High-heat-dissipation control box and production method

A production method and control box technology, which is applied in the field of control boxes, can solve the problems of rivet head leakage, fusibility, and easy slippage of tapping internal threads, etc., and achieve the effects of cost reduction, good reflectivity, and good paintability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

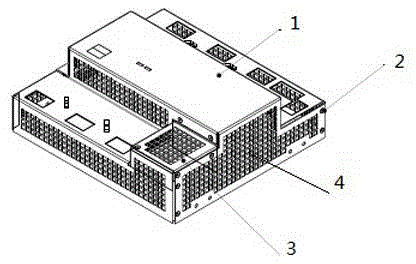

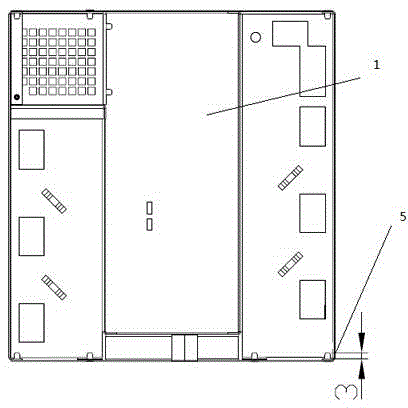

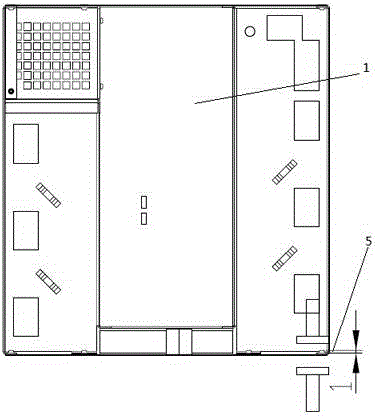

[0025] The high heat dissipation control box includes: the control box body, the control box bottom cover plate fixed on the control box body, the vent hole on the surface of the control box body, and the fixing piece for fixing the control box body; the vent hole is linear Arranged in an array, the distance between the air holes is 2mm, and the distance between the air holes and the bending edge is greater than or equal to 7mm; as a preference, the air holes are square holes of 6*6mm. Such a design not only ensures the strength and flatness of the control box, but also maximizes the heat dissipation effect and achieves a beautiful appearance.

[0026] The production method of the high heat dissipation control box comprises the following steps:

[0027] Step 1: Use aluminum-zinc alloy steel plate as the material, and punch the surface of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com