Flexible locating device for riveting cone shell segment wall plate products

A technology of flexible riveting and positioning device, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of high labor intensity, poor openness, unstable product quality, etc., to ensure product quality consistency, rapid positioning and The effect of flexible assembly and improving the level of production automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

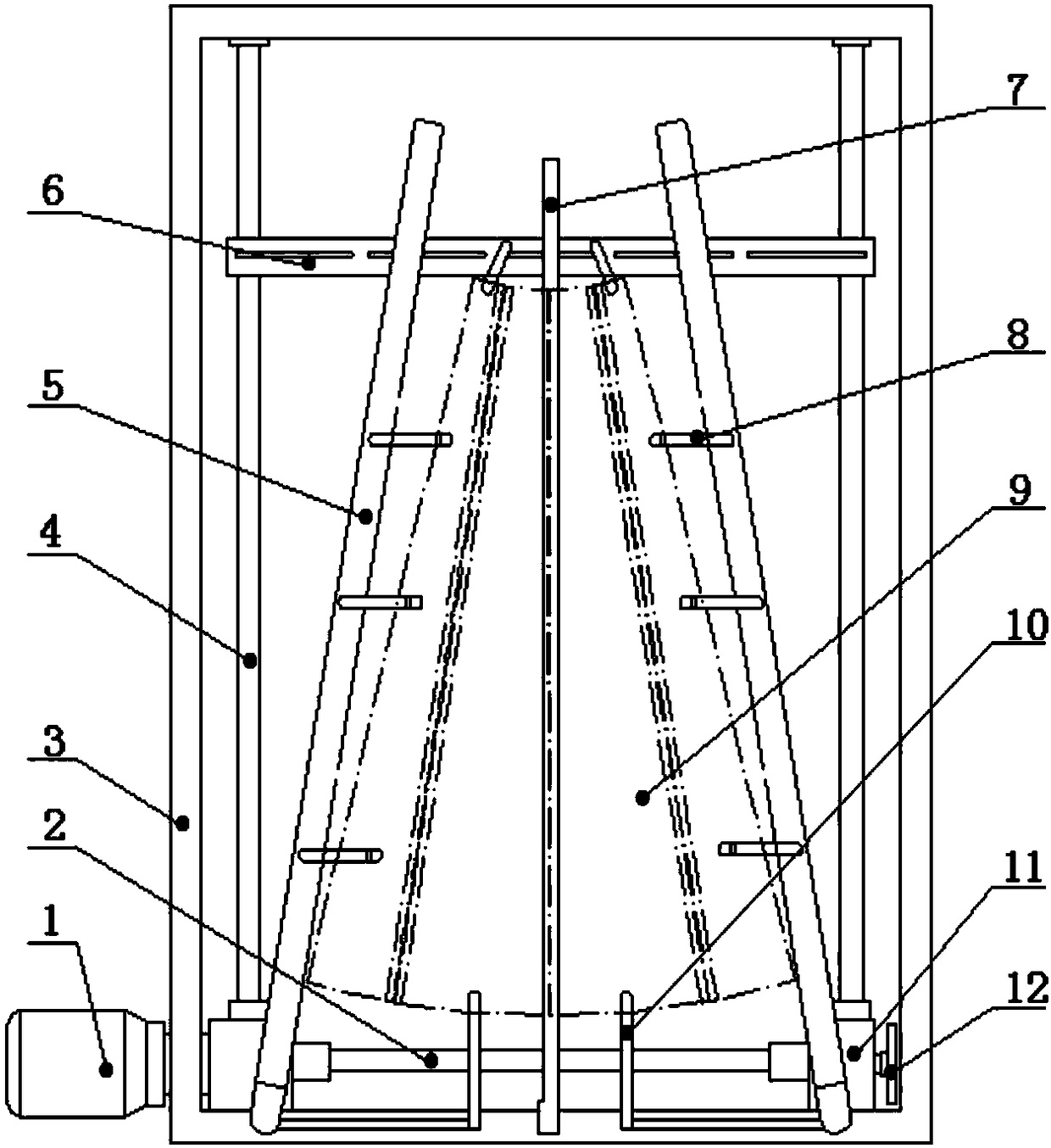

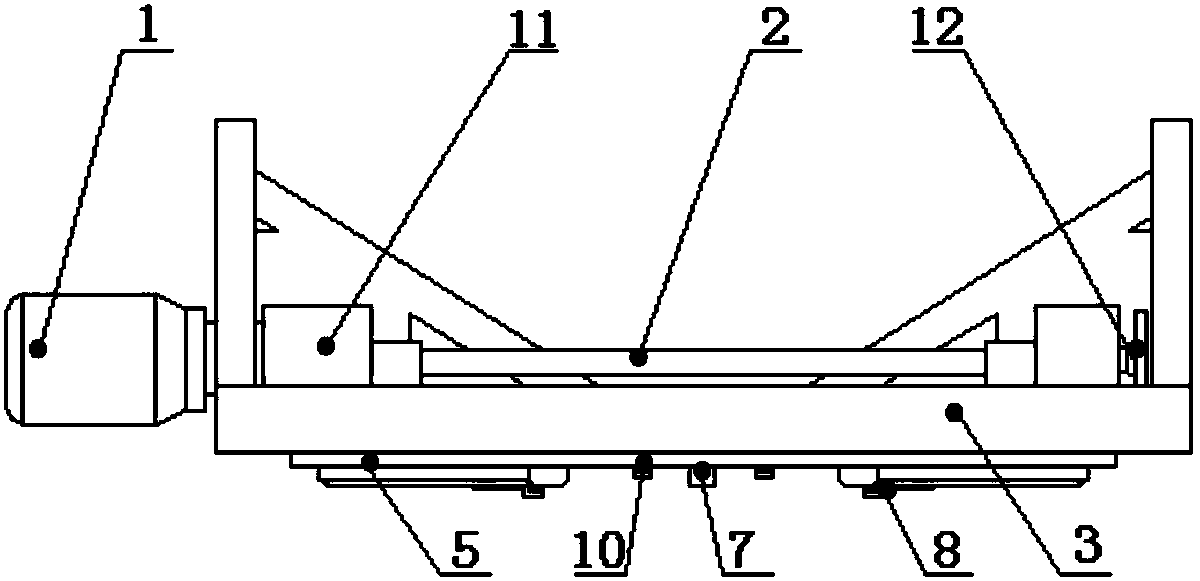

[0019] The following is a further description of a flexible positioning device for riveting of conical shell section wall panel products according to the present invention with reference to the accompanying drawings and specific embodiments.

[0020] like figure 1 and figure 2 As shown in the present invention, a riveting flexible positioning device for conical shell section wallboard products, which includes a fixed surrounding frame, a convertible swing frame, a transmission structure and a supporting clamping part; wherein,

[0021] The fixed enclosure includes a frame-shaped frame body 3 and a vertical positioning plate 7; the vertical positioning plate 7 is fixed at the center of the frame body 3 and is perpendicular to the bottom of the frame body 3;

[0022] The transmission structure includes a motor 1, a horizontal transmission shaft 2, a vertical transmission shaft 4, a transmission assembly 11, and a hand wheel 12; wherein, the motor 1 is fixed on the lower part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com