Medical fully-austenitic cobalt-chromium-molybdenum alloy and preparation method and application thereof

A cobalt-chromium-molybdenum alloy and full austenitic technology is applied in the field of medical full austenitic cobalt-chromium-molybdenum alloy and its preparation. High strength, reducing the difficulty of alloy deformation, and the effect of good elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

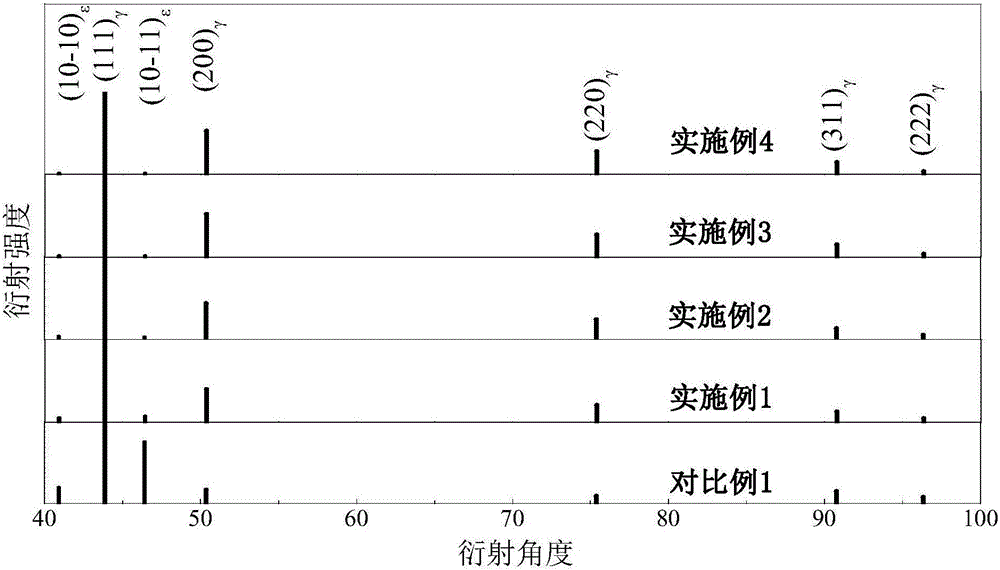

Embodiment 1

[0019] Melt the following components at 1490°C to obtain a liquid alloy, solidify and cool to 1050°C for 3 hours to obtain an ingot, and air-cool to obtain a fully austenitic cobalt-chromium-molybdenum alloy.

[0020] The content of components is as follows: 29kg of chromium; 6kg of molybdenum; 0.08kg of nitrogen; 64.92kg of cobalt;

Embodiment 2

[0022] Melt the following components at 1530°C to obtain a liquid alloy, solidify and cool to 1200°C for 2.7 hours to obtain an ingot, and obtain a fully austenitic cobalt-chromium-molybdenum alloy after air cooling.

[0023] The content of the components is as follows: 29kg of chromium; 6kg of molybdenum; 0.14kg of nitrogen; 64.86kg of cobalt;

Embodiment 3

[0025] The liquid alloy is obtained by smelting the following components at 1600°C, solidified and cooled to 1200°C for 2.5 hours to obtain an ingot, and after air cooling, a fully austenitic cobalt-chromium-molybdenum alloy is obtained; the total weight of the full-austenitic cobalt-chromium-molybdenum alloy 100kg.

[0026] The content of components is as follows: chromium 29kg; molybdenum 6kg; nitrogen 0.19kg; cobalt 64.81kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com