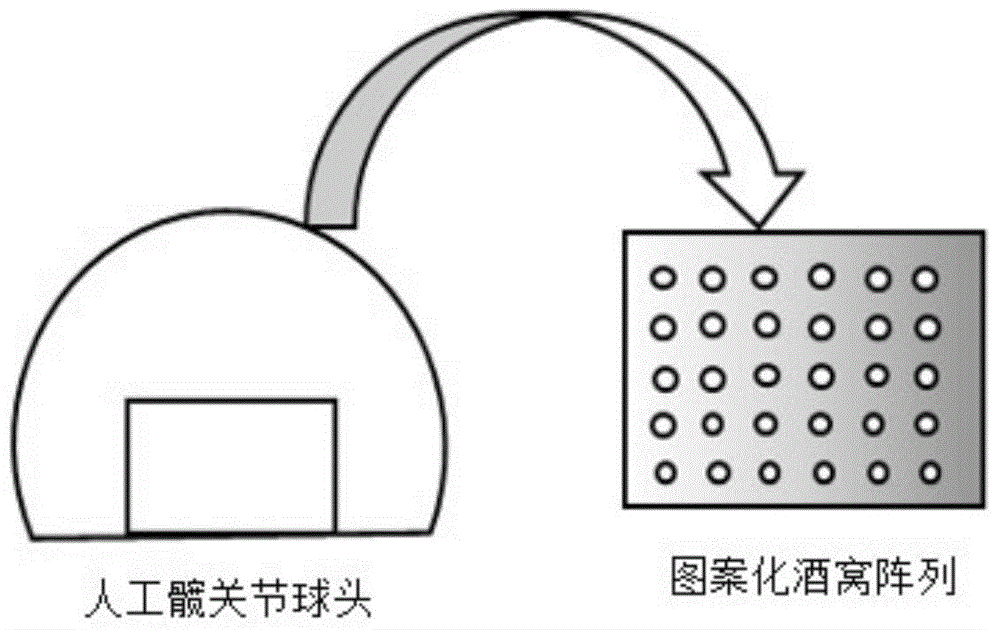

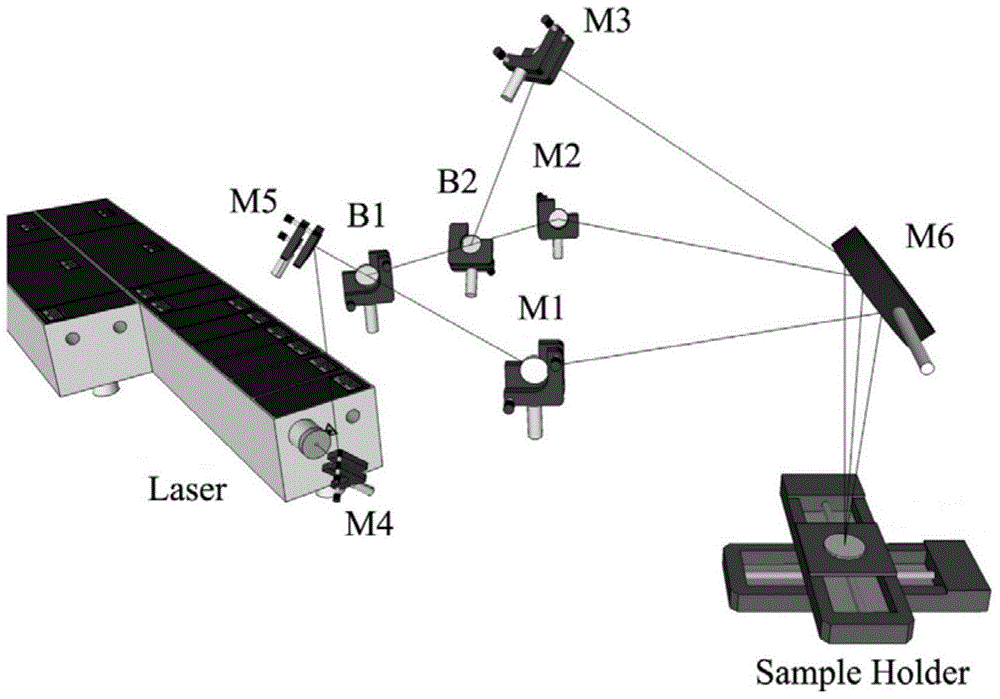

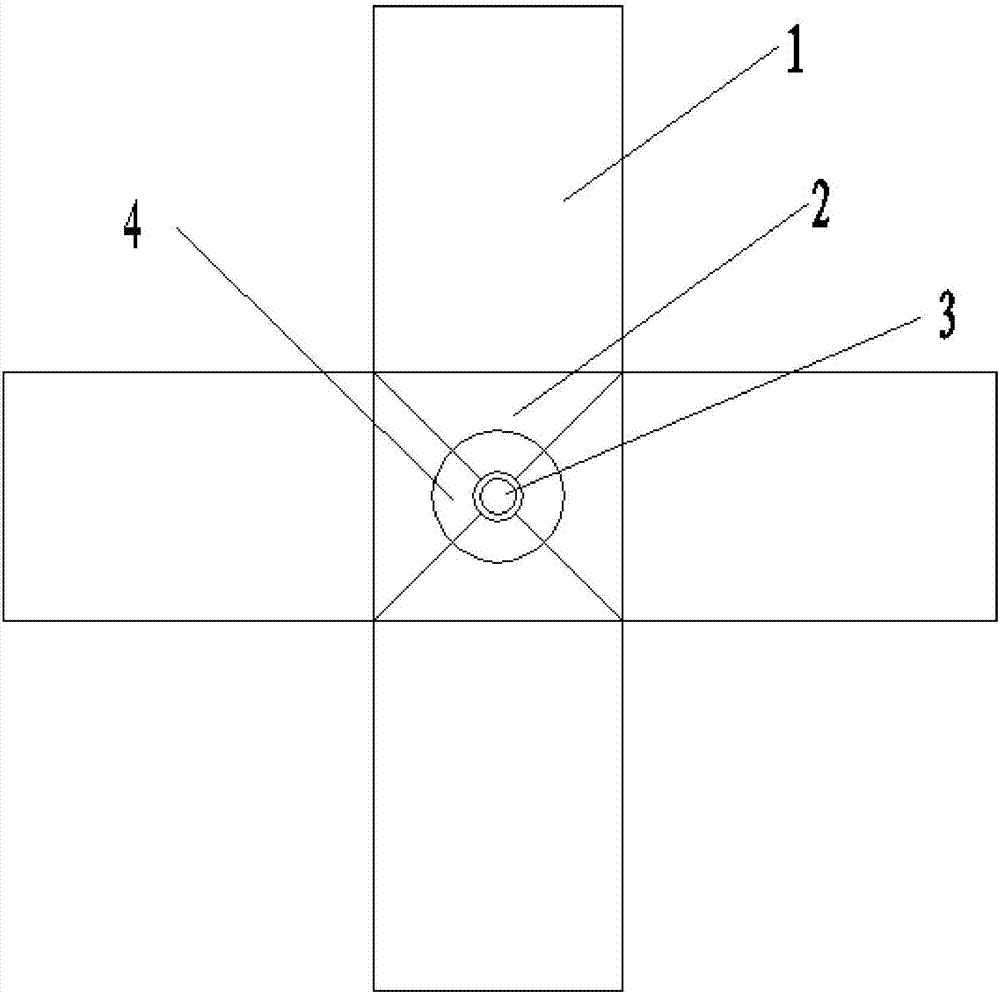

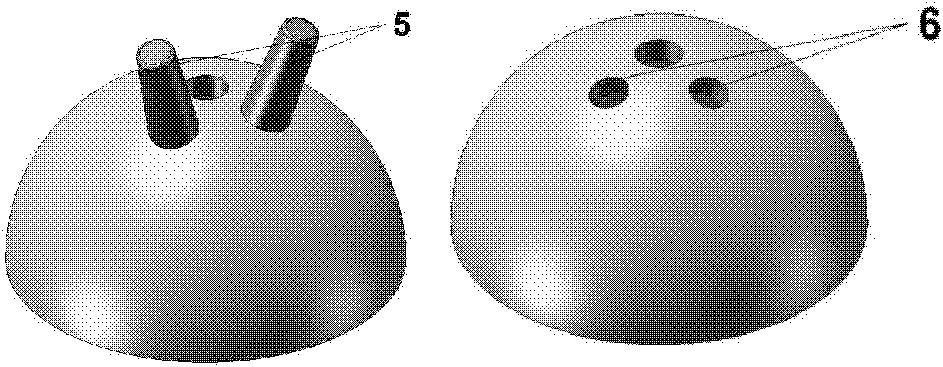

Method for preparing low-friction and high-hardness artificial hip joint ball through surface patterning

ActiveCN105055050AImprove tribological performanceHigh hardnessJoint implantsHip jointsFriction effectTissue fluid

The invention relates to a method for preparing a low-friction and high-hardness artificial hip joint ball through surface patterning. The low-friction and high-hardness artificial hip joint ball is made from a CO-Cr-Mo alloy material, and the method is characterized in that patterned dimple arrays are formed on the surface of the artificial hip joint ball, namely the patterned dimple arrays are made on the friction surface of the artificial hip joint ball through laser interferometric lithography to form a small temporary synovial fluid or tissue fluid storage device, and meanwhile the actual contact area between friction pairs is decreased and abrasive grains produced in the friction process are accommodated to achieve the friction-reducing purpose. The instantaneous high temperature of laser enables the grains to be refined, the material hardness is enhanced, and the artificial hip joint with low friction and high hardness is obtained. The low-friction and high-hardness artificial hip joint ball has good lubricating property and can reduce the friction effect between interfaces of the friction pairs of the artificial hip joint and reduce friction. In addition, the hardness is improved, the abrasion is reduced, and the friction and abrasion resisting performance of an existing artificial hip joint ball is optimized.

Owner:CHANGCHUN UNIV OF SCI & TECH

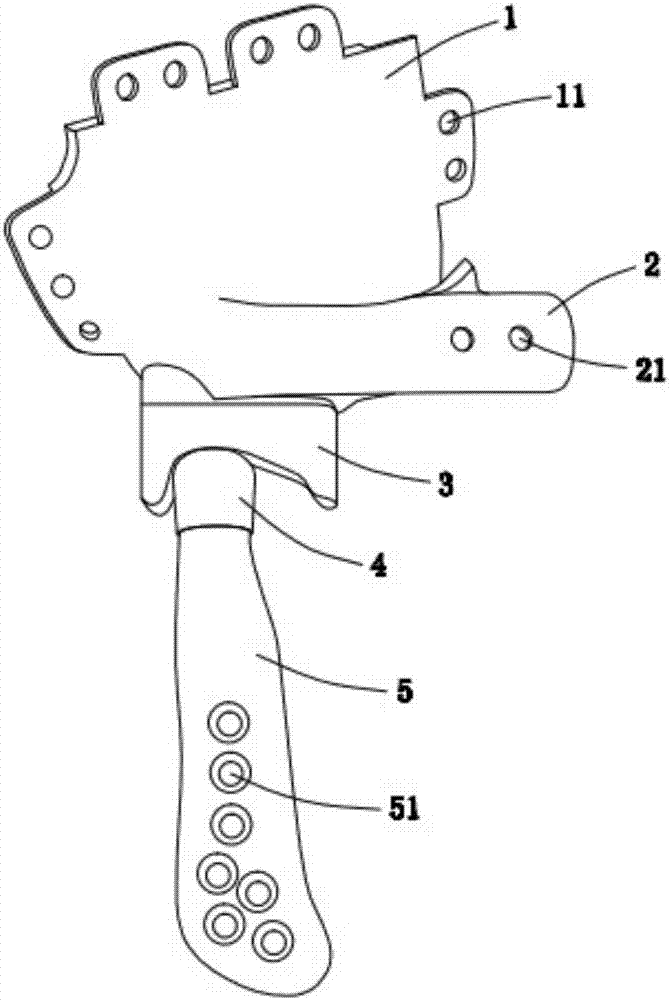

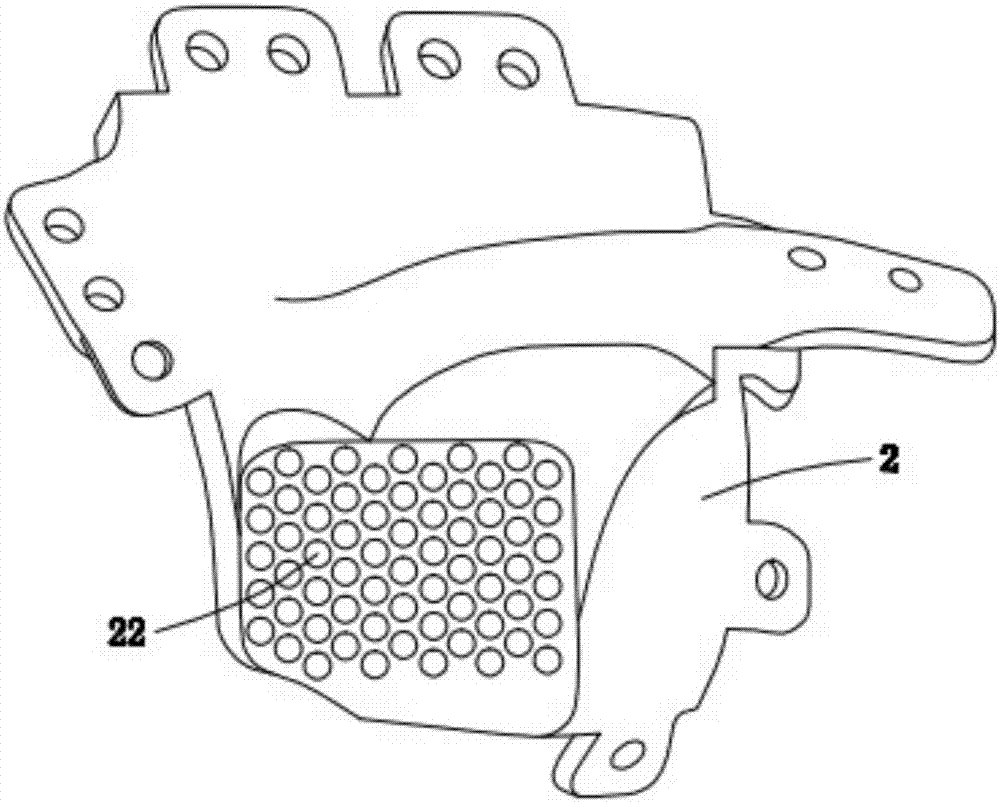

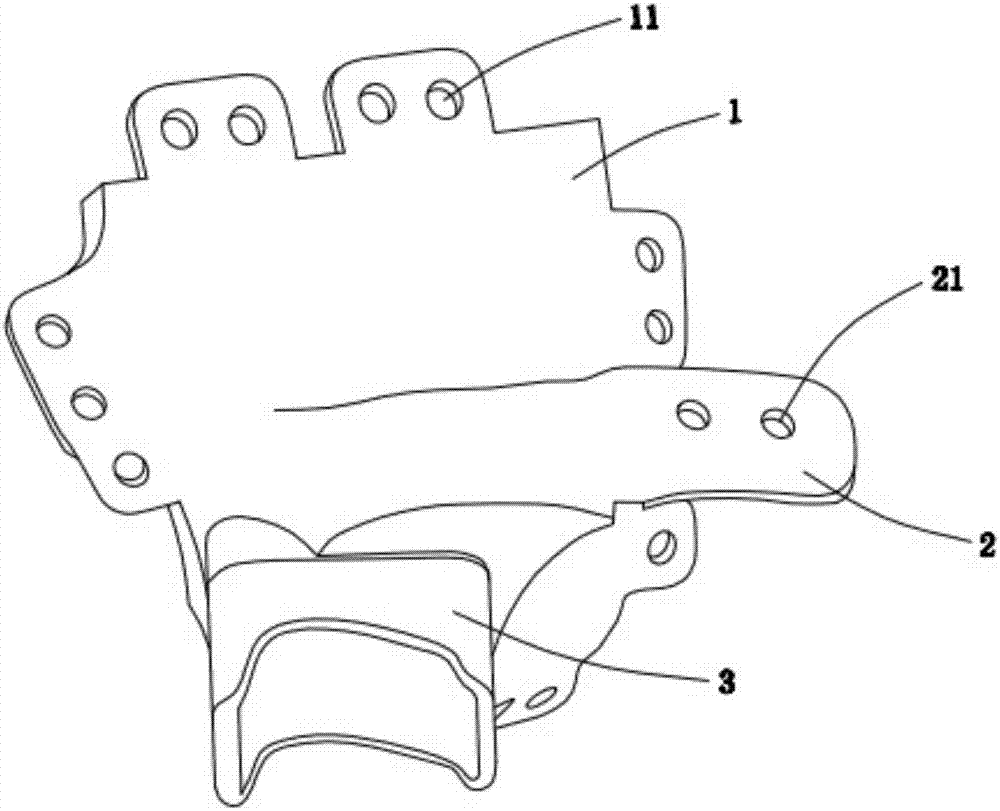

A kind of locking plate for femoral periprosthetic fracture revision and locking

InactiveCN105640635BNo need to increase the widthStrong bending resistanceBone platesStress concentrationInternal fixation

The invention relates to a fracture revision locking plate around the femoral prosthesis, which has a U-shaped main body matching the shape of the femur. The material of the main body can be titanium alloy or cobalt-chromium-molybdenum alloy; the bottom end of the main body has a constriction; two side wings are extended on both sides of the main body, which are respectively the first side wing, the second side wing, and the second side wing. Three flanks and a fourth flank; the main body and the flanks are provided with several nail holes. The present invention can fix the proximal end of the fracture at multiple angles without increasing the width of the steel plate, and the screw holding force, steel plate anti-bending force, and anti-rotation ability are all stronger than any previous fixing materials; the locking design can avoid excessive stripping of the periosteum due to the plate being too close to the bone surface and blood supply damage caused by soft tissue; the moment arm of the present invention is longer, and dispersed fixation can avoid steel plate fracture caused by stress concentration or bone nonunion caused by stress shielding; combined with minimally invasive percutaneous plate internal fixation technology, soft tissue damage can be further reduced .

Owner:黑龙江高德医疗科技有限责任公司

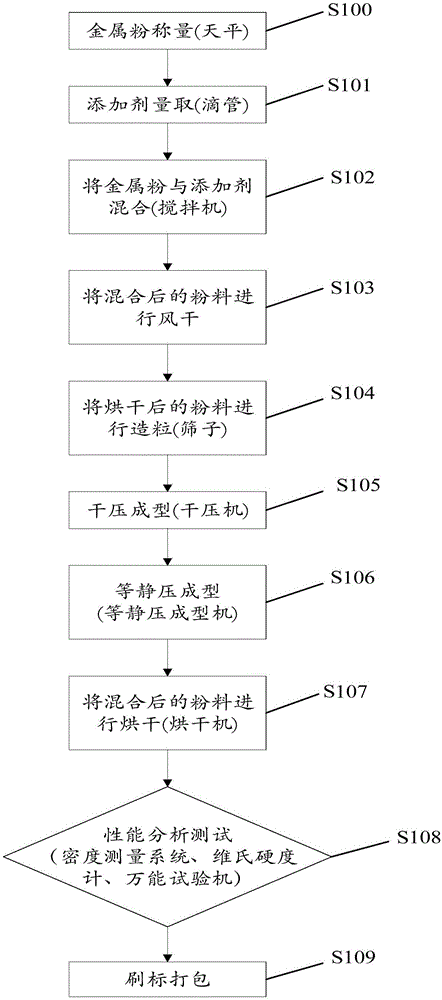

Soft metal crown and machining method thereof

InactiveCN106756258AReduce wearEasy to cutImpression capsTransportation and packagingMaterial resourcesMachining

The invention discloses a soft metal crown and a machining method thereof. The machining method comprises the following steps that (1) the weight of cobalt-chromium-molybdenum alloy powder needed by a soft metal block is calculated; (2) the cobalt-chromium-molybdenum alloy powder is weighed, an additive is added, and uniform mixing and stirring are conducted to obtain mixed powder, wherein the cobalt-chromium-molybdenum alloy powder comprises, by weight, 27.0-29.0% of Cr, 5.5-6.5% of Mo, smaller than 0.05% of O and the balance Co; (3) the mixed powder is air-dried, and the pelleted cobalt-chromium-molybdenum alloy powder is pressed and dried to obtain the soft metal block; and (4) a dental crown is firstly designed through CAD, cut through a dental milling machine and then sintered to obtain the soft metal crown. According to the soft metal crown and the machining method thereof, the metal block is easily cut through the dental milling machine, and bur abrasion is greatly reduced; and by adoption of the soft metal crown and the machining method thereof, compared with traditional casting processes, the machining precision is higher, manpower and material resource input can be greatly reduced, the production speed is increased, the cost is lowered, and the production efficiency is improved.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

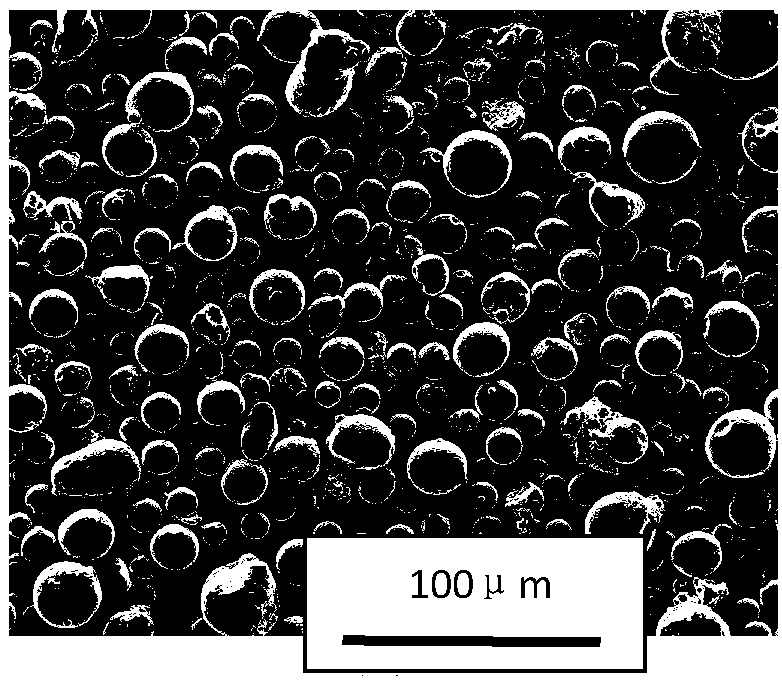

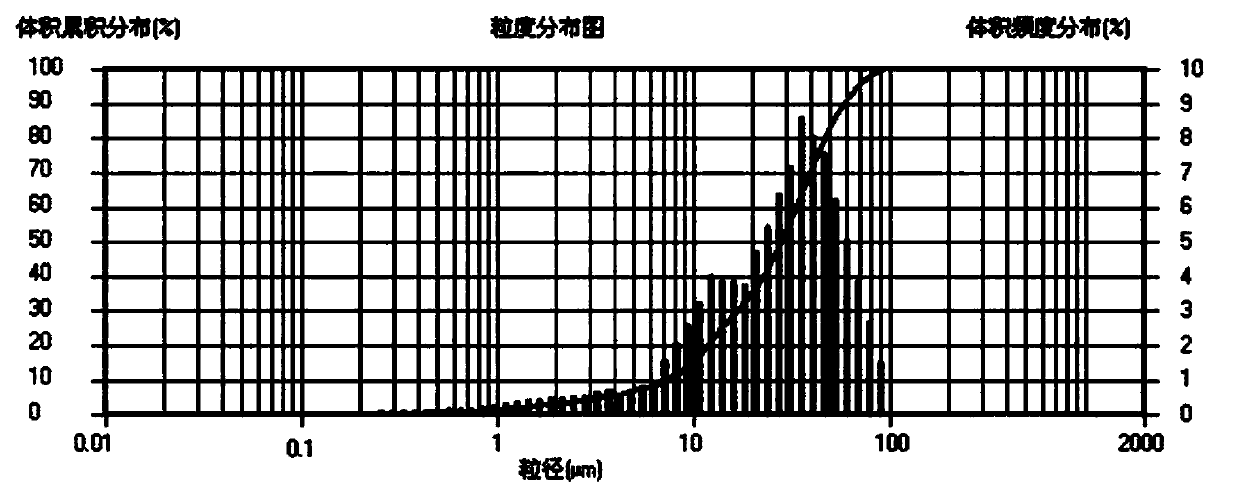

Preparation method for medical cobalt chromium molybdenum alloy powder for laser 3D printing

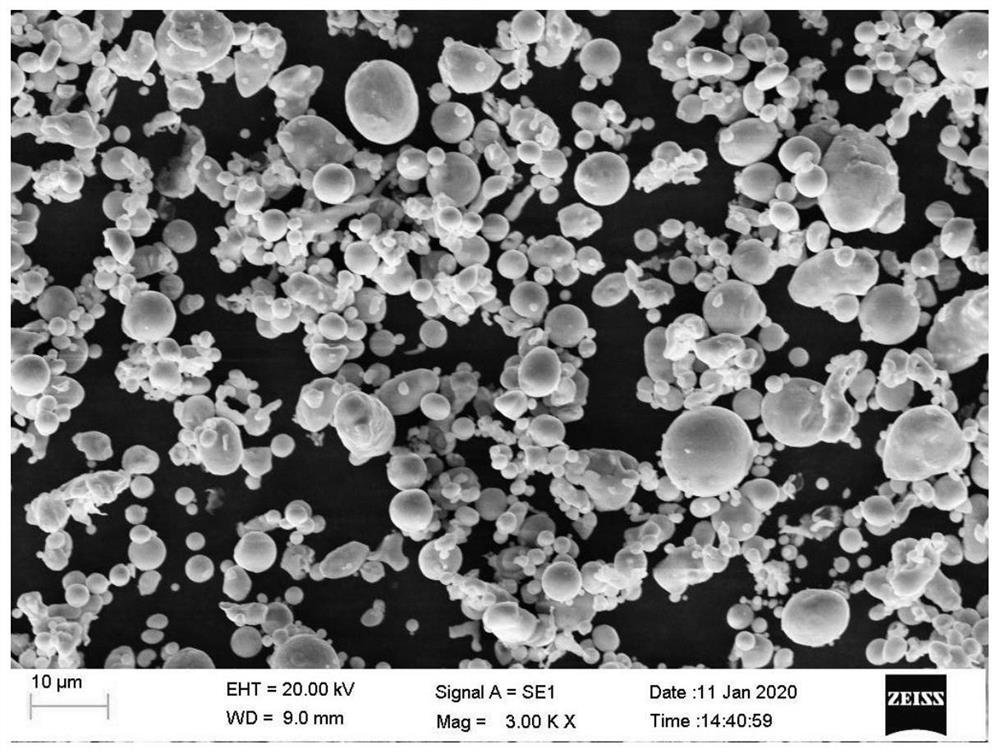

PendingCN111790913AUniform chemical compositionLow oxygenAdditive manufacturing apparatusMaterials scienceCobalt-Chromium-Molybdenum Alloy

The invention discloses a preparation method for medical cobalt chromium molybdenum alloy powder for laser 3D printing and belongs to the technical field of preparation of alloy powder for 3D printing. According to the technical scheme, the preparation method comprises the steps of burdening smelting, vacuumizing, argon filling, preparation of cobalt chromium molybdenum alloy liquid, forming of alloy powder through atomization, preparation of cobalt chromium molybdenum alloy fine powder of the grain size smaller than or equal to 53 [mu]m through vibratory screening and airflow classification of ultrafine grains. Aiming at characteristics of laser 3D printing technology, the prepared medical cobalt chromium molybdenum alloy powder has the characteristics of being uniform in chemical components, low in oxygen content, high in sphericity degree, low in hollow sphere rate and good in liquidity, and special requirements of the laser 3D printing technology for powder performance are met. Theprepared medical cobalt chromium molybdenum alloy powder for laser 3D printing is high in fine powder yield, the yield of the powder of the grain size smaller than or equal to 53 [mu]m reaches 80% orabove, finally the yield of qualified powder (of the grain size between 15 and 53 [mu]m) reaches 50% or above, and production cost is lowered effectively.

Owner:JINCHUAN GROUP LIMITED

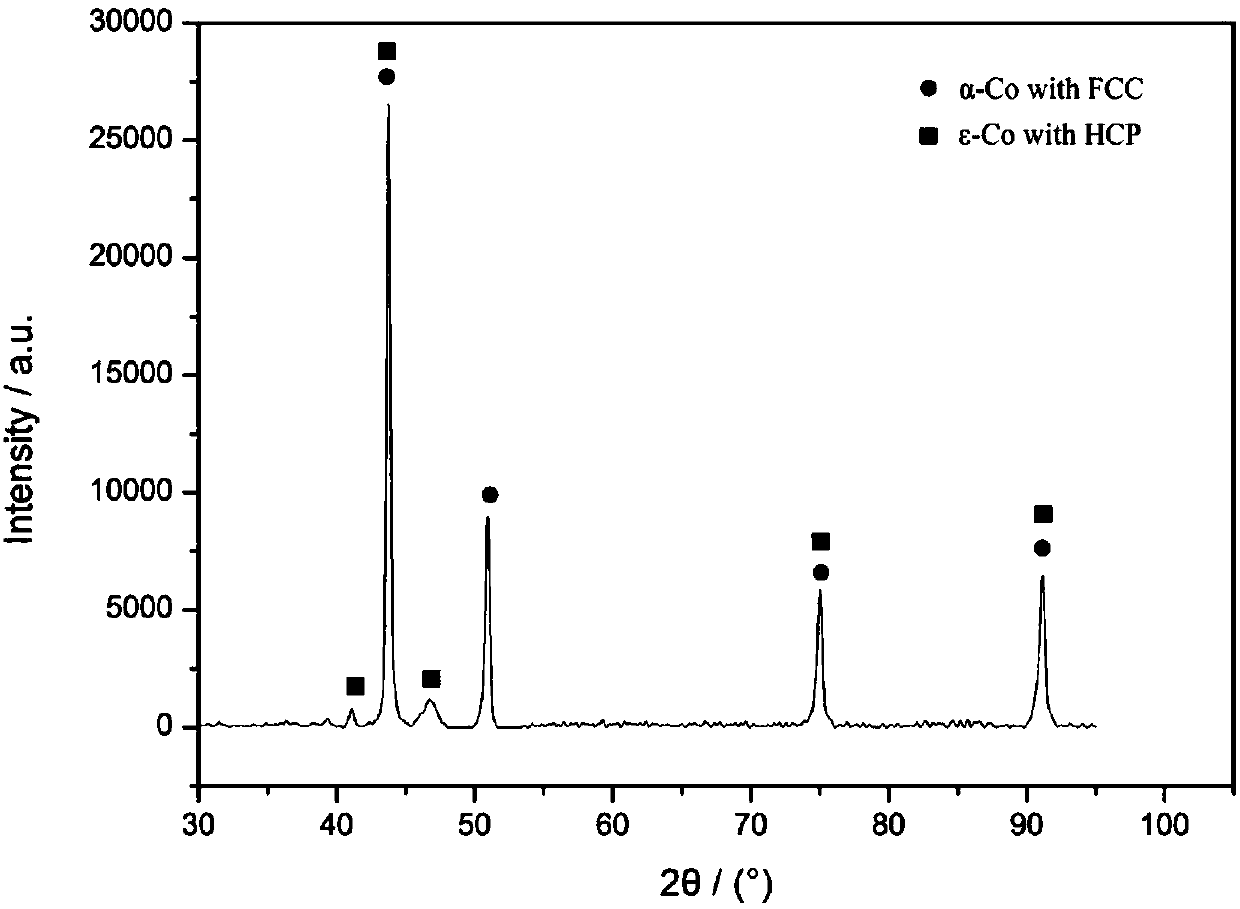

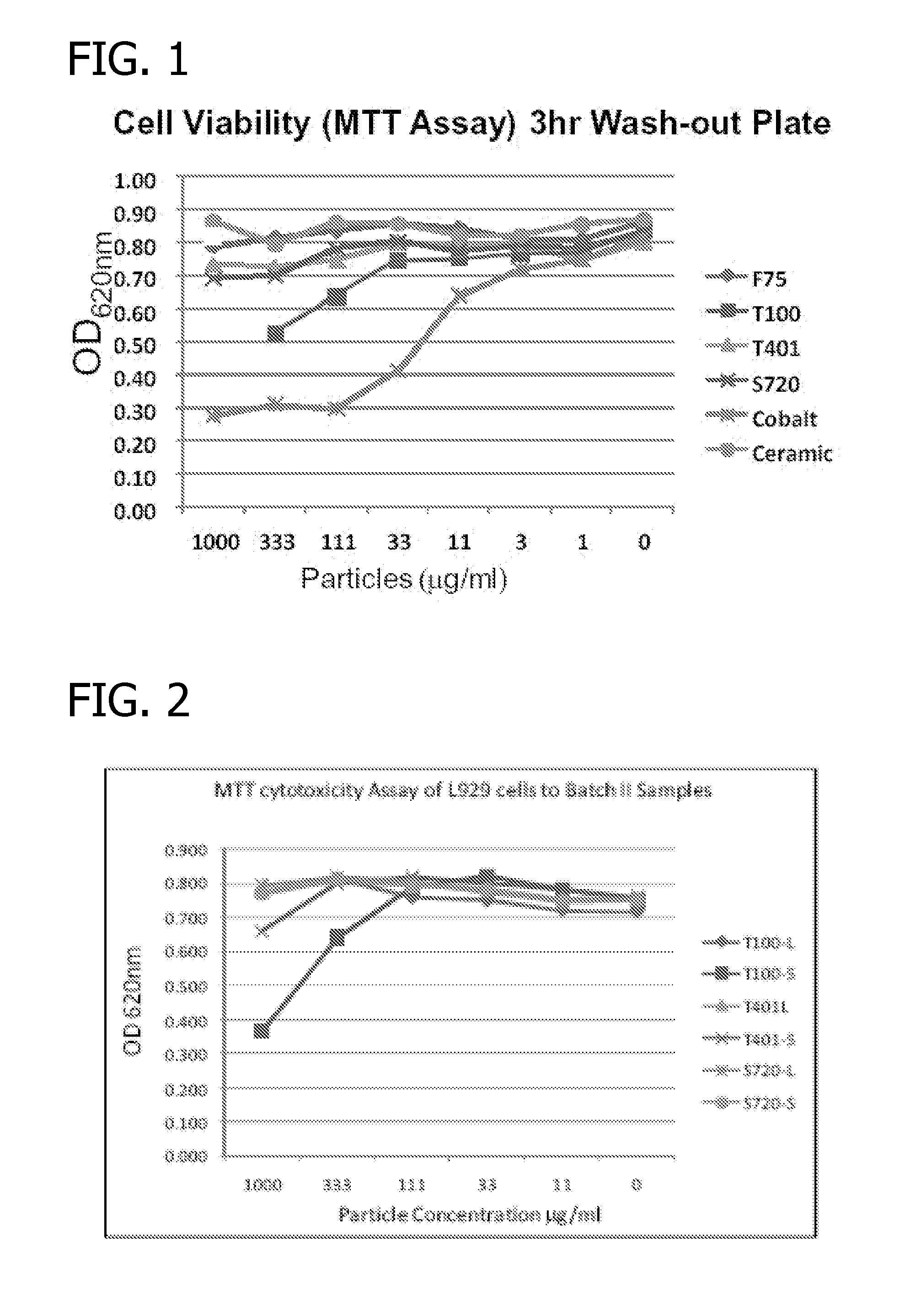

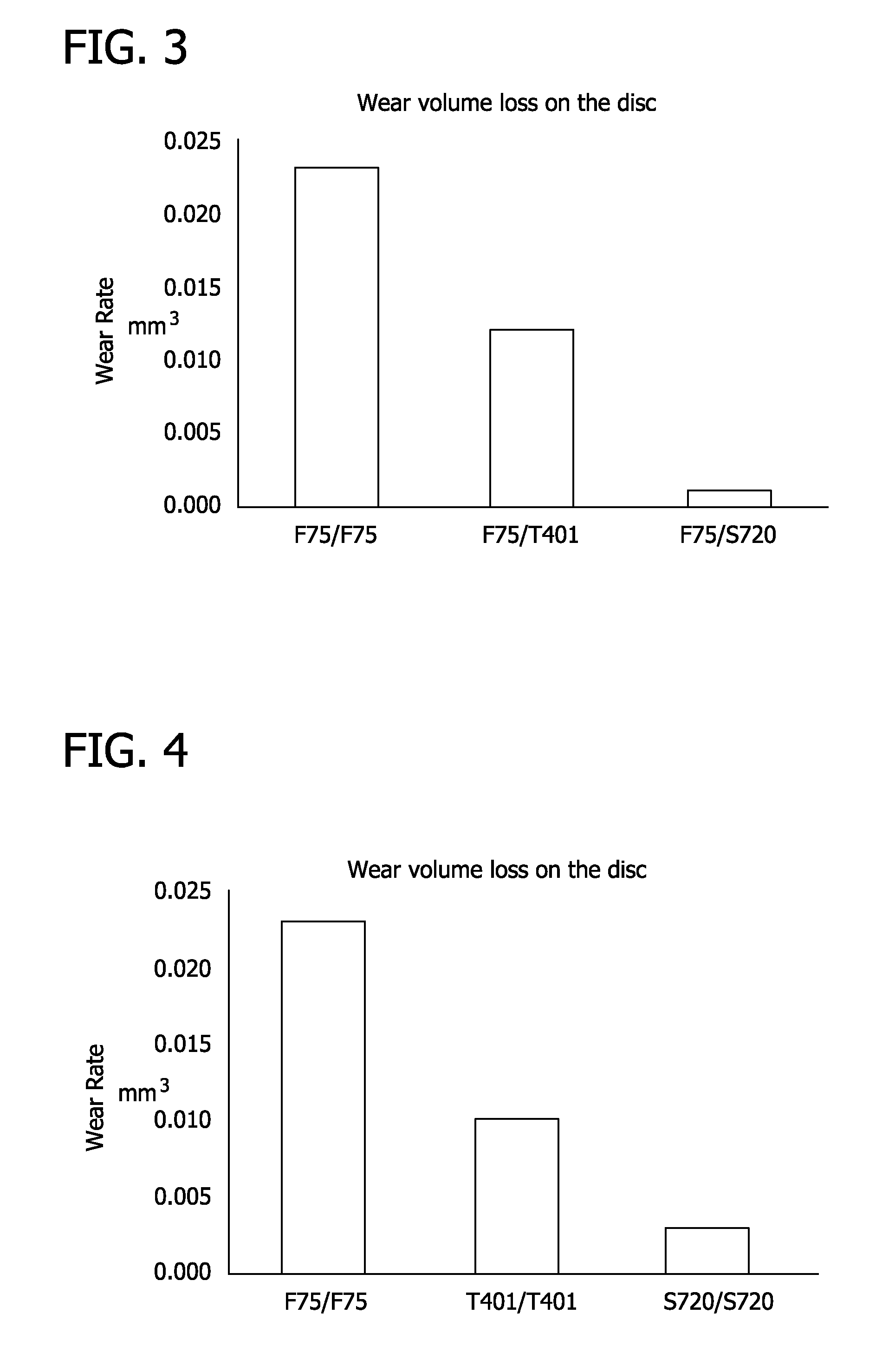

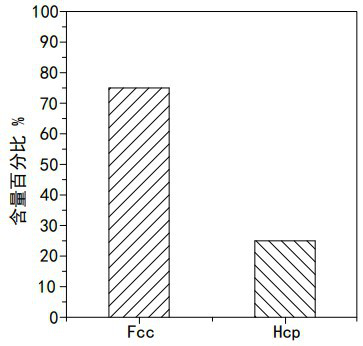

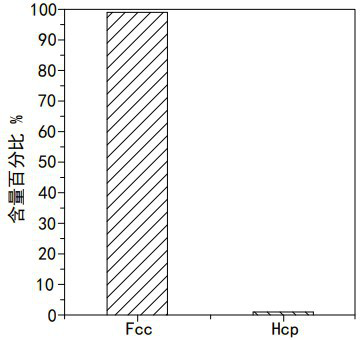

Surgical orthopedic implants made from wear-resistant cobalt-chromium-molybdenum alloys

A surgical implant component comprising an implant component body manufactured from an alloy comprising from about 23 to about 33 wt % Cr, from about 8 to about 20 wt % Mo, from about 0.05 to about 1.5 wt % Si, from about 0.35 to about 3.5 wt % C, from about 40 to about 60 wt % Co, and incidental impurities. The implant component alloy has an atomic % ratio of (Cr+Mo+Nb) / Co of at least 0.59, a matrix metallurgical microstructure comprising between about 45% and about 85% by volume face-centered cubic structure, and between about 15% and about 55% by volume hexagonal close-packed structure; and a Rockwell C hardness of greater than 35. A method for manufacturing a surgical implant component body for a surgical implant by a manufacturing method selected from the group consisting of casting, forging, and powder metallurgy pressing-plus-sintering from an alloy.

Owner:KENNAMETAL INC

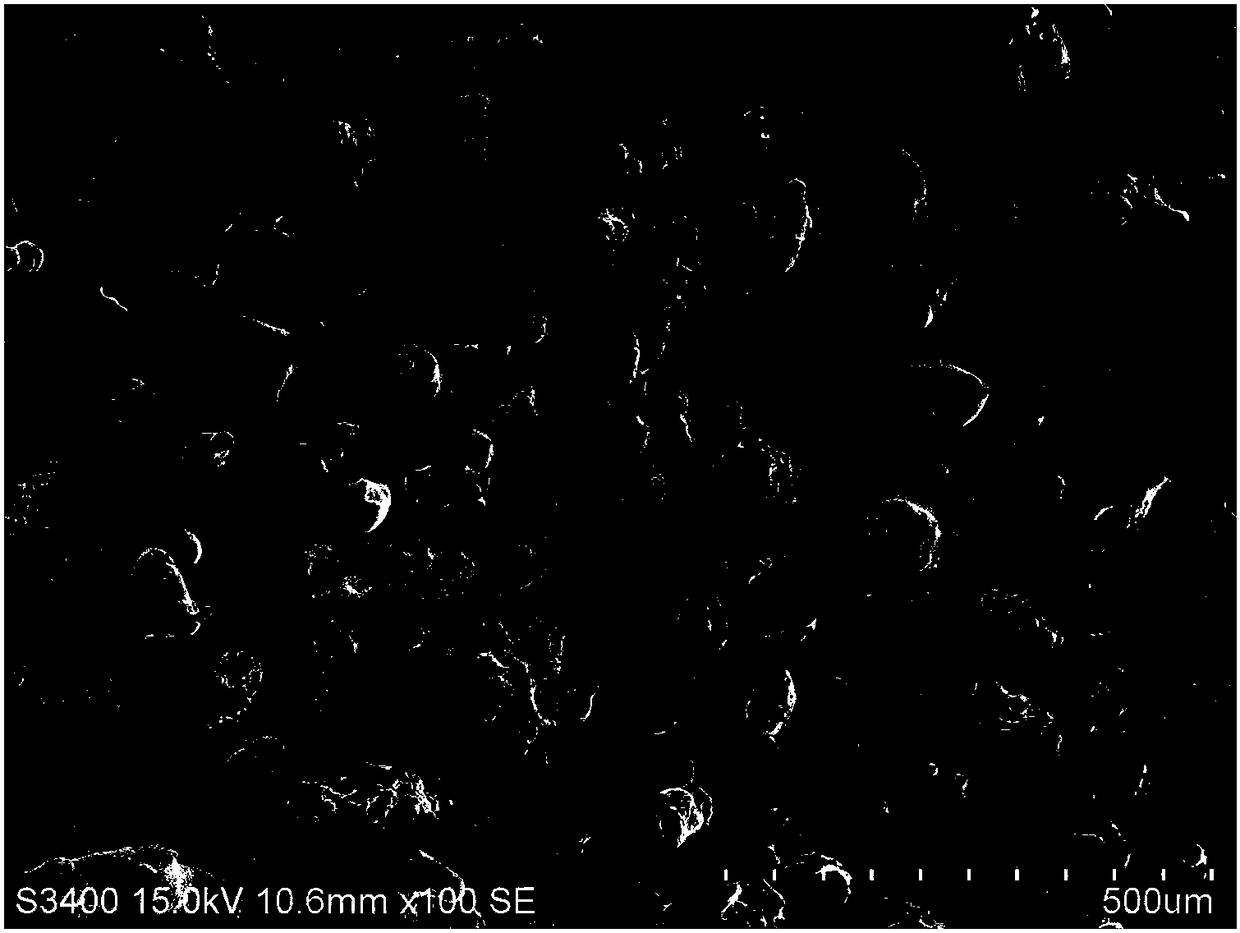

Method for preparing spherical cobalt-chromium-molybdenum alloy powder for micron-level additive material manufacturing

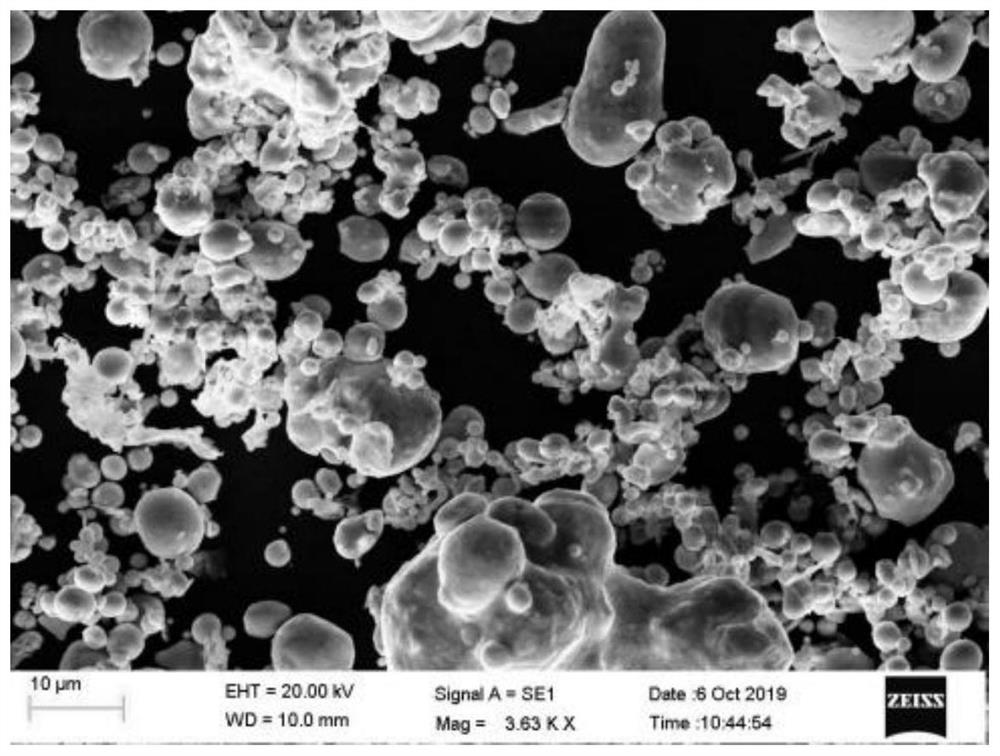

InactiveCN108856699AMorphological rulesHigh nodularityAdditive manufacturing apparatusTransportation and packagingCobalt-chromeAdditive layer manufacturing

The invention provides a method for preparing spherized cobalt-chromium-molybdenum alloy powder for micron-level additive material manufacturing. The adopted raw material is irregular cobalt-chromium-molybdenum alloy powder prepared through water atomization, and the micron-level spherical cobalt-chromium-molybdenum alloy powder with the irregular shape, the high nodularity larger than or equal to90%, the high sphericity degree and the high stacking density can be obtained through adjusted experiment parameter spheroidizing, and the spherical cobalt-chromium-molybdenum alloy powder can be directly used for additive material manufacturing due to good mobility.

Owner:LONGYAN ZIJIN INNOVATION RES INST

Die for rotary swaging machine and manufacturing method of die

InactiveCN107030241AImprove the performance of swagingLow costForging/hammering/pressing machinesManufacturing cost reductionWear resistant

The invention discloses a mold for a rotary forging machine, which comprises a mold main body. The mold main body is sequentially assembled from a plurality of mold blocks along the circumferential direction. The mold blocks include a support body and a working body, and the working bodies of each mold block are assembled to form a mold. In the working area of the main body, a mold hole is opened at the center of the working area of the mold body, and a surfacing layer is provided on the inner wall of the mold hole. The inner surface of the surfacing layer is the working surface of the swaging machine for swaging the workpiece. The material of the welding layer is cobalt-chromium-tungsten alloy or cobalt-chromium-molybdenum alloy; the mold hole is a circular through hole, and the ports on both sides of the mold hole expand outward and have a conical structure. In addition, the invention also provides a method for manufacturing the mold. The invention has a simple structure, and a layer of high-strength, high-strength, high-toughness, high-fatigue resistance and high-wear-resistant surfacing layer is provided on the inner wall of the mold hole, so as to improve the usability of the mold for the swaging machine, shorten the swaging manufacturing cycle, Reduce the amount of high-performance expensive mold materials and significantly reduce manufacturing costs.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Alloy powder and preparation method thereof

The invention discloses alloy powder and a preparation method thereof, belonging to the technical field of the preparation of alloy powder. The alloy powder comprises the following components by weight percent: 25-95% of cobalt, 4-55% of chromium, 1-15% of molybdenum, 0-2% of carbon and 0-3% of silicon. The preparation method comprises the following steps: weighting raw materials, placing the raw materials in a mixer to mix, then placing the obtained mixture in a sintering furnace to sinter, cooling, discharging, vibrating to crush, and screening twice to obtain cobalt-chromium-molybdenum alloy powder, wherein after screening, raw materials can be added in the screen underflow to prepare the cobalt-chromium-molybdenum alloy powder continuously. The cobalt-chromium-molybdenum alloy powder prepared by the method of the invention has the advantages of irregular shape of granule, high surface activity, low cost and the like and is particularly suitable to be used as the raw material of surface hot spraying. The preparation method does not need the device and mean of high temperature melting, thus the device cost and maintenance cost are lower.

Owner:有研资源环境技术研究院(北京)有限公司

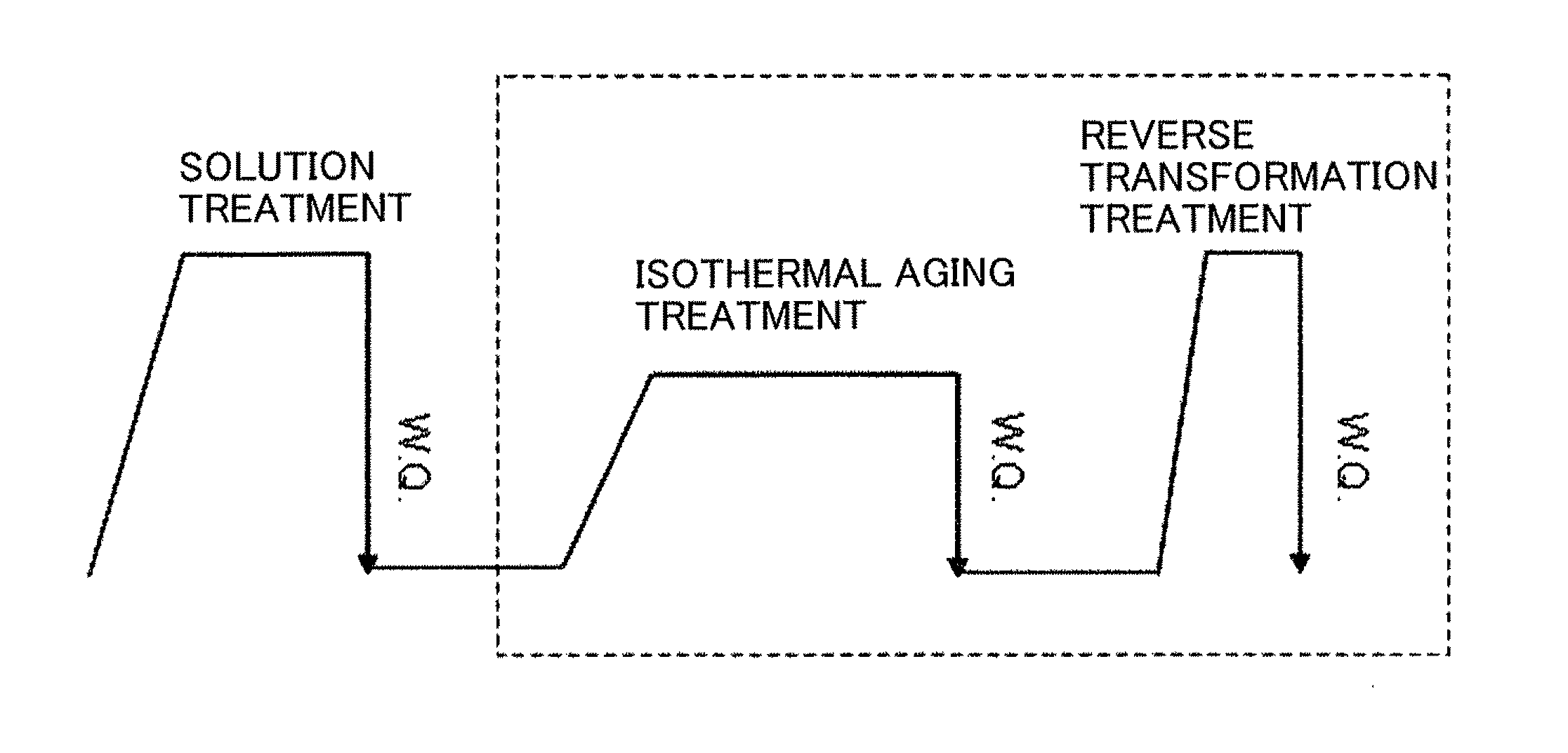

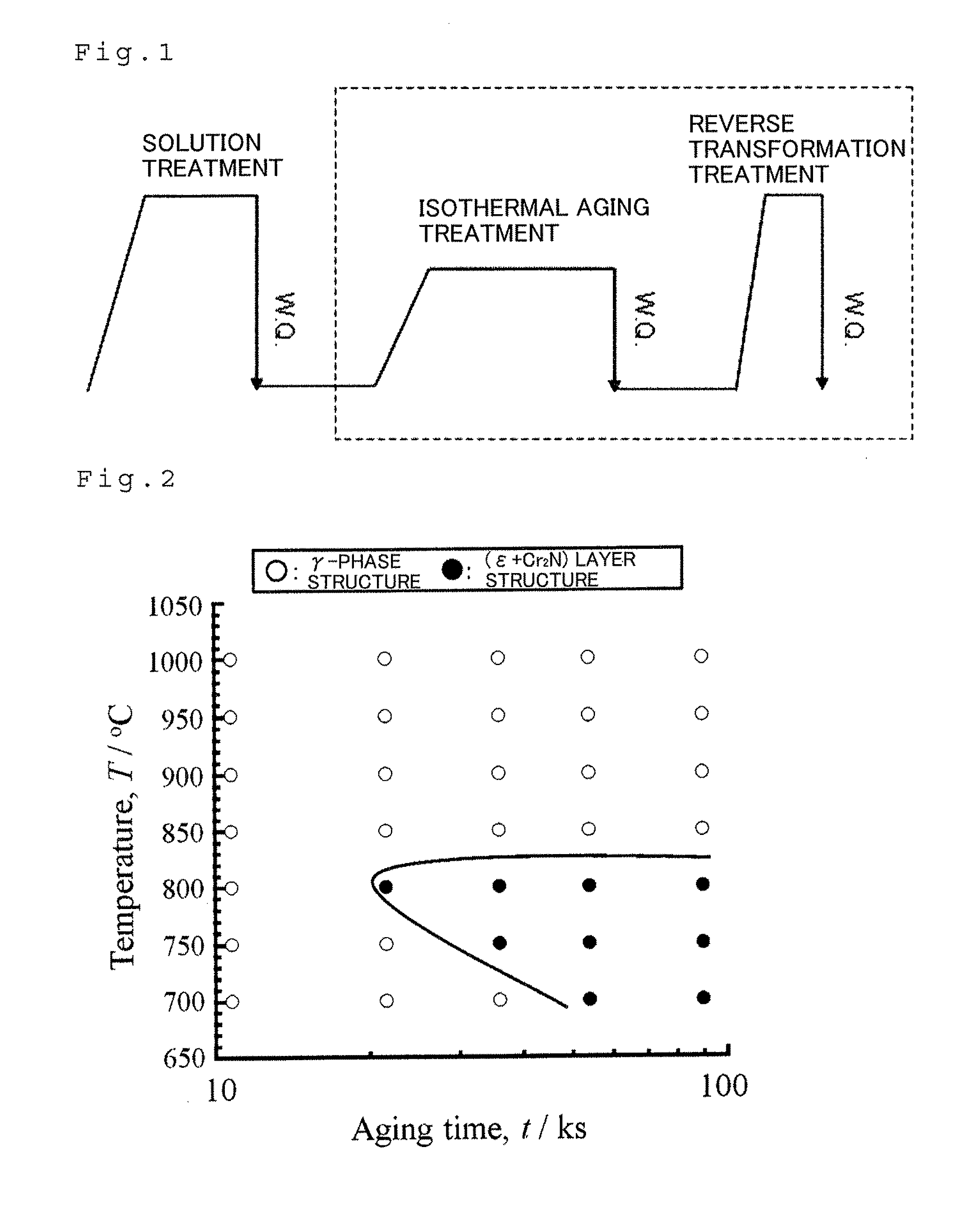

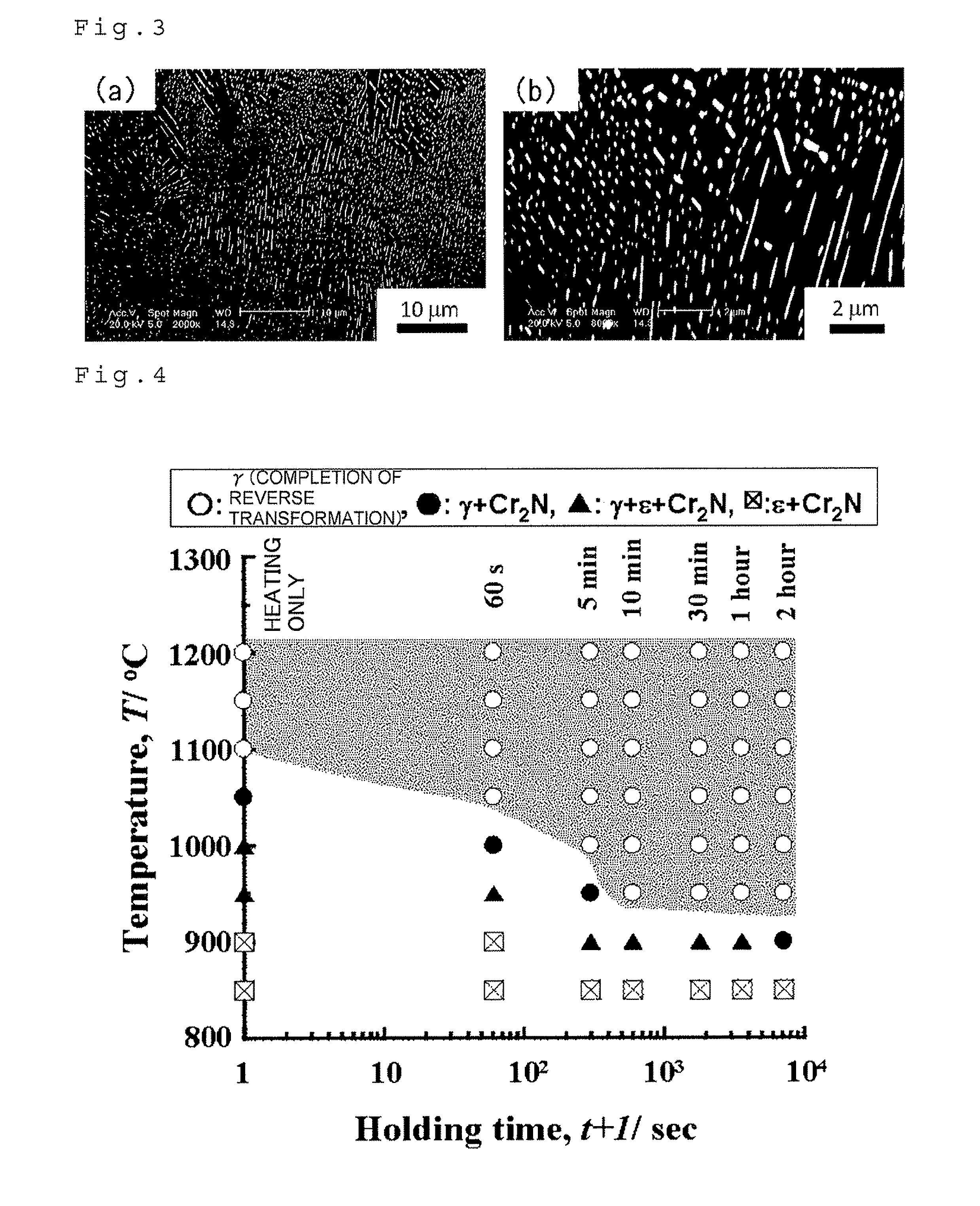

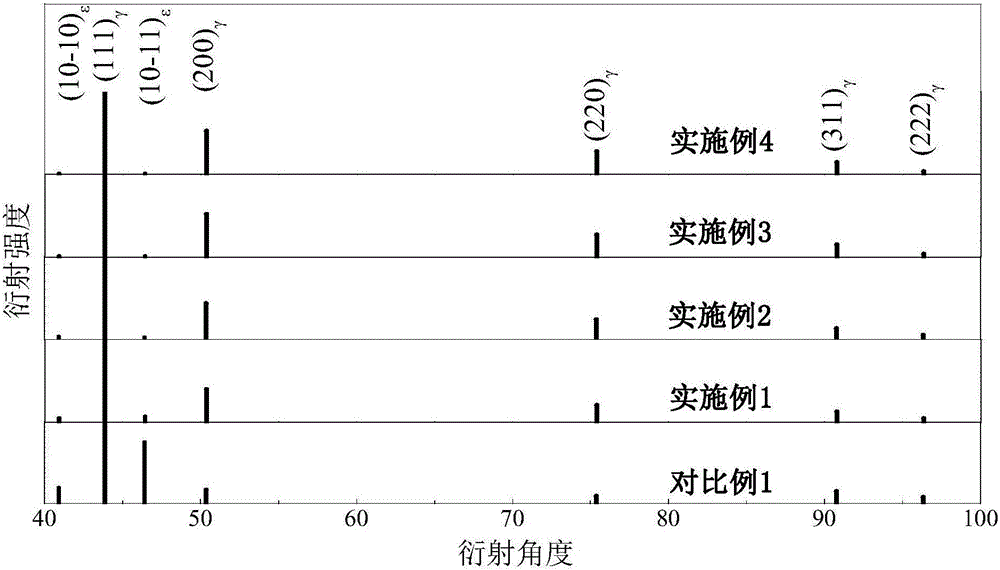

Method of forming fine grains of co-cr-mo alloy with nitrogen addition and co-cr-mo alloy with nitrogen addition

InactiveUS20110209799A1Easy to getHigh mechanical reliabilityJoint implantsSolid state diffusion coatingSolution treatmentNitrogen

A Co—Cr—Mo alloy with nitrogen addition composed of 26 to 35% by weight of Cr, 2 to 8% by weight of Mo, 0.1 to 0.3% by weight of N, and balance of Co is subjected to solution treatment and then subjected to isothermal aging treatment holding the alloy at 670 to 830° C. for a predetermined period of time to form a multi-phase structure composed of an ε-phase and a Cr nitride by means of an isothermal aging effect. After cooling, the alloy subjected to reverse transformation treatment in which the alloy is heated at a temperature range of 870 to 1100° C. for reverse transformation to a single γ-phase from the multi-phase structure composed of an ε-phase and a Cr nitride.

Owner:TOHOKU UNIV

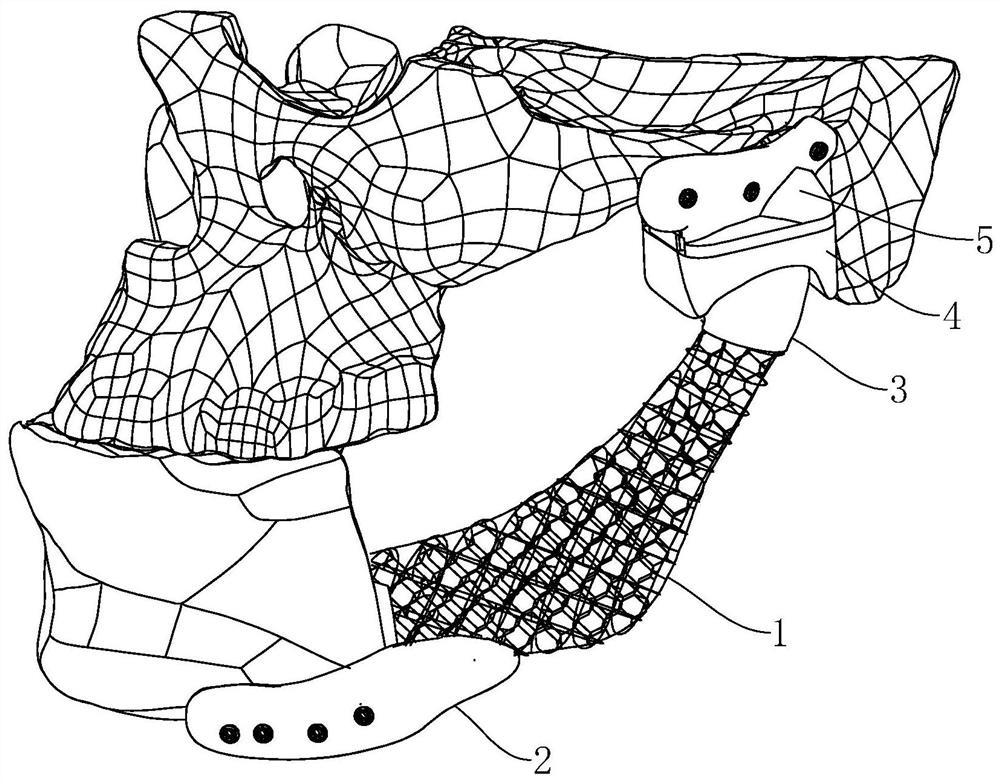

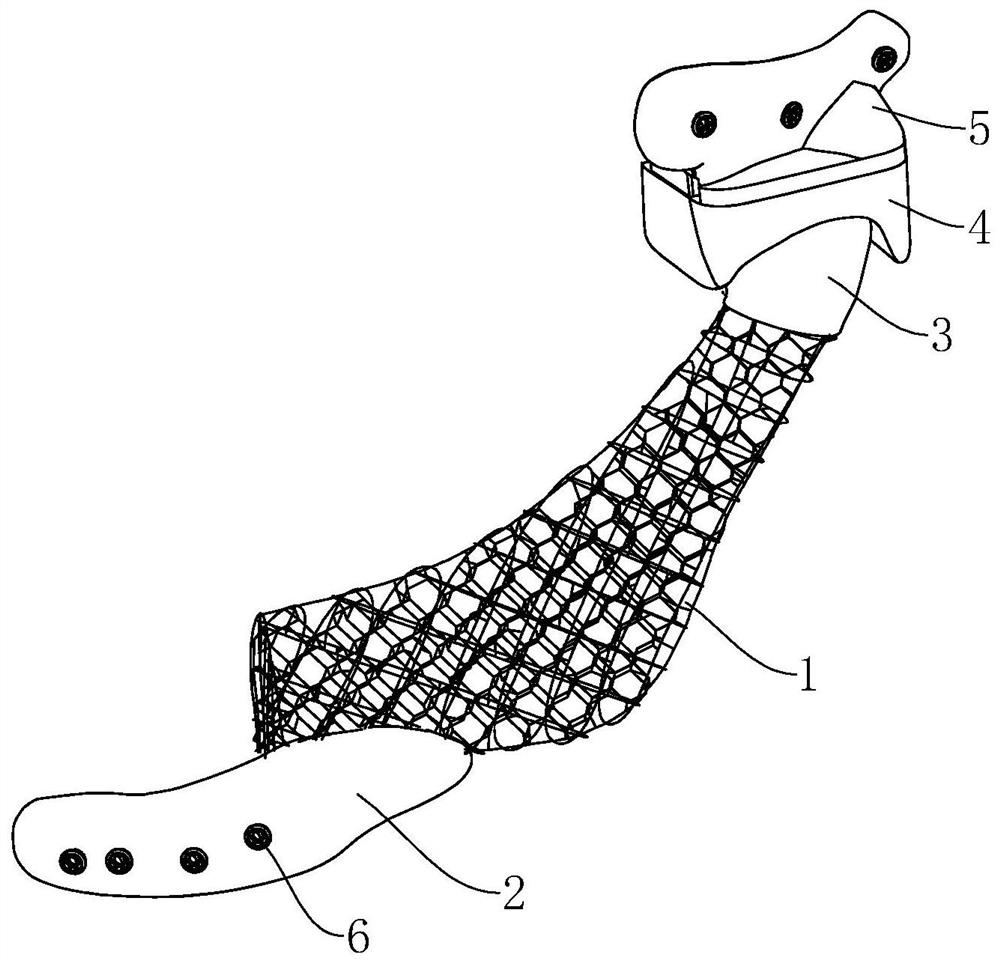

Basis cranii-temporo-mandibular joint combination prosthesis

The invention discloses a basis cranii-temporo-mandibular joint combination prosthesis, which comprises a basis cranii portion, a zygomatic arch portion, an articular fossa portion, a condylar process head portion and a joint handle, wherein the basis cranii portion, which is in charge of repairing basis cranii defect, is made from a titanium alloy material; a plurality of fixing holes are formed in the edge of the basis cranii portion, so that the basis cranii portion is fixed to temporal bone; the zygomatic arch portion, which is in charge of repairing zygomatic arch defect, is made from a titanium alloy material; a plurality of fixing holes are formed in the front end of the zygomatic arch portion, so that the zygomatic arch portion is fixed to zygomatic arch; the articular fossa portion is an articular surface capable of simulating mandibular movements of a human body, and the articular fossa portion is made from an ultrahigh molecular weight polyethylene material; the basis cranii portion, the zygomatic arch portion and the articular fossa portion are integrally connected; the condylar process head portion, which is made from a cobalt-chrome-molybdenum alloy material, is represented as a hollow cylindrical structure; the joint handle, which is made from a titanium alloy material, is used for repairing partial ascending limbs; a fixing hole is formed in the joint handle; and the condylar process head portion and the joint handle are integrally connected. The best effect can be achieved since different parts are made from different materials; and the individual basis cranii portion, zygomatic arch portion and articular fossa portion as well as the condylar process head portion and the joint handle, which are made from special materials, are integrally connected, so that the prosthesis is more stable and firmer and is better in fixing effect.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

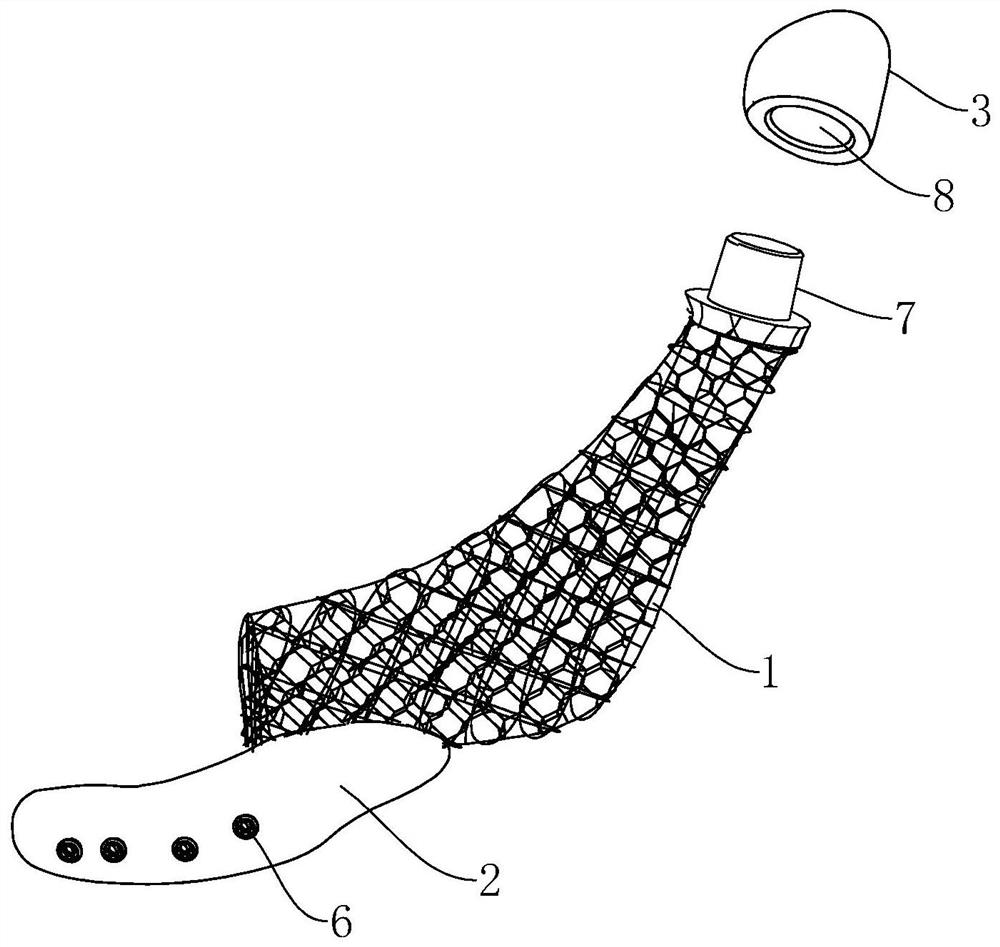

Temporomandibular joint prosthesis

PendingCN112137769ASolve the problem of osteolysisImprove structural strengthJoint implantsTomographyTitanium alloyCobalt-Chromium-Molybdenum Alloy

The present invention relates to the field of implant prostheses and particularly to a temporomandibular joint prosthesis. The temporomandibular joint prosthesis comprises a mandible prosthesis, a mandible fixing plate, a glenoid fossa prosthesis made of ultra-high molecular weight polyethylene / ceramic, a glenoid fossa fixing plate and a condyle process prosthesis prepared from cobalt-chromium-molybdenum alloy by mechanical processing / ceramic, a positioning boss is formed at one end, matched with the condyle process prosthesis, of the mandible prosthesis, and a positioning groove matched withthe positioning boss is formed in the condyle process prosthesis. A condyle process on the mandible prosthesis is designed into the separated single condyle process prosthesis, and the condyle processprosthesis is made of the cobalt-chromium-molybdenum alloy or ceramic and matched with the glenoid fossa prosthesis made of the high polymer polyethylene material or ceramic to form a structure of amovable joint part. Therefore, the mandible joint and the mandible fixing plate can be subjected to 3D printing by a titanium alloy material to adapt to a unique face shape of each patient, and meanwhile, a problem of osteolysis caused by long-term use is also solved.

Owner:北京中安泰华科技有限公司

Cobalt-chromium-molybdenum alloy powder material for injection molding and manufacturing method of cobalt-chromium-molybdenum alloy powder material

InactiveCN112553506AReduce oxygen contentImprove yieldTransportation and packagingMetal-working apparatusManganeseCobalt

The invention relates to the technical field of powder metallurgy, in particular to a cobalt-chromium-molybdenum alloy powder material for injection molding and a manufacturing method of the cobalt-chromium-molybdenum alloy powder material. The cobalt-chromium-molybdenum alloy powder material comprises the following components including, by weight, 27%-30% of chromium, 5.0%-6.0% of molybdenum, 1.0% of nickel, 1.0% of manganese, 0.35% of carbon and the balance cobalt. A production method of the cobalt-chromium-molybdenum alloy powder material comprises the steps that the raw material componentsare analyzed; materials are prepared; melting and alloying are carried out; an alloy of a uniform structure is obtained through a smelting and sintering process; water atomization powder preparationis carried out, and high-sphericity-degree cobalt-chromium-molybdenum alloy powder is produced through a water-gas combined atomization powder preparation device; the powder is dehydrated; low-temperature vacuum drying is carried out; airflow is graded; and the powder with high tap density and high fluidity is obtained by combining airflow grading and vibration screening and matching powder particle size distribution. The cobalt-chromium-molybdenum alloy powder which is stable in quality, high in sphericity degree, high in fluidity, uniform in alloy structure and low in oxygen content is prepared through a water-gas combined atomization method, and therefore the yield of sintered products is increased, and the manufacturing cost is saved.

Owner:SHIJIAZHUANG LIDE POWDER MATERIAL CO LTD

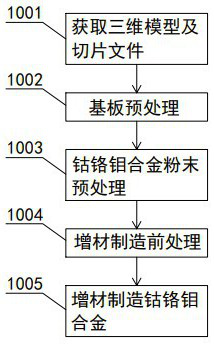

Method for regulating and controlling two-phase proportion of cobalt-chromium-molybdenum alloy in laser additive manufacturing

ActiveCN113102773AAvoid time costReduce economic costsAdditive manufacturing apparatusIncreasing energy efficiencyEconomic benefitsLaser additive manufacturing

The invention discloses a method for regulating and controlling the two-phase proportion of a cobalt-chromium-molybdenum alloy in laser additive manufacturing, and belongs to the technical field of additive manufacturing. The method is characterized by comprising the following steps that Step a, a three-dimensional part model is established, and slicing treatment is performed; Step b, the cobalt-chromium-molybdenum alloy powder is dried; Step c, before additive manufacturing, inert gas is introduced for protection; and Step d, additive manufacturing is carried out, in the additive manufacturing process, laser cladding is carried out on each layer of cobalt-chromium-molybdenum alloy powder at least once after preheating, cladding is carried out on the cobalt-chromium-molybdenum alloy powder layer by layer, and the cobalt-chromium-molybdenum alloy component is obtained. By means of the method for regulating and controlling the two-phase proportion of the cobalt-chromium-molybdenum alloy in laser additive manufacturing, the defect that in the prior art, the two-phase proportion of the cobalt-chromium-molybdenum alloy needs to be changed through follow-up heat treatment is overcome, the follow-up needed complicated heat treatment steps and corresponding heat treatment equipment can be omitted, the part preparation time is greatly shortened, the economic cost is greatly reduced, and the economic benefits of parts can be effectively improved.

Owner:SHANDONG UNIV OF TECH +1

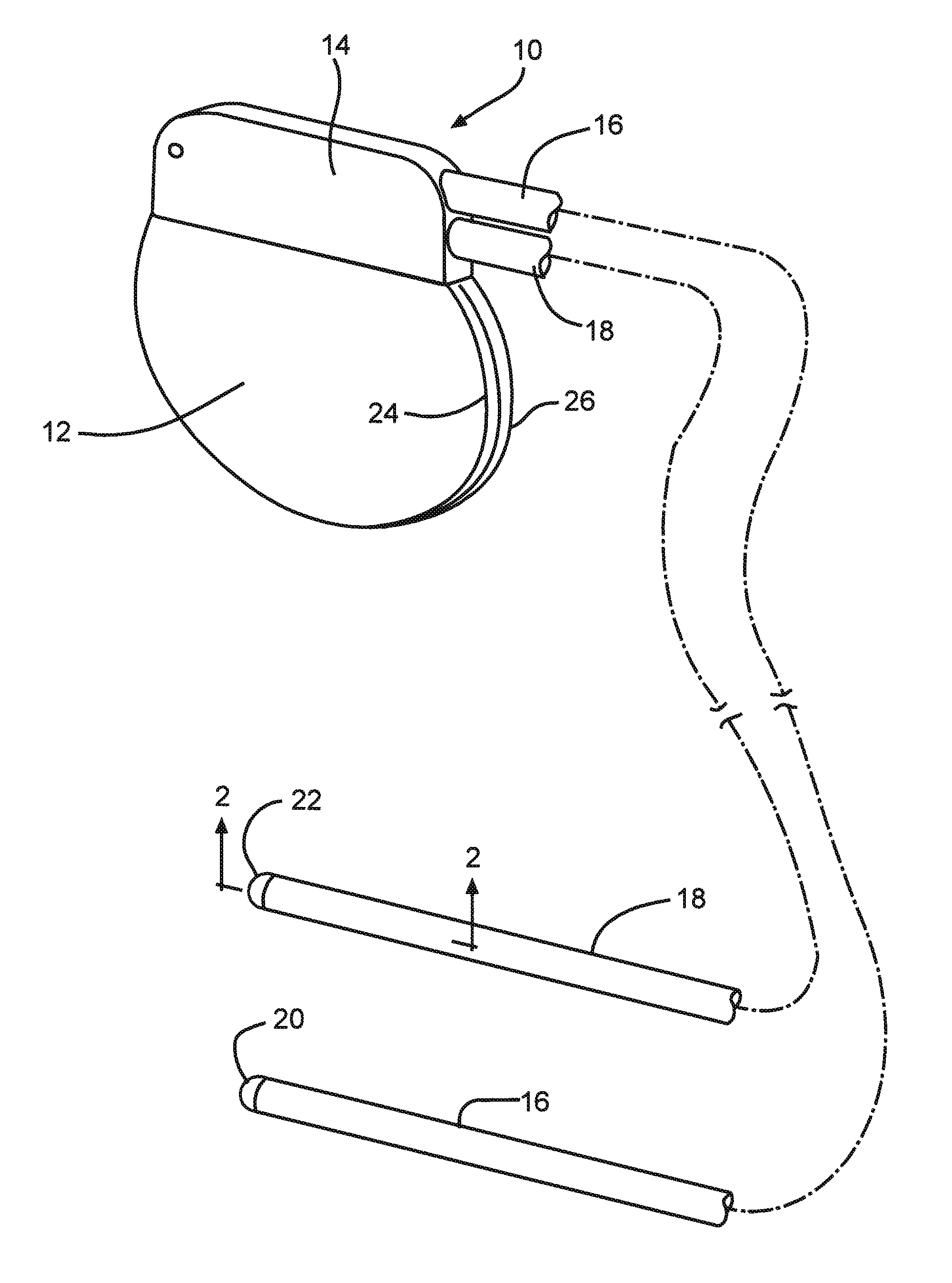

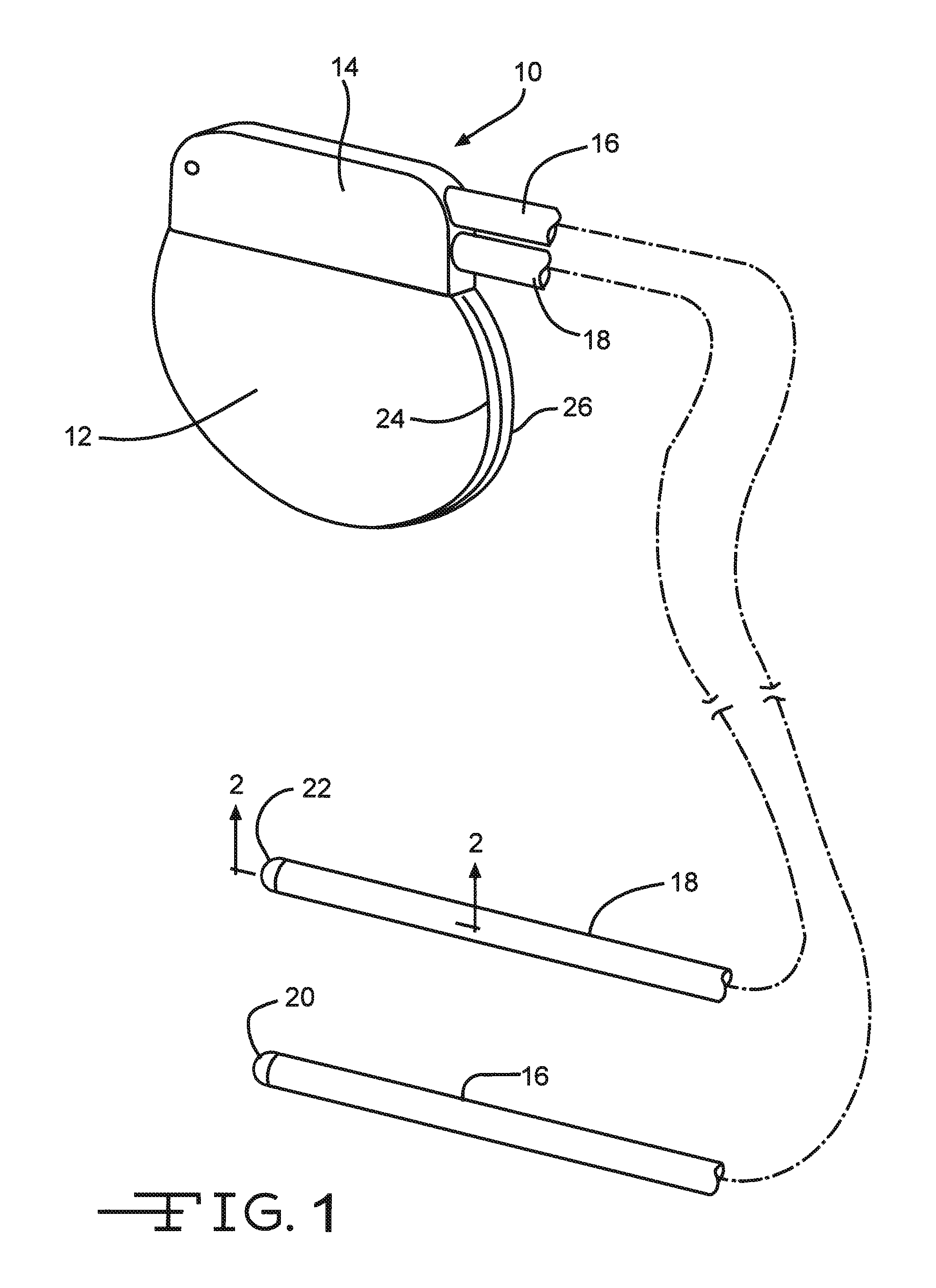

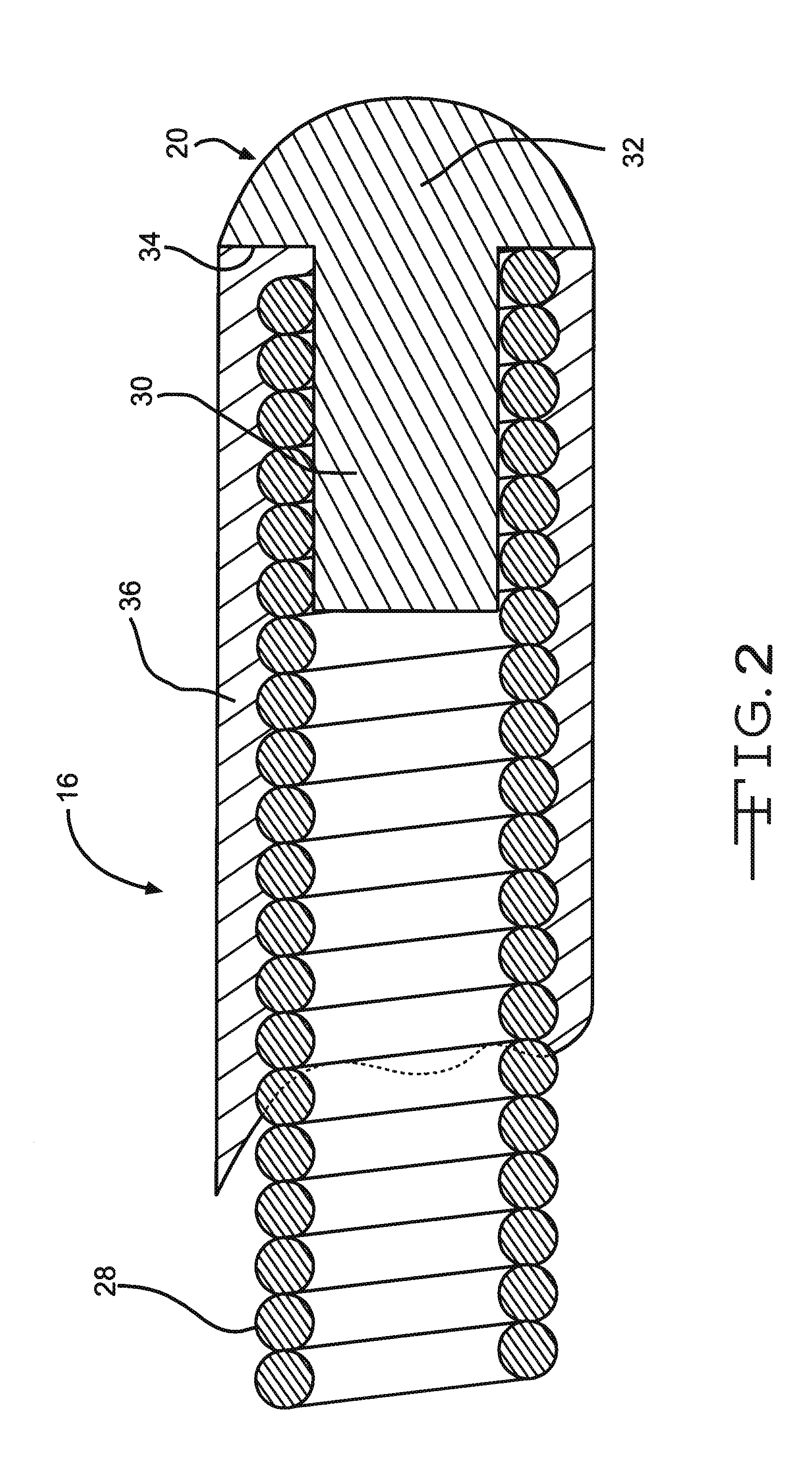

Method For Providing An Implantable Electrical Lead Wire

InactiveUS20100189879A1Good hardness and durability and adhesionPrevent degradationSpinal electrodesTransvascular endocardial electrodesElectricitySputtering

Implantable electrical lead wires, such as cobalt-chromium-molybdenum alloy wires, are coated with a metal, ceramic, or carbon to a thickness of about 100 nm or less to provide a non-reactive interface to polyurethane sheathing materials. Preferred is sputter coating an amorphous carbon intermediate the alloy wire and the polyurethane sheath.

Owner:WILSON GREATBATCH LTD

Cobalt-chromium-molybdenum alloy smelting method capable of preventing remelting splashing

PendingCN114561550AReduce splashPrevent splashIncreasing energy efficiencyMolten stateSmelting process

A cobalt-chromium-molybdenum alloy smelting method capable of preventing remelting splashing comprises the steps of raw material pretreatment, vacuumizing, induction preheating, argon partial pressure, intermittent smelting, pressurized smelting and blowing-out pouring, in the intermittent smelting process, by continuously adjusting the power of a power source, an alloy material is in a molten state that the outer side edge part is molten, and the center part is solid, and the alloy material is in a molten state; the lasting time of subsequent pressurized smelting can be shortened, and the possibility of molten metal splashing is reduced; in the pressurized smelting process, due to the action of argon backfilling pressure, liquid can be effectively prevented from splashing under vacuum negative pressure, and alloy liquid is stirred and turned to be in a component uniform state through the electromagnetic action in vacuum induction smelting. By designing and formulating reasonable smelting power, smelting time, argon backfilling pressure and backfilling time, the uniformity of alloy components can be improved under the condition of preventing alloy smelting splashing, and the conditions of alloy liquid splashing and non-uniform alloy components in the smelting process are solved.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Antioxidant alloy material for sealing valve

InactiveCN104999732ACorrosion resistantScratch resistantOperating means/releasing devices for valvesMetal layered productsStellite alloyOxidation resistant

The invention discloses an antioxidant alloy material for sealing a valve. The antioxidant alloy material for sealing the valve is formed by combining stellite arranged on the uppermost layer, a deoxidizing agent arranged on the middle layer and stainless acid-resisting steel arranged on the bottommost layer; the stellite is cobalt-chromium-tungsten alloy or Co-Cr-Mo alloy or cobalt-base alloy, the stellite accounts for 74%-76% of the total weight of the antioxidant alloy material for sealing the valve, the deoxiding agent accounts for 3%-5% of the total weight of the antioxidant alloy material for sealing the valve, and the stainless acid-resisting steel accounts for 20%-22% of the total weight of the antioxidant alloy material for sealing the valve. The antioxidant alloy material for sealing the valve has the advantages of corrosion resistance, scratch resistance, erosion resistance and oxidation resistance.

Owner:苏州市大力电器有限公司

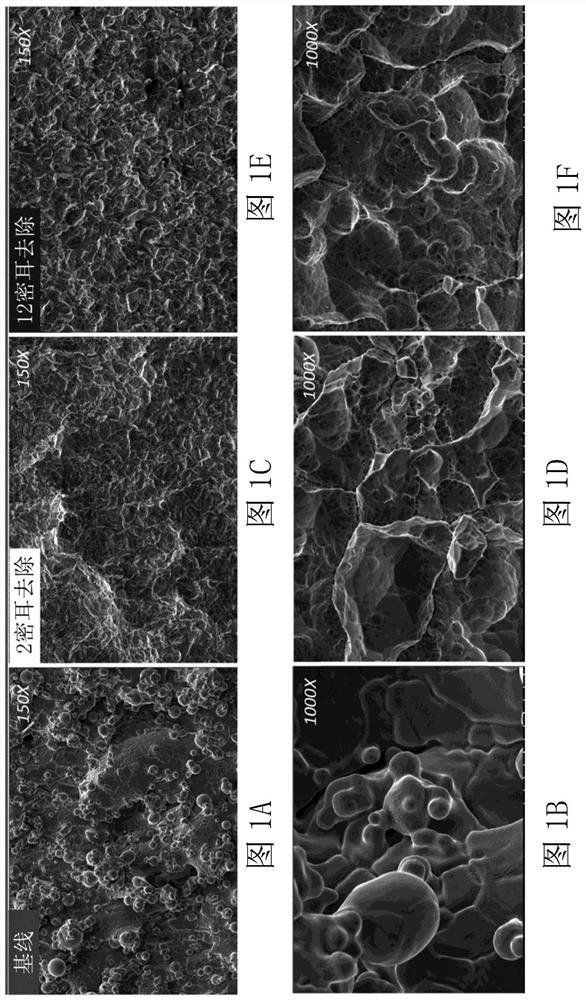

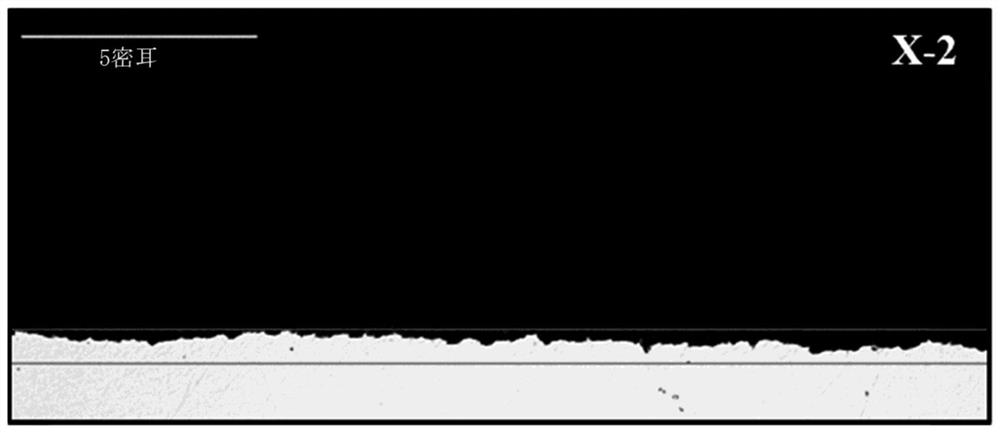

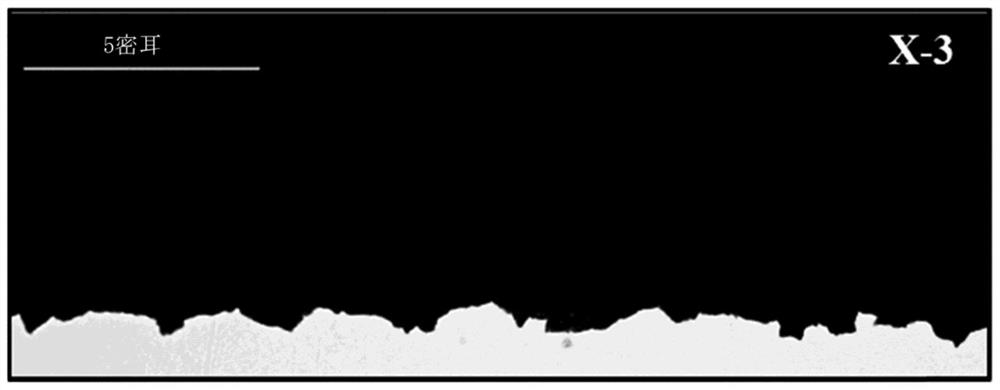

Cobalt chrome etching process

Compositions and methods for etching cobalt chromium alloys are disclosed. The compositions generally include at least two mineral acids, certain component metals of the alloy to be etched, and optionally iron (Fe). For example, when etching a cobalt chromium molybdenum alloy, the metals may include chromium (Cr), molybdenum (Mo), and optionally, cobalt (Co). The at least two mineral acids may include hydrochloric acid (HCl), nitric acid (HNO3), and hydrofluoric acid (HF). The methods provide for etching an entire surface of a substrate or etching a surface of a substrate in a pattern using selective coating patterns and / or coating removal. Thus, unlimited patterns, as well as etch depths and variations in etch depths are achievable using the compositions and methods disclosed.

Owner:MAT TECH BV

Acetabular prosthesis of artificial hip joint with rotational ellipsoid joint interface

ActiveCN102125472BImprove joint interface stress concentration phenomenonMeet personalized treatment needsJoint implantsAcetabular cupsStress concentrationTarsal Joint

The invention belongs to the technical field of medical devices and discloses an acetabular prosthesis of an artificial hip joint with a rotational ellipsoid joint interface, which comprises an acetabular outer cup made of a cobalt / chrome / molybdenum alloy and an acetabular liner made of polyethylene. The liner of the acetabular prosthesis comprises a spherical outer surface and a rotational ellipsoid inner surface, wherein the radius of the spherical outer surface, i.e. the outside diameter of the liner, is equal to the subtraction of the thickness of the acetabular outer cup from the radius of the acetabular prosthesis outer cup; the length of the major axis of the rotational ellipsoid inner surface is equal to the subtraction of the thickness of the liner from the outside diameter of the liner; and the length of the minor axis of the rotational ellipsoid inner surface is equal to the multiplication of the length of the major axis by 0.98. A positioning groove and a clamping ring arearranged between the liner and the outer cup to achieve the effect of fixation. According to the shapes of acetabular fossa of different patients, the acetabular prostheses of different specifications are designed and manufactured so as to solve the problem of stress concentration on the joint interface of the spherical artificial hip joint in the prior art and meet the needs for individual treatment of different patients. Therefore, the acetabular prosthesis provided by the invention is truly put into effect in clinics.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Medical fully-austenitic cobalt-chromium-molybdenum alloy and preparation method and application thereof

The invention discloses medical fully-austenitic cobalt-chromium-molybdenum alloy. The medical fully-austenitic cobalt-chromium-molybdenum alloy comprises, by weight, 26%-33% of chromium, 4.5%-7.5% of molybdenum, 0.08%-0.25% of nitrogen, and the balance cobalt and impurities. The invention further discloses a preparation method of the fully-austenitic cobalt-chromium-molybdenum alloy. The preparation method includes the steps of conducting smelting under the condition of 1490-1600 DEG C to obtain liquid alloy, conducting solidification and cooling till 1050-1250 DEG C, keeping the temperature for 2.5-3 hours, and then conducting air cooling so as to obtain a fully-austenitic cobalt-based alloy ingot. The invention aims at providing the non-magnetic fully-austenitic cobalt-based alloy which can be forged and subjected to heat treatment.

Owner:METALINK SPECIAL ALLOYS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com