Patents

Literature

118results about How to "Simple pretreatment process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

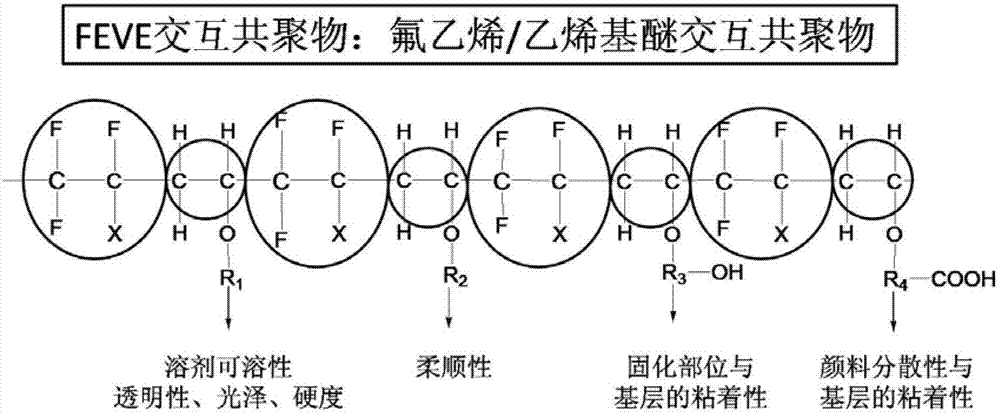

Self-cleaning super-weather-proof powder paint and preparation method thereof

ActiveCN103194140AImprove stabilityProtect against agingPowdery paintsPolyester coatingsPolyesterAging resistance

The invention belongs to the field of powder paints and particularly relates to a self-cleaning super-weather-proof powder paint. The self-cleaning super-weather-proof powder paint comprises a carboxyl-terminated polyester particle system and a fluorocarbon resin particle system in a weight part ratio of 4:1-1:4, wherein the fluorocarbon resin particle system contains TiO2 nano-particles. As carboxyl-terminated polyester is introduced into a pure fluorocarbon paint, the phase separation occurs in a solidification process, and the fluorocarbon resin floats up to the surface of a coating to serve as coating protection and ageing resistance; the carboxyl-terminated polyester and the like and a substrate can be well wetted, so that the coating and the substrate can be well adhered and can hardly crack and spall; as the TiO2 nano-particles only exist in a fluorocarbon phase, the resin on a bottom layer cannot be broken, and the excellent stability of the system is guaranteed; and the TiO2 nano-particles are scattered in a dry blending manner, and the complex preprocessing is avoided, so that the preprocessing process can be greatly shortened, the cost is lowered, and the efficiency is improved.

Owner:NINGBO SOUTH SEA CHEM

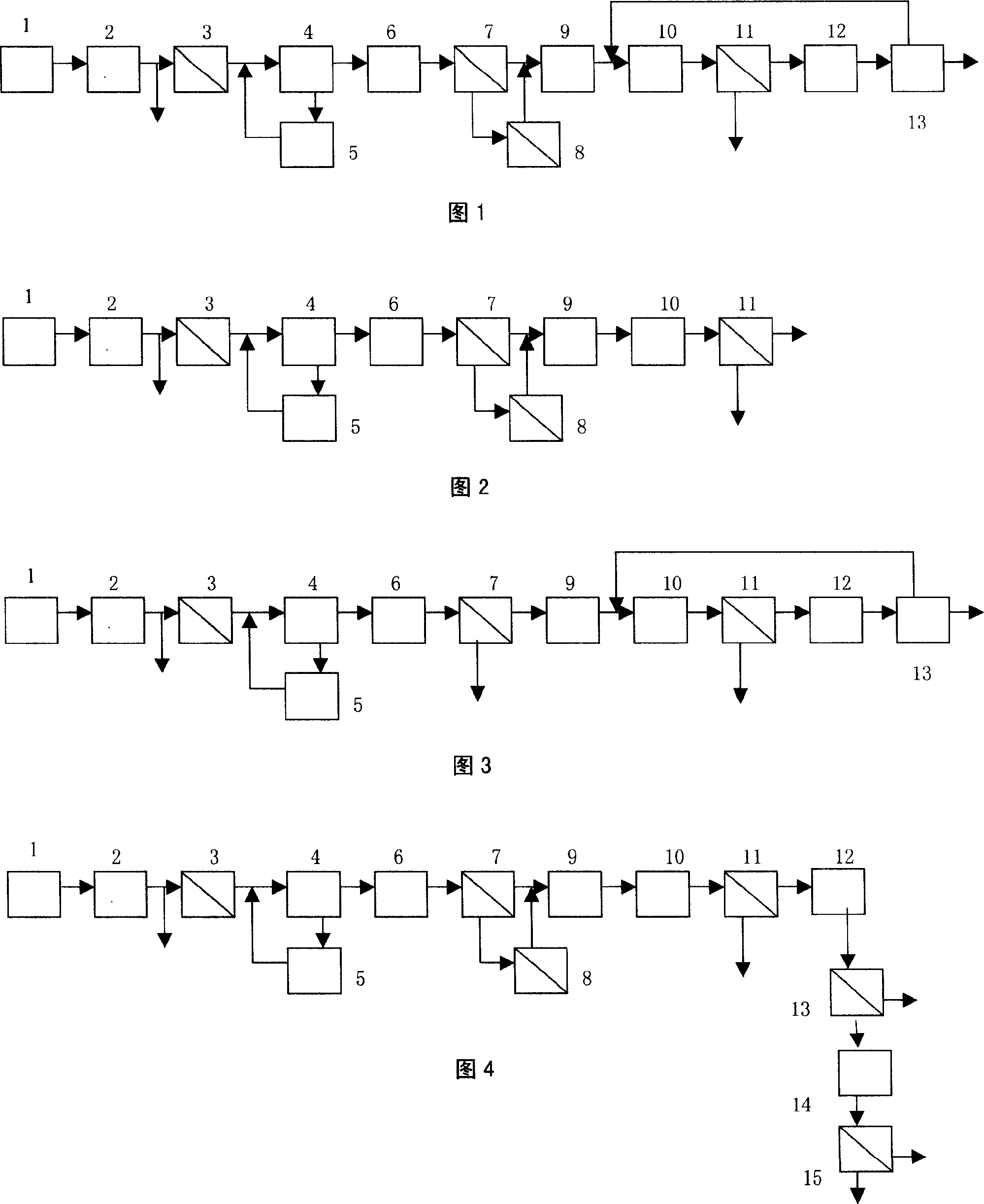

Sea water nanofiltration desalination method and device

InactiveCN1994904ALow operating pressureReduce energy consumptionGeneral water supply conservationSeawater treatmentDesalinationFresh water

The invention discloses a seawater desalinating method, which comprises the following steps: hyperfiltering; nanofiltering; desalinizing. The device comprises the following parts: raw water tank, booster pump, hyperfiltering preprocessor, middle tank, high-pressure pump I, nanofiltering element, adjusting tank, at least one desalinization unit and recoil washing pump, wherein the water inlet of recoil washing pump connects middle tank and the outlet connects the water outlet of hyperfiltering predisposer.

Owner:陈益棠 +1

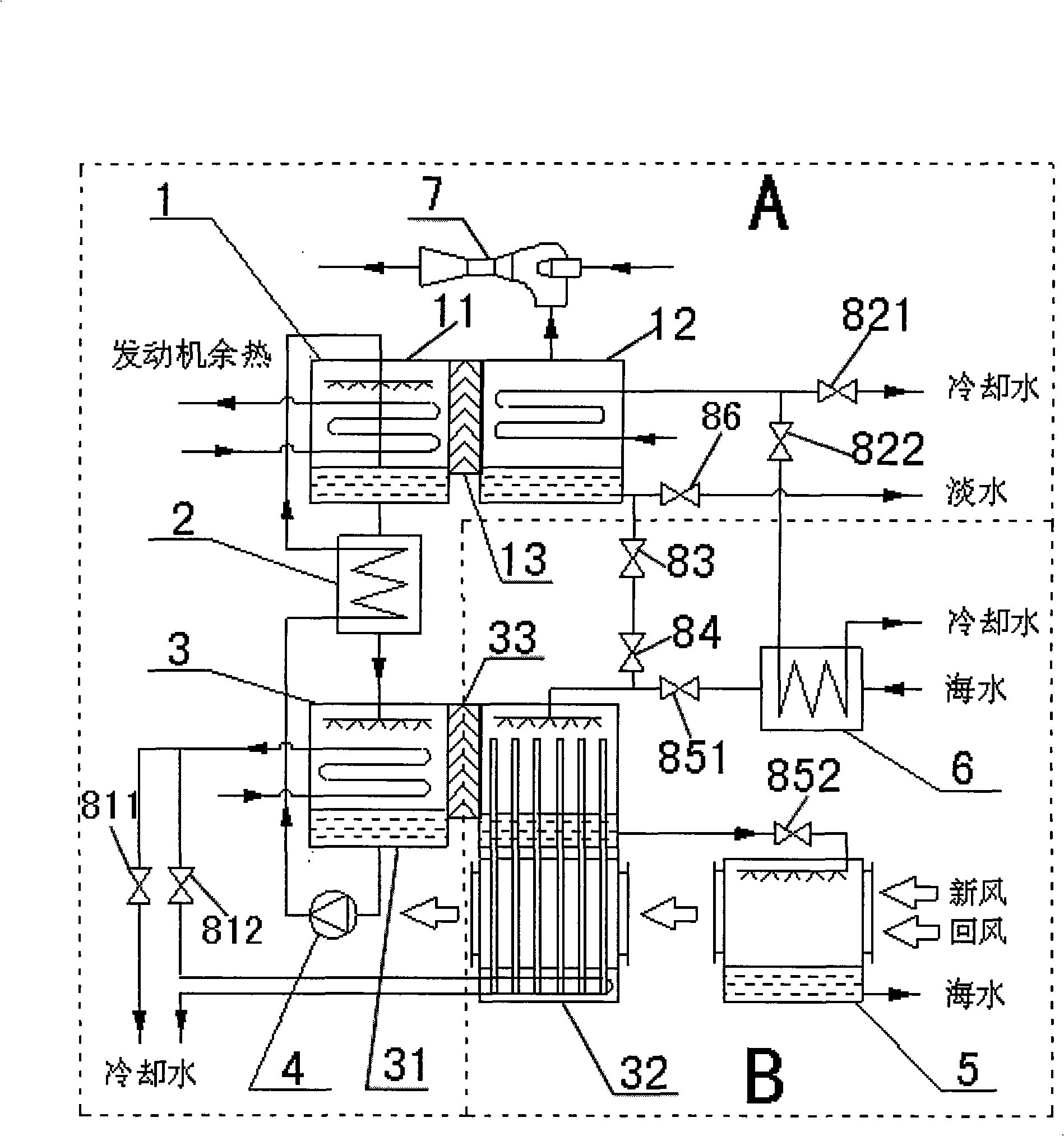

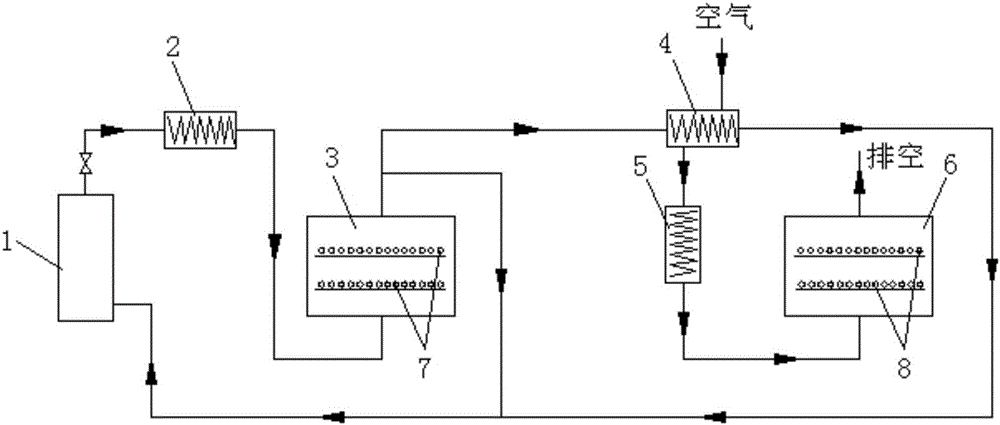

Air conditioner and sea water desalination combined operation system

InactiveCN101344298AImprove efficiencySimple pretreatment processGeneral water supply conservationSeawater treatmentLithium bromideSeawater

The invention relates to an air-conditioning and seawater desalination joint operation system which comprises a lithium bromide solution circulating water yielding system and a sea water evaporation and air processing system. The lithium bromide solution circulating water yielding system comprises: a generation condenser, a heat exchanger, an absorption evaporator, a circulating pump and a regulating valve group; wherein, the generation condenser comprises a generator and a condenser, and a water retaining device is connected between the generator and the condenser. The sea water evaporation and air processing system comprises: the absorption evaporator, a sea water spray chamber, a pre-heater, a regulating valve, a throttle valve and a valve group; wherein, the absorption evaporator comprises an absorber and an evaporator, and the water retaining device is connected between the absorber and the evaporator. The air-conditioning and seawater desalination joint operation system of the invention has the functions of air-conditioning and sea water desalination, simplifies the two separate separation systems of the prior air-conditioning system and the sea water desalination circulating system and effectively saves the energy.

Owner:SHANGHAI MARITIME UNIVERSITY

Seawater desalination device and method

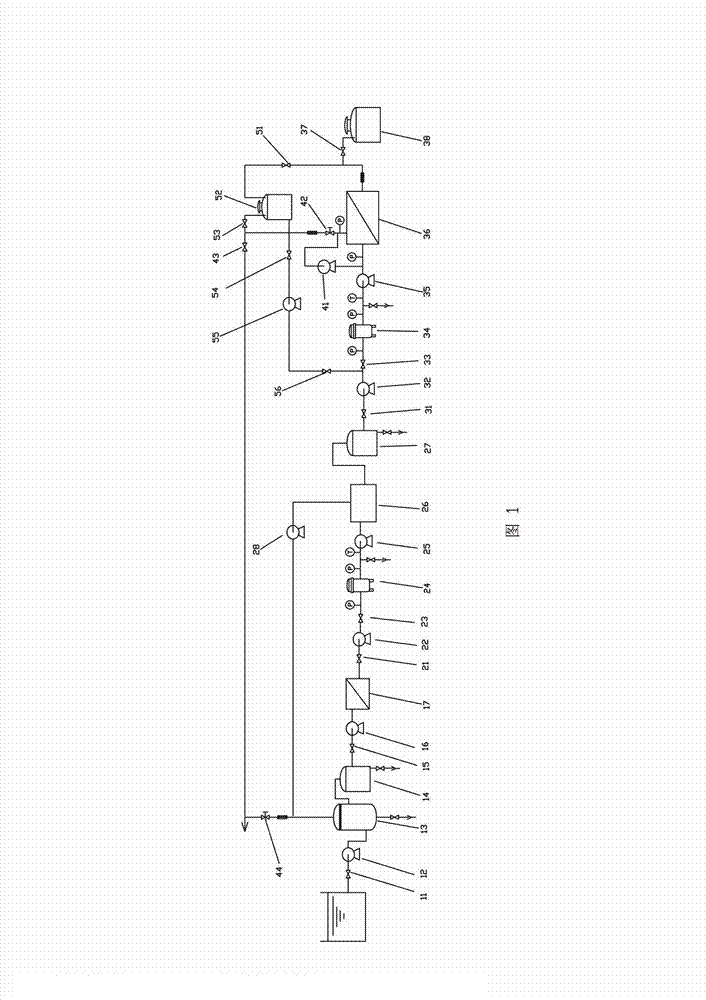

InactiveCN102786174ASolve the technical problems of seawater desalinationEliminate pollutionGeneral water supply conservationSeawater treatmentCapacitanceElectrolysis

The invention relates to a seawater desalination device and a method, and relates to the seawater device and its method by combining an electrolytic technology, a capacitance adsorption deionization technology and a low pressure reverse osmosis technology. The device comprises an electrolytic purifying system, a capacitance adsorption deionization system and a low pressure reverse osmosis system; the electrolytic purifying system comprises a stop valve, a water supply pump, an electrolytic machine, a deposition pot and a microfiltration apparatus; the capacitance adsorption deionization system comprises the stop valve, an elevator pump, a cartridge filter, the water supply pump, a capacitance adsorption deionization apparatus, a primary fresh water storage tank and a concentrated water booster pump; the low pressure reverse osmosis system comprises the stop valve, the water supply pump, the cartridge filter, a high pressure pump, a low pressure reverse osmosis membrane component and a fresh water storage tank. The method comprises the following steps: electrolyzing, performing capacitance adsorption deionization and primarily desalinating, finally performing low pressure reverse osmosis desalination. The method has the advantages of short process flow, small investment and less environmental pollution, the reverse osmosis system material has the advantages of low requirement and low cost, and solves the problem of nationalization, and the seawater desalination device has the advantages of high efficiency, low energy consumption, low production cost, high integrated level of the device, small volume, easy operation and the like.

Owner:BOYING XIAMEN SCI & TECH

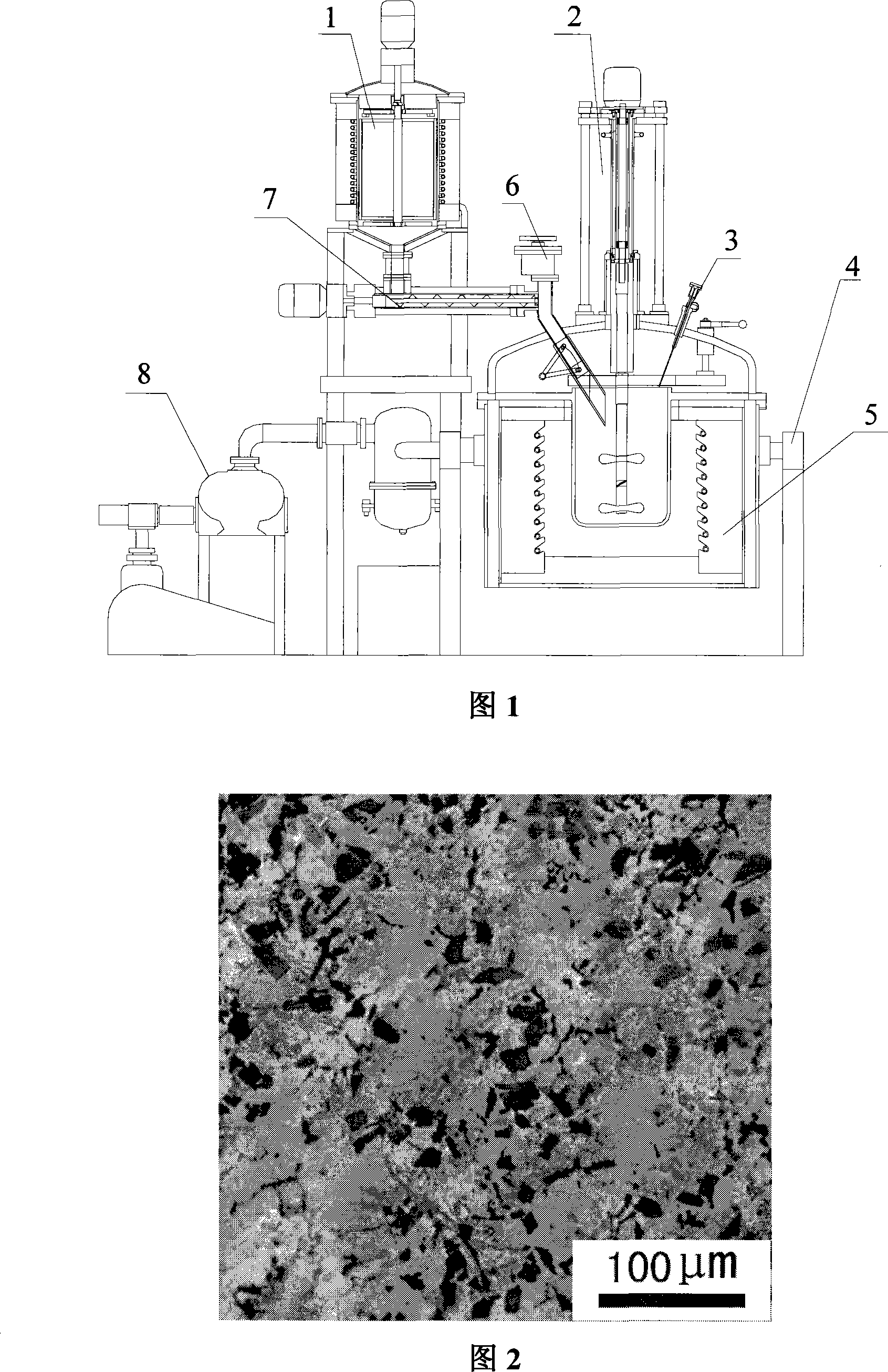

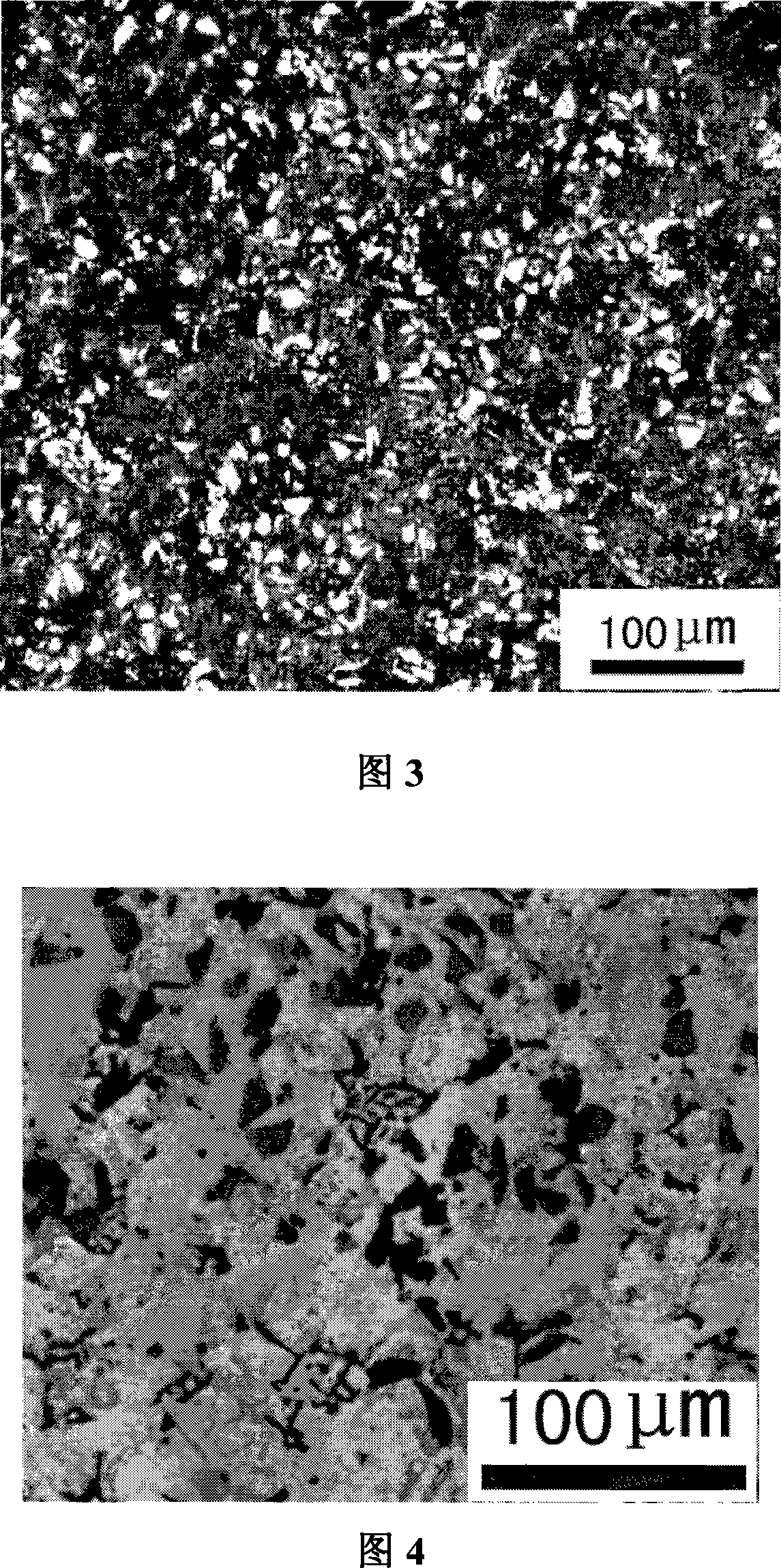

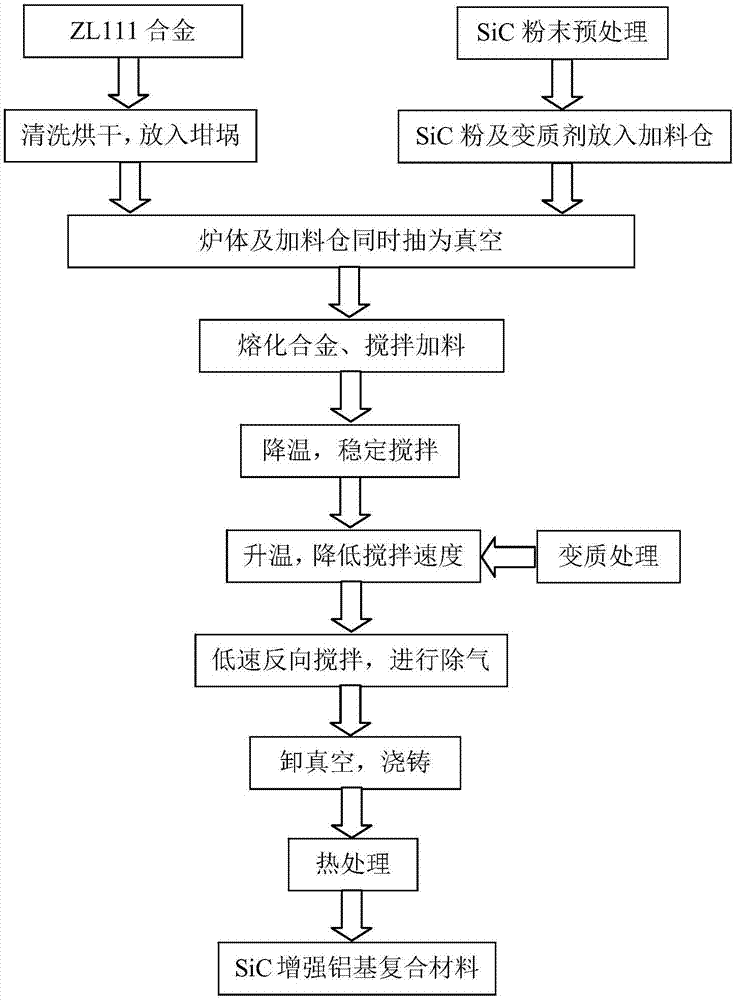

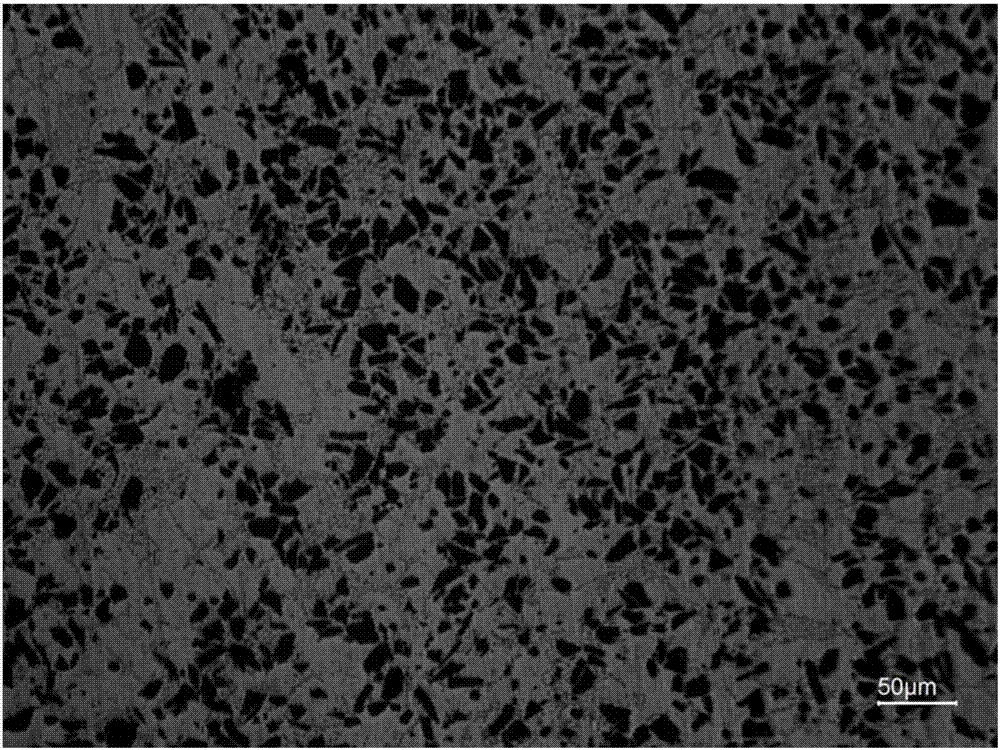

Vacuum stirring composite granule reinforcing aluminium-based composite material and preparation technique thereof

The invention relates to a composite material of vacuum churning composite granule enhanced aluminum matrix and a preparation technique, which comprises: Si 0-15Wt%, Mg 0-1.5Wt%, Cu 0-2.0Wt%, Mn 0-1.0Wt%, Cr 0-0.4Wt%, Ti 0-0.2Wt%, SiC 0.1-20% (volume proportion). Firstly base alloy is smelted, slag is removed, and refined, churned slowly in vacuum to complete degassing procedure for base melt, the pre-treated enhanced granule is continuously added into the aluminum base melt, mechanical churning to roll the granule into the melt, after the granule is completely rolled in the melt, strong churning and slow churning in reverse direction are conducted so as to disperse the granule evenly in the base; the temperature raises, modifier and refiner are added; the vacuum is dismounted, and placed in static, the floating slag is removed above the melt, and cast. The composition between the granule and the base is realized via vacuum mechanical churning, the joining interface is good, the enhanced granule is evenly dispersed in the base, the prepared composite material has low porosity rate, which is easy to realize industrial mass production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

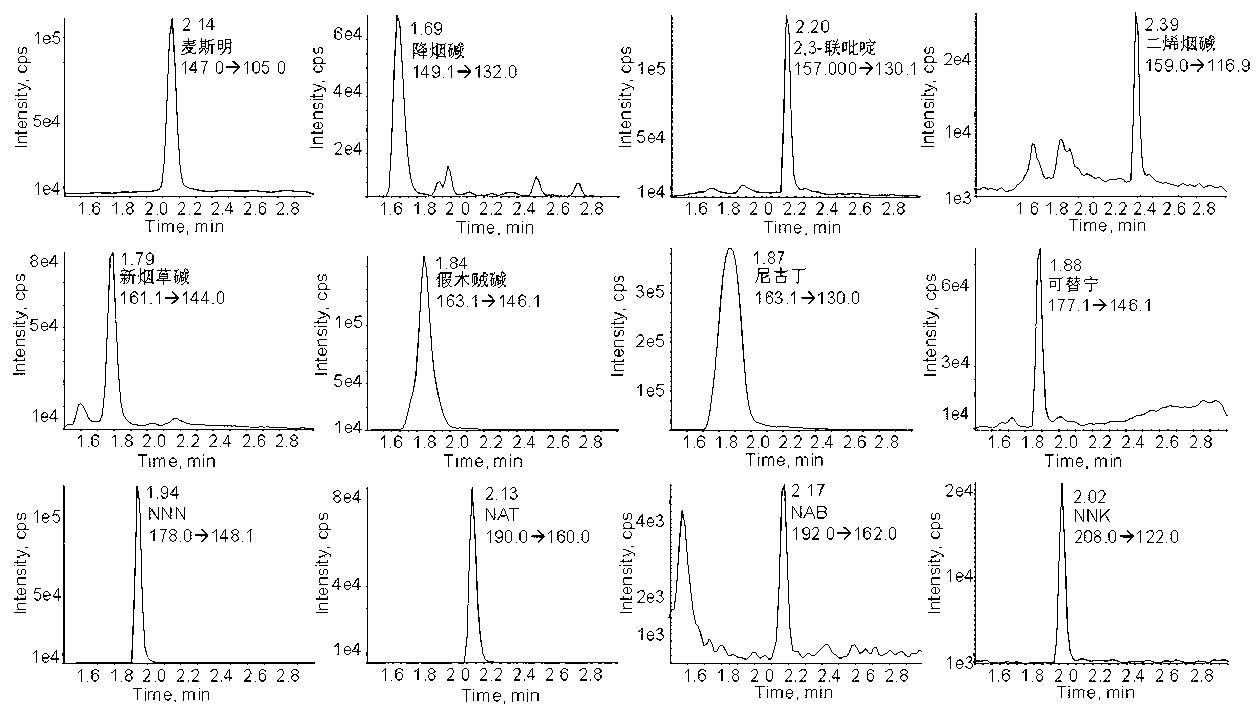

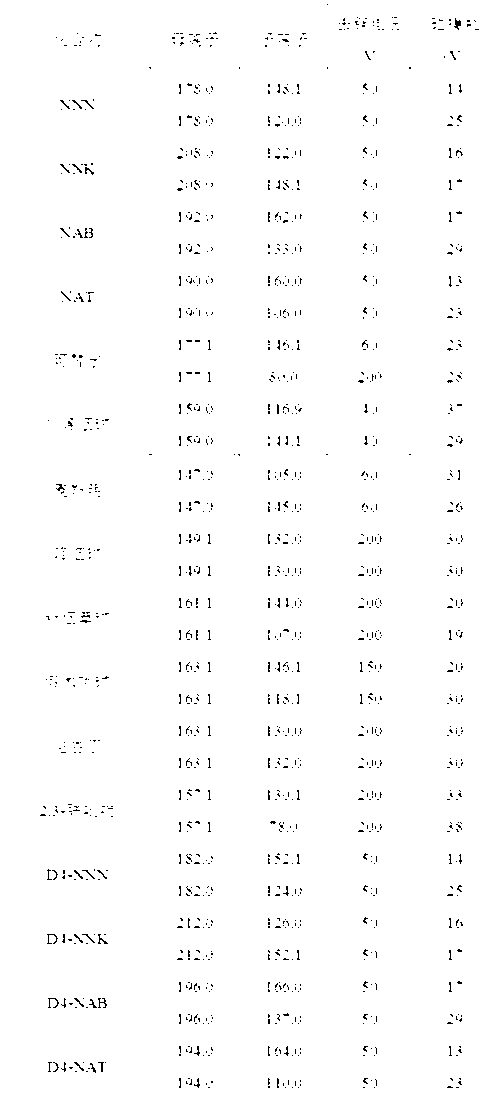

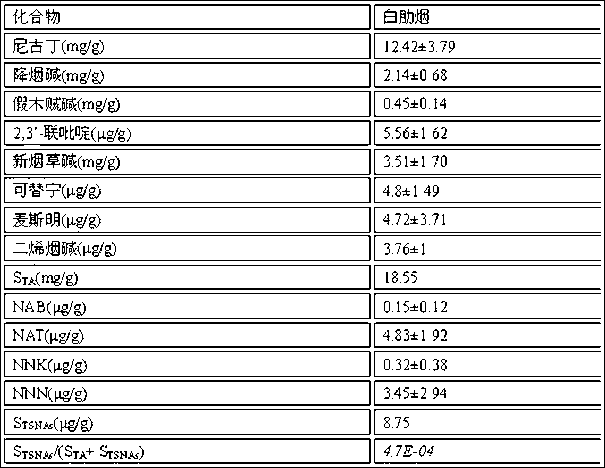

Method for detecting alkaloids and nitrosamines in tobaccos simultaneously

ActiveCN103257196ASimple pretreatment processReduce sample preparation timeComponent separationNicotiana tabacumTobacco chemistry

The invention discloses a method for detecting alkaloids and nitrosamines in tobaccos simultaneously, and belongs to the technical field of tobacco chemical composition detection. The method comprises the working procedures of: sample extraction, purification, analysis and quantification. Firstly an internal standard solution and ultrapure water are added into tobacco leaf powder, extract liquor passes through a filter film after ultrasonic extraction, then methanol is added, protein is removed through centrifugation after shaking, and supernatant is subjected to liquid chromatography-mass spectrometry. After standard solutions of compounds to be detected with different concentration gradients are prepared by adopting a mixing preparation method, and the liquid chromatography-mass spectrometry is carried out, standard curves of instrument responses of the compounds to the actual concentrations of the solutions are drawn, curve equations are fitted, and the detection concentrations are calculated according to measured values of the instrument responses of the compounds to be detected and converted to the actual concentrations of the compounds to be detected in tobacco samples. The detection method provided by the invention can be used for carrying out the qualitative and quantitative analysis on alkaloids and nitrosamines in the tobacco samples simultaneously, and is easy and convenient to operate, good in reproducibility, high in analytic sensitivity and accurate in quantification.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Preparing method for SiC particle enhanced aluminum-base composite material

The invention aims at disclosing a specially-made vacuum smelting furnace and a preparing technology for a SiC particle enhanced aluminum-base composite material. A certain component proportion and a special smelting casting technology are adopted. The vacuum smelting furnace is adopted in the technology, overall closing and vacuum-state charging can be achieved, the inner temperature of melt can be measured in real time, the particles accurately fall into a melt vortex center with a certain speed and are evenly distributed in the melt under powerful stirring, the functions of deoxygenation and degassing can be effectively achieved on the composite material melt, and therefore the composite material uniform in component, low in porosity, high in mechanical performance and excellent in heat-conducting property can be produced through the technology. The crucible lifting type vacuum smelting furnace comprises a crucible composite device and lifting platform system, a stirring device and lifting platform system, a charging device, a vacuum system, a handheld lifting thermocouple, a sealing system and an electric control system.

Owner:SUZHOU WUCHUANG MATERIAL TECH DEV CO LTD

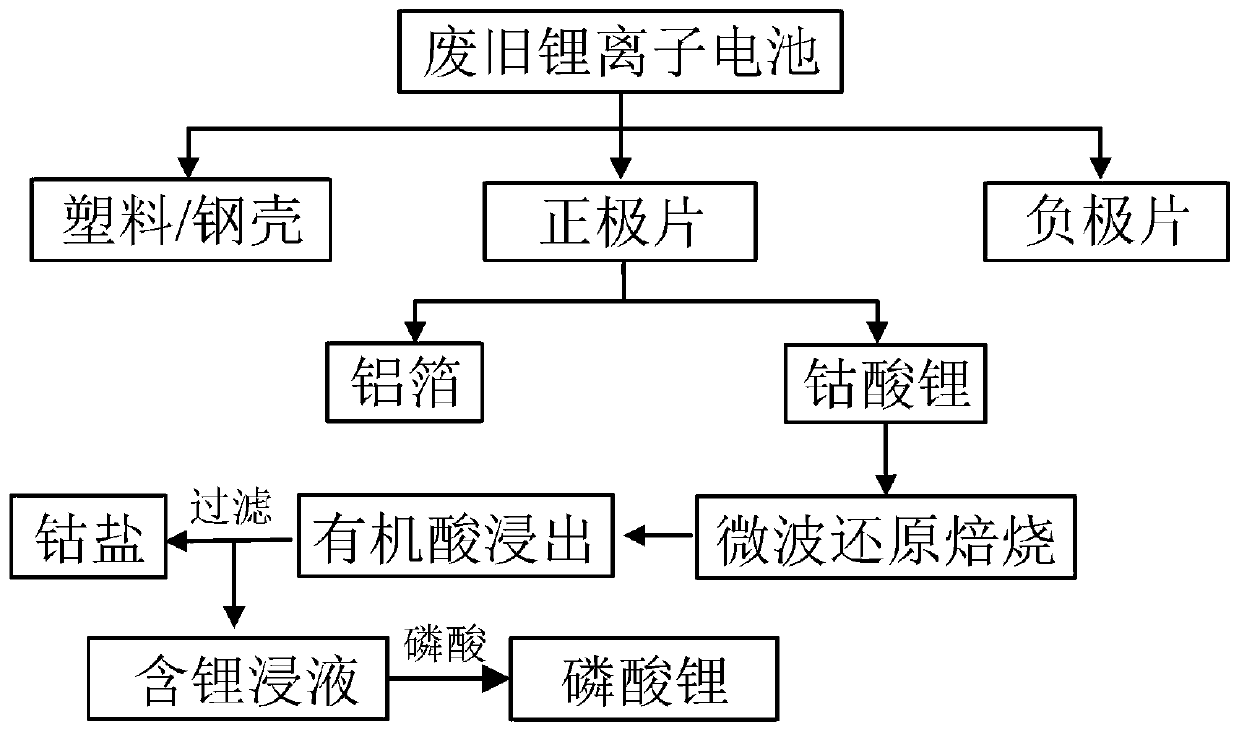

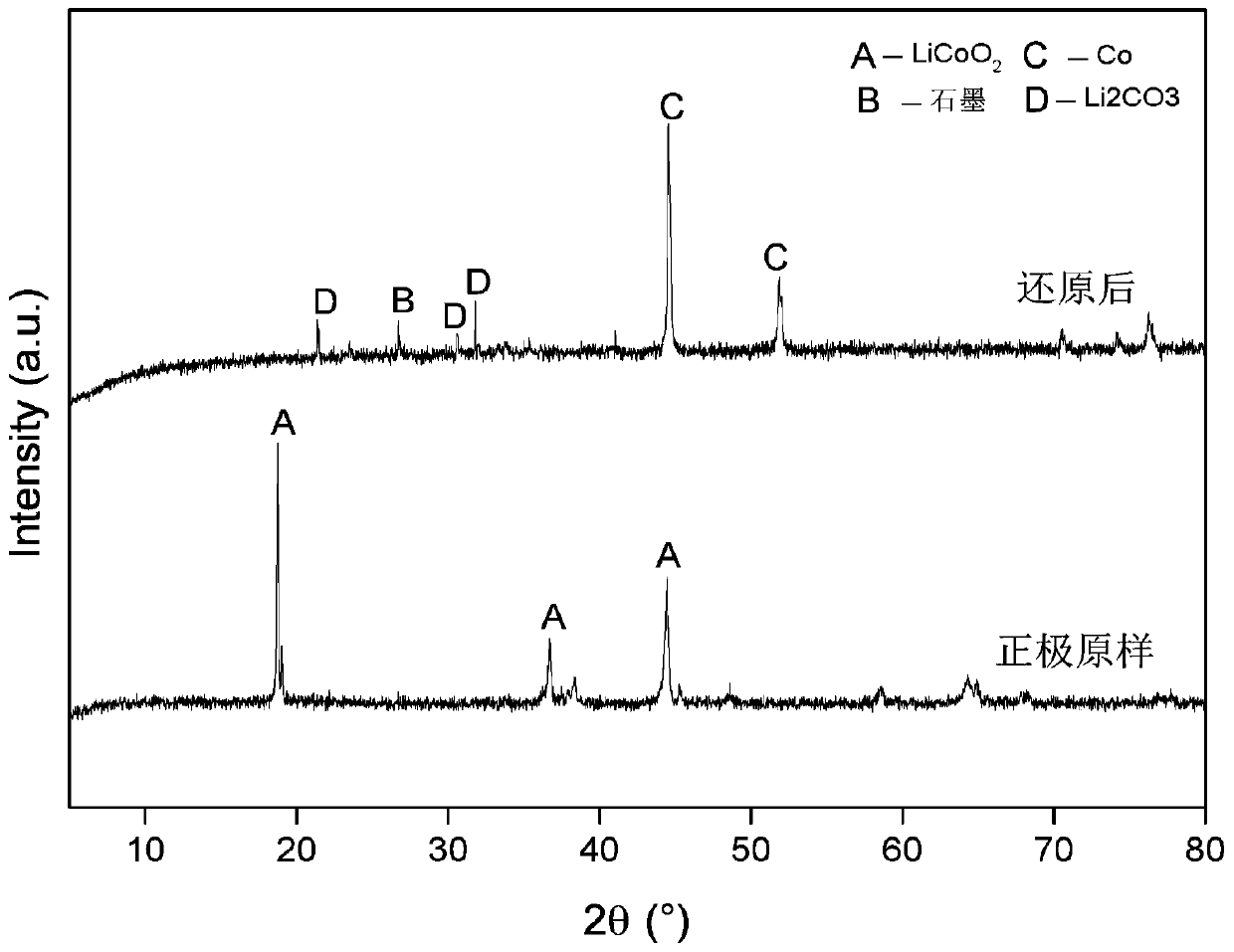

Method for assisting recovery of lithium and cobalt in waste electrode material through microwave roasting

ActiveCN110343864AOptimizing Pickling PropertiesReduce consumptionWaste accumulators reclaimingProcess efficiency improvementOrganic acidLithium

The invention discloses a method for assisting recovery of lithium and cobalt in a waste electrode material through microwave roasting. The method comprises the following steps of, step (1), crushingand screening a positive plate to obtain electrode material powder; step (2), putting the obtained positive electrode active material into a microwave tube furnace filled with inert protective gas forroasting, and collecting the roasted solid-phase product; step (3), mixing the solid-phase product with excess organic acid, preparing an acid leaching solution, and recovering cobalt salt precipitate; and step (4), adding any one of phosphoric acid, phosphate or carbonate into the leaching solution, and recovering the precipitate of the lithium. According to the method, the electrode material ispre-reduced in a microwave roasting mode, a binder PVDF plays a role of a reducing agent, the acid leaching characteristic of the lithium and the cobalt in the positive electrode material is optimized, the energy consumption and the gent consumption in the recovery process are reduced, and the pretreatment process is simplified; and the method has the advantages of high efficiency, low energy consumption, environmental friendliness and the like.

Owner:CHINA UNIV OF MINING & TECH

Method for preprocessing Asiatic wormwood to preserve color in combination with quick-freezing and unfreezing for keeping quality

InactiveCN102422875AInhibits polyphenol oxidase activityInhibit endogenous enzyme activityFruits/vegetable preservation by heatingFruits/vegetable preservation by freezing/coolingEnzyme inhibitorIon

The method for preprocessing Asiatic wormwood to preserve the color in combination with quick-freezing and unfreezing for keeping quality belongs to the technical field of fruit-vegetable food storage and processing. The process of the method is as follows: Asiatic wormwood with tender leaves and stalks is chosen, washed and then added with compound enzyme inhibitor, and by regulating the components, content and material-to-solution ratio of the enzyme inhibitor, the activity of polyphenol oxidase in the Asiatic wormwood is inhibited; the Asiatic wormwood is then blanched in boiled water, thepH value of the solution is regulated, the blanching time is adjusted, and while substances with bed flavor, such as absinthin, are completely removed, the loss of the Asiatic wormwood pigment is reduced; after cooling, metal ion color-preserving processing is carried out, and the dosage of metal ions and the pH value of color preservative are determined; after being sufficiently blanched, the Asiatic wormwood is pulped and filtered, vacuum packages are adopted for precooling and medium-frequency ultrasonic quick-freezing, and the Asiatic wormwood is refrigerated under the condition of negative 18 DEG C, and is ultrasonically unfrozen when being applied later. High-quality Asiatic wormwood product is produced by the method, the method is economic and practical, the cost investment is low,the process is simple and easy to implement, and the method can provide technical support for the industrialized production of Asiatic wormwood.

Owner:JIANGNAN UNIV +1

Blackfungus beverage and preparation method thereof

InactiveCN101331967APromote absorptionEasy to lower blood fatFood preparationWater soluble polysaccharidesWater soluble

The invention discloses a beverage and a preparation method thereof, and auricularia auricula is taken as the main material to make the beverage. The beverage uses the auricularia auricula as the main material, and is supplemented by jujubes and hawthorns; the beverage is prepared to richly contain a plurality of nutritive components such as water-soluble polysaccharide and the like by virtue of softening, rubber grinding and high pressure homogeneous cell wall break of the materials of three tastes of 'homology of medicine and food'. The beverage of the invention has functions of reducing blood-fat, enhancing immunity and resisting fatigue, etc. No chemical preservatives and pigments are added in the product formula of the invention, and an auricularia auricula carbon dioxide beverage can be made by adding CO2.

Owner:夏中军

Anti-pollution reverse-osmosis water purification machine

ActiveCN101597110AImprove water qualityReduced Possibility of ContaminationWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationSolenoid valve

The invention provides an anti-pollution reverse-osmosis water purification machine, which solves the problems of poor quality, easy generation of secondary pollution and the like of water produced by the existing water purification machine. The water purification machine comprises a water inlet valve, a pre-filter, a booster pump, a post-filter and a water outlet faucet, wherein the water inlet end of the water inlet valve is connected with a water source; the water outlet end of the water inlet valve is communicated with the water inlet end of the pre-filter; the water outlet end of the pre-filter is sequentially connected in series with a low-voltage switch and a solenoid valve; the water inlet end of the booster pump is connected with the water outlet end of the solenoid valve; the post-filter is connected between the booster pump and the water outlet faucet; a high-voltage switch is connected between the water outlet faucet and the booster pump; and the water flows into the post-filter, flows through the high-voltage switch, and finally flows out of the water outlet faucet. The water purification machine has the advantages of pretreatment process simplification by using an ultrafiltration membrane for pretreatment and prevention of the problem of secondary pollution caused by a single active carbon filter element by replacing a traditional active carbon filter element with a composite hydrophilic membrane filter element.

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

Waste lubricating oil pretreatment method

ActiveCN105754703ALess investment in equipmentSimple pretreatment processLubricant compositionPre treatmentPrinting ink

The invention relates to waste lubricating oil pretreatment method. The method comprises steps as follows: oxidative decolorization, flocculation, demulsification, sedimentation and separation. According to the waste lubricating oil pretreatment method, impurities such as colloid, asphaltene, metal powder, ash and the like in waste lubricating oil can be removed, and transparent pretreated oil is obtained; the method adopts a simple process and is energy-saving, environment-friendly, low in operating cost and simple and safe to operate; further, waste residues produced after flocculation are reprocessed to be used for printing ink and the like, secondary pollution can be avoided, certain economic benefits are obtained, and accordingly, the method is suitable for national conditions of small scale, low funds and backward technology for waste lubricating oil recovery.

Owner:盱眙凹土能源环保材料研发中心 +1

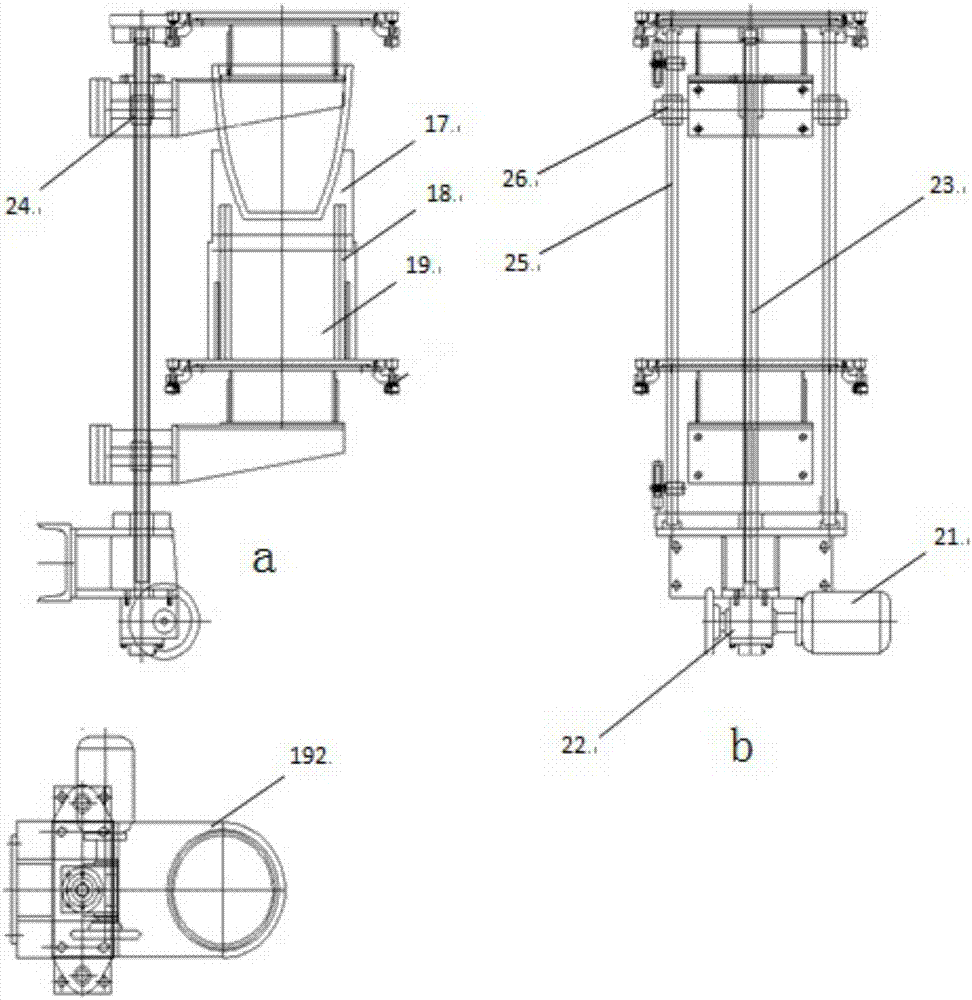

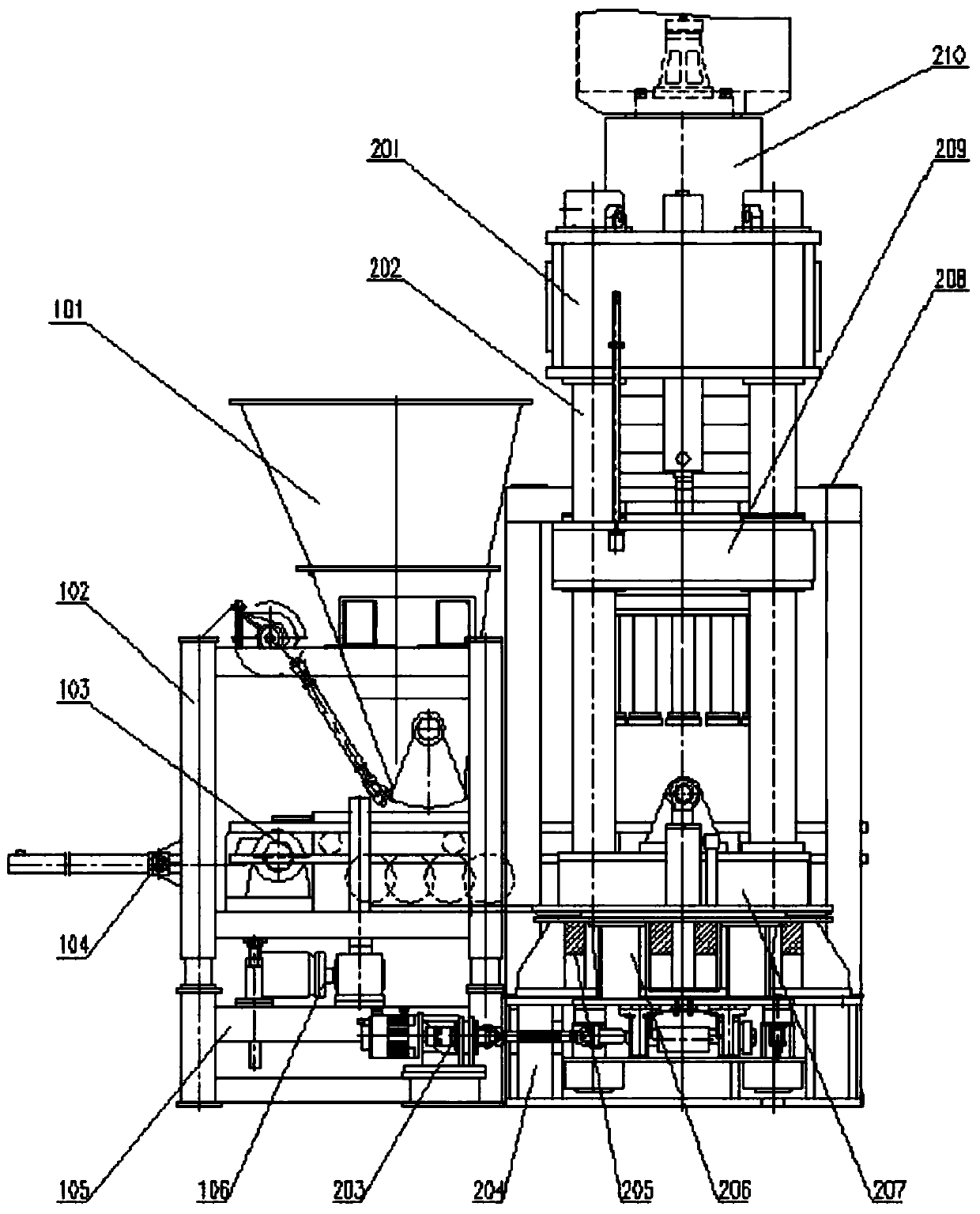

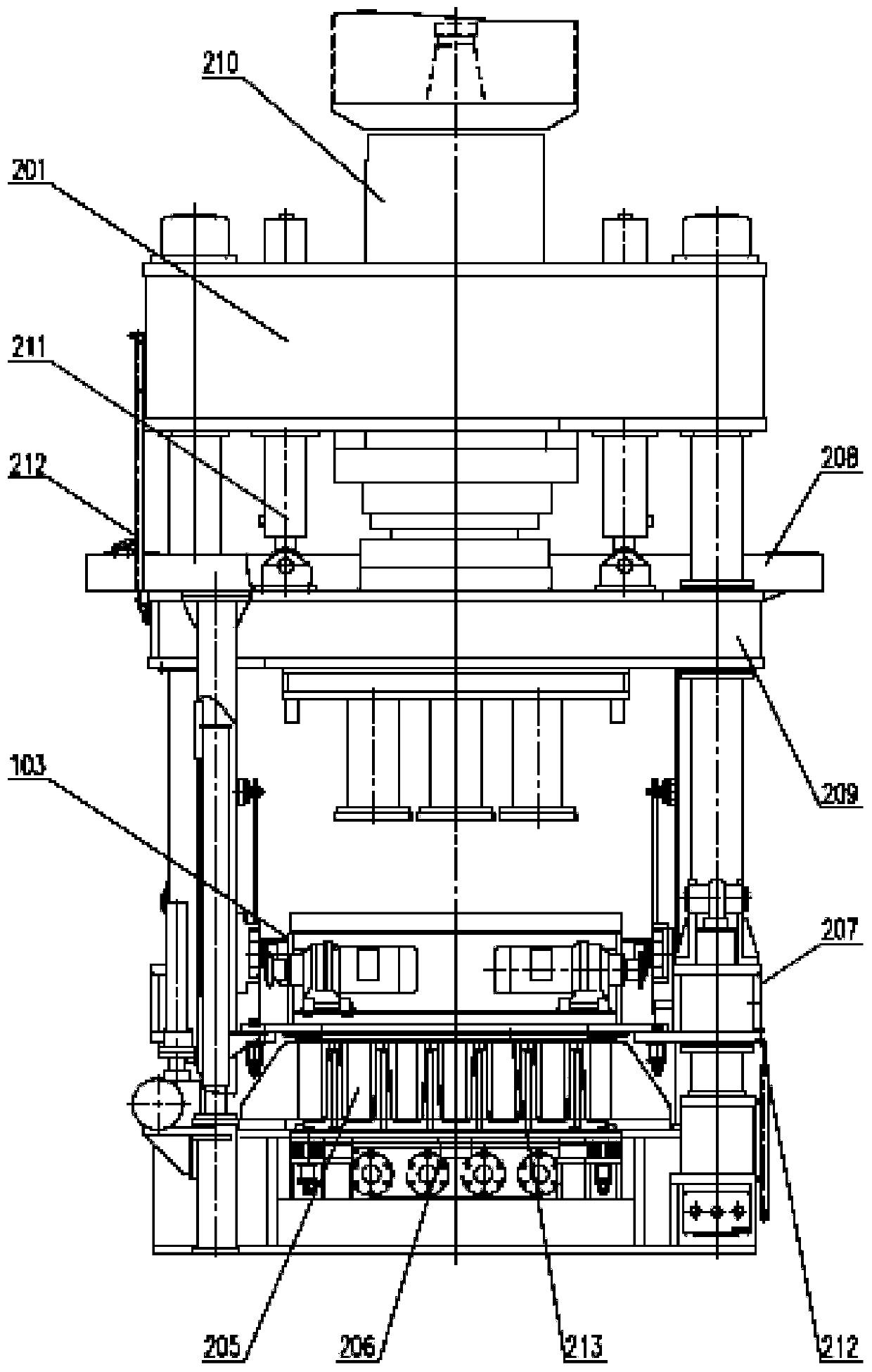

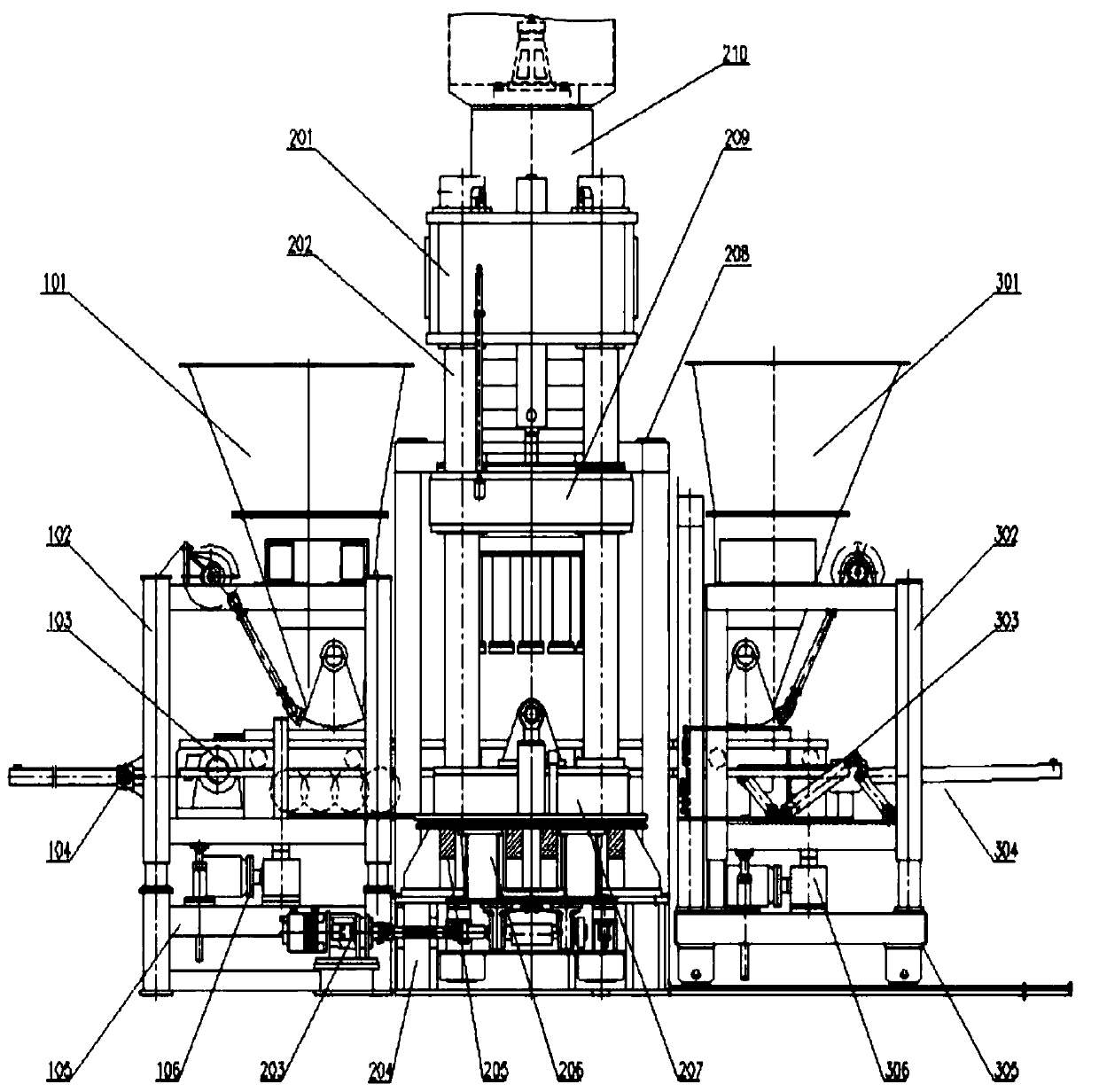

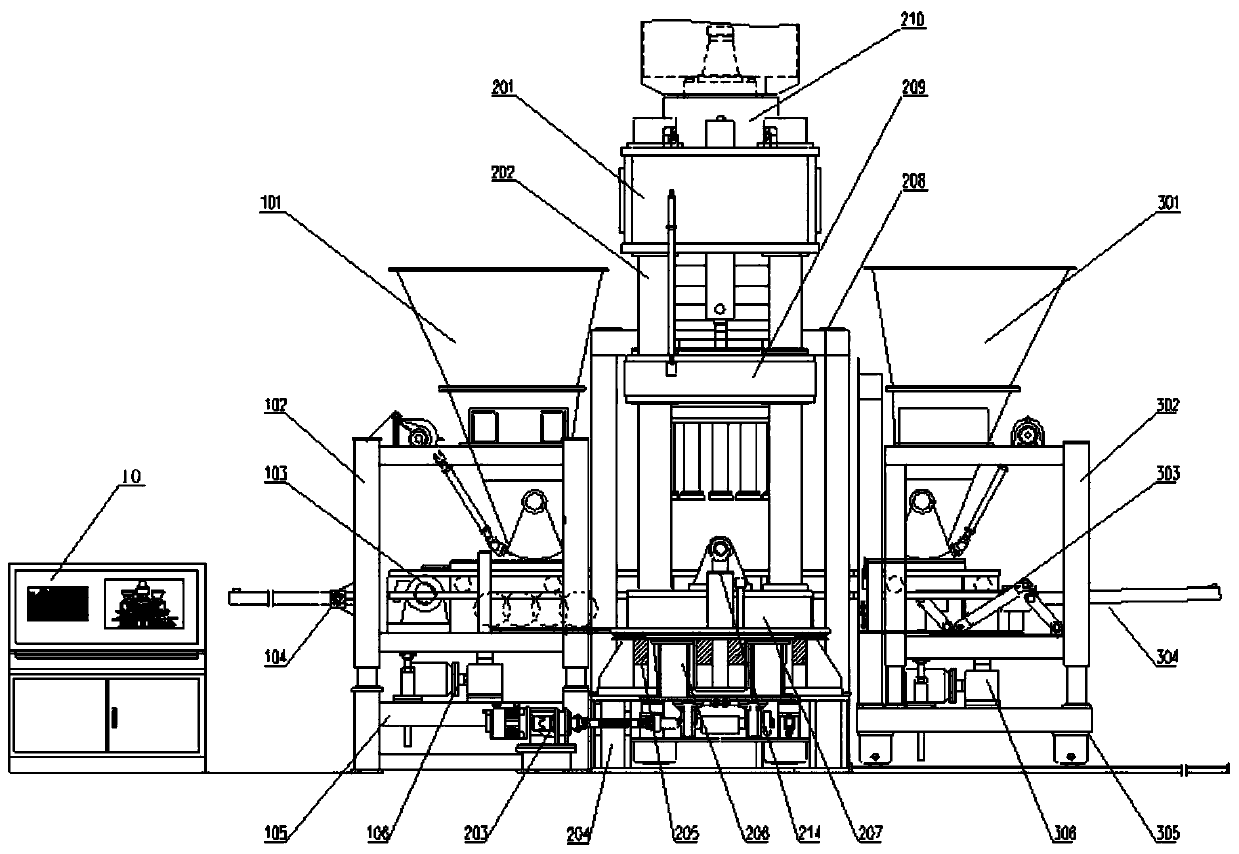

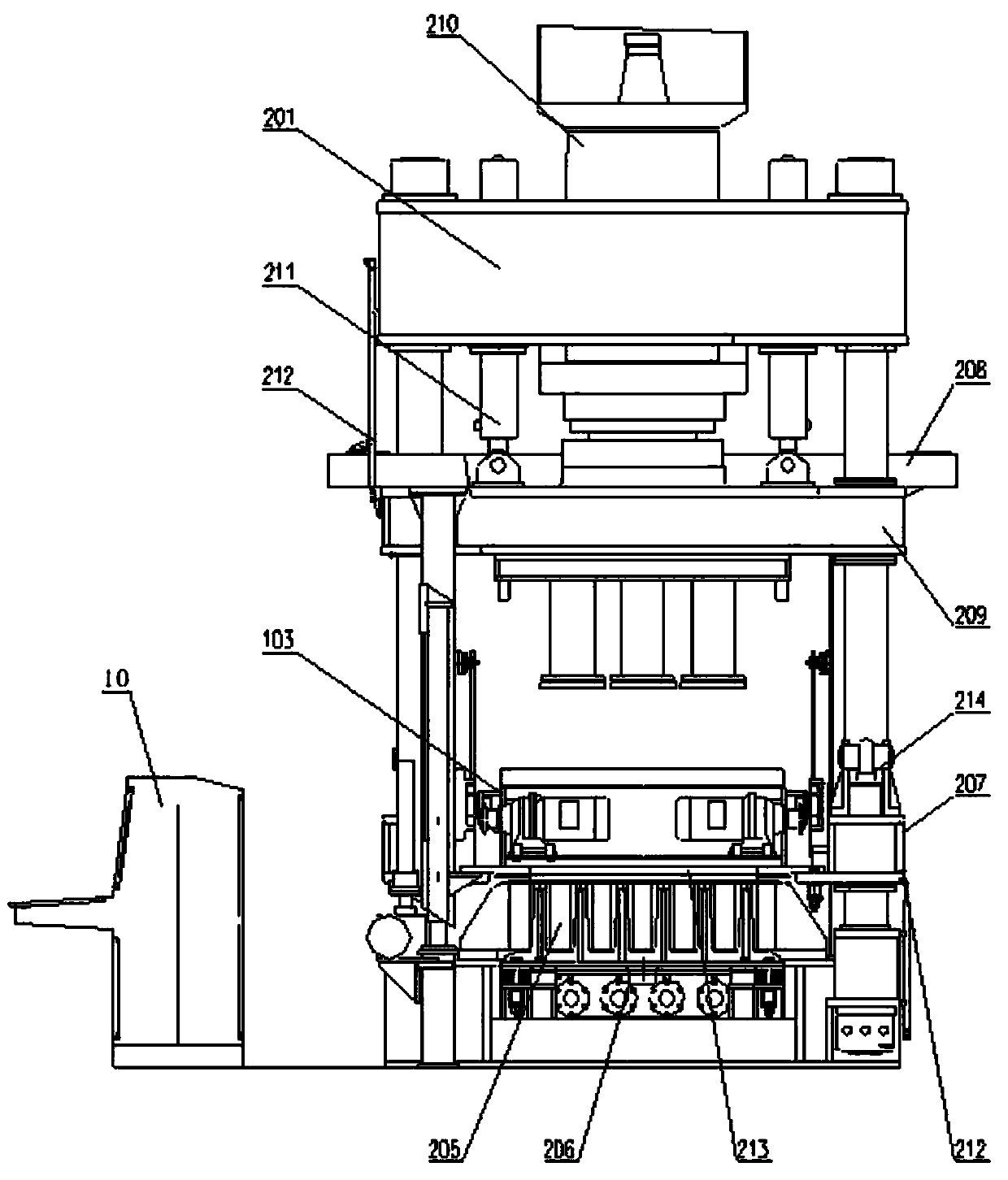

Fixed efficient vibration static-pressure forming machine

InactiveCN109968496AGuaranteed Targeted ReleaseEfficient use ofDischarging arrangementFeeding arrangmentsHydraulic cylinderDistribution system

The invention discloses a fixed efficient vibration static-pressure forming machine. The forming machine consists of a distribution system and a vibration static-pressure system; the distribution system fills blank forming materials in a mold box of the vibration static-pressure system; the vibration static-pressure system performs pre-vibration on the materials to compact virtual materials in themold box; then, the distribution system continuously fills the blank forming materials in the mold box; when a material preset value is reached, the vibration static-pressure system continuously performs vibration, and meanwhile, applies pressure to the materials in the mold box until a material preset height is reached; and then, finished products are demolded and delivered for maintenance. Theforming machine adopts the forming process of pressing after vibration, so that the materials form plastic bodies under the vibration force effect of a vibrator; then, the materials form elastic plastic bodies under coaction of a medium-pressure hydraulic cylinder and vibration; and when the material height is higher than a required product height by 3-5 mm, one-way rigid bodies are formed under the effect of a high-pressure one-way main oil cylinder of hundreds of tonnages, so that the building material product mechanization is more perfect, and the immeasurable value is achieved.

Owner:XIAN SILVER HORSE IND DEV CO LTDRIAL DEV CO LTD

Method for pretreating lignocellulose by using betaine eutectic solvent

ActiveCN110258157AImprove enzymatic hydrolysis efficiencySimple preparation processCellulose treatment using microorganisms/enzymesNon-woody plant/crop pulpCelluloseBetaine

The invention belongs to the technical field of efficient conversion and utilization of biomass resources, and discloses a method for pretreating lignocellulose by using a betaine eutectic solvent. The method comprises the following specific steps: 1) synthesizing a eutectic solvent with betaine as a hydrogen bond receptor and natural amino acid as a hydrogen bond donor; 2) employing a mixed solution of a eutectic solvent and water as a pretreatment solvent, and uniformly mixing a lignocellulose raw material with the pretreatment solvent according to a mass ratio of lignocellulose to the pretreatment solvent of 1:5-1:30, stirring the mixture at 50-140 DEG C for 2-48 h, cooling the pretreated mixture to room temperature, and finally carrying out solid-liquid separation to obtain pretreated solid-phase cellulose residues. The method not only can effectively improve the enzymolysis efficiency of lignocellulose, but also has the advantages of being environmentally friendly, renewable, easy to operate, low in viscosity, low in cost and the like.

Owner:SHANDONG UNIV OF SCI & TECH

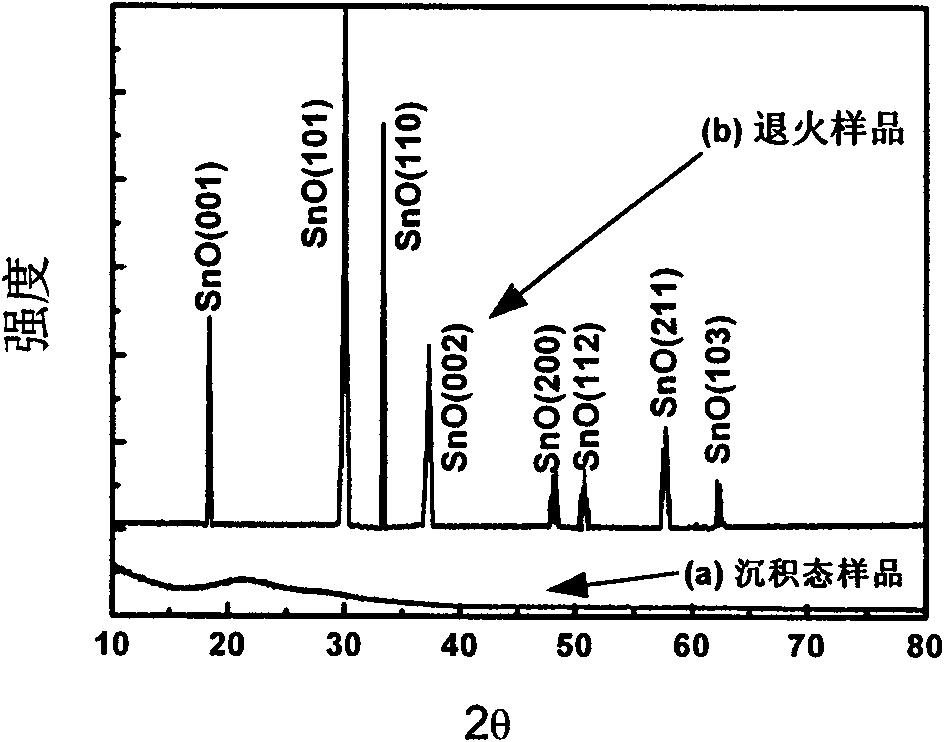

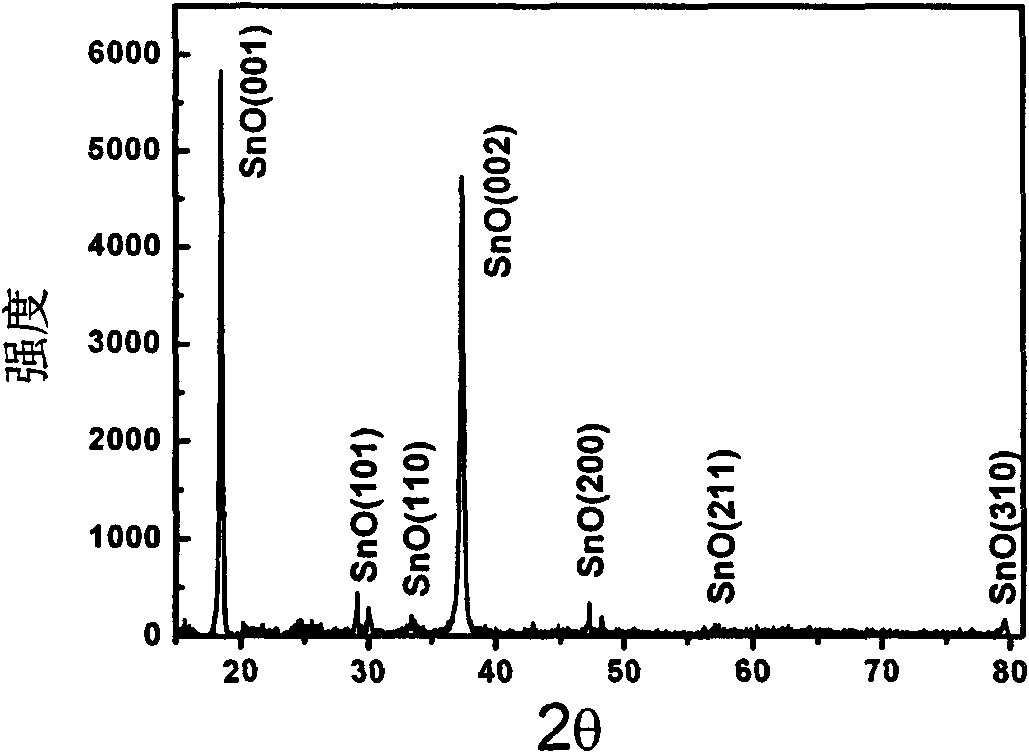

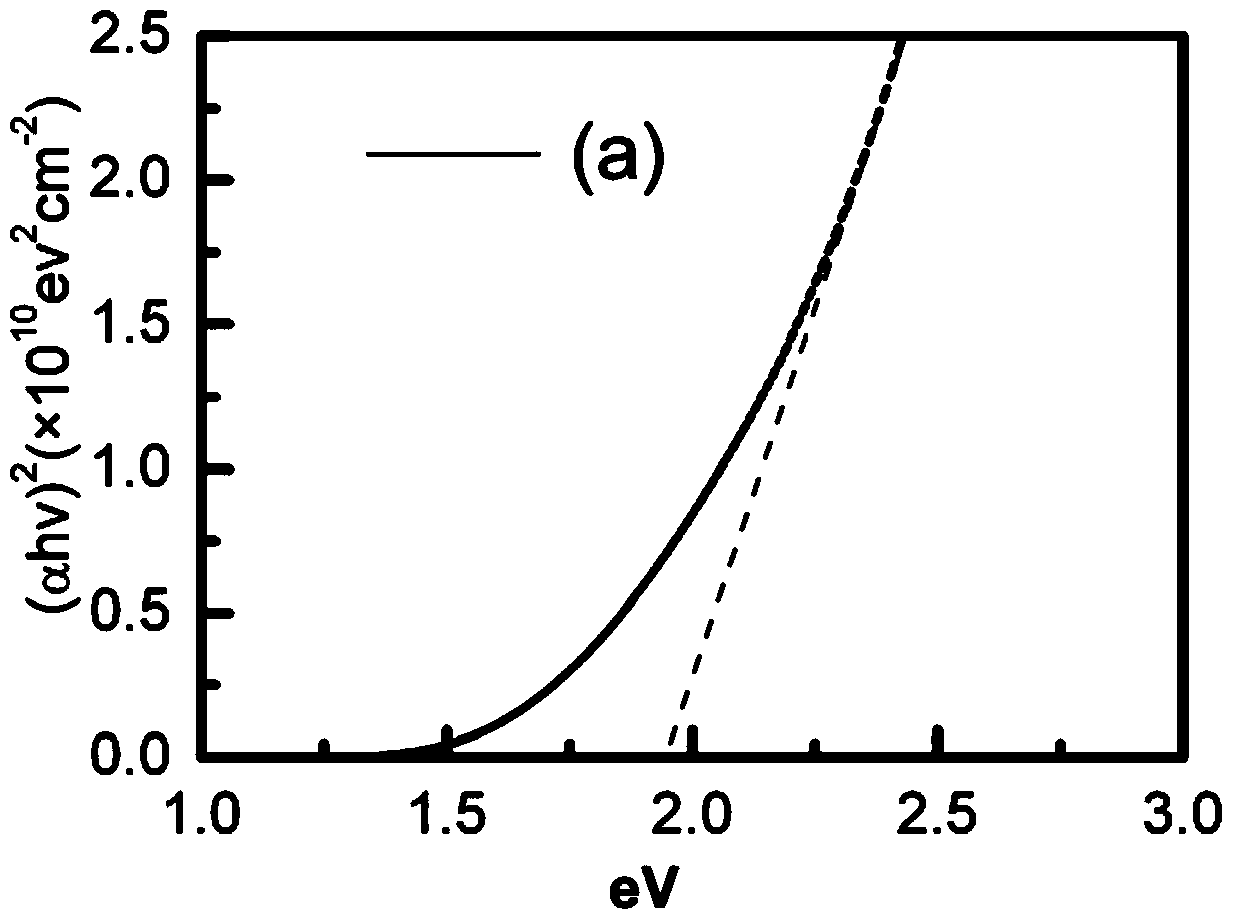

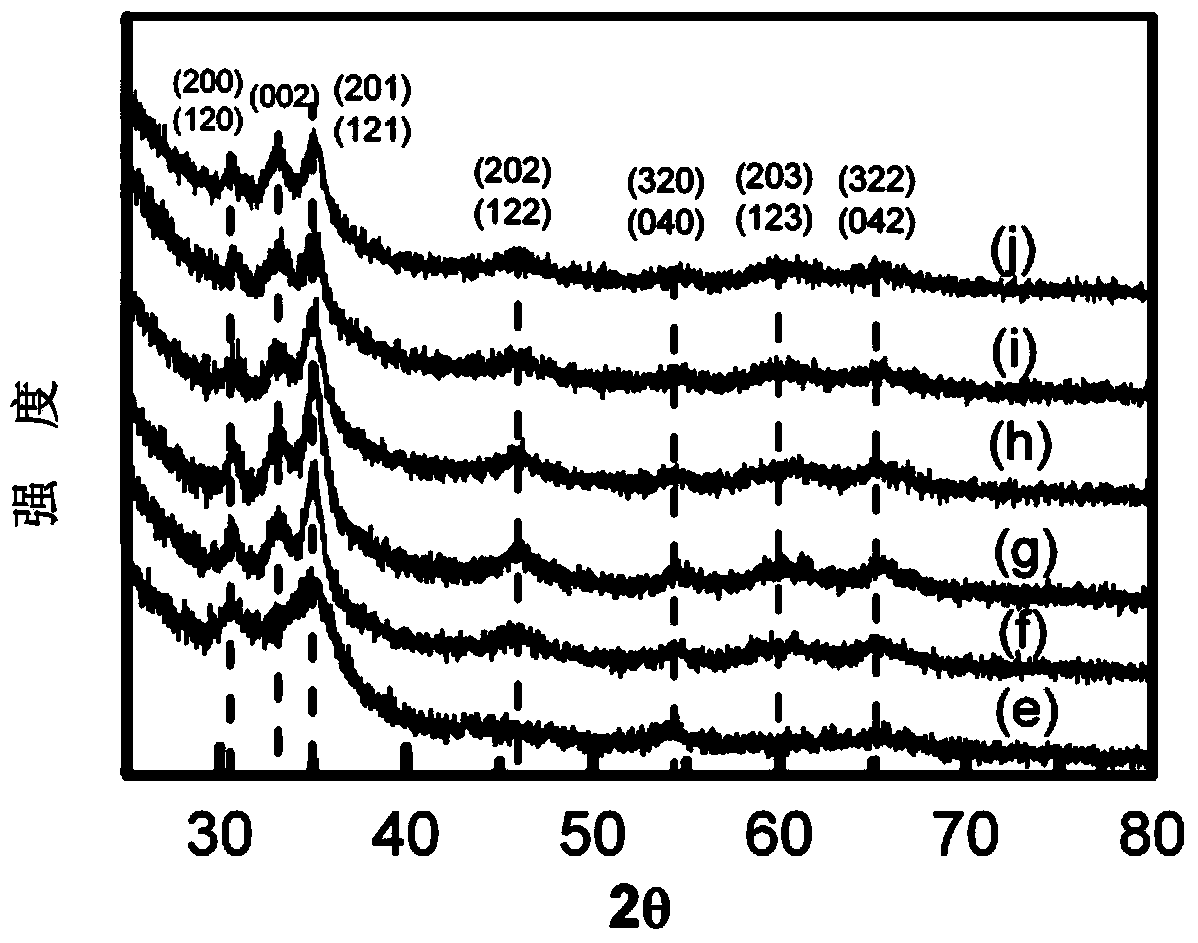

Preparation method of stannous oxide polycrystalline film

InactiveCN102021519ASimple preparation processReduce manufacturing difficultyVacuum evaporation coatingSemiconductor/solid-state device manufacturingSTANNOUS OXIDEEvaporation

The invention relates to a preparation method of polycrystalline stannous oxide film. The invention utilizes stannic oxide (SnO2) as the evaporation material and electron beam evaporation equipment. The preparation method comprises the following steps: preparing SnOx (x is bigger than 1 and smaller than 2) amorphous film at a low temperature firstly, conducting vacuum annealing treatment at high temperatures, therefore obtaining stannous oxide (SnO) polycrystalline film. The invention is advantageous in that: the preparation method is simple and controllable, in addition a large-area uniform film can be formed on a substrate such as quartz glass, and the film-forming repeatability is good. Stannous oxide is p-type electric conductive oxide and can be used to prepare oxide-based photoelectron and electron device.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

System and method for superheated steam and hot air combined drying of prawns as well as application of system and method

InactiveCN105685200AGuaranteed qualityAchieve recyclingMeat/fish preservation by dryingPrawnProcess engineering

The invention discloses a system and a method for superheated steam and hot air subsection combined drying of prawns as well as application of the system and the method. The system comprises a steam generator, a steam heater, an overheat steam drying box, a heat exchanger, an electric heater and a hot air drying box. The method comprises the following steps of firstly, pretreating fresh prawns; secondly, performing first-stage drying on the prawns by using overheat steam, and reducing the water content of the prawns to be 45 to 50 percent; finally, performing second-stage drying on the prawns by using hot air until the water content of the prawns is reduced to be 15 to 20 percent. The pretreated prawns are directly dried by using the overheat steam, so that the prawns are quickly dehydrated, the drying efficiency is high, the drying time is greatly shortened, and sterilizing and disinfecting effects are realized; for the prawns dried by the overheat steam, prawn flesh and prawn skins are well separated, so that peeling and eating are easily realized; the prawns are dried by using the hot air with 50 to 55DEG C, so that residual partial water in the prawns is removed until the water content in the prawns is reduced to be 15 to 20 percent. The prawns dried by the method have the advantages of separation of the skins and the flesh, plump individuals, pure color and excellent mouthfeel.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

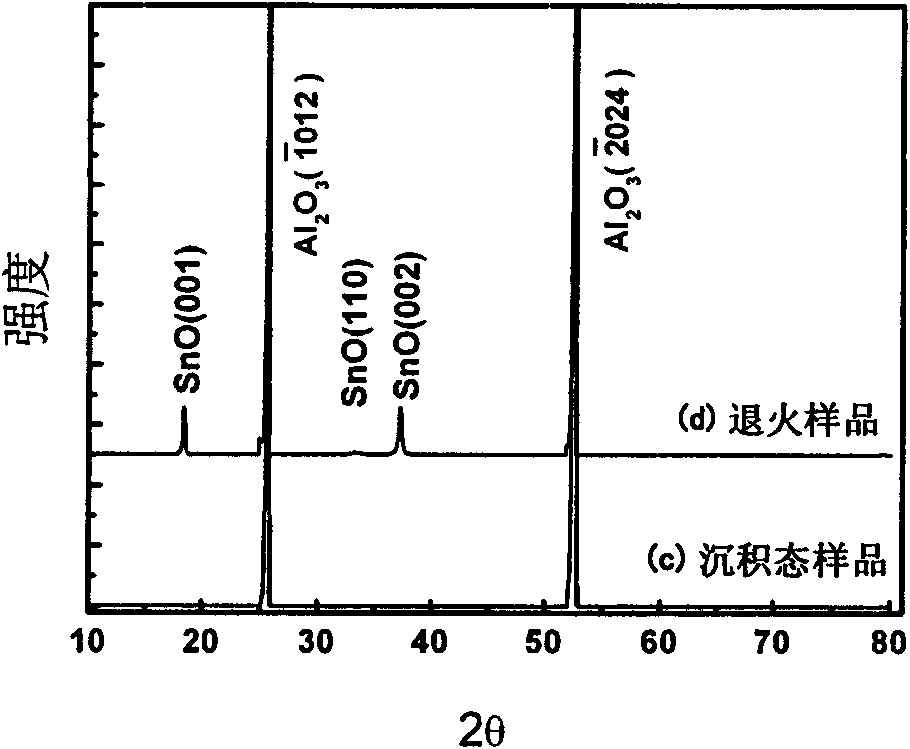

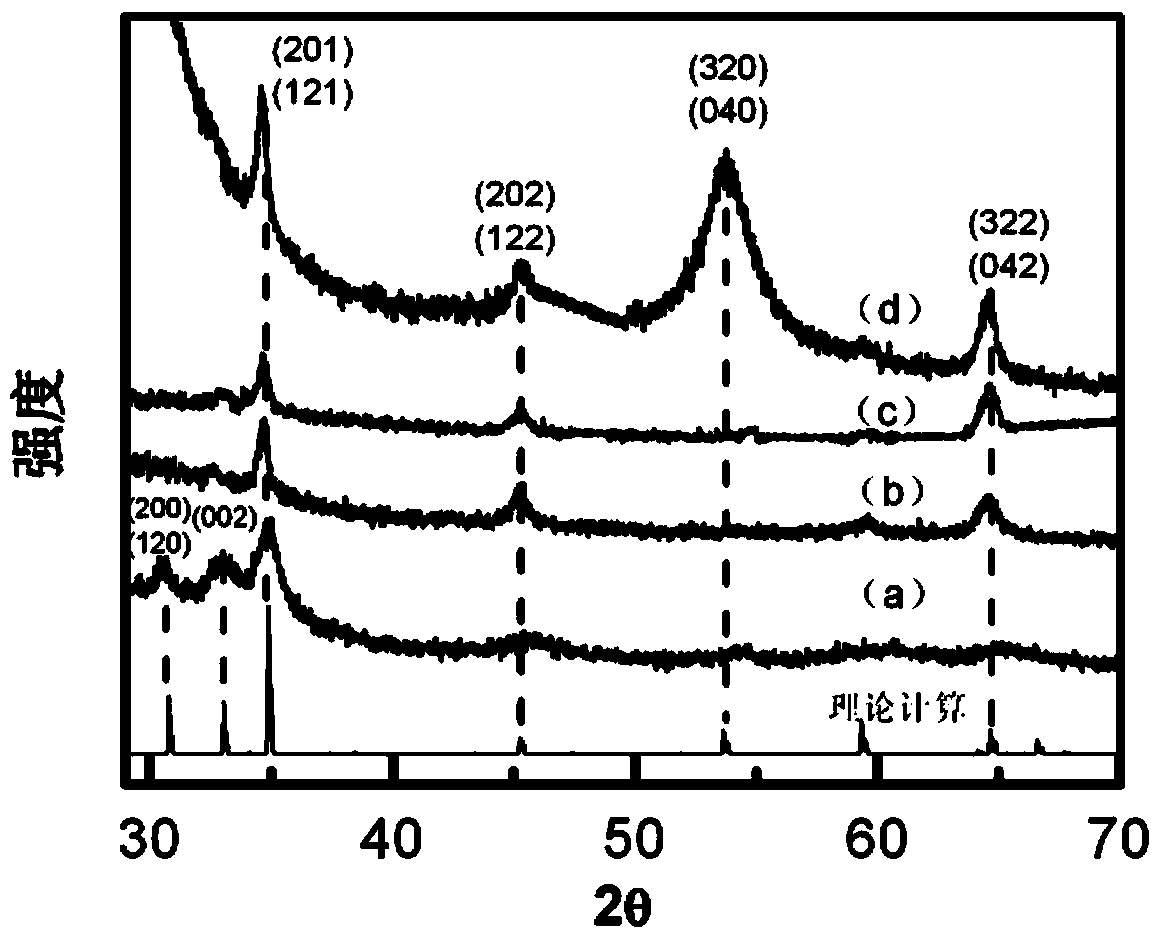

Preparation method for zinc tin nitride polycrystalline film

ActiveCN104195514ASimple processReduce manufacturing costVacuum evaporation coatingSputtering coatingIonNitrogen gas

The invention discloses a preparation method for a zinc tin nitride polycrystalline film. The preparation method comprises the following steps: firstly, placing a cleaned substrate and a zinc tin alloy target material onto corresponding positions of magnetron sputtering equipment, and carrying out vacuum-pumping; ventilating nitrogen gas, regulating working gas pressure to 1-3Pa and sputtering power to 120-300W, bombarding the cathode zinc tin alloy target material by virtue of N ions, and depositing on the substrate to form the zinc tin nitride polycrystalline film. According to the preparation method, by virtue of a magnetron sputtering method, the ZnSnN2 polycrystalline film is grown in a vacuum cavity by one step without other thermal treatment under a low temperature condition, and the preparation method is simple in process, low in energy consumption and capable of greatly lowering the production cost. A quartz slice, a silicon slice, a glass slice or PET flexible plastic, and the like can be adopted as the substrate which has the advantages of low cost, a simple substrate pretreatment process, and the like in comparison with other monocrystal substrates such as an sapphire substrate; and moreover, the ZnSn alloy target material and the nitrogen gas can be used as raw materials, and can be directly purchased, so that the preparation difficulty for the raw materials is lowered.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

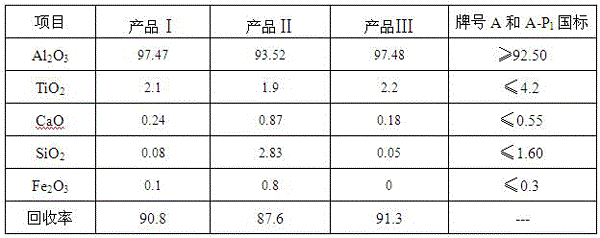

Method of melting aluminum ash to prepare brown aluminum oxide

InactiveCN106747301AAchieving processing powerImplement resourcesCeramic materials productionClaywaresCoesiteHigh-temperature corrosion

The invention discloses a method of melting aluminum ash to prepare brown aluminum oxide. At first, aluminum ash is subjected to an acidification treatment and an alkalization treatment in sequence; then solid-liquid separation is performed to obtain aluminum ash; the obtained aluminum ash is subjected to drying dehydration and high temperature burning; after the aluminum ash is cooled, the aluminum ash is mixed with iron chips and coke, and finally the mixture is sintered to obtain brown aluminum oxide. In the melting step, burned aluminum ash, iron chips, and coke are mixed according to a ratio of 100:3-4:8-13, the mixture is melted for 2 to 3 hours at a high temperature of 2300 to 2700 DEG C, and finally the mixture is ground and graded to obtain the brown aluminum oxide. The aluminum ash is subjected to a harmless treatment and converted into valuable resources. The problem of shortage of high aluminum bauxite is solved, and the production cost of brown aluminum oxide is also reduced.

Owner:HENAN UNIV OF SCI & TECH

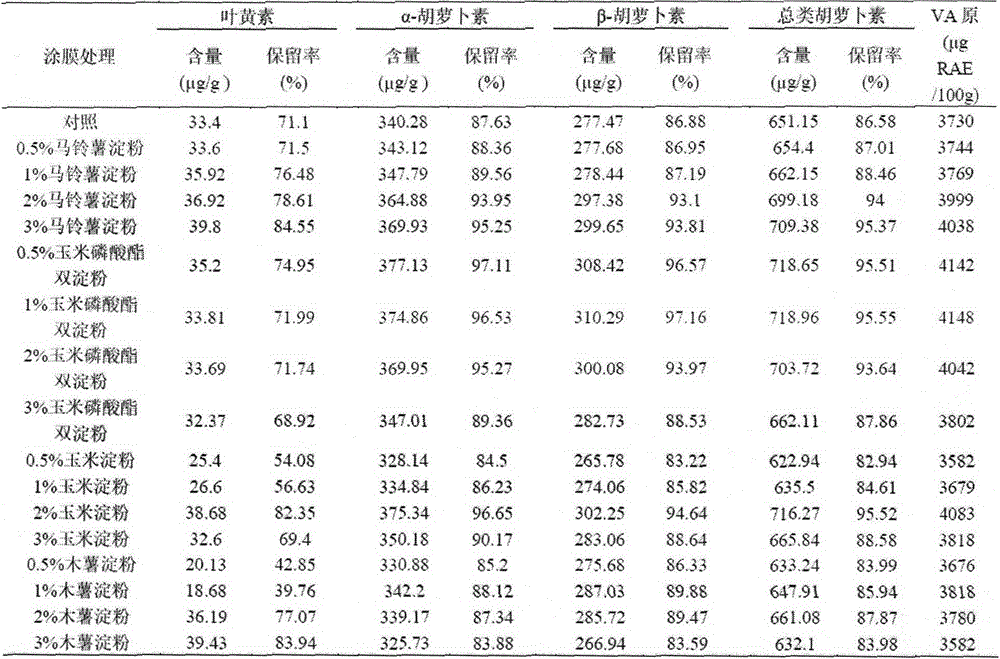

Drying and processing method for improving retention rate of carotenoid in pumpkins

ActiveCN105994581AImprove drying qualitySimple pretreatment processFruits/vegetable preservation by heatingFood dryingBeta-CarotenePotato starch

The invention relates to the technical field of fruits and vegetables, in particular to a drying and processing method for improving the retention rate of carotenoid in pumpkins. Namely, the pumpkins are selected, cleaned and peeled, pulp and seeds are removed, the pumpkins are cut into slices of 4-6 mm, and then coating treatment is performed in a potato starch solution with the mass concentration of 2%-3% or a corn phosphate double-starch solution with the mass concentration of 0.5%-1.5% at the temperature of 80-85 DEG C for 5-15 minutes; drying treatment is performed in a vacuum microwave drying device after air drying, the microwave power is controlled to be 4-5 W / g, the vacuum degree is controlled to be 80-90 KPa, and the drying time is controlled to be 3-5 minutes; then freeze drying is performed, drying stops when the water content of the pumpkin slices is 3%-5%, and nitrogen filled packaging is conducted on products. The drying and processing method improves the retention rate of the carotenoids in the pumpkins to the most degree, the beta-carotene retention rate is 93% or above, the alpha-carotene retention rate is 94% or above, the lutein retention rate is 71% or above, and the provitamin A and color and luster of the products are kept well. In addition, by the adoption of the method, the drying time is saved, and the energy consumption of production is reduced.

Owner:JIANGSU ACAD OF AGRI SCI

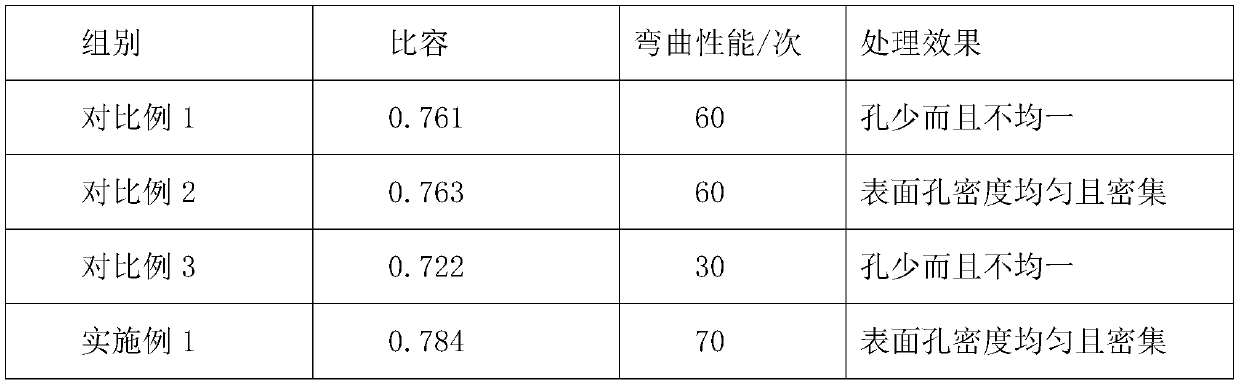

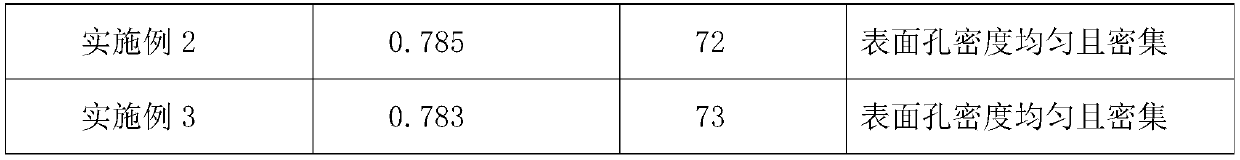

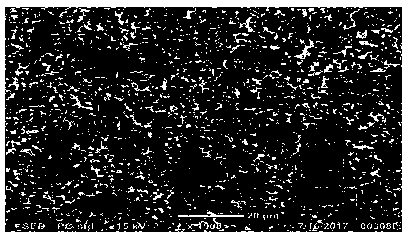

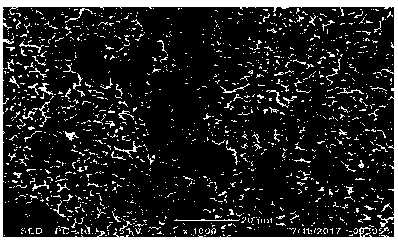

Manufacturing process for middle-high-voltage etched foil

InactiveCN109750346AStrong activation surfaceImprove bending performanceCapacitor manufactureAluminium electrolysisAluminum foil

The invention discloses a manufacturing process for middle-high-voltage etched foil, and relates to the technical field of production of etched foil. In order to solve the problem that etched foil isprone to deforming in the prior art, the manufacturing process comprises the steps of pretreatment, primary foaming corrosion, secondary foaming corrosion, third hole expansion corrosion and aftertreatment for high-purity aluminum foil; in the pretreatment, the aluminum plain foil is put into pretreatment liquid to be soaked for 40-50 seconds; then the aluminum plain foil is washed and then put into primary corrosion mixing liquid with the temperature of 80-90 DEG C, the foil is washed with pure water to be put into 2% of nitric acid liquid with the temperature of 70-80 DEG C, and direct current with the current density of 0.15 A / cm2 is applied for electrolytic corrosion for 500-600 seconds; and the aftertreatment adopts two-stage annealing heat treatment of different temperatures. The pretreatment process is simple, operation is convenient, deformation is avoided, the annealing process is improved in the aftertreatment, the two-stage annealing heat treatment of different temperaturesis adopted, and the bending performance of the etched foil for an aluminum electrolytic capacitor is greatly improved.

Owner:CENT SOUTH UNIV

Method for preprocessing plant cellulose raw material

InactiveCN102839556APrevent mildewEasy to crushFinely-divided cellulose conservationPretreatment with acid reacting compoundsFiberPretreatment method

The invention relates to the field of biochemical industry and particularly relates to a method for preprocessing a plant fiber raw material. The method for preprocessing the plant fiber raw material comprises the following steps: processing the plant fiber raw material by use of a dilute inorganic acid solution, namely contacting the dilute inorganic acid inorganic acid solution with the plant fiber raw material so as to enable the plant fiber raw material to carry the inorganic acid; then carrying out waterproof storage on the plant fiber raw material with the acid and naturally air-drying the plant fiber raw material with the acid; and after detecting that the stored plant fiber raw material is embrittled, smashing the stored plant fiber raw material, wherein the smashed material is the well preprocessed plant fiber raw material. By utilizing the method, the preprocessed plant fiber raw material cannot go mouldy during the storage process and can be easily smashed into a fine concentrated acid hydrolysis material with a loose structure after being stored.

Owner:陈培豪

Novel aluminum corrosive foil pre-treatment process

The invention relates to a novel aluminum corrosive foil pre-treatment process which comprises the following steps of: (1) putting an aluminum plain foil in a pre-treatment liquid to be soaked for 45s; (2) then cleaning the foil thoroughly, putting the foil in a primary corrosive mixed liquid at 70 DEG C, and applying a direct current, the current density of which is 0.70A / cm<2> for electrolytic corrosion for 60s; (3) cleaning the foil thoroughly with pure water, putting the foil in a tank liquid containing 2% of nitric acid at 70 DEG C, and applying a direct current, the current density of which is 0.15A / cm<2> for electrolytic corrosion for 600s; and (4) finally, cleaning the foil thoroughly with pure water, and then putting the foil in an oven at 220 DEG C to be dried. The process provided by the invention overcomes related defects that the corrosive foil which is pre-treated is likely to deform, the surface of the foil is of chromatic aberration after treatment, trace elements beneficial for generating holes will be removed through treatment, follow-up operations are not facilitated and the like.

Owner:江苏国瑞科技有限公司

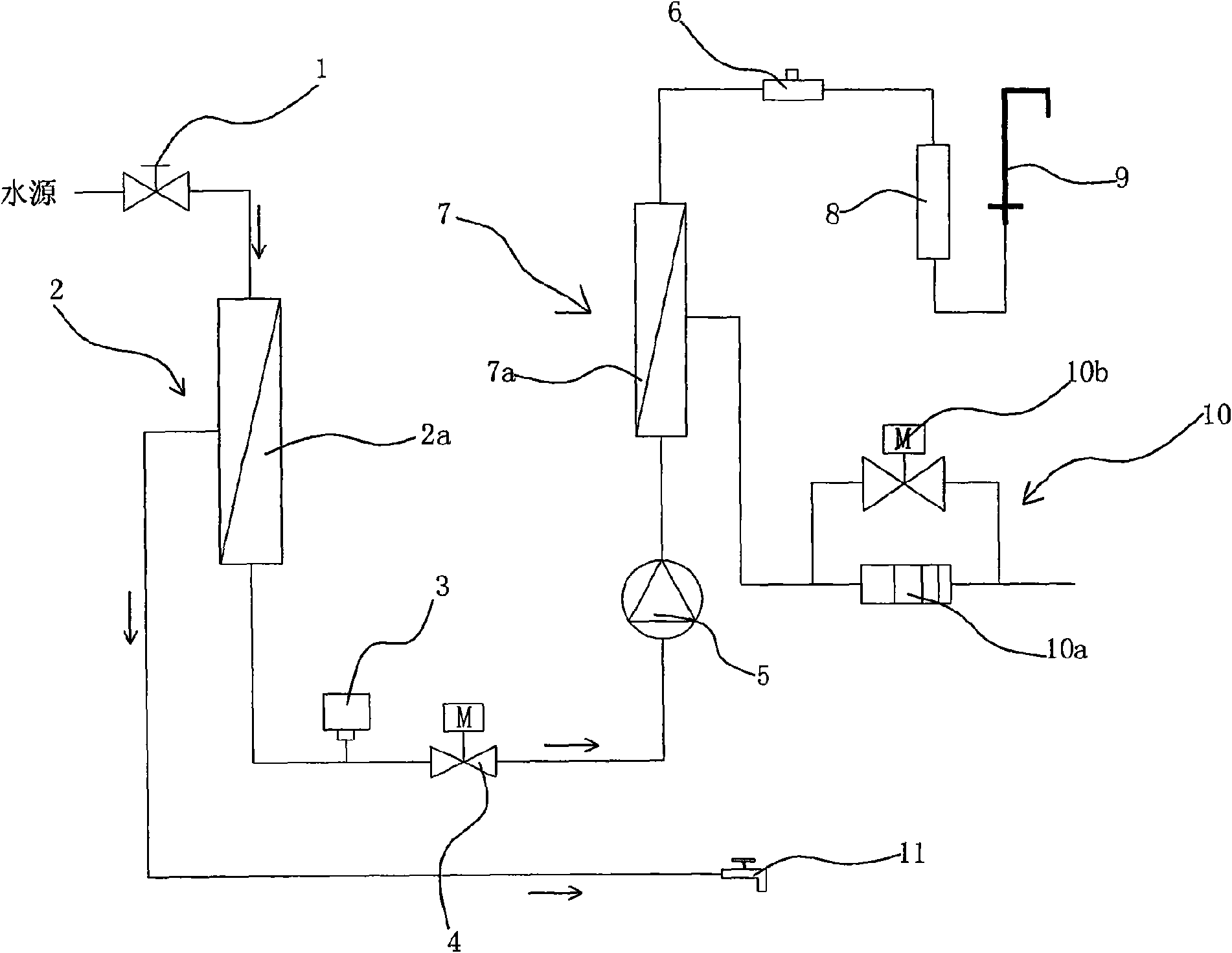

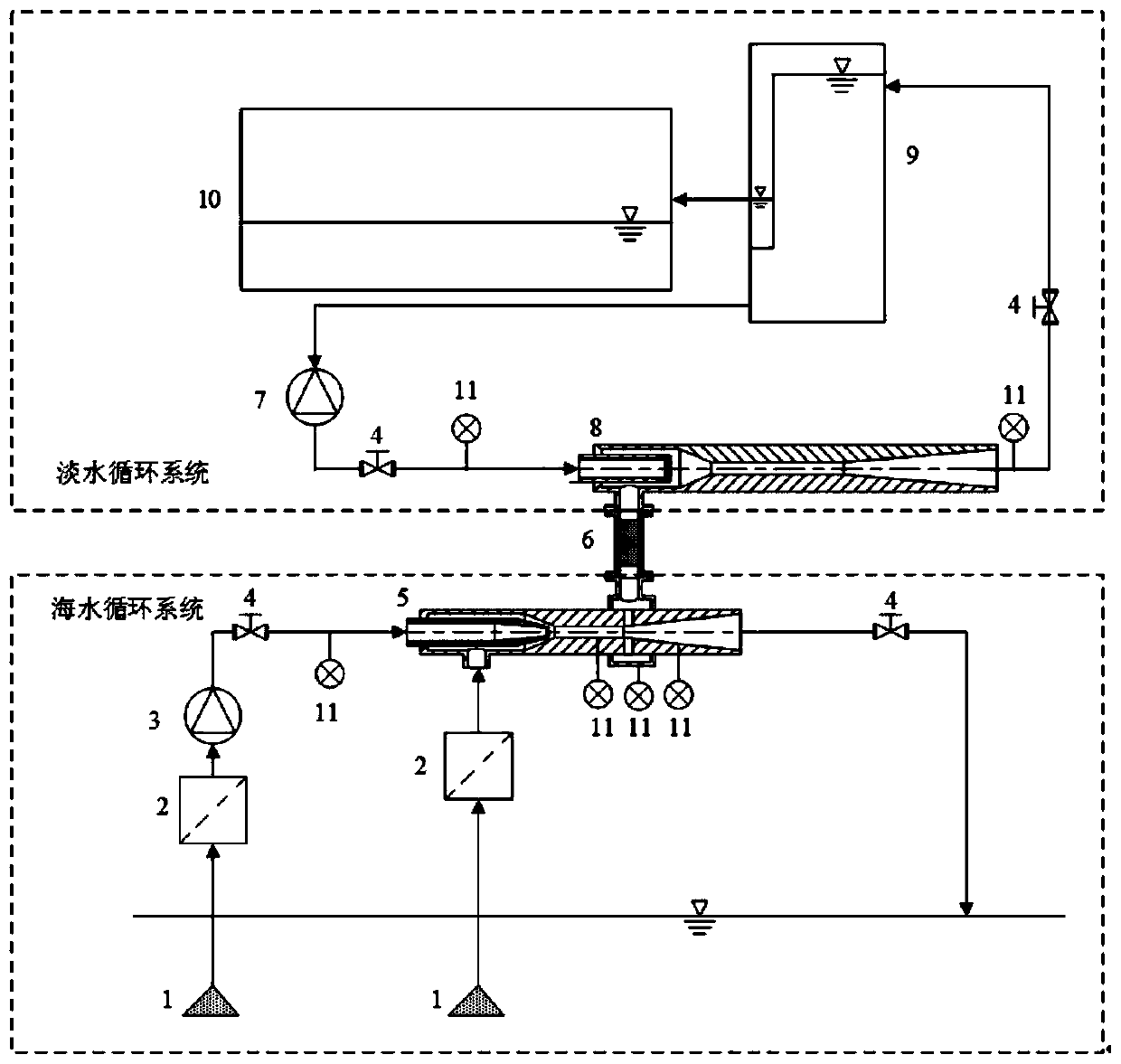

Normal temperature low-pressure seawater desalination system based on ejection cavitation technology

PendingCN109851134ASimplify and reduce the desalination processSimple structureSeawater treatmentMultistage water/sewage treatmentFiltration membraneCavitation

The invention provides a normal temperature low-pressure seawater desalination system based on the ejection cavitation technology. The seawater desalination system comprises a seawater circulating system and a freshwater circulating system, wherein the seawater circulating system comprises water suction apparatuses, coarse filtration apparatuses, a seawater working pump and an ejection-type cavitation generator which are successively connected through a pipeline, the freshwater circulating system comprises a freshwater working pump, a liquid vapor jet pump and a circulating water tank which are circularly connected through a pipeline, the circulating water tank communicates with a water storage apparatus through an overflow apparatus, and the ejection-type cavitation generator in the seawater circulating system communicates with the liquid vapor jet pump in the freshwater circulating system through a filtration membrane apparatus. The system has the advantages of simple structure, lowcost, low temperature environment requirements and stable performances. Compared with a system of an existing desalination apparatus, the system simplifies and reduces the desalination treatment process. The cavitation is produced by utilizing the high-speed and low-pressure and shear-flowing of the jet flow, so that the effect of the seawater phase transformation is achieved. The temperature requirement limit of water vaporization is small, the vaporization amount is large, and the effect is reliable.

Owner:WUHAN UNIV

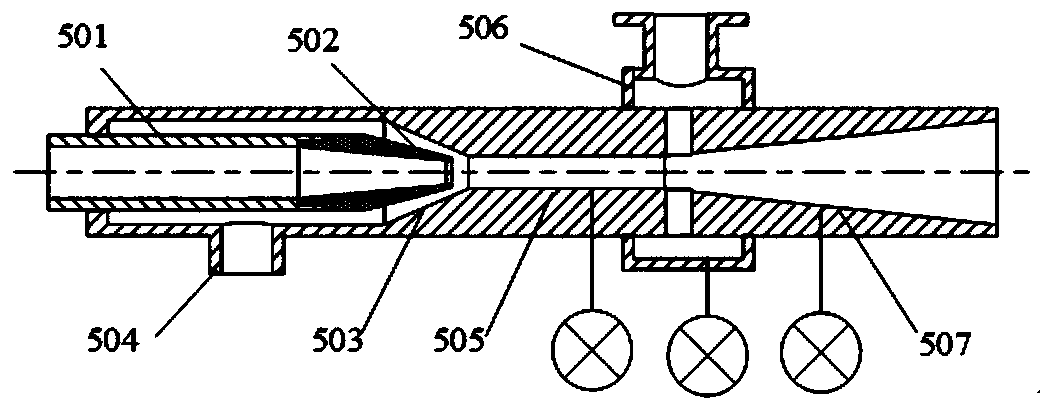

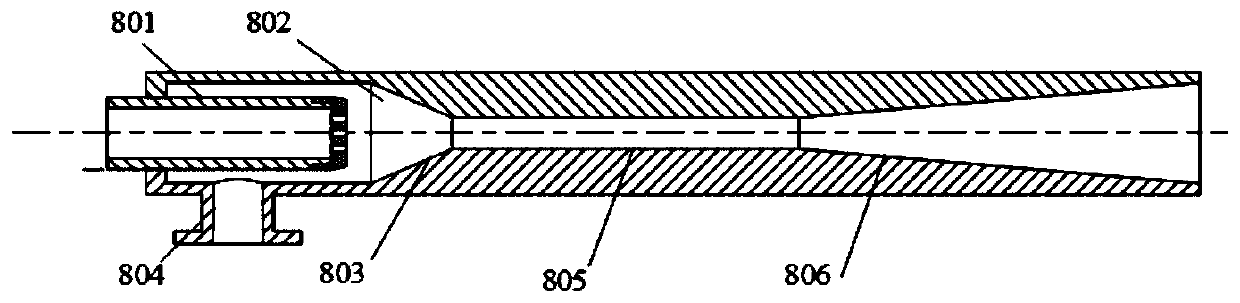

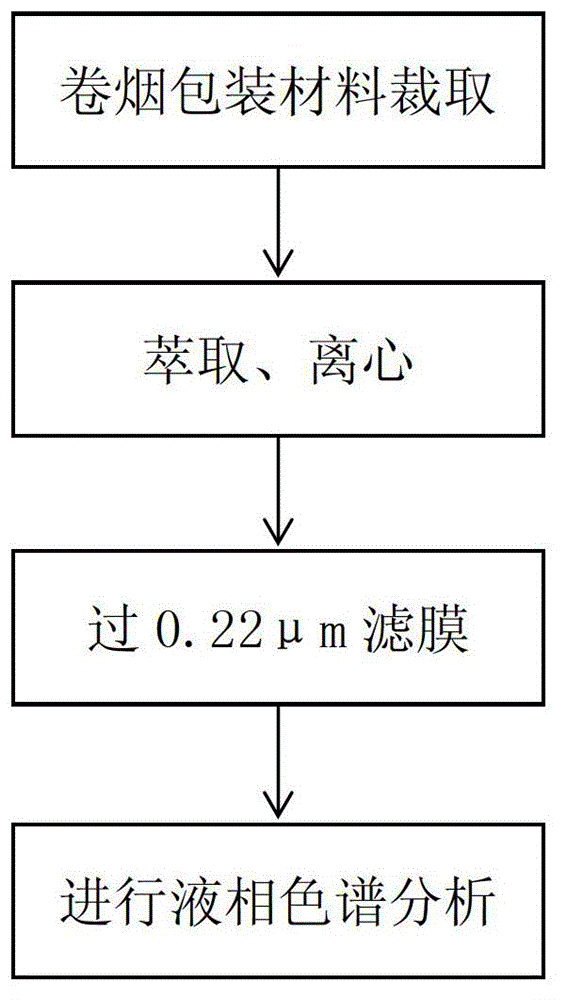

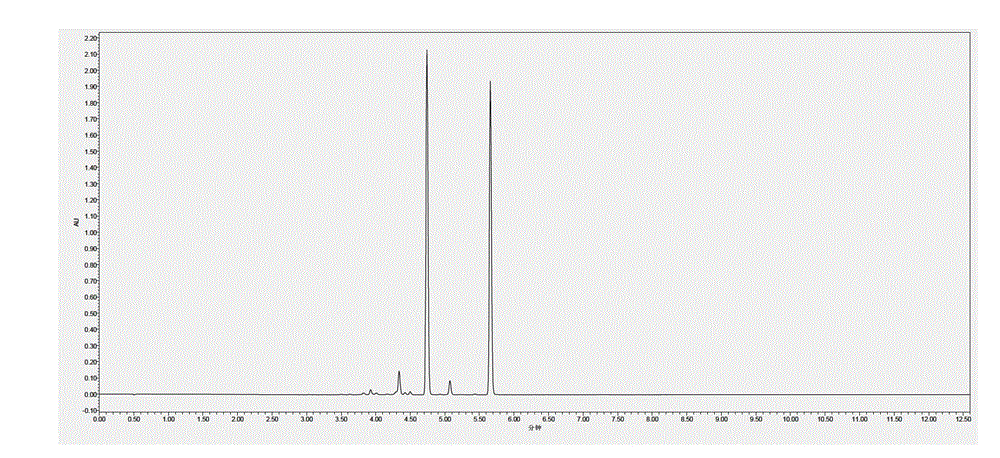

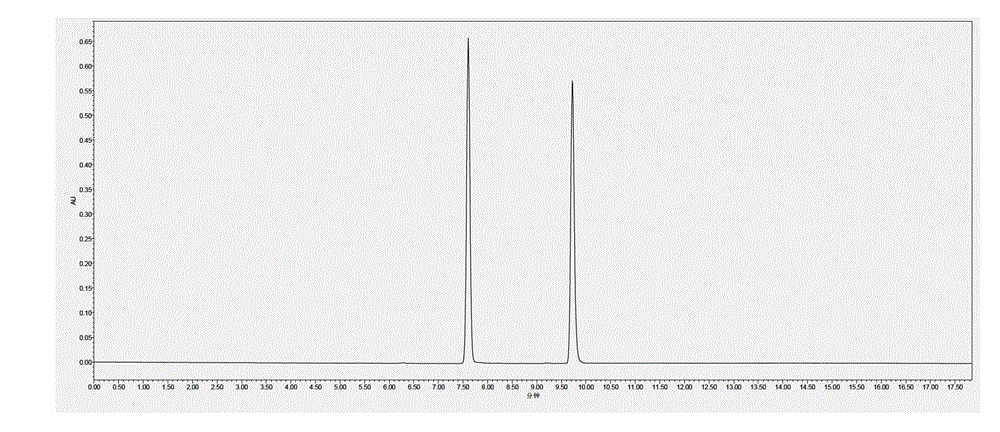

Rapid measurement method of residual amounts of two photoinitiators in paper packaging material

InactiveCN103336068ARespond to access requirementsSimple pretreatment processComponent separationFood contact materialsBenzophenone

The invention discloses a rapid measurement method of residual amounts of two photoinitiators in a paper packaging material. The method comprises the preparation of a sample, the pretreatment of the sample, the preparation of a standard working solution, and the analysis and result calculation by an instrument. By adopting the method disclosed by the invention, a liquid-phase chromatographic analysis technique is firstly applied to the measurement of the residual amounts of the two photoinitiators in the paper packaging material; 4,4-bis(diethylamino)benzophenone and 4,4-bis(dimethylamino)benzophenone in the paper packaging material can be quantitatively analyzed and screened rapidly, simply and conveniently so as to better deal with the raw material access requirement for a foreign relevant food contact material; the method has the characteristics of simple pretreatment process, fast analysis, high detection sensitivity, high accuracy and high repeatability.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

High-thermal-conductivity low-porosity graphite for curved glass hot bending mold and preparation method thereof

The invention discloses high-thermal-conductivity low-porosity graphite for a curved glass hot bending mold. The thermal conductivity is not lower than 94W / (m.K), the porosity is not higher than 20%,the thermal expansion coefficient is not higher than 5.8 * 10<-6> / DEG C, and the average particle size is not higher than 5mu m. The preparation method of the graphite comprises the following steps: preparing petroleum coke powder, crystalline flake graphite powder and modified asphalt powder into modified asphalt coke flake powder, uniformly mixing the modified asphalt coke flake powder with modified mesocarbon microbeads, crushing, standing, carrying out isostatic pressing molding, roasting carbonization, dipping treatment and graphitization treatment to obtain the high-thermal-conductivitylow-porosity graphite. According to the graphite material, the petroleum coke powder is used as a main material, the modified asphalt mesocarbon microbeads and crystalline flake graphite are used as auxiliary materials, aggregate types and proportions are reasonably matched, mirror surface heat conduction, pores and expansion coefficients of the processed graphite material can be improved, the average particle size of the graphite material is not larger than 5 micrometers, and the graphite material can be applied to curved glass hot bending molds.

Owner:HUNAN CHANGYU NEW CARBON MATERIALS

Graphite material for heat exchanger and preparation method of graphite material

Provided is a graphite material for a heat exchanger. The graphite material is mainly prepared by mixing pitch meso-carbon microbeads, a petroleum coke stage material and modified pitch, wherein the petroleum coke stage material is needle petroleum coke subjected to secondary coking or third-time coking. A preparation method comprises the steps that the petroleum coke and modified pitch slurry are subjected to mixing kneading and rolling and flaking under vacuum condition, cooling and smashing are conducted in sequence, the smashed materials are subjected to mixing, standing, isostatic press molding, calcining and smashing, and the petroleum coke stage material is obtained; the petroleum coke stage material and the pitch meso-carbon microbeads are subjected to mixing kneading, the modified pitch is added and rolled to be flakes, cooling and smashing are conducted in sequence, the smashed materials are subject to mixing, standing, isostatic press molding, calcining carbonization treatment and graphitization treatment, and the graphite material for the heat exchanger is obtained. According to the graphite material for the heat exchanger, the needle petroleum coke subjected to secondary coking or third-time coking is used for the first time, toughness and self-lubrication of graphite are enhanced, the processing efficiency of graphite machinery is improved, and thermal conductivity of graphite pieces can be increased.

Owner:HUNAN CHANGYU NEW CARBON MATERIALS

High-Arsen gold ore pretreatment method

The invention relates to a high-Arsen gold ore pretreatment method which comprises the following steps of: crushing high-Arsen gold ore into power which is not more than 200 meshes; enriching to obtain high-Aresen gold concentrate fines; adding NaCl, NaOH and diethyldithiocarbamate in proportion; uniformly stirring and filling in an oxidizer; heating and pressurizing for a while under a closed condition; and recovering residual gas by using active carbon or an alkaline solution, wherein solid substances generated after oxidation contain native gold, limonite, ferric oxide, arsenic bloom and mixtures of other impurities. The method solves the problems of the prior art, such as under-burning, over-burning, environment pollution, difficult recovery of other useful components and the like. Through pretreatment experiments of several high-Arsen gold fine mines, after oxidization, Arsen, gold and other components are converted into native gold, ferric oxide, arsenic bloom, gypsum and other independent minerals or oxides; the method facilitates the recovery of other useful components, has no problems of under-burning and over-burning, and ensures that the pretreatment process has no environment pollution, simple process and convenient operation.

Owner:JILIN UNIV

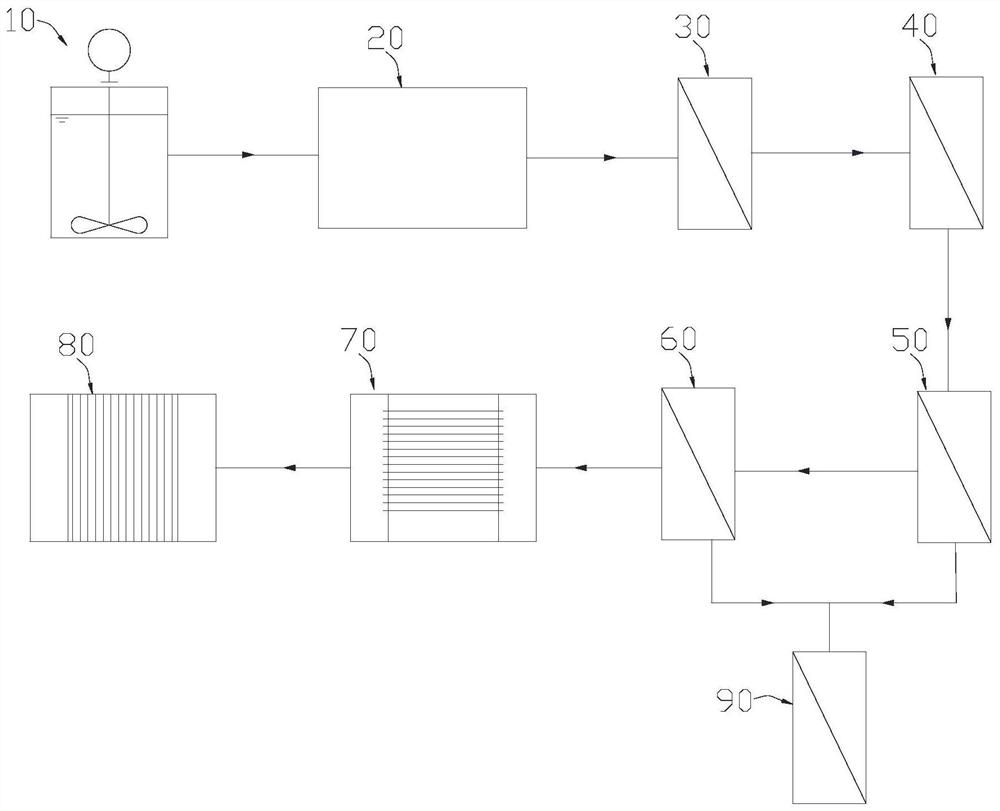

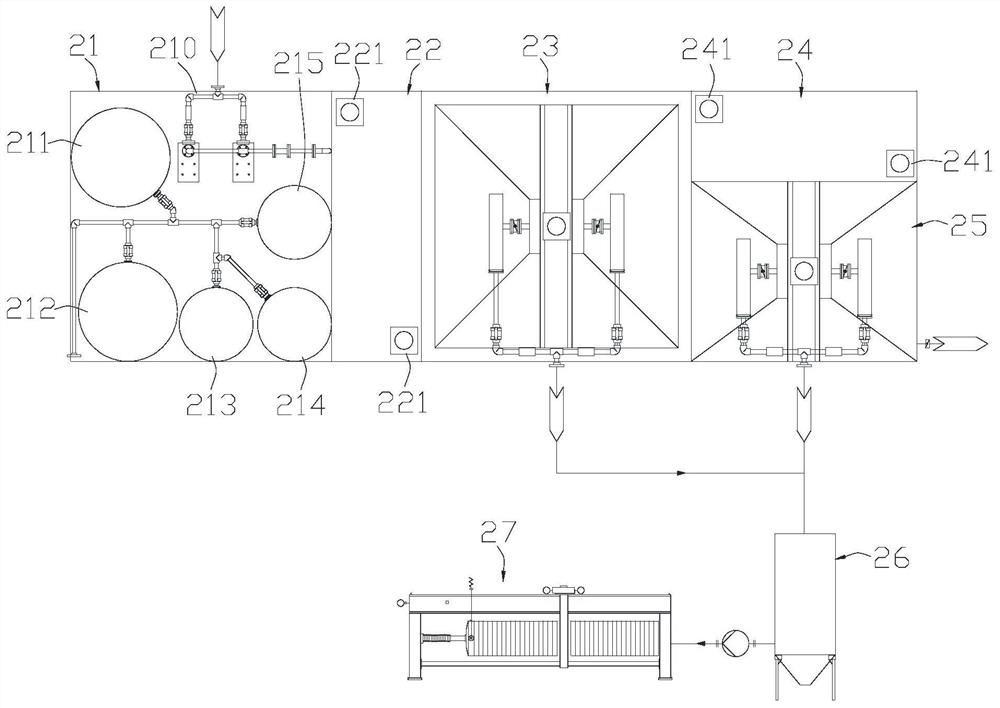

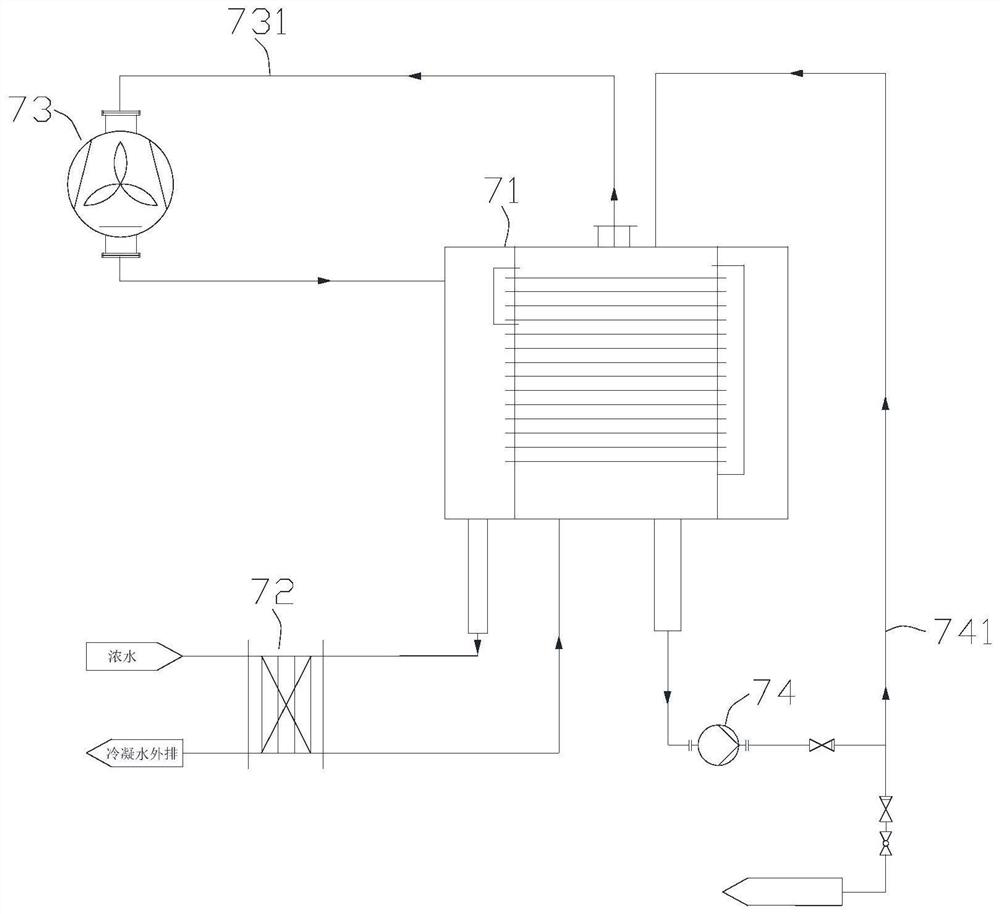

Desulfurization wastewater zero-discharge treatment system and method

PendingCN111635053ASmall scaleReduce process energy consumptionWater contaminantsWater softeningPre treatmentNanofiltration

The invention discloses a desulfurization wastewater zero-discharge treatment system and method. The desulfurization wastewater zero-discharge treatment system comprises an adjusting tank, an integrated pretreatment device, a microfiltration device, a nanofiltration device, a high-pressure reverse osmosis device, an ultrahigh-pressure reverse osmosis device, a horizontal pipe falling film concentration device and an evaporative crystallization device; wherein the adjusting tank, the integrated pretreatment device, the microfiltration device, the nanofiltration device, the high-pressure reverseosmosis device, the ultrahigh-pressure reverse osmosis device, the horizontal pipe falling film concentration device and the evaporative crystallization device are sequentially connected in the treatment direction of desulfurization wastewater. Zero discharge of wastewater is achieved, the scale of an evaporation system is reduced, the energy consumption of an evaporation crystallization processis reduced, the purity of crystalline salt is improved, the pretreatment process flow is simplified, and the floor area and equipment investment are reduced.

Owner:深圳能源资源综合开发有限公司

Brick forming machine, application of brick forming machine and brick forming method

InactiveCN110497504AAccelerated squeeze-melt liquefactionReduce porosityDischarging arrangementFeeding arrangmentsBrickControl system

The invention discloses a brick forming machine which comprises a material distributing system, a vibrating system, a static pressure system and a control system. The material distributing system is used for filling a mold box of the vibrating system and the static pressure system at the same station with blank forming materials. When the technical parameters of the blank forming materials in themold box reach the preset value in the control system, the vibrating system and the static pressure system apply vibration and pressure on the blank forming materials in the mold box at the same timeaccording to respective set running parameters till the preset height set for the blank forming materials is reached, then a finished blank is disengaged from a mold, and the blank manufacturing process is completed. By means of the brick forming machine, the blank forming requirement needed by a building material product which is attractive and durable and has high strength performance can be obtained according to normal-state blank forming work conditions, and a very compact unidirectional rigid solid is formed.

Owner:XIAN SILVER HORSE IND DEV CO LTDRIAL DEV CO LTD

Chemical fiber slurry cellulose alkali squeezing liquid treatment and recovery technology

The invention discloses a chemical fiber slurry cellulose alkali squeezing liquid treatment and recovery technology. The technology mainly comprises first-grade film separation, second-grade film separation, hemicellulose precipitation, third-grade film separation and hemicellulose recovery. The invention provides a novel technology for recovering hemicellulose and alkali from an alkali squeezing liquid. Compared with the prior art utilizing a nanofiltration system for recovering alkali, the treatment and recovery technology provided by the invention utilizes an inorganic material membrane to recover alkali, has simple pretreatment processes and has system operation stability, a long cleaning period and a high alkali recovery rate.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com