Laser butt riveting method and device for ultra-thin plates

A plate and laser technology, applied in laser welding equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as limited production efficiency and stability, difficult discharge of bulging liquid, and increased interlocking embedding volume, etc. Achieve the effect of convenient operation, not easy to break, and large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

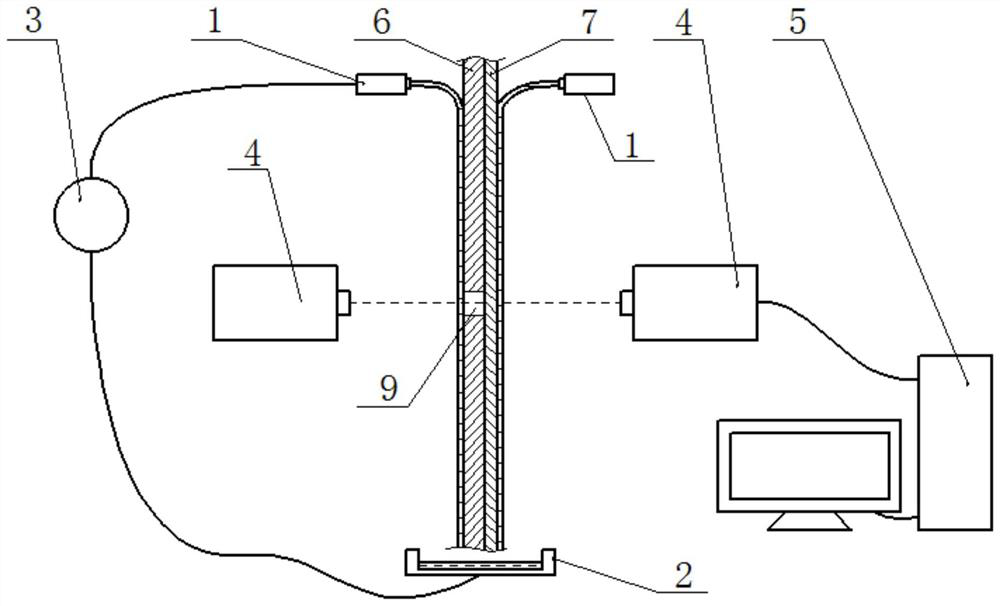

[0038] first embodiment ,refer to figure 1, an example of an ultra-thin plate laser butt riveting device designed in the present invention, including: a water curtain generator 1, a water tank 2, a water pump 3, a pulse laser 4 and a computer terminal 5. Wherein: the water curtain generator 1 is installed above the water tank 2, a water pump 3 is arranged on the connecting pipeline between the water curtain generator 1 and the water tank 2, so as to recycle the water in the water tank, and the water curtain generator 1 is Two, so that the left side plate 6 and the right side plate 7 are provided with water curtain 8 respectively; The pulse laser 4 is two, and symmetrically arranged on the left and right sides of the water curtain formed by the water curtain generator 1, The computer terminal 5 is used to control the pulsed laser 4 .

[0039] It can be understood that on the basis of the first embodiment, technical solutions including but not limited to the following can als...

no. 2 example

[0040] second embodiment , use a laser and a beam splitting device to replace the above two pulse lasers, use the beam splitting device to divide the beam emitted by the laser into two beams, and perform opposite impact.

no. 3 example

[0041] third embodiment , a kind of laser hedge riveting of ultra-thin plates, which is realized by the device described in the first embodiment, includes the following steps:

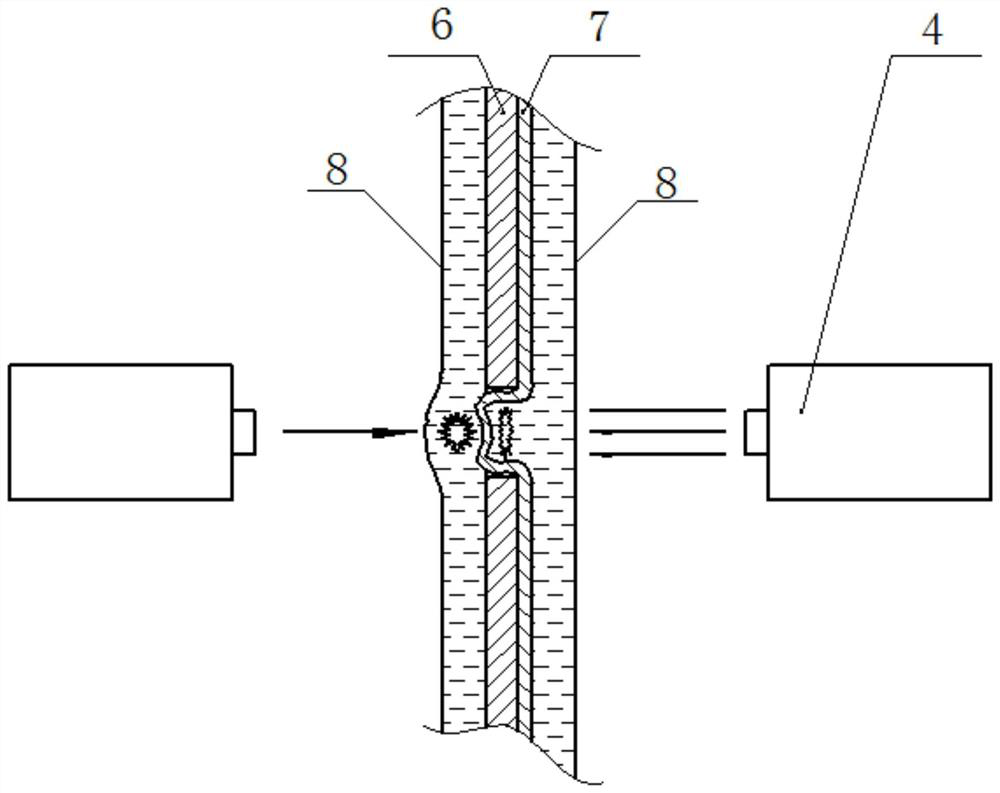

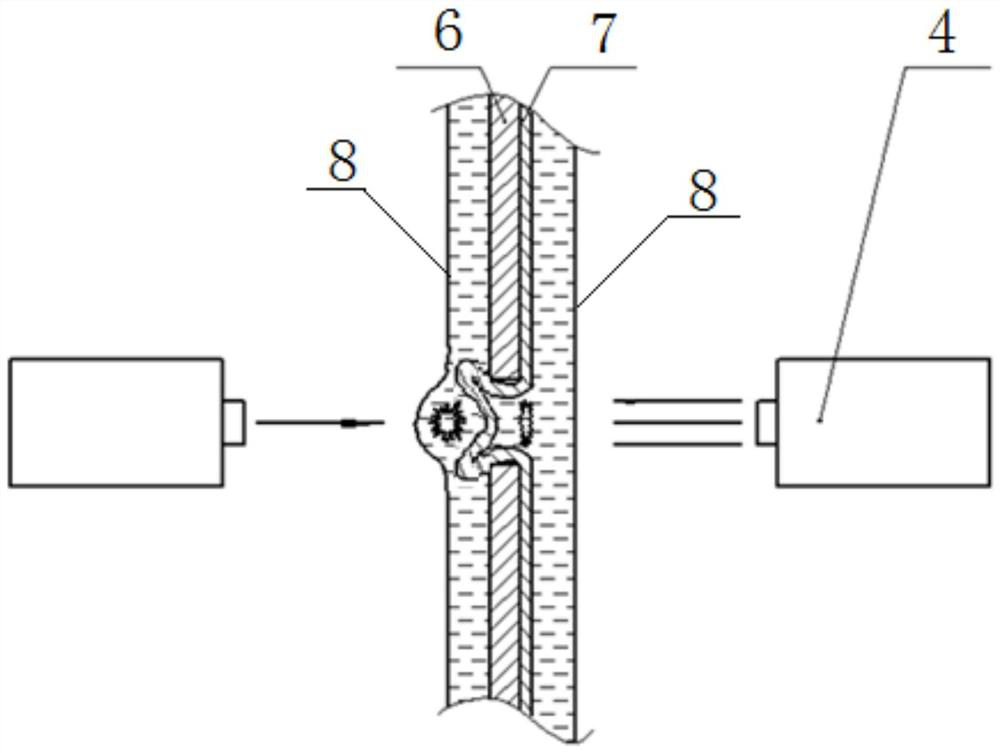

[0042] (1) Select a stainless steel plate with a thickness of 0.2mm as the left plate, and the diameter of the hole on it is 2.5mm; select a pure copper plate with a thickness of 0.05mm as the right plate.

[0043] (2) Install two plates to be riveted vertically side by side in a left-right manner to form a composite plate, wherein the left plate 6 is provided with a through hole 9, and the right plate 7 does not have a through hole; in the composite plate The two outer surfaces form a water curtain 8 through the water curtain generator 1;

[0044] (3) Control the center of the laser beam to align with the center of the through hole, and use the laser beam to simultaneously impact the right side plate 7 from the left and right sides of the composite plate. The spot diameter of the laser beam on the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com