Fast assembly, rolling riveting and bending integrated forming method and device

A forming method and rolling riveting technology, applied in the field of riveting and bending, can solve the problems of difficulty in guaranteeing the quality of rolling riveting, easy shaking of the heat sink, and difficulty in manually adjusting the position and righting, so as to ensure the effect of carding and righting, ingenious structural design, The effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

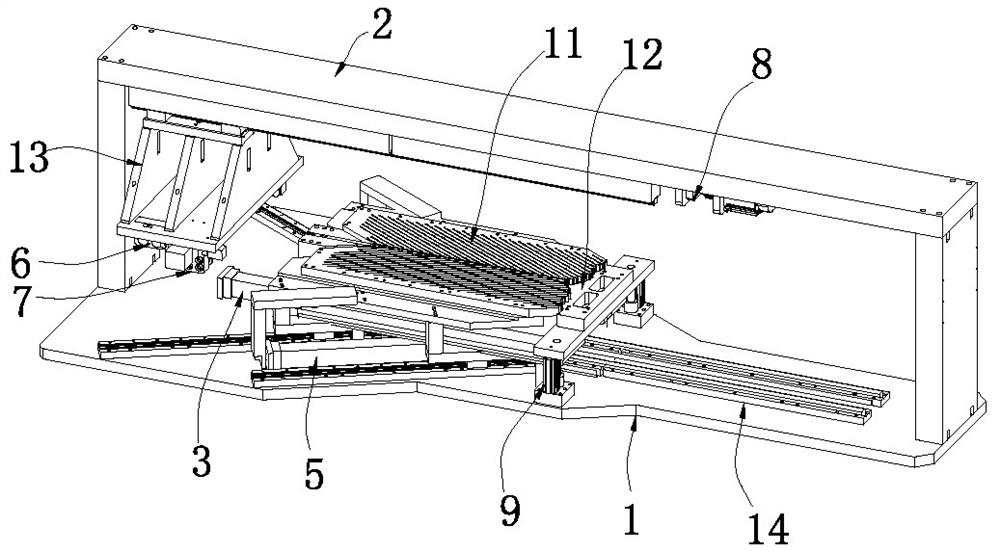

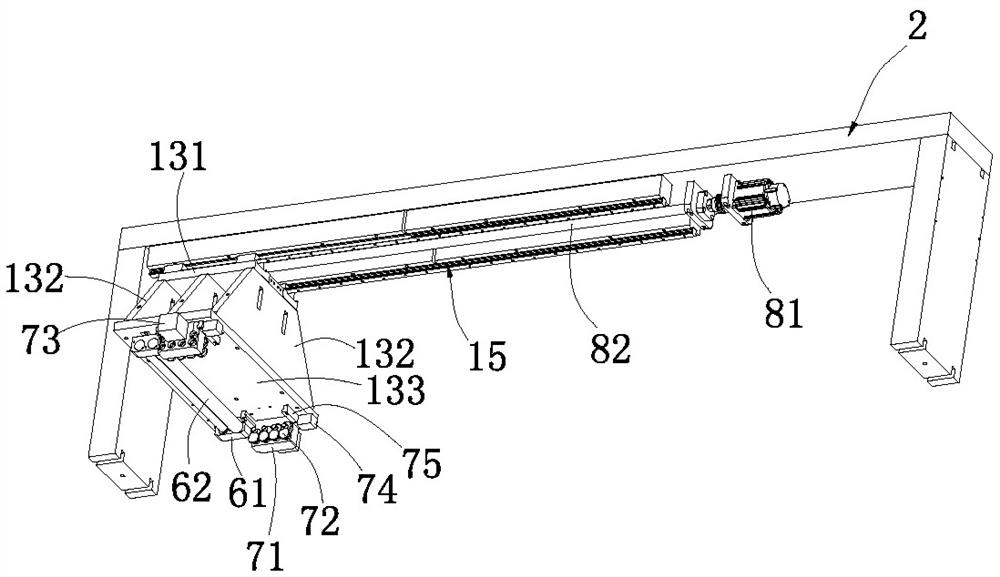

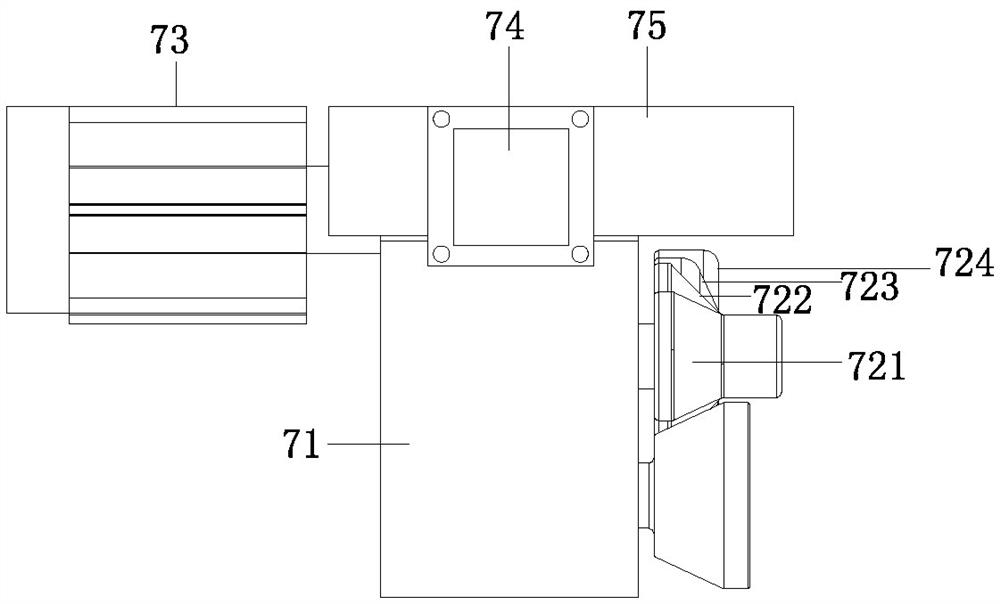

[0049] see Figure 1 to Figure 8 , the one-piece fast-installation, rolling-riveting and bending-forming equipment provided in this embodiment is only used to illustrate the implementation of the quick-installing, rolling-riveting, bending-integrated forming method of the present invention, but it is not limited thereto. Other structural equipment can also be used to realize the fast-installation rolling riveting bending integral forming method. Before riveting, the heat sink 17 is riveted on the aluminum plate base 18 in advance, and the riveting holes corresponding to the riveting points of the heat sink 17 are pre-punched on the cover plate 19 .

[0050] A fast-loading rolling riveting and bending integrated forming equipment, which includes a workbench 1, a pushing gantry 2, a pushing device 3, a positioning device 4, an oblique pushing device 5, a rolling riveting device 6, a bending device 7, and a riveting screw rod Driving mechanism 8, reference lifting mechanism 9, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com