A method for riveting medium and thick metal plates without protrusions on both sides

A technology for protrusions and metal plates, applied in the field of riveting of medium and thick metal plates, can solve the problems of cumbersome riveting steps, difficult production, complex rivet structure, etc., and achieve the effect of simple structure, reduced grinding process and high-quality riveting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, which are explanations of the present invention rather than limitations.

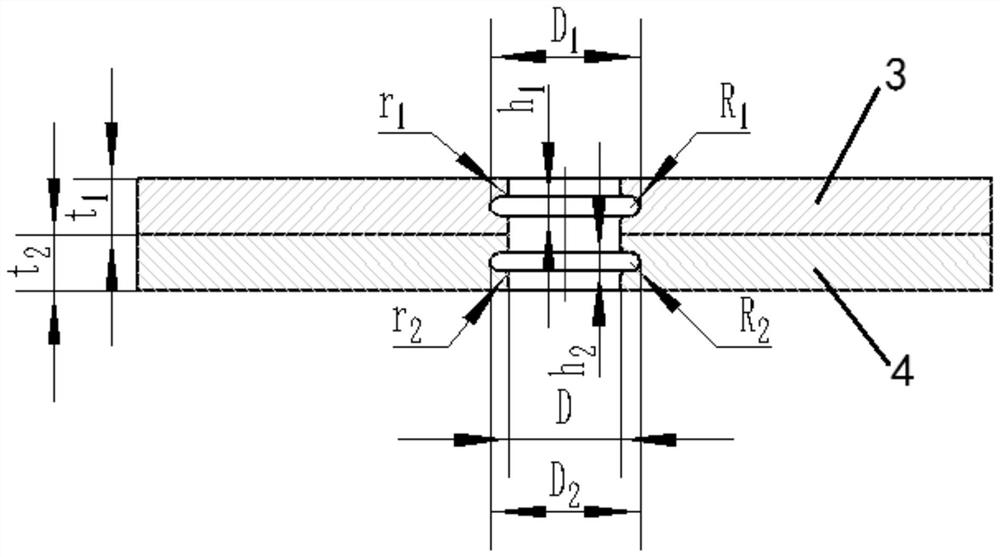

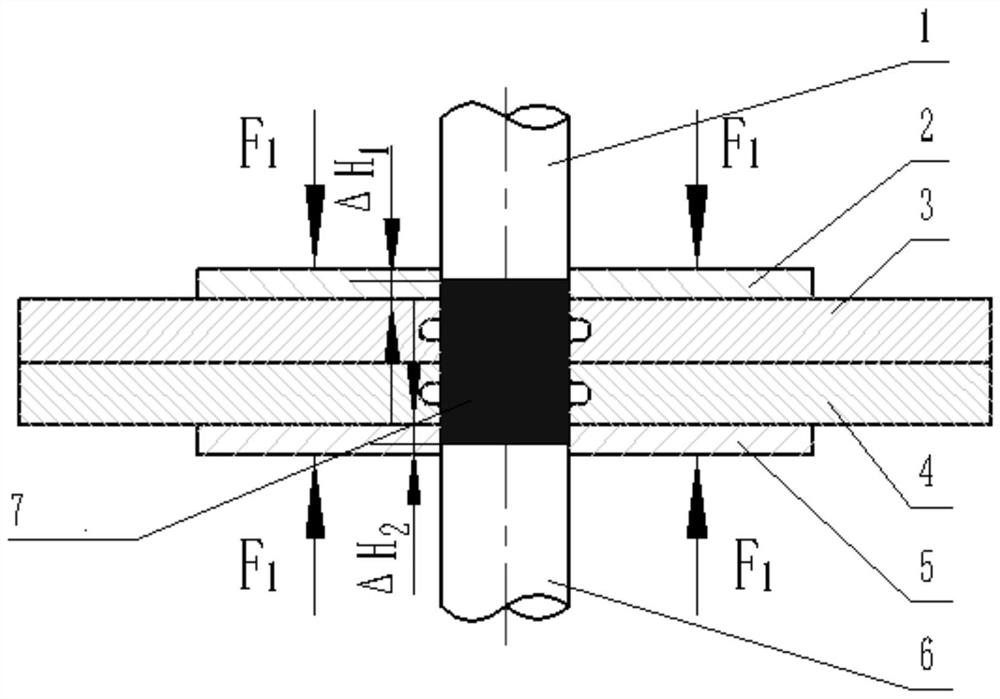

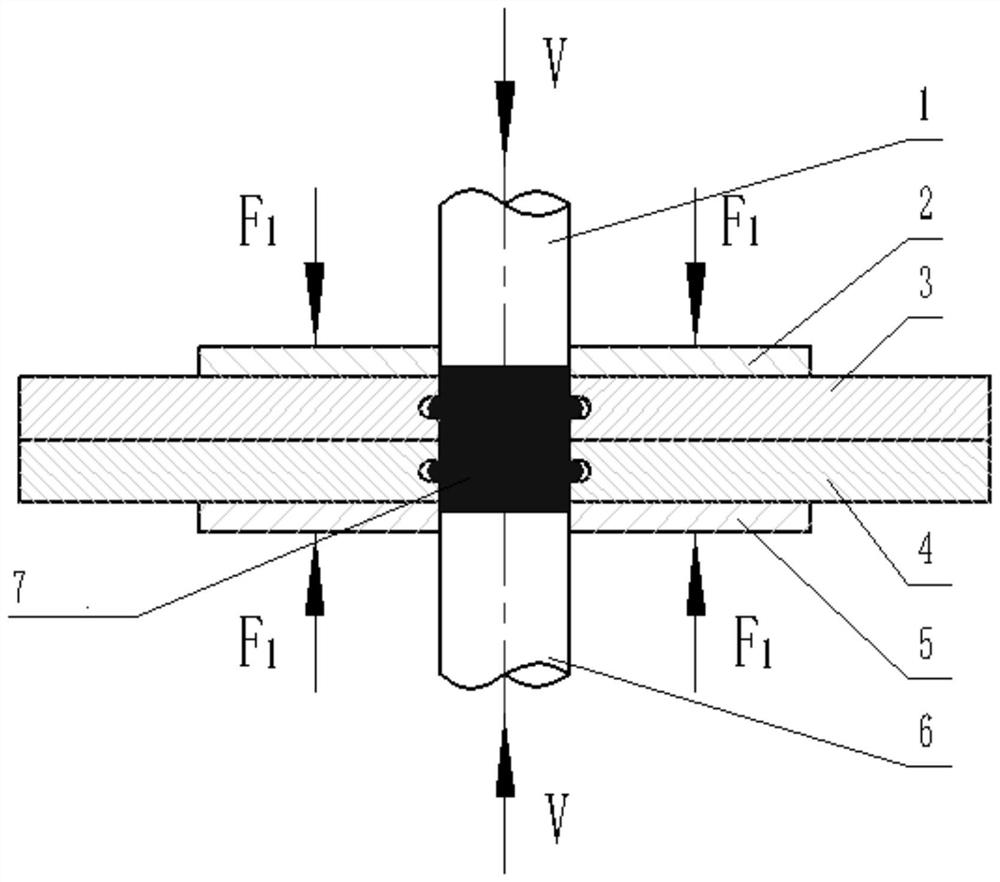

[0041] The method for the riveting of medium-thick metal plates with no protrusions on both sides of the present invention first pre-treats the upper sheet material 3 and the lower sheet material 4 to be riveted, such as figure 1 , at wall thickness t 1 A round hole with a diameter of D is processed on the upper plate 3 to be riveted, and several holes with a diameter of D are processed on the inner wall of the round hole. 1 , the height is h 1 The annular groove; at wall thickness t 2 A round hole with a diameter of D is processed on the lower plate 4 to be riveted, and several holes with a diameter of D are processed on the inner wall of the round hole. 2 , the height is h 2When the number of annular grooves in the upper circular hole of the upper plate 3 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com