Brick forming machine, application of brick forming machine and brick forming method

A molding machine and masonry technology, applied in ceramic molding machines, supply devices, unloading devices, etc., can solve the problems of not being able to form the best blanks, technical difficulties, etc., to eliminate the gap between materials, and to ensure the Density, the effect of improving the molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 (being commonly called as whole body product)

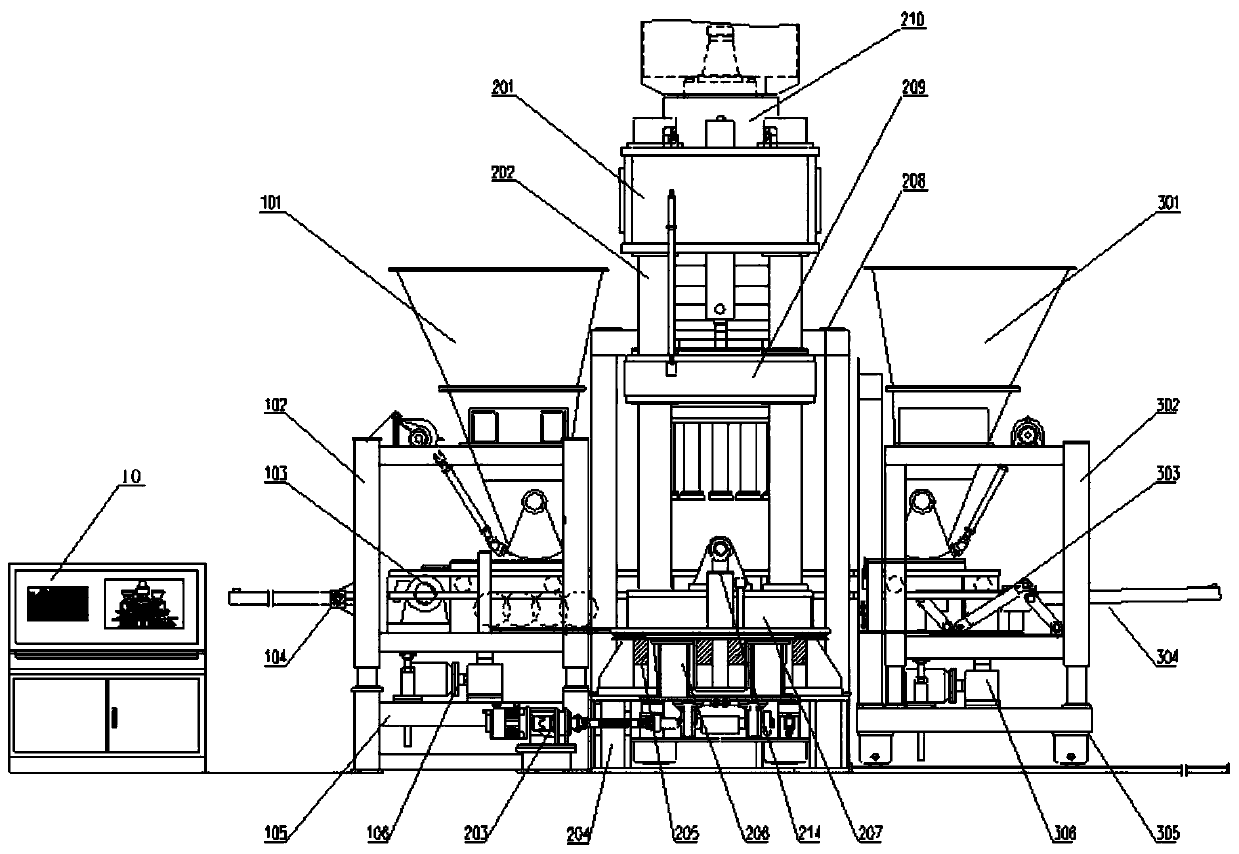

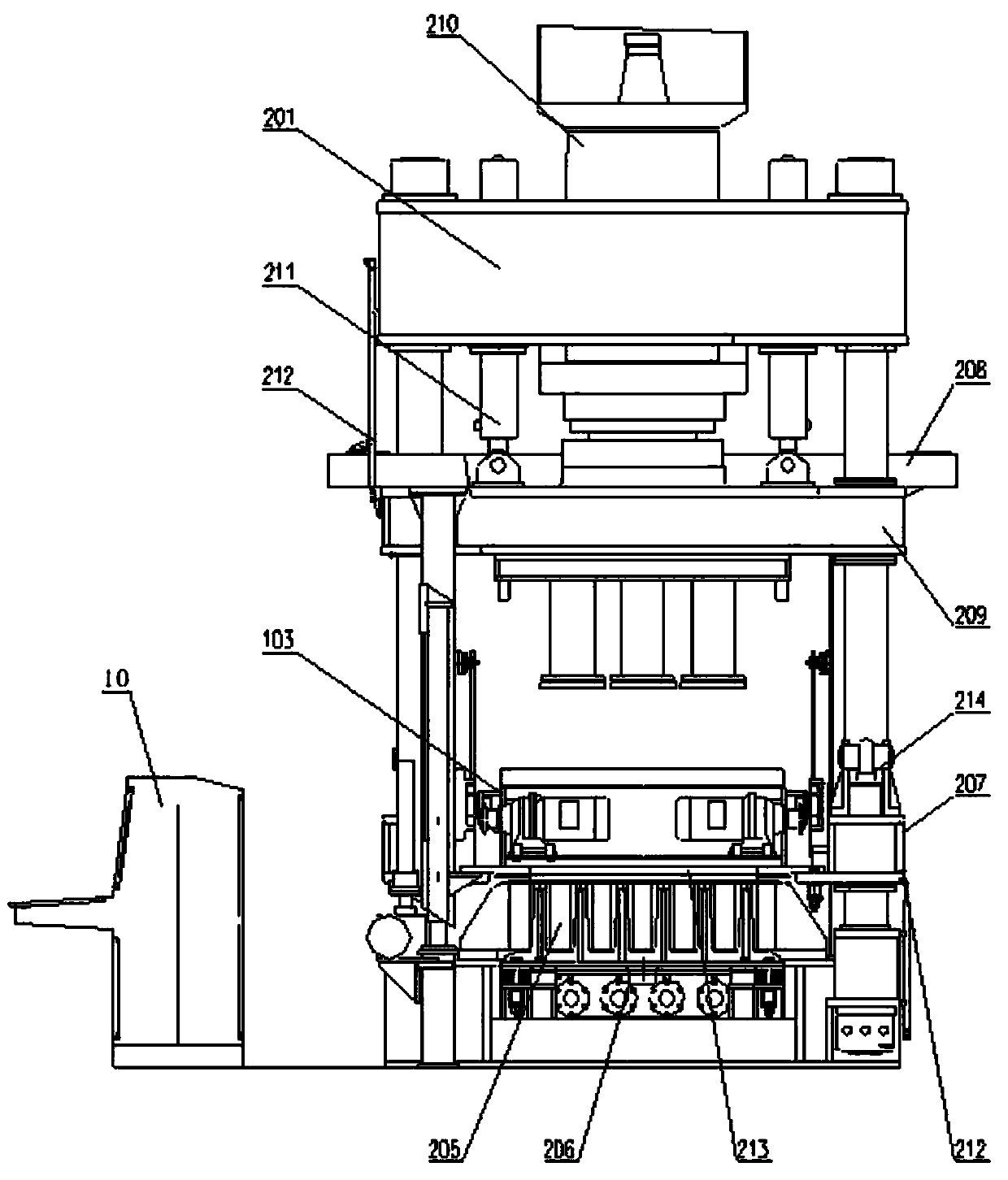

[0055] Such as figure 1 and figure 2 Shown, the masonry forming machine of the present embodiment, this forming machine comprises:

[0056] Material distribution system, the material distribution system is used to fill the blank material into the mold box of the vibration system and the static pressure system;

[0057] Vibration system, through the horizontal vibration platform, the vibration system generates simple harmonic vibration in the vertical direction to act on the bottom of the billet material in the mold box, so that the material has a finished product billet material to achieve a more dense material homogenization effect and reduce the billet material Internal gaps and air;

[0058] Static pressure system, the static pressure system acts vertically on the upper surface of the blank material in the mold box, and is used to squeeze the blank material in the mold box, reduce the gap and air inside...

Embodiment 2

[0080] Such as figure 1 and figure 2 As shown, the present embodiment is a masonry forming machine, which comprises:

[0081] Material distribution system, the material distribution system is used to fill the blank material into the mold box of the vibration system and the static pressure system;

[0082] Vibration system, through the horizontal vibration platform, the vibration system generates simple harmonic vibration in the vertical direction to act on the bottom of the billet material in the mold box, so that the material has a finished product billet material to achieve a more dense material homogenization effect and reduce the billet material Internal gaps and air;

[0083] Static pressure system, the static pressure system acts vertically on the upper surface of the blank material in the mold box, and is used to squeeze the blank material in the mold box, reduce the gap and air inside the blank material, and obtain a more dense masonry molding Products; a control s...

Embodiment 3

[0104] The present invention also provides a method for forming masonry, wherein the steps included in the method for forming masonry include:

[0105] a. When the control system starts the material distributing system, after the material distributing system fills the blank material into the mold box of the vibration system and the static pressure system, the control system 10 controls the vibration system to start, reducing the internal pressure of the blank material in the mold box. gap and air;

[0106] b. When the blank material filled in the mold box of the vibration system and the static pressure system reaches the preset value of the masonry forming technical parameters set by the control system, the control system 10 starts the vibration system and the static pressure system at the same time, and the vibration system and the static pressure system The static pressure system applies vibration and static pressure to the blank material in the mold box at the same time, fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com