Patents

Literature

32results about How to "Improve molding cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

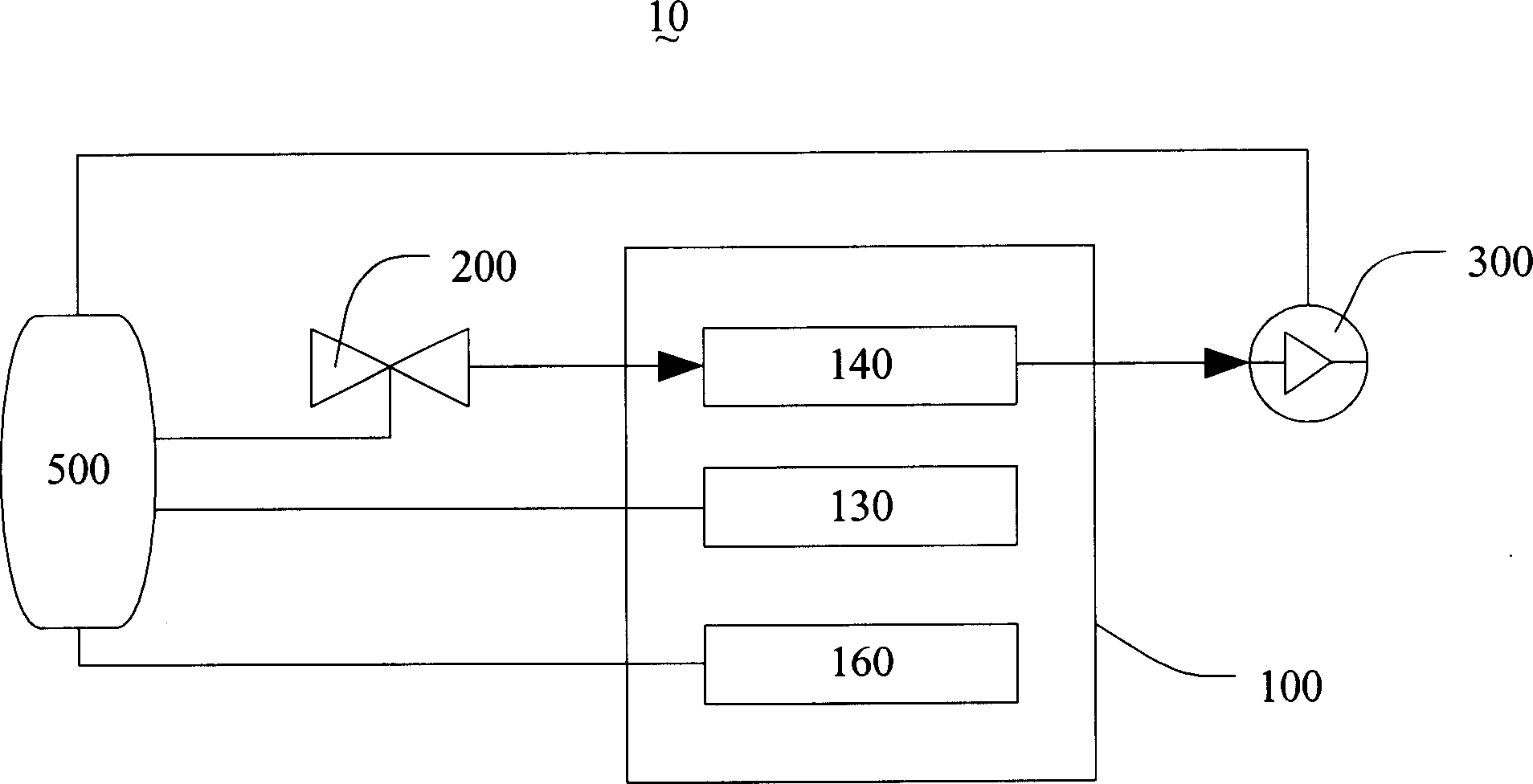

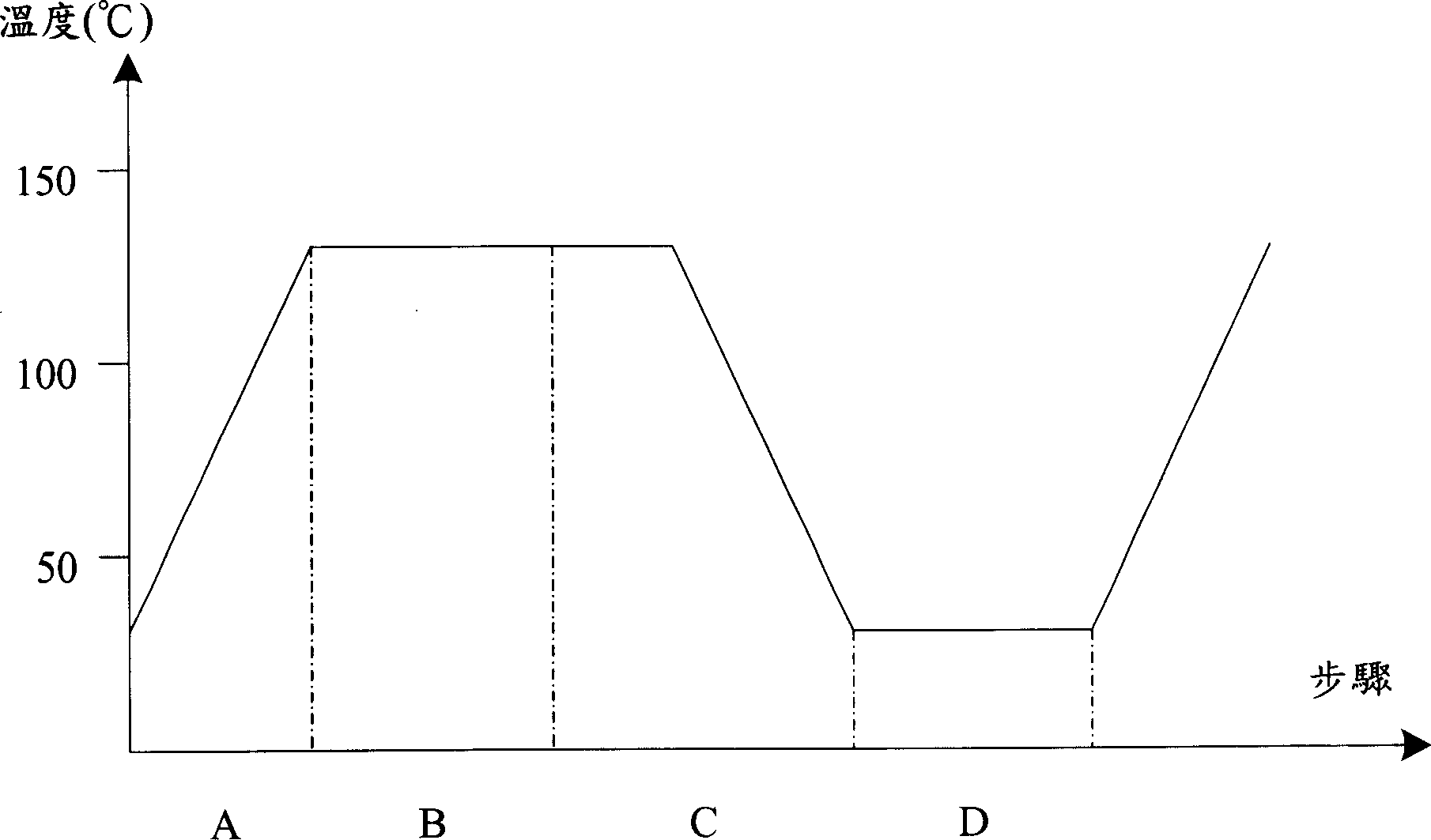

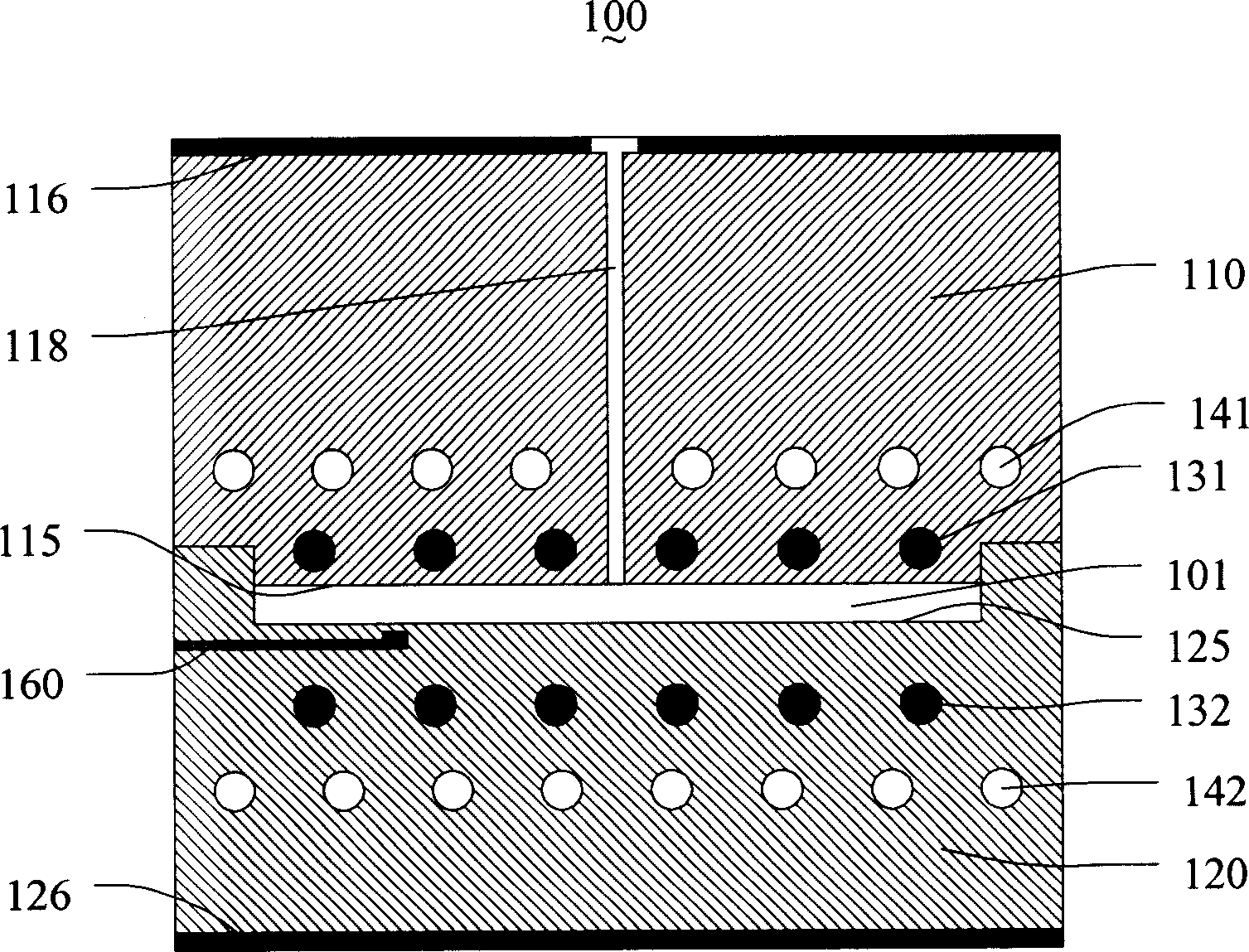

Jet forming system and method

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

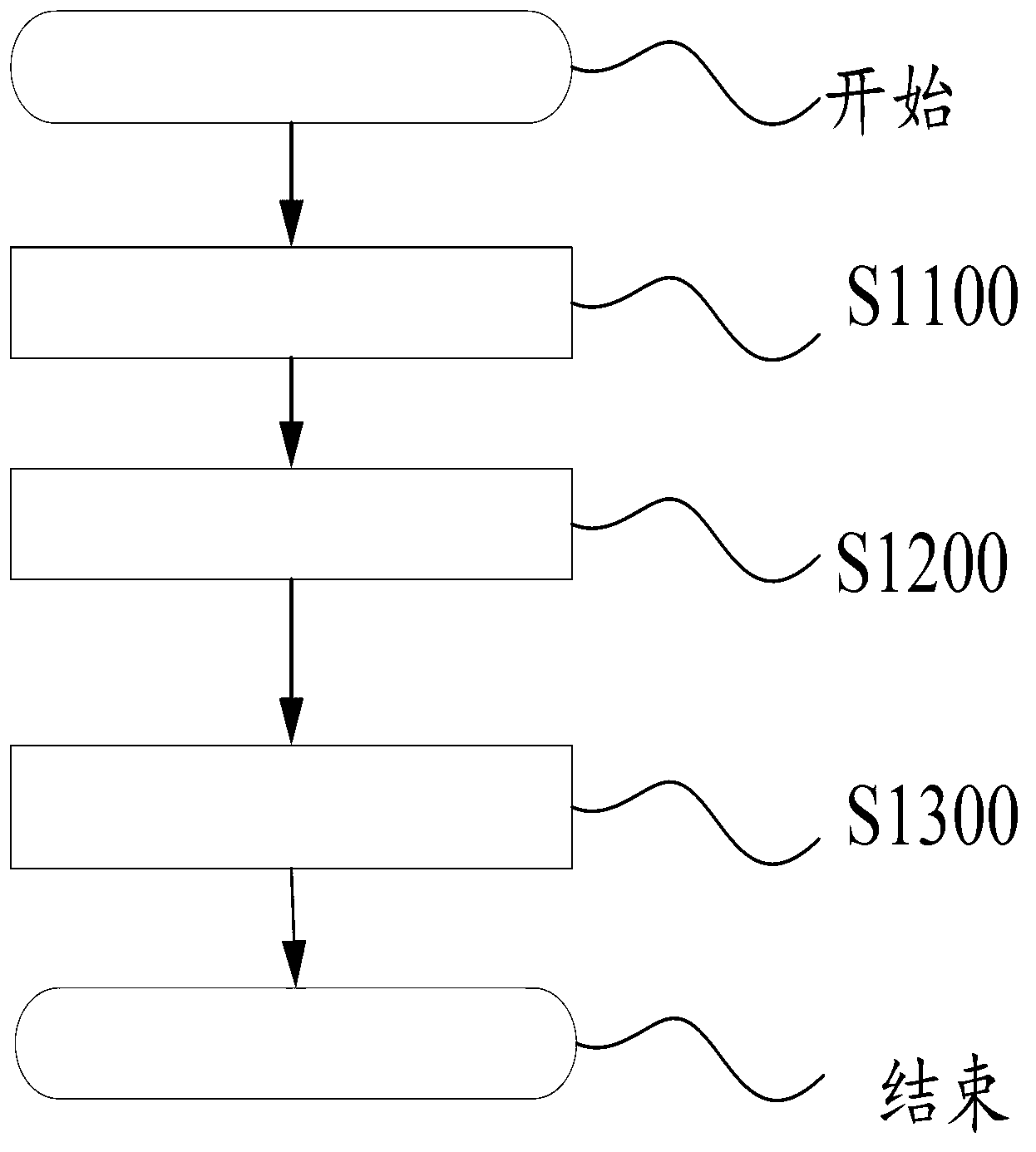

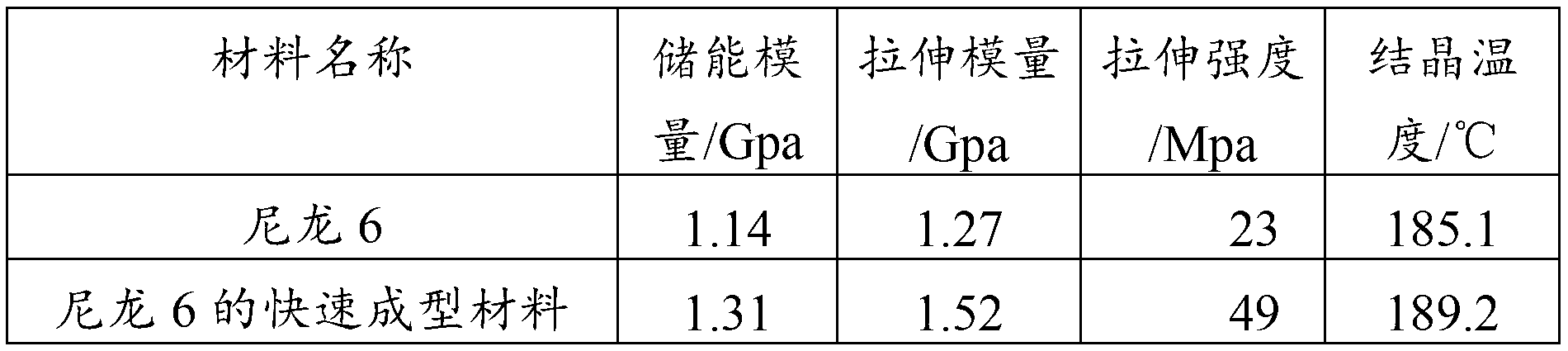

Rapid prototyping material and preparation method thereof

The invention discloses a preparation method of a rapid prototyping material. The preparation method comprises the steps of providing raw materials, wherein raw materials comprise the following ingredients in parts by weight: 85-97.5 parts of engineering plastics, 0.5-5 parts of nanocellulose and 2-10 parts of viscosity reducer; (S1100) weighing the raw materials: drying the raw materials for 4-10 hours at the temperature of 105 DEG C, and then, weighing the raw materials according to a weight ratio; (S1200) carrying out blending modification: carrying out three-dimensional stirring and blending on the weighed raw materials for 30-90 min; and (S1300) sieving: sieving the blended raw materials by using a sieve of 70-140 meshes. The invention further discloses the rapid prototyping material obtained through the preparation method. According to the rapid prototyping material disclosed by the invention, the preparation process is simple, and the industrialization is easy to realize; and the material is short in prototyping cycle, good in thermal stability and high in mechanical strength.

Owner:珠海市红旌发展有限公司

Polyethylene glycolterephthalate composition and its preparing method

The invention relates to a kind of polyethylene glycol terephthalate combination and its manufacturing method, which involves in the field of polyester resin crossblending and modifying. The combination contains the constituents as follows: polyethylene glycol terephthalate, styrene-butadiene pyrrole powder rubber containing cross-linking structure with average grain size of 30-200nm, and so on; among them, the part by weight of polyethylene glycol terephthalate is 100, and the part by weight of styrene-butadiene pyrrole powder rubber is 1-20. Melting and crossblending the constituents mentioned above can get polyethylene glycol terephthalate combination. The combination has fine tenacity and excellent processing ability, and meanwhile, it can keep well heat resistance and rigidity.

Owner:CHINA PETROLEUM & CHEM CORP +1

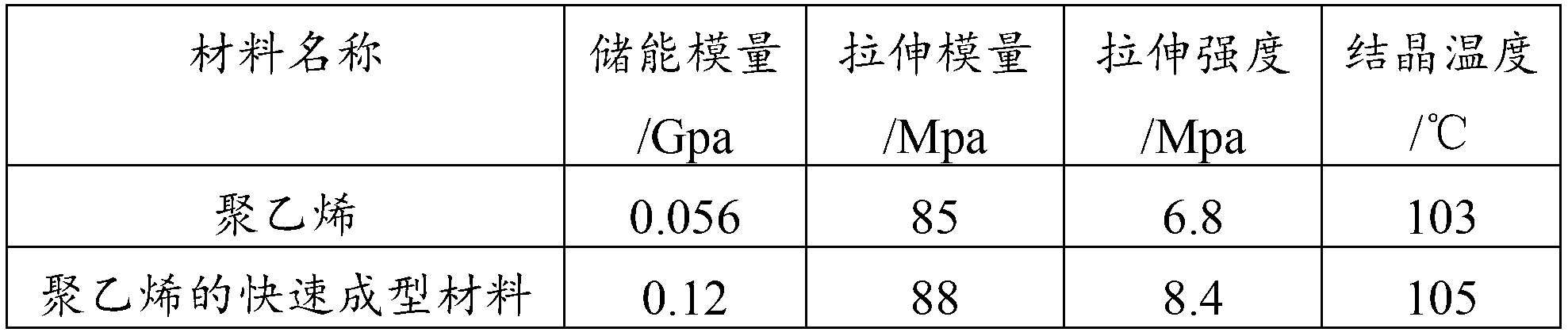

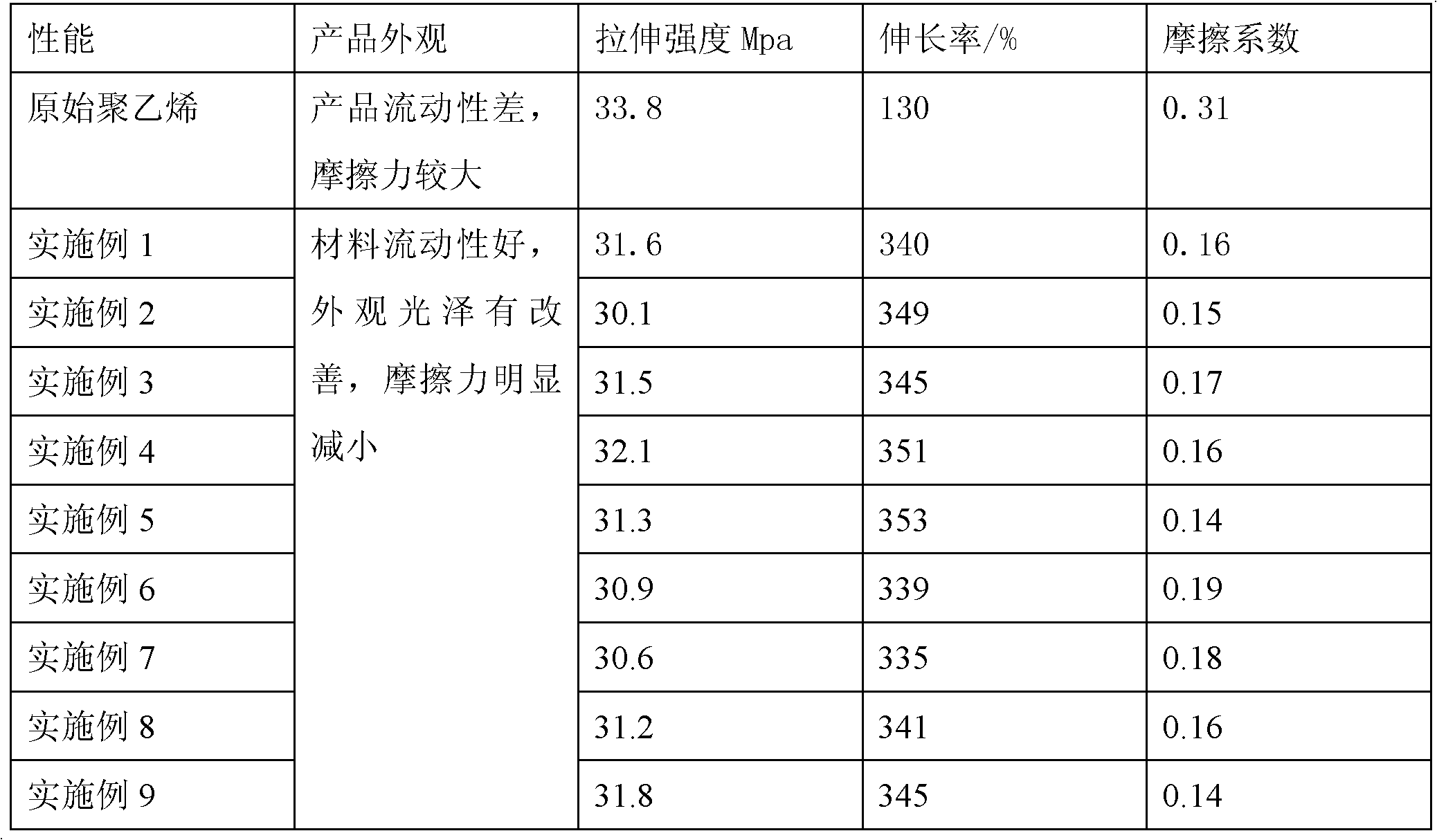

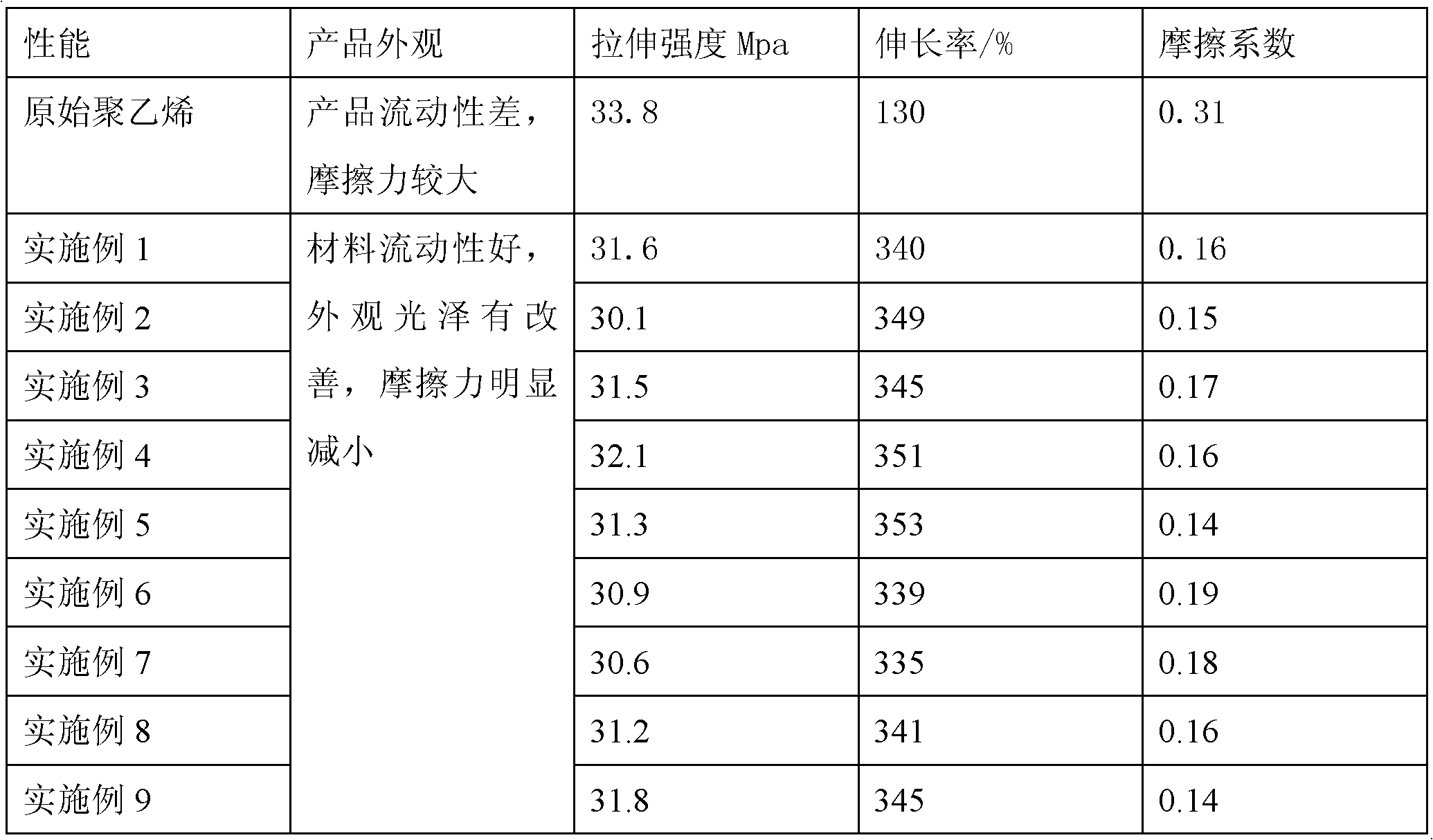

High-density polyethylene material and application thereof

ActiveCN102206374AReduce coefficient of frictionHigh surface glossFibre mechanical structuresAntioxidantPhosphate

The invention relates to a high-density polyethylene material and application thereof. The material comprises the components in percent by weight: 100% of high-density polyethylene, 5-80% of para-phthalic metal salt, 1-8% of silicone oil and 0.5-5% of antioxidant. The para-phthalic metal salt is selected from calcium terephthalate, magnesium terephthalate, zinc terephthalate, potassium terephthalate, sodium terephthalate, barium terephthalate, lead terephthalate, aluminum terephthalate, ferrum terephthalate or a mixture thereof. The silicone oil is selected from active silicone oil, dimethyl silicone oil, 201 methyl silicone oil or a mixture thereof. The antioxidant is selected from tris(2,4-ditert-butylphenyl) phosphate, pentaerythrite tetra [beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], 2,6-di-tert-butyl-4-methylphenol, 2,2'-methylenebis[6-(1,1-dimethylethyl)-4-methyl-phenol or a mixture thereof. The polyethylene material provided by the invention has a small friction coefficient and favorable self-lubricity and can be used for manufacturing optical cable protection sleeves.

Owner:江苏爱特恩高分子材料有限公司

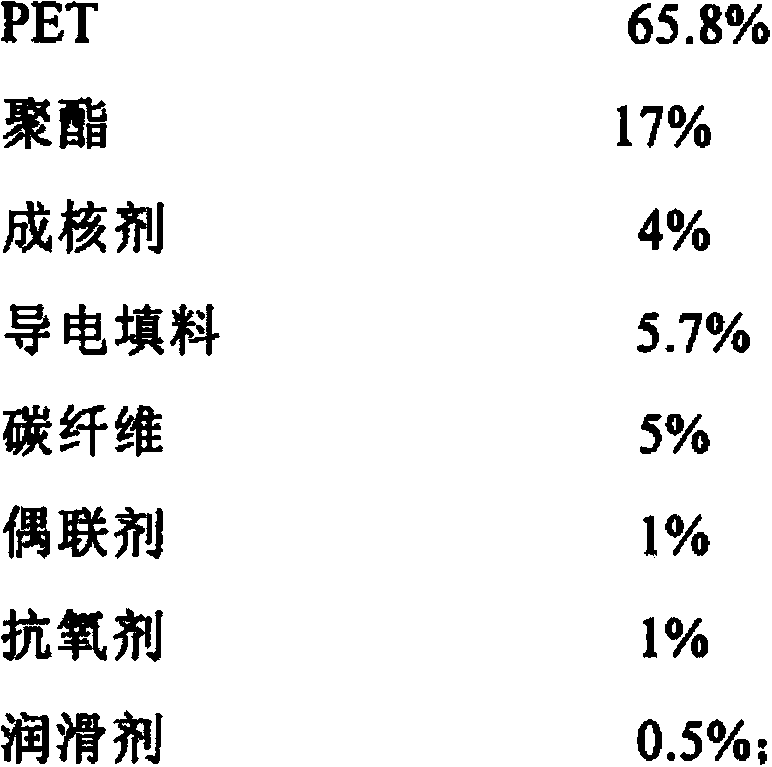

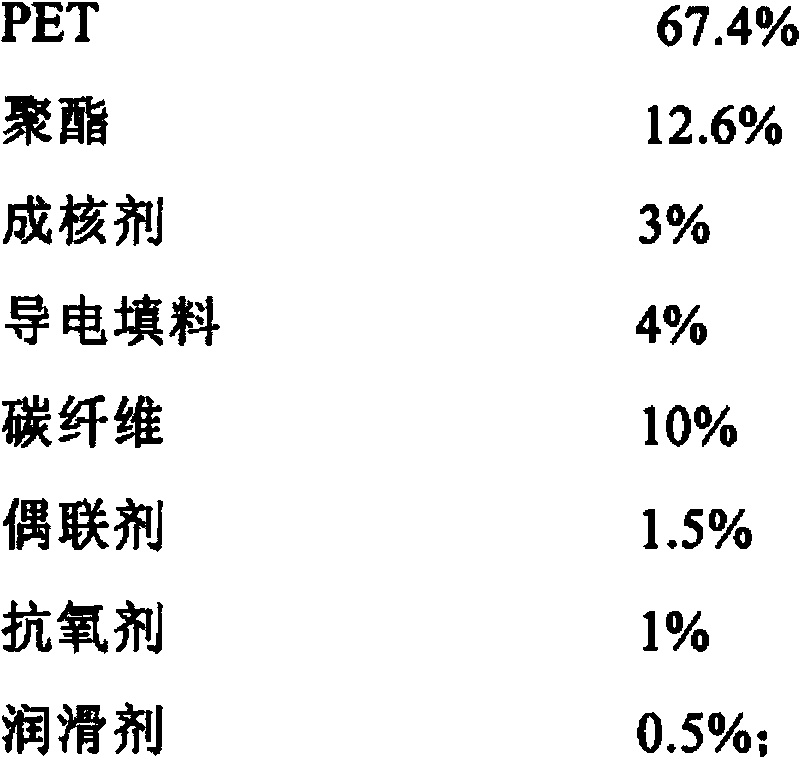

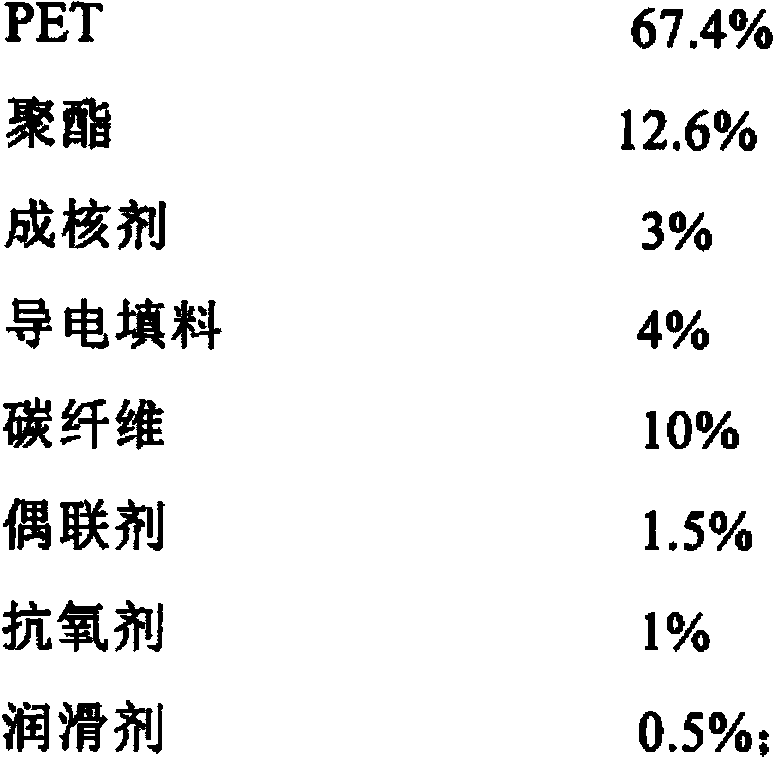

Carbon fiber conductive enhanced PET/polyester alloy and preparation method thereof

The invention relates to a carbon fiber conductive enhanced PET / polyester alloy and a preparation method thereof. The carbon fiber conductive enhanced PET is prepared from the following raw materials in percentage by weight: 60-70 percent of PET, 5-20 percent of polyester, 2-4 percent of nucleating agent, 0.5-10 percent of conductive fillers, 5-20 percent of carbon fibers, 1-2 percent of coupling agents, 0.5-1 percent of antioxygen and 0.5-1 percent of lubricants. The preparation method comprises the following steps of: filling PET, the polyester, the nucleating agents, the conductive fillers, the coupling agents, the antioxygen and the lubricants into a high blending machine for blending for 3-5 minutes; adding the mixture from a first section of a cylinder body of a twin-screw extruder and adding carbon fibers from a fourth section of the cylinder body of the twin-screw extruder; extruding and pelleting at the temperature of 240-250 DEG C while controlling the rotation speed of the twin-screw extruder to be 1050-1200rpm to obtain the carbon fiber conductive enhanced PET / polyester alloy with high mechanical property, short formation period and attractive appearance of the product.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

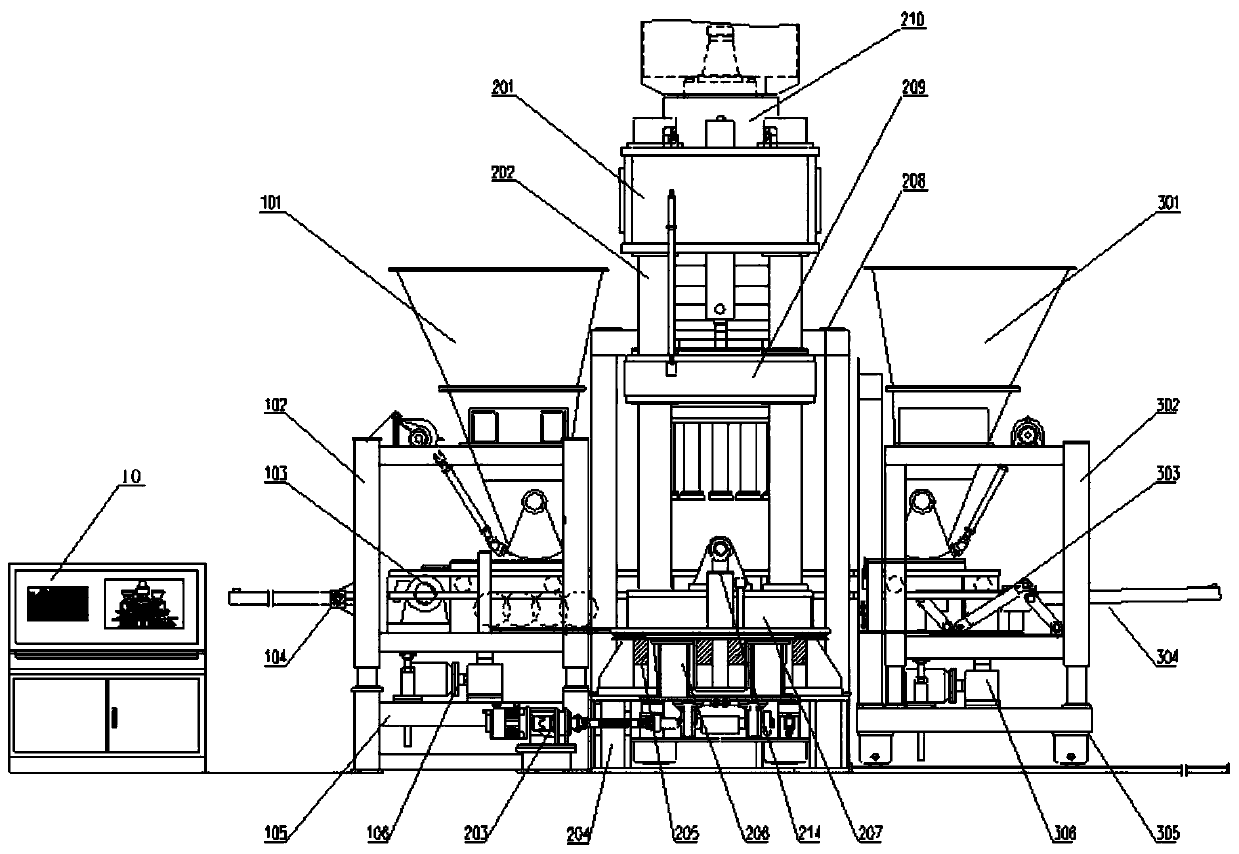

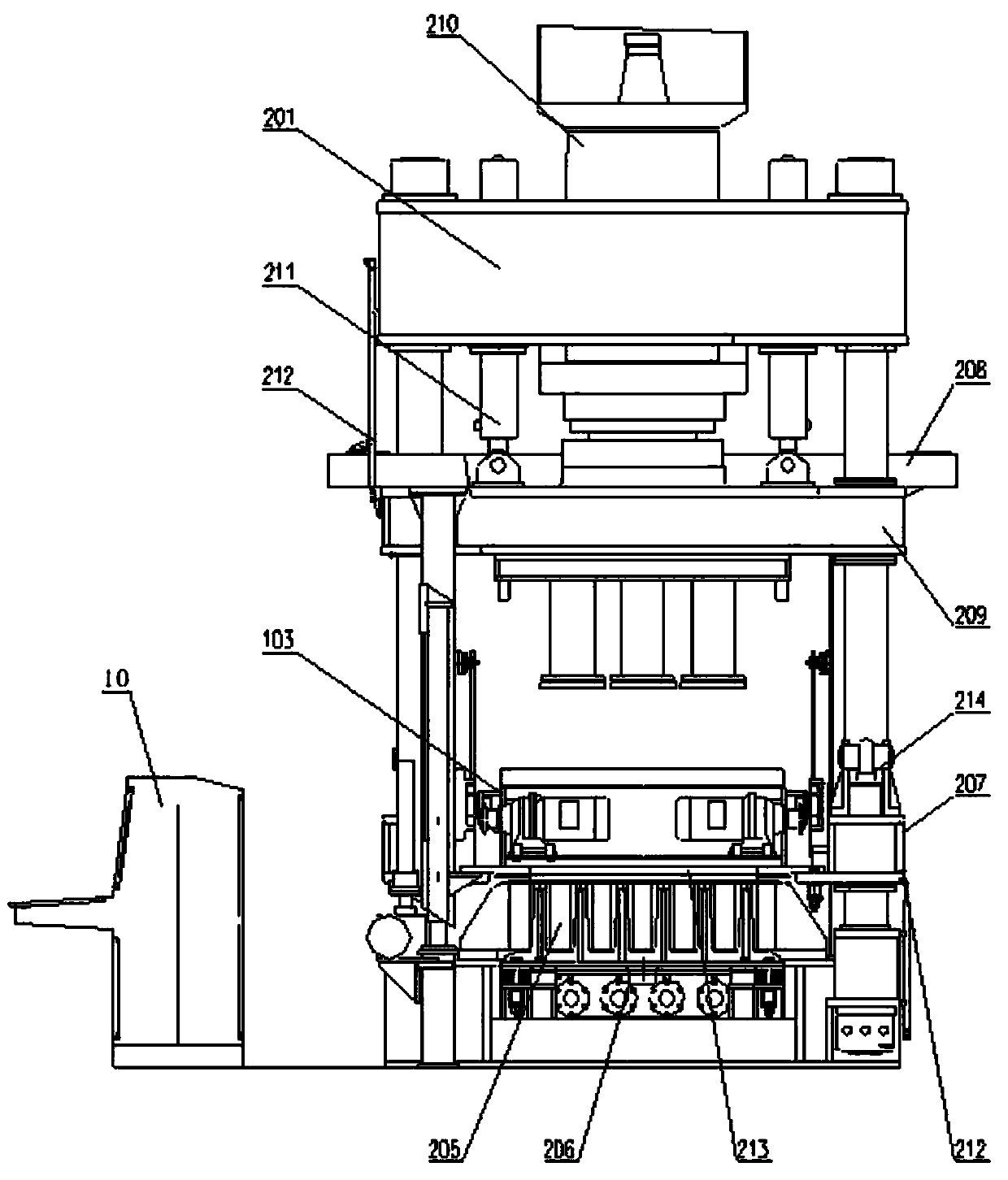

Brick forming machine, application of brick forming machine and brick forming method

InactiveCN110497504AAccelerated squeeze-melt liquefactionReduce porosityDischarging arrangementFeeding arrangmentsBrickControl system

The invention discloses a brick forming machine which comprises a material distributing system, a vibrating system, a static pressure system and a control system. The material distributing system is used for filling a mold box of the vibrating system and the static pressure system at the same station with blank forming materials. When the technical parameters of the blank forming materials in themold box reach the preset value in the control system, the vibrating system and the static pressure system apply vibration and pressure on the blank forming materials in the mold box at the same timeaccording to respective set running parameters till the preset height set for the blank forming materials is reached, then a finished blank is disengaged from a mold, and the blank manufacturing process is completed. By means of the brick forming machine, the blank forming requirement needed by a building material product which is attractive and durable and has high strength performance can be obtained according to normal-state blank forming work conditions, and a very compact unidirectional rigid solid is formed.

Owner:XIAN SILVER HORSE IND DEV CO LTDRIAL DEV CO LTD

Environmentally-friendly plastic thrust bearing bush and production method thereof

The invention relates to an environmentally-friendly plastic thrust bearing bush and a production method thereof. The environmentally-friendly plastic thrust bearing bush comprises a steel bush base and a surface plastic layer, wherein the surface plastic layer is bonded on the steel bush base directly by a solvent-free adhesive to form the thrust bearing bush, a spring cushion does not need to be arranged between the steel bush base and the surface plastic layer, and brazed connection is also not required between the steel bush base and the surface plastic layer. Compared with the prior art, the environmentally-friendly plastic thrust bearing bush and the production method provided by the invention have the advantages of short molding cycle, outstanding environmental performance, uniform elastic modulus and the like.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

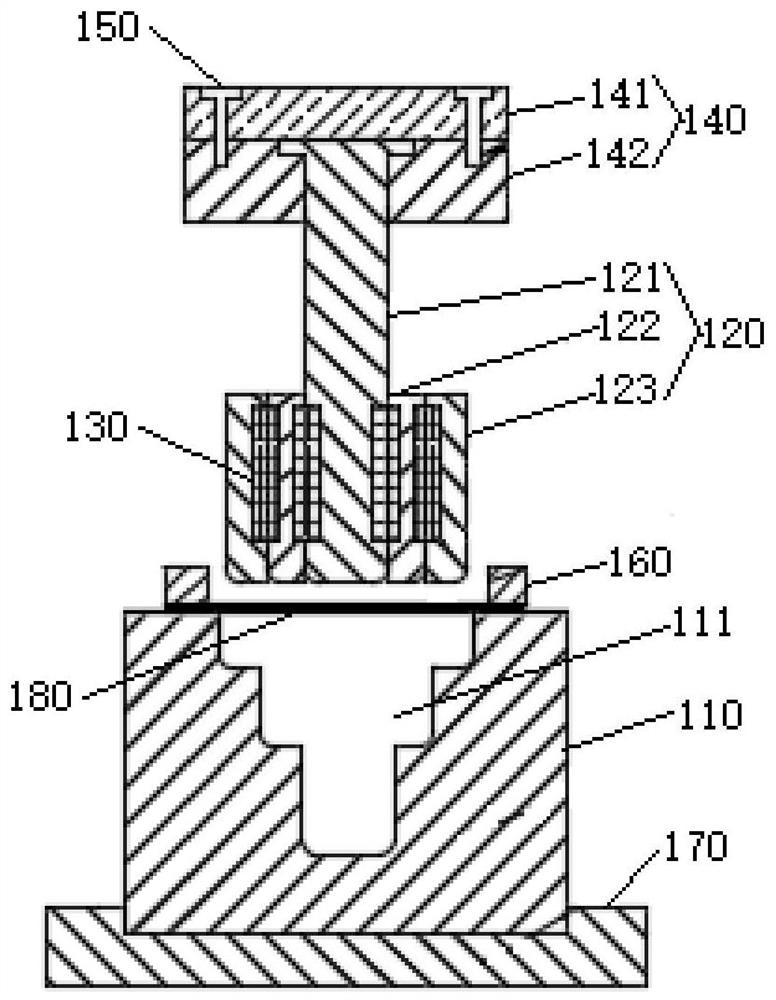

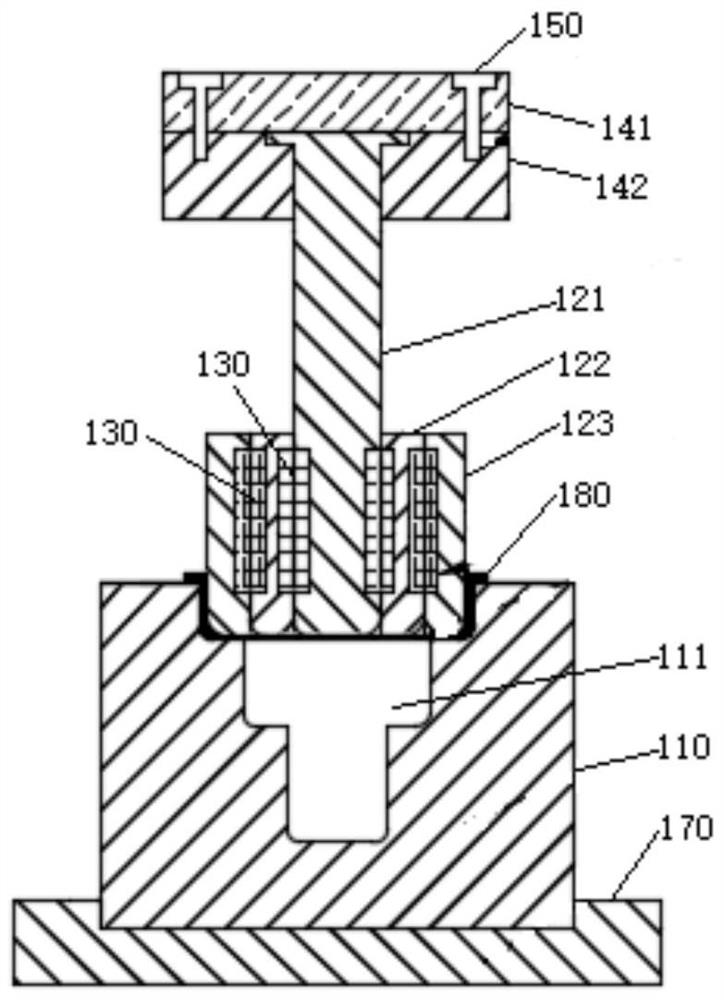

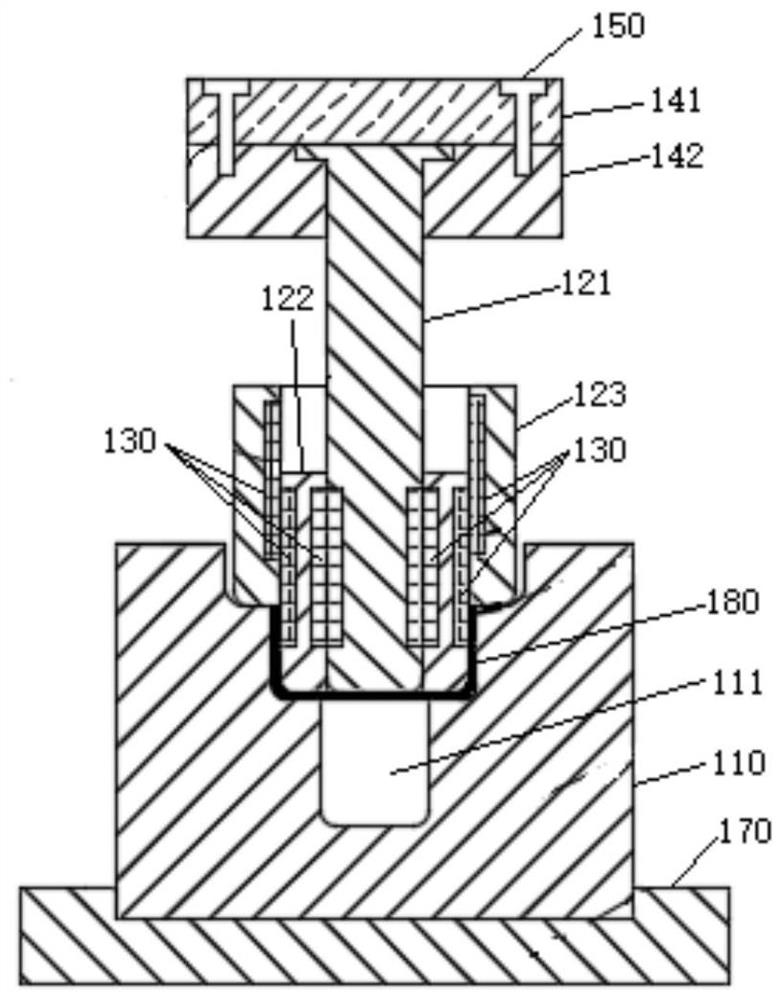

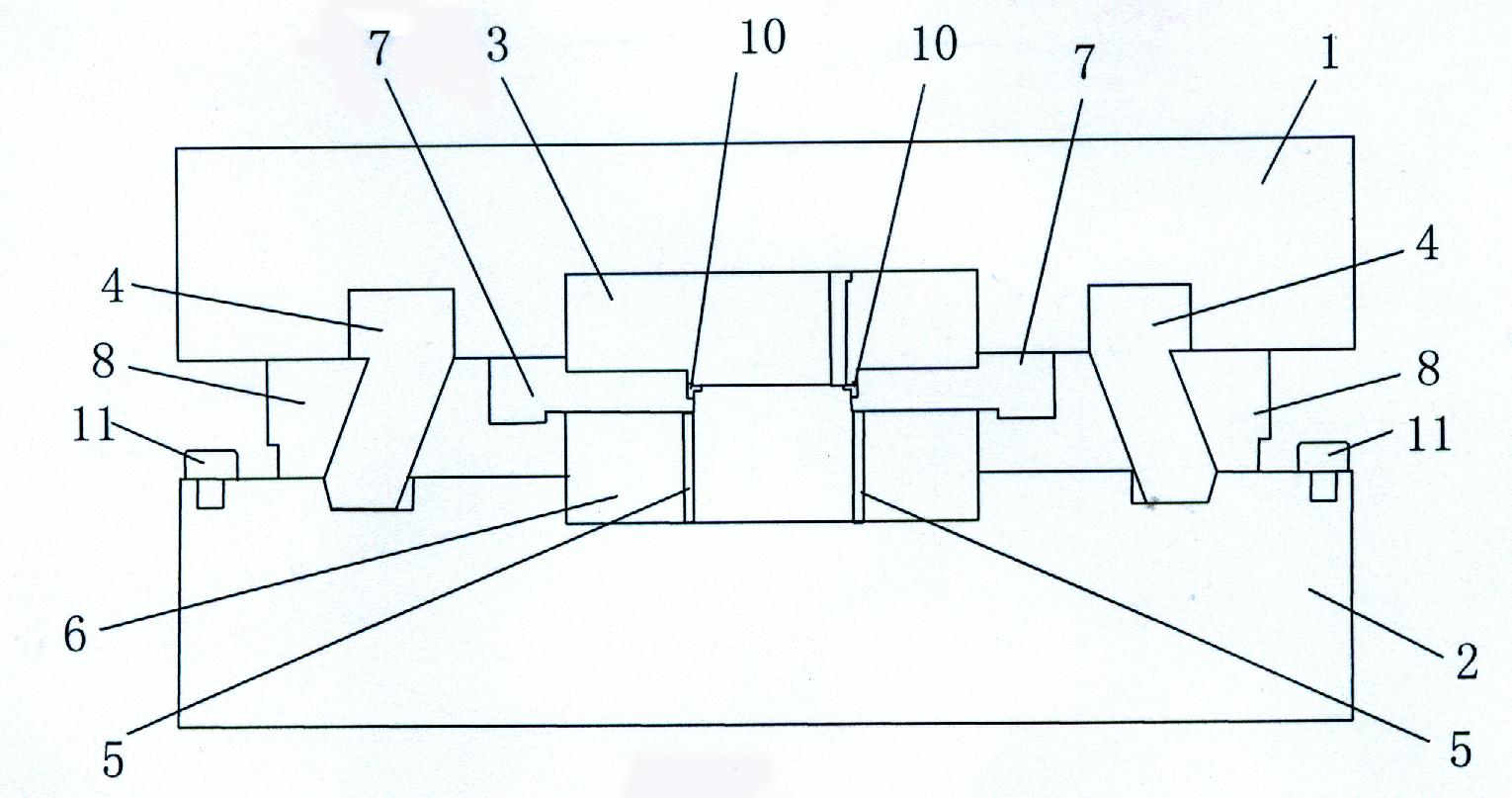

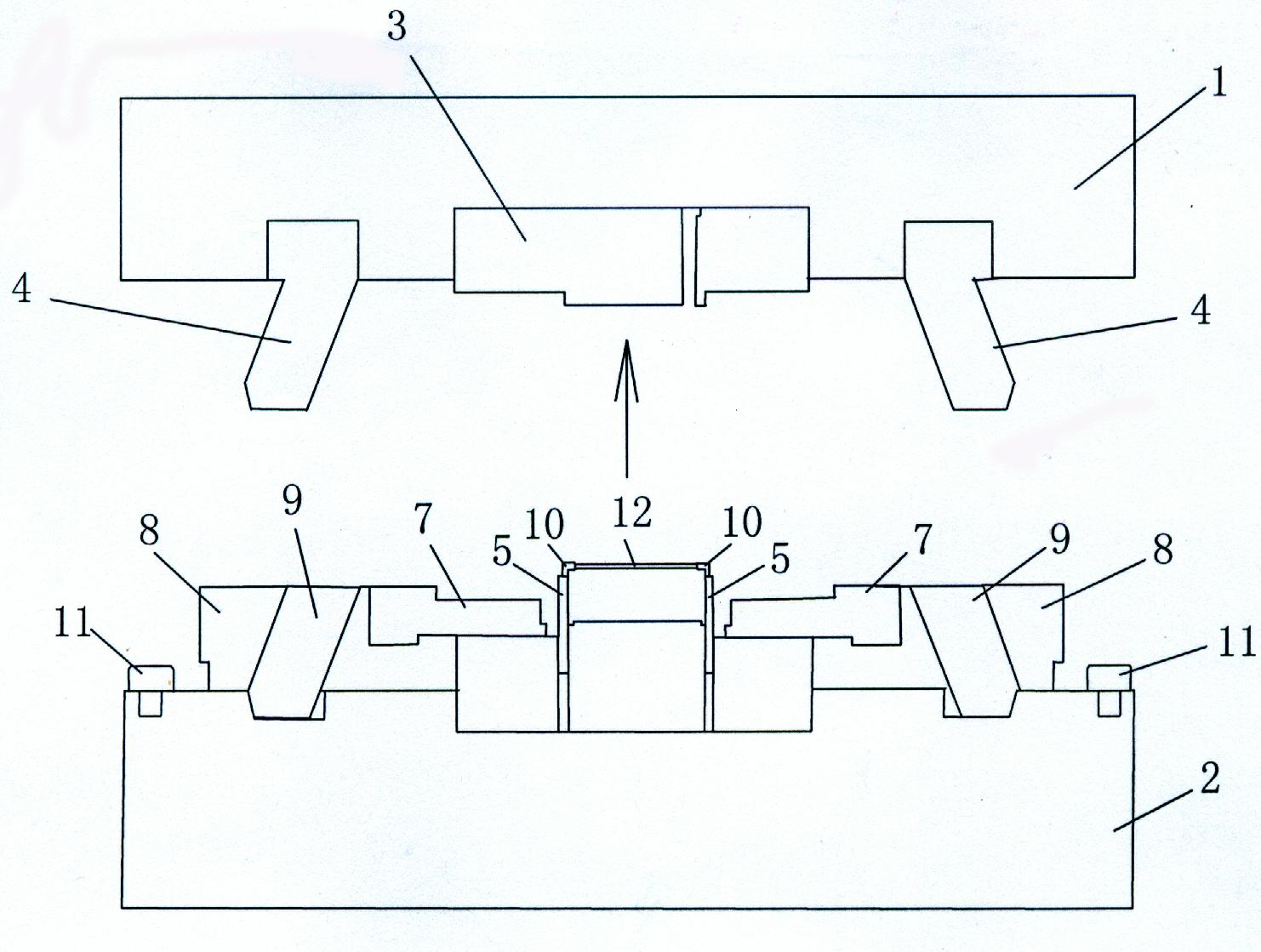

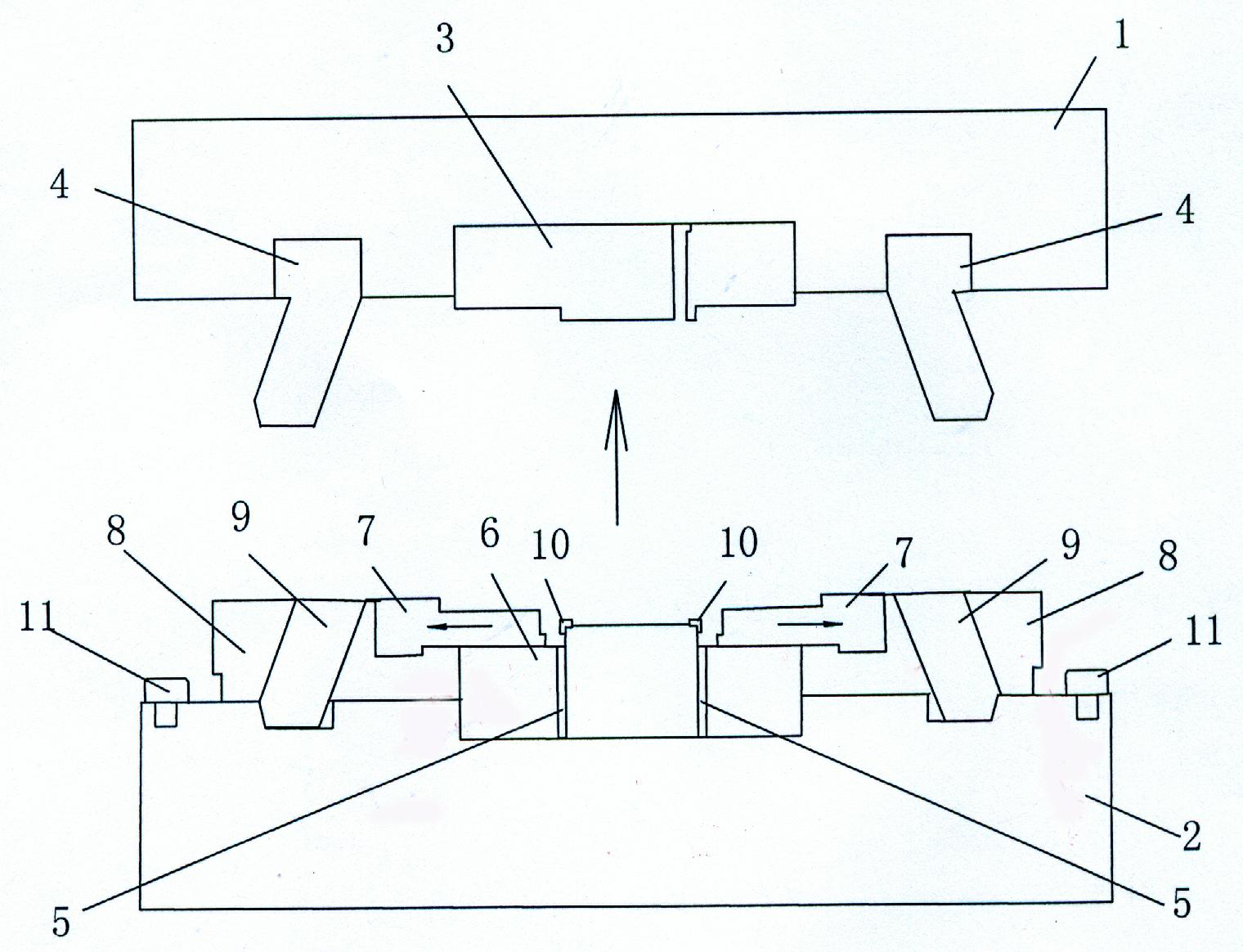

Progressive drawing die and operation method thereof

The invention discloses a progressive deep drawing die and an operation method thereof.The die comprises a lower die base, a male die assembly and an electromagnet, a forming cavity is formed in the lower die base and comprises multiple layers of parting cavities arranged from top to bottom, the cross sectional areas of the parting cavities are sequentially decreased from top to bottom, and the male die assembly comprises a center male die; the center male die is sleeved with a middle male die, the middle male die is sleeved with an outer-layer male die, the center male die, the middle male die and the outer-layer male die can move relatively in the vertical direction, and the center male die, the middle male die and the outer-layer male die can stretch into the corresponding parting cavities; electromagnets are embedded in the two side walls of the center male die, the two side walls of the middle male die and the inner side wall of the outer layer male die, the electromagnets can be powered on and powered off, and the one-step deep drawing forming die has the advantages that one-step deep drawing forming can be conducted on workpieces with the too large deep drawing ratio, and the die cost is low.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

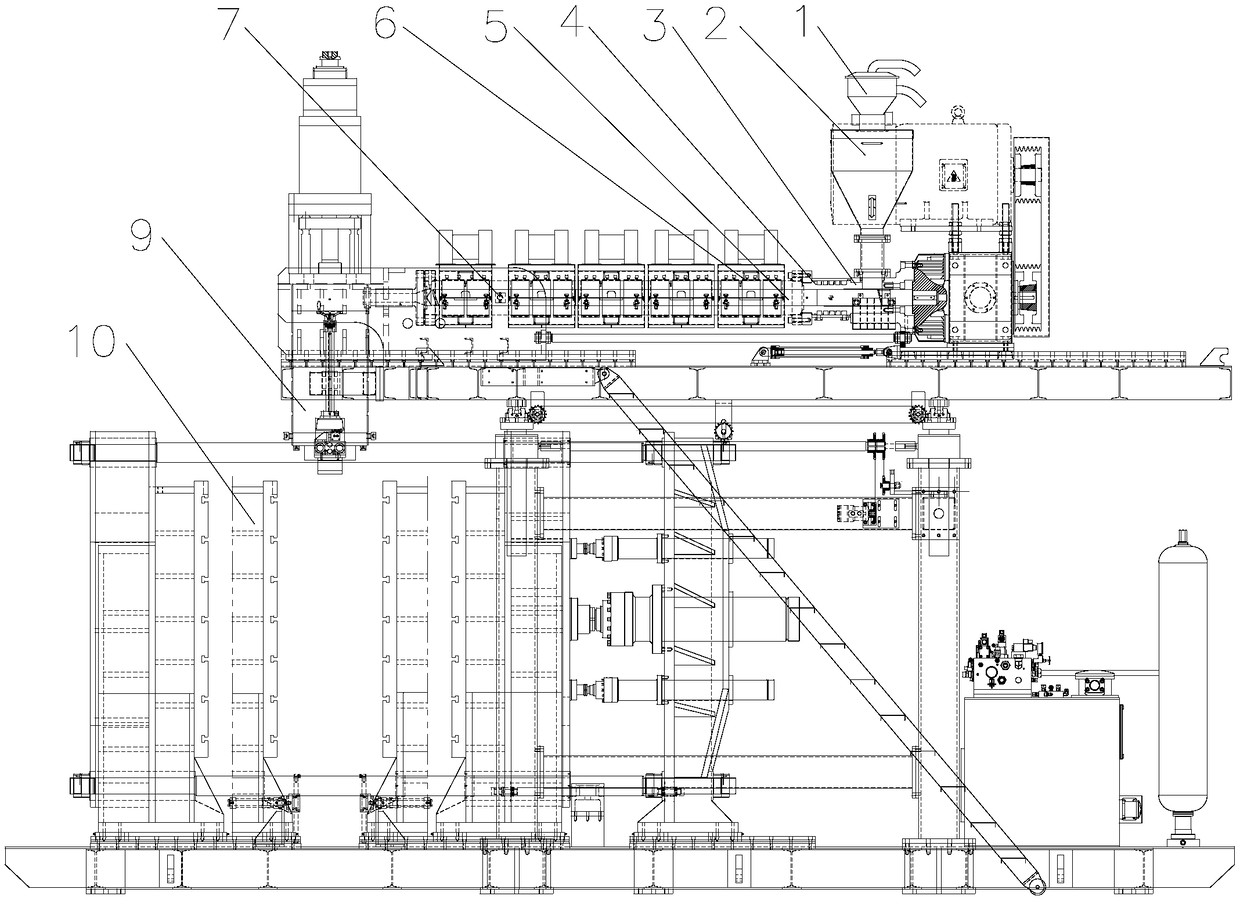

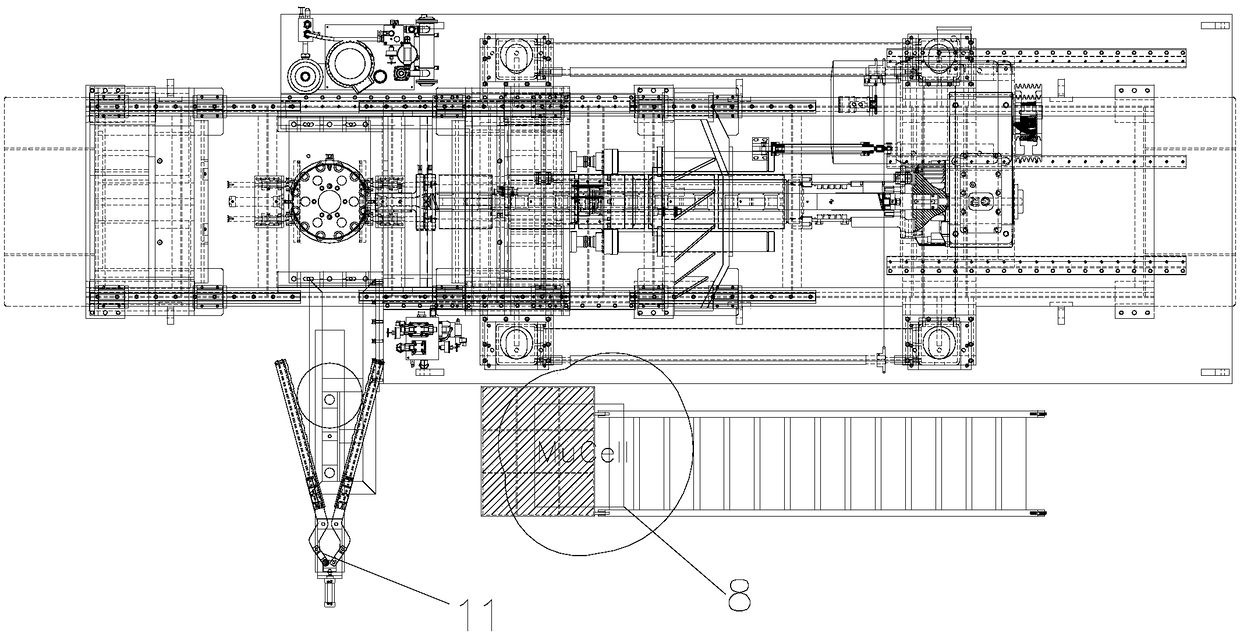

Foam blow-molding machine and micro-foaming hollow molding method thereof

The invention relates to a foam blow-molding machine and a micro-foaming hollow molding method thereof. The foam blow-molding machine comprises an automatic material suction machine, an extruder, a gas inflating device and a blow molding machine, wherein the extruder comprises a hopper, a feeding seat, a charging barrel and a screw; the hopper is fixedly connected one end of the charging barrel bythe feeding seat; the automatic material suction machine is in communication with the hopper; the screw is arranged in the charging barrel and driven by a motor; the outer side of the charging barrelis wrapped with an electric heating sheet; the end, away from an automatic suction molding machine, of the screw is further provided with a gas inflating hole; the gas inflating device is fixedly mounted on one side of the blow molding machine and communicates with the gas inflating hole; the blow molding machine comprises a material storage type mold head, a mold and a mold driving unit; the material storage type mold head communicates with the other end of the charging barrel; the mold is driven by the mold driving unit to perform mold closing and opening; and the mold closing position of the mold is directly located under the material storage type mold head. The foam blow-molding machine and the micro-foaming hollow molding method of the invention have high production efficiency; and aproduced product has good quality and the effects of sound insulation, electric insulation and heat preservation.

Owner:鼎浩(长兴)包装科技有限公司

Mould requiring no thimble to participate in molding process

The invention provides a mould requiring no thimble to participate in a molding process and relates to an injection mould, which comprises a moveable mould and a fixed mould, wherein a front mould core is arranged on the moveable mould; sliding block binding blocks are symmetrically arranged on the moveable mould; a product cavity is arranged on the fixed mould; thimbles are symmetrically arranged at the left and right sides of the product cavity; sliding block inserts are symmetrically arranged at the upper ends of the thimbles at the left and right sides and of the upper surfaces at the left and right sides of a back mould core, so as to keep the upper ends of the thimbles lower than the lower surfaces of the sliding block inserts; the sliding block inserts are fixedly inserted in sliding block bases; the sliding block bases can slide left and right; the sliding block base at the left side is moveably matched with the sliding block binding block at the left side of the moveable mould; the sliding block base at the right side is moveably matched with the sliding block binding block at the right side of the moveable mould; and the upper ends of the thimbles are shielded or exposed. The mould requiring no thimble to participate in a molding process has the advantages that the thimbles are free from participating in molding and only have the function of ejecting the product out of the mould after the mould is opened, so the product formed in the manner of injection molding is free from deckle edge, the quality of product is increased, the investment is greatly reduced, the production efficiency is increased and the labor cost is lowered.

Owner:HUBEI YIDONG PRECISION MFG

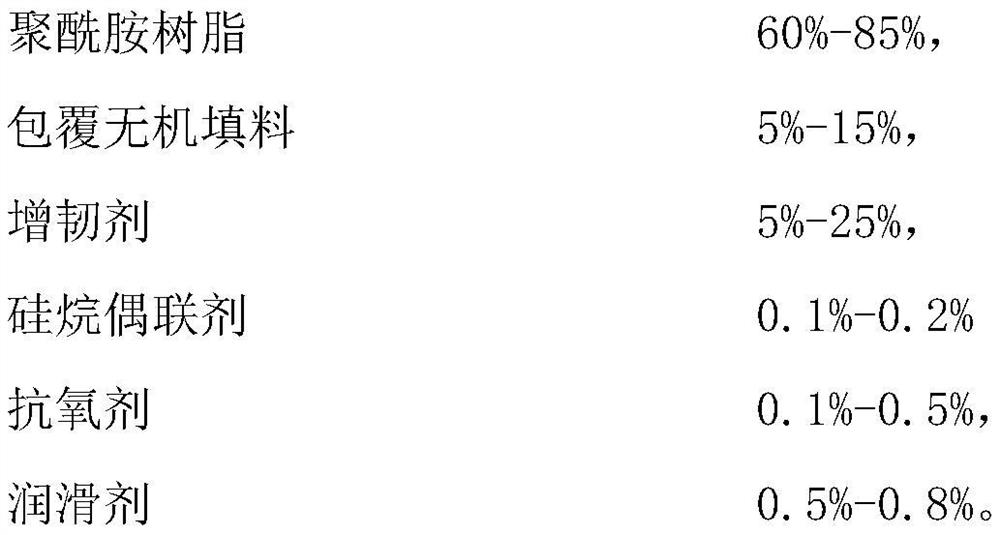

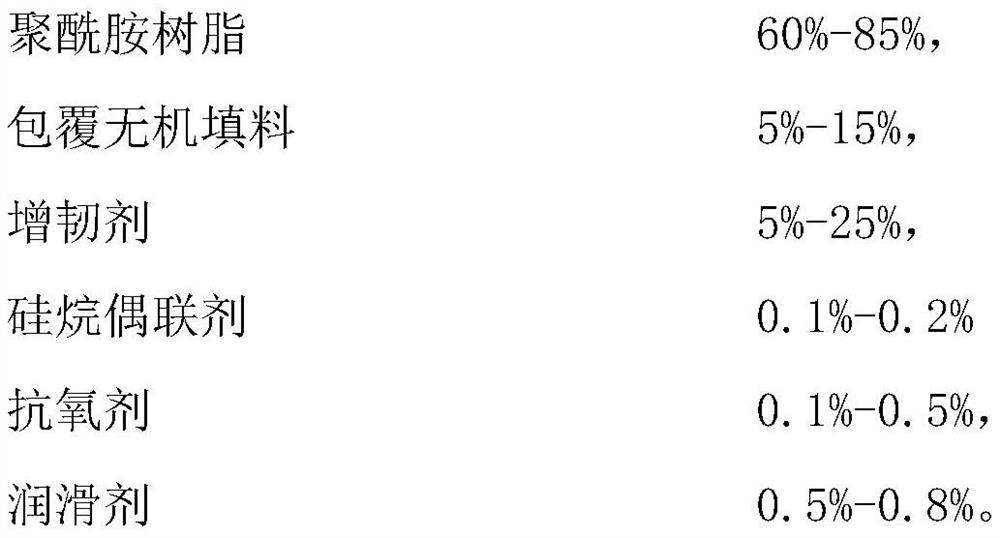

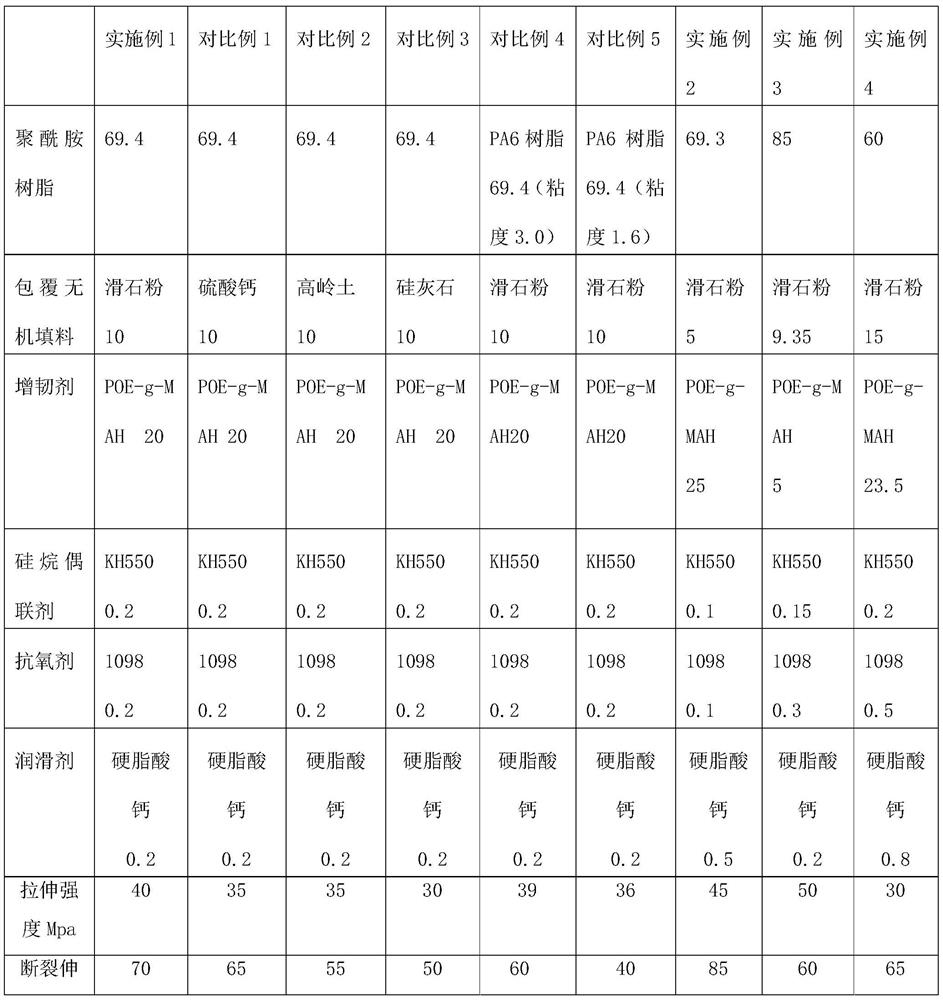

High-friction-coefficient polyamide material and preparing method and application thereof

ActiveCN109943065AHigh coefficient of kinetic frictionImprove wear resistancePolyamideWear resistance

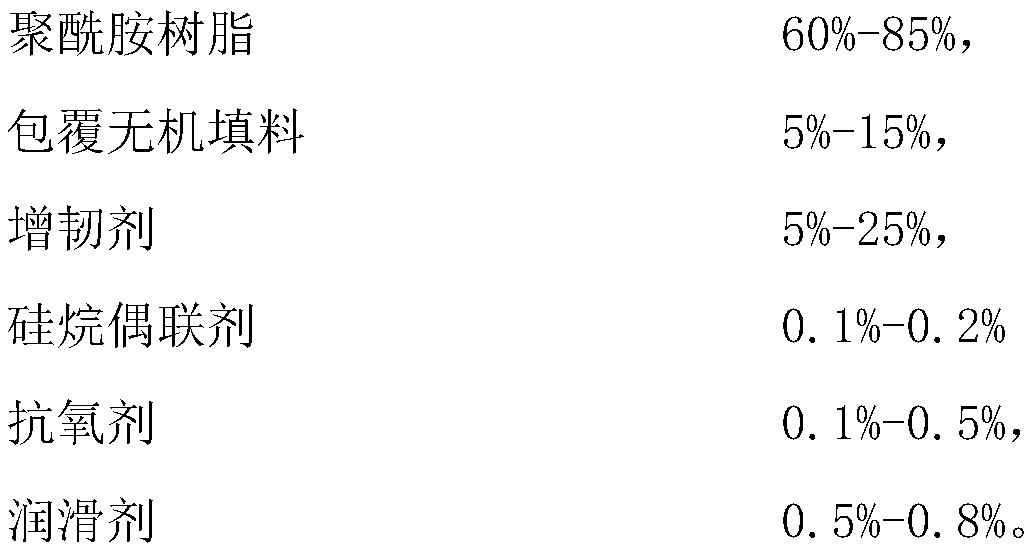

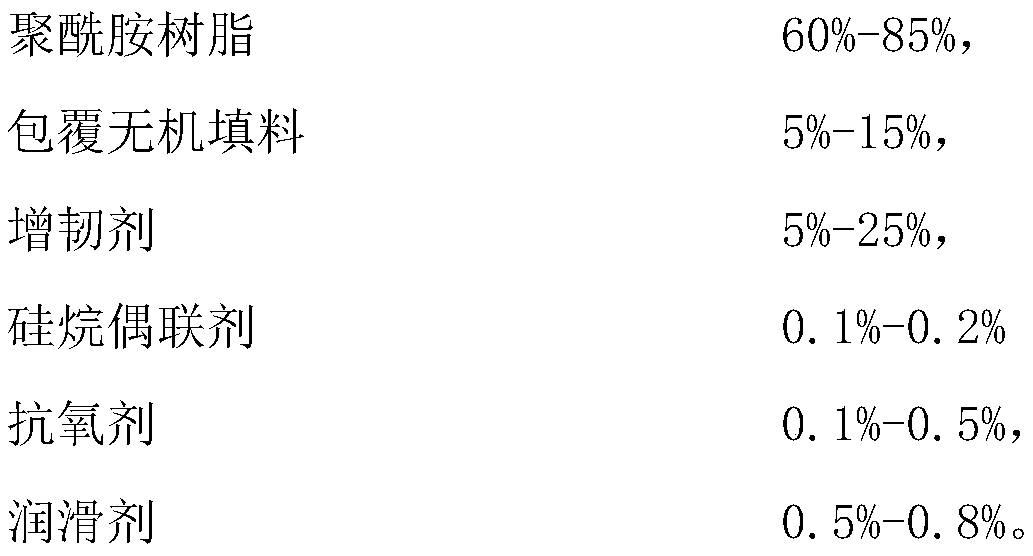

The invention discloses a high-friction-coefficient polyamide material and a preparing method and application thereof. The high-friction-coefficient polyamide material is prepared from, by weight, 60%-85% of polyamide resin, 5%-15% of a coating inorganic filler, 5%-25% of a toughening agent, 0.1%-0.2% of a silane coupling agent, 0.1%-0.5% of an antioxidant and 0.5%-0.8% of a lubricating agent. Thehigh-friction-coefficient polyamide material has the advantages of being good in abrasive resistance, high in dynamic friction coefficient and excellent in mechanical property.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Polyethanediol terephthalate composition and its preparation method

An ethanediol polyterephthalate composition is prepared from the ethanediol polyterephthalate, rubber particles (0.02-0.3 micron) with cross-linking structure, and the grafted substance between unsufurized rubber and polar monomer and / or the grafted substance between thermoplastic elastomer and polar monomer through fusing and proportionally mixture. Its advantages are high toughness and machinability and better strength and rigidity.

Owner:CHINA PETROLEUM & CHEM CORP +1

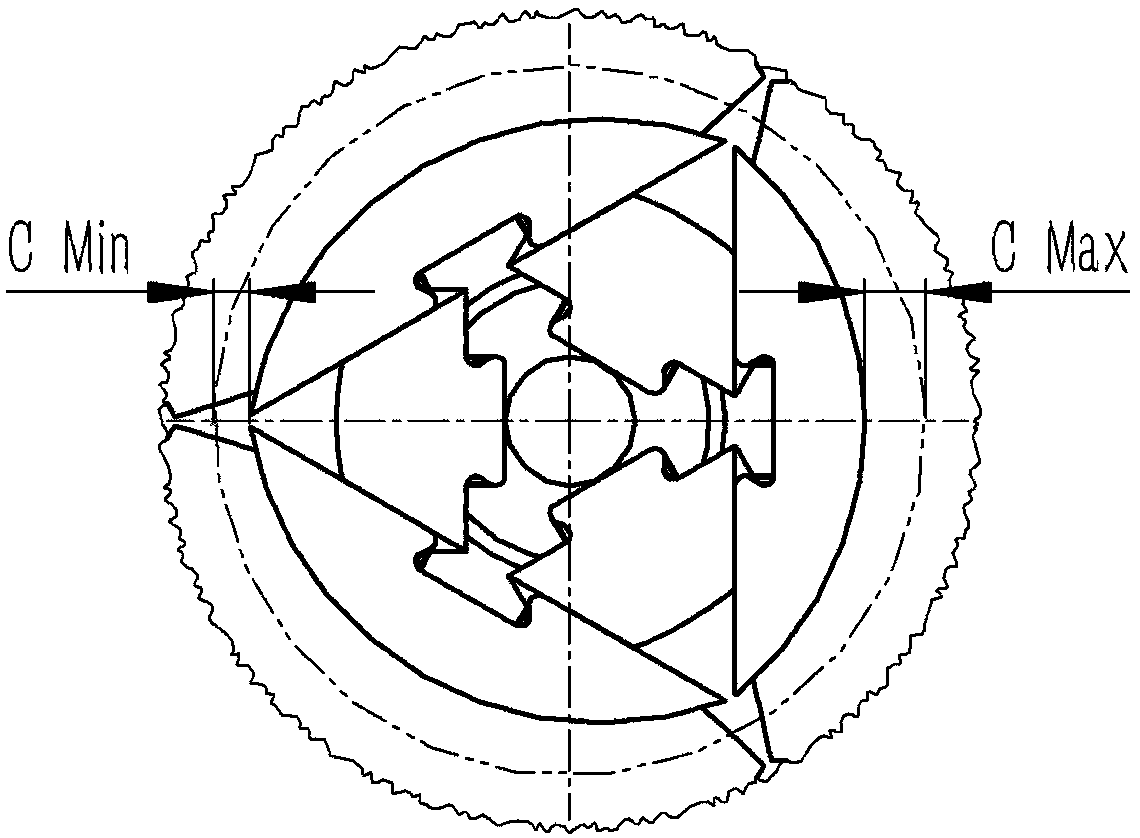

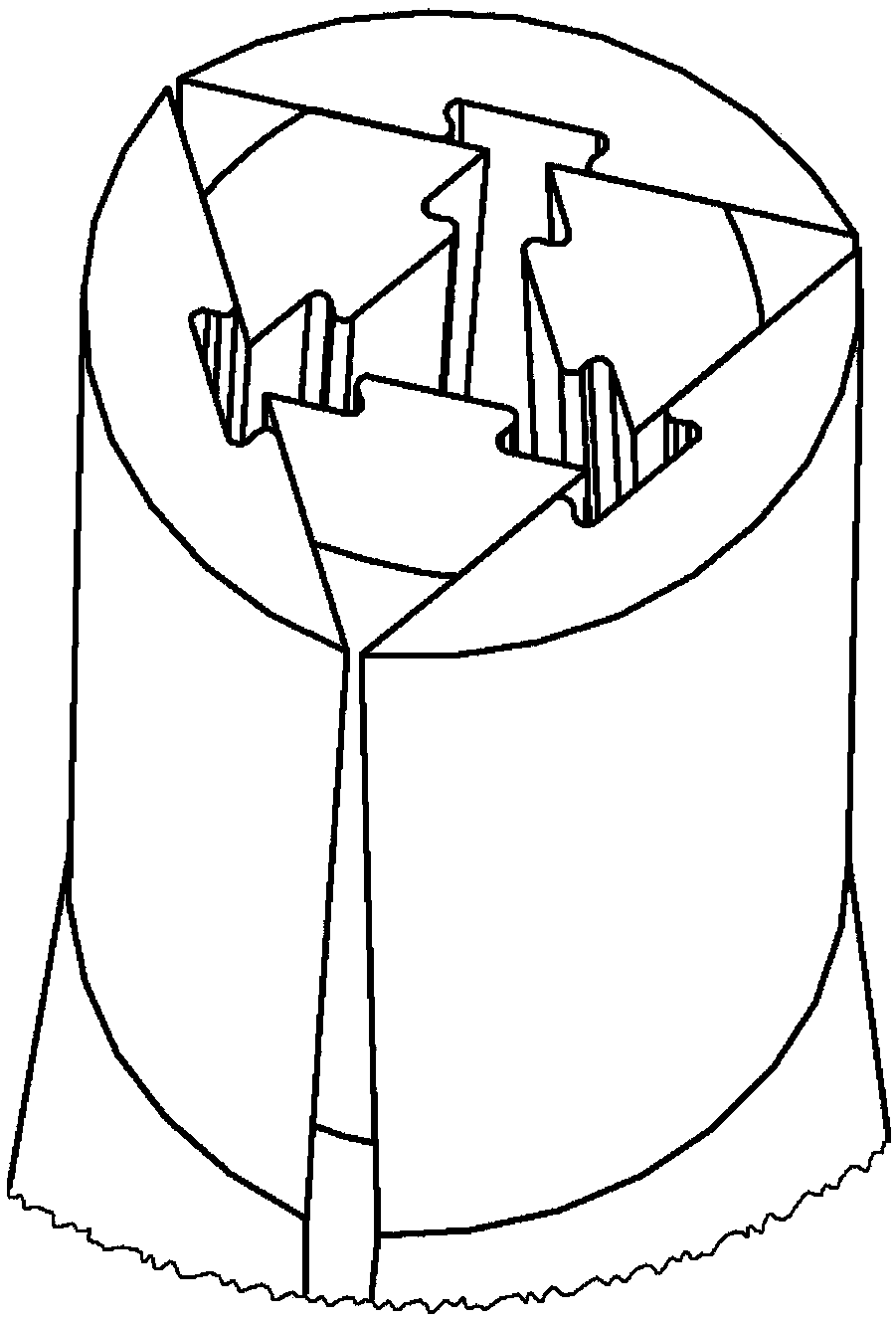

Dovetail telescopic core

Owner:陈锦珊

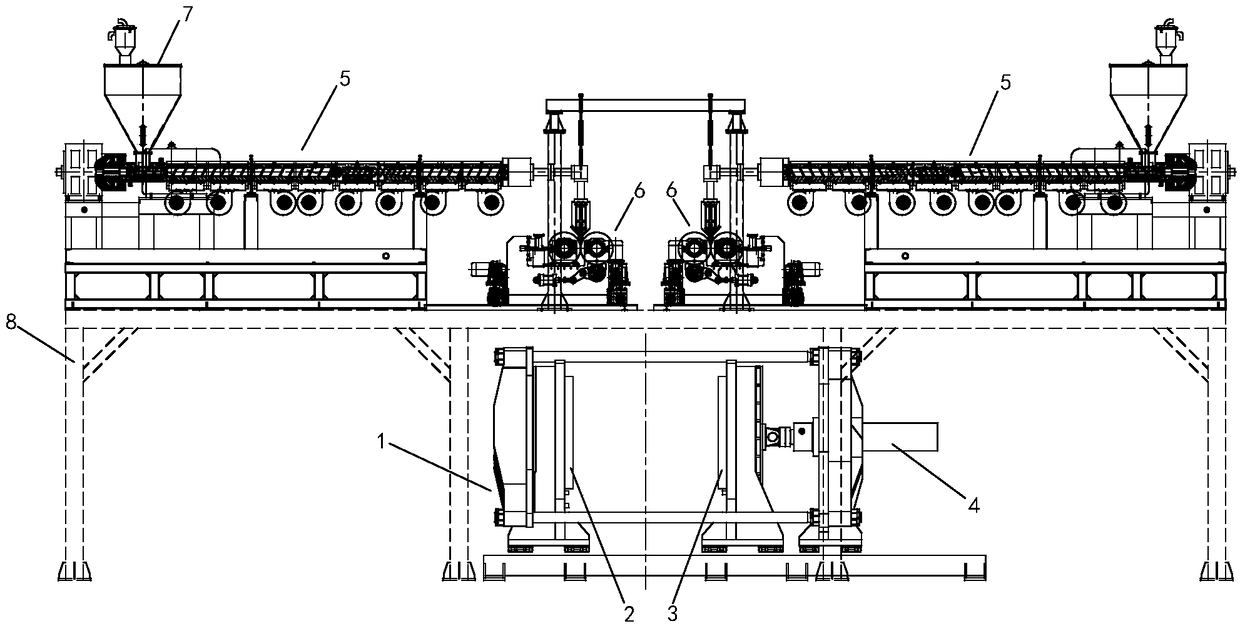

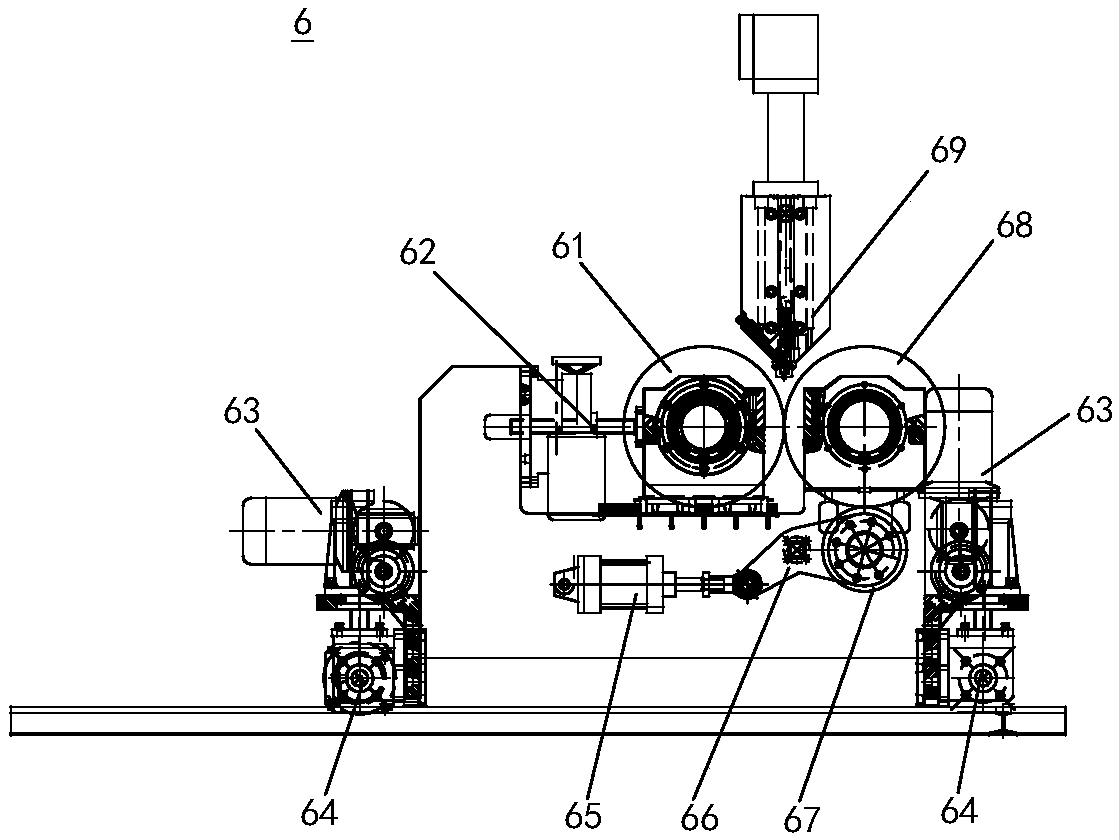

Double-layer blister forming integrated machine and one-time molding method for double-layer plate

The invention relates to a double-layer blister forming integrated machine and a one-time molding method for a double-layer plate. The double-layer blister forming integrated machine comprises a blister forming mould, a first driving mechanism, two extruders and two roller sets, wherein the blister forming mould is equipped with a left mould and a right mould; the first driving mechanism is used for driving the left mould and the right mould to open and close; the two extruders are correspondingly arranged above the left mould and the right mould; the two roller sets are arranged between the left mould and the extruder above the left mould as well as between the right mould and the extruder above the right mould. The method comprises the following steps: using two extruders for synchronously extruding two plastic strips; using two roller sets for respectively flatting the two strips and then hanging on the edges of the roller sets; controlling the two roller sets to move and moving thestrips hung on the edges of the roller sets to the left mould and the right mould of the blister forming mould along vertical direction; performing blister forming; assembling the mould and integrally hot melting the two strips. The integrated machine occupies less space. The method is short in molding period and high in production efficiency.

Owner:亚美三兄(广东)科技有限公司

A kind of rapid prototyping method of glass bottle cold machine

Owner:四川天马玻璃有限公司

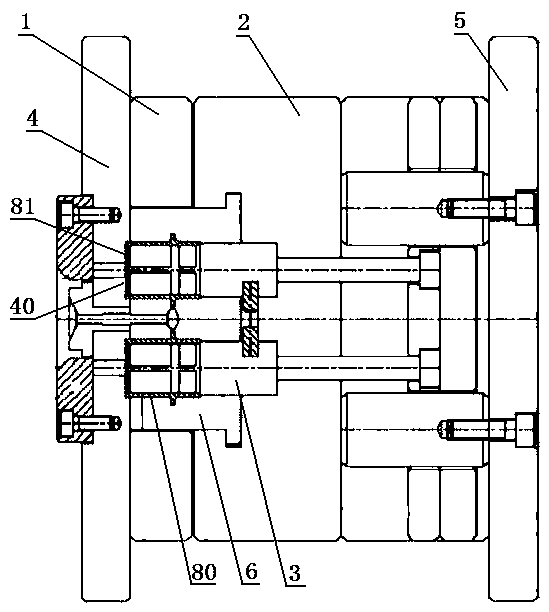

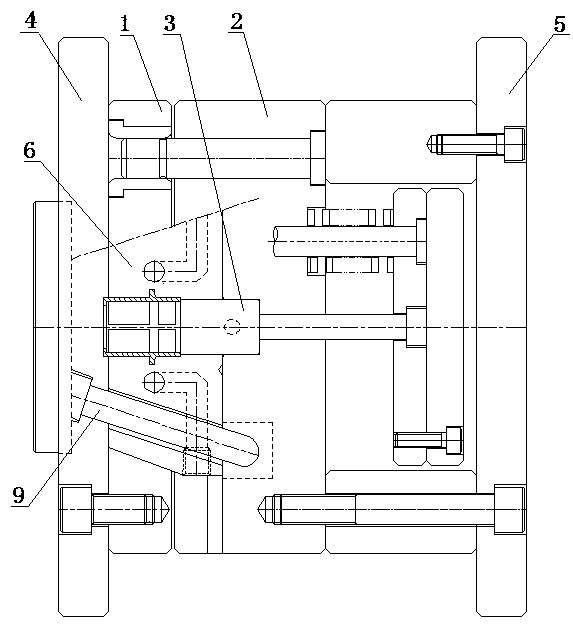

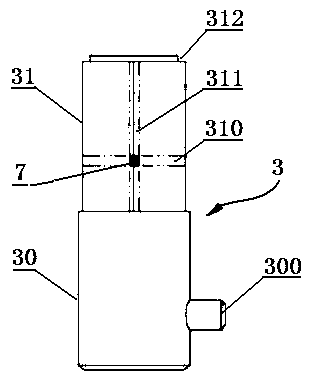

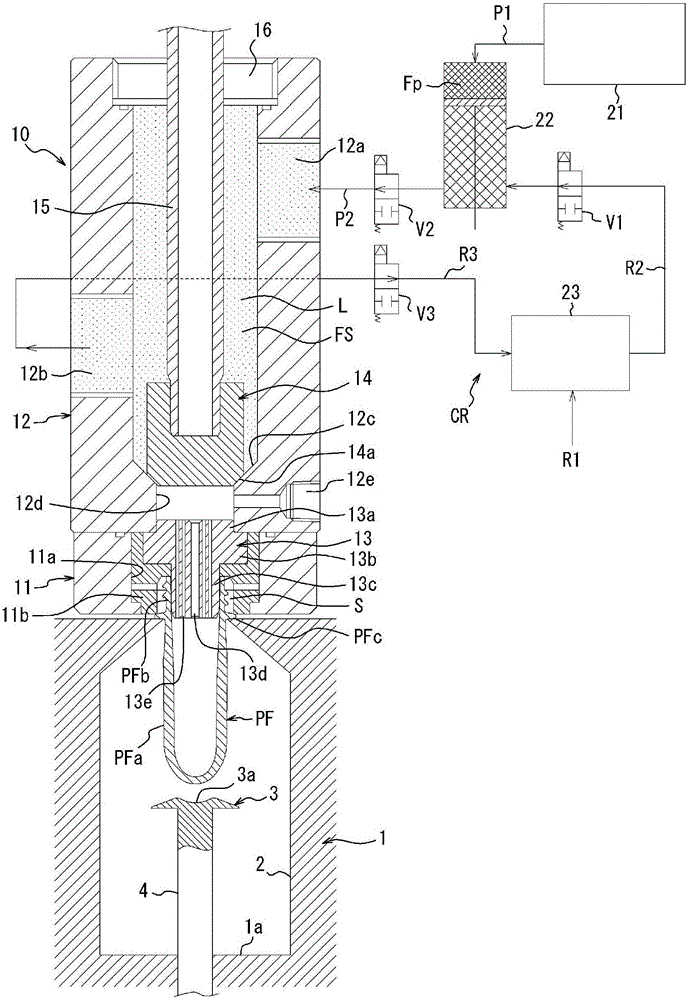

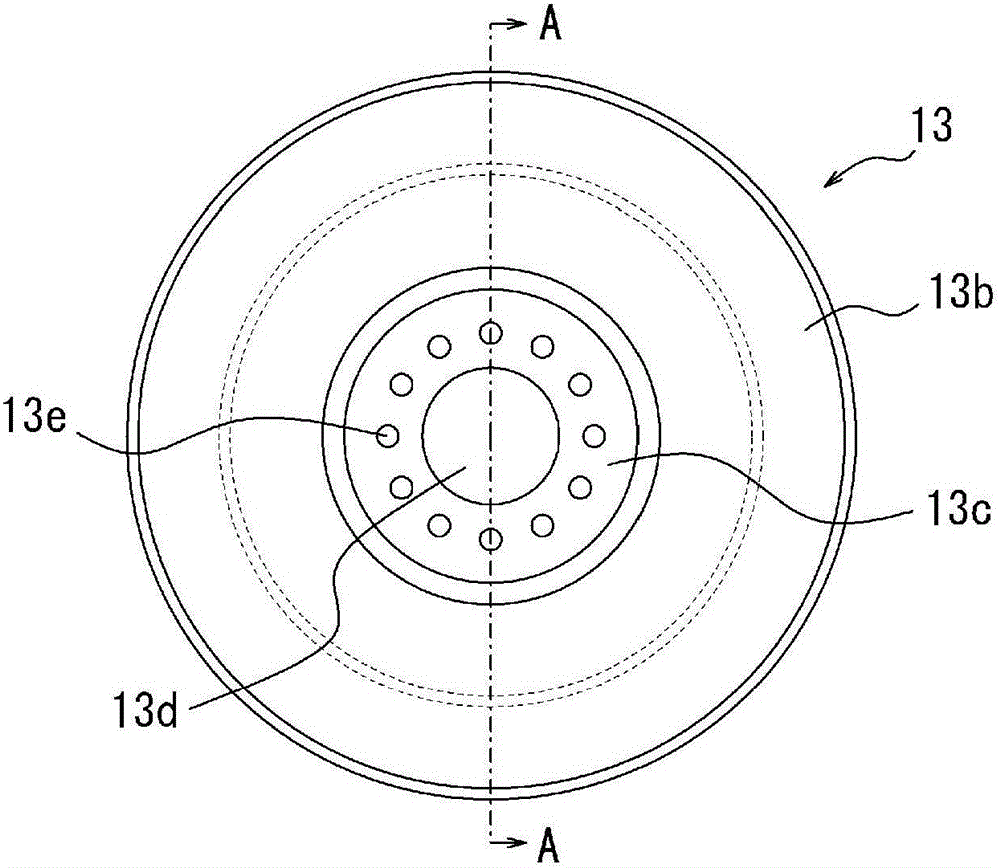

Blow molding device

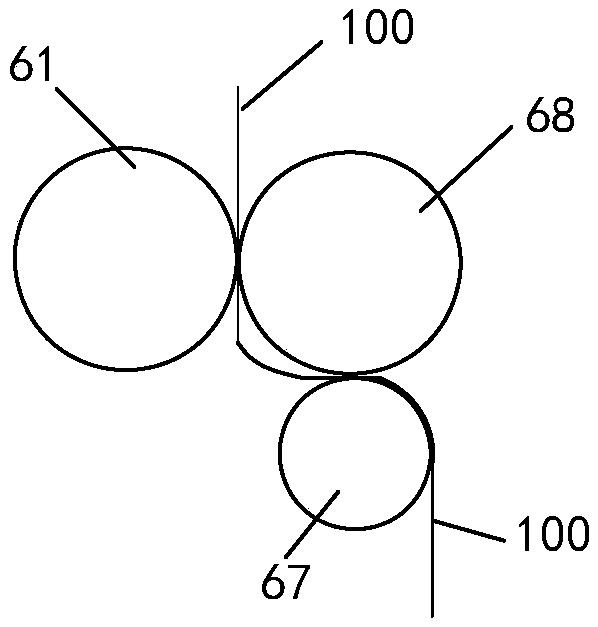

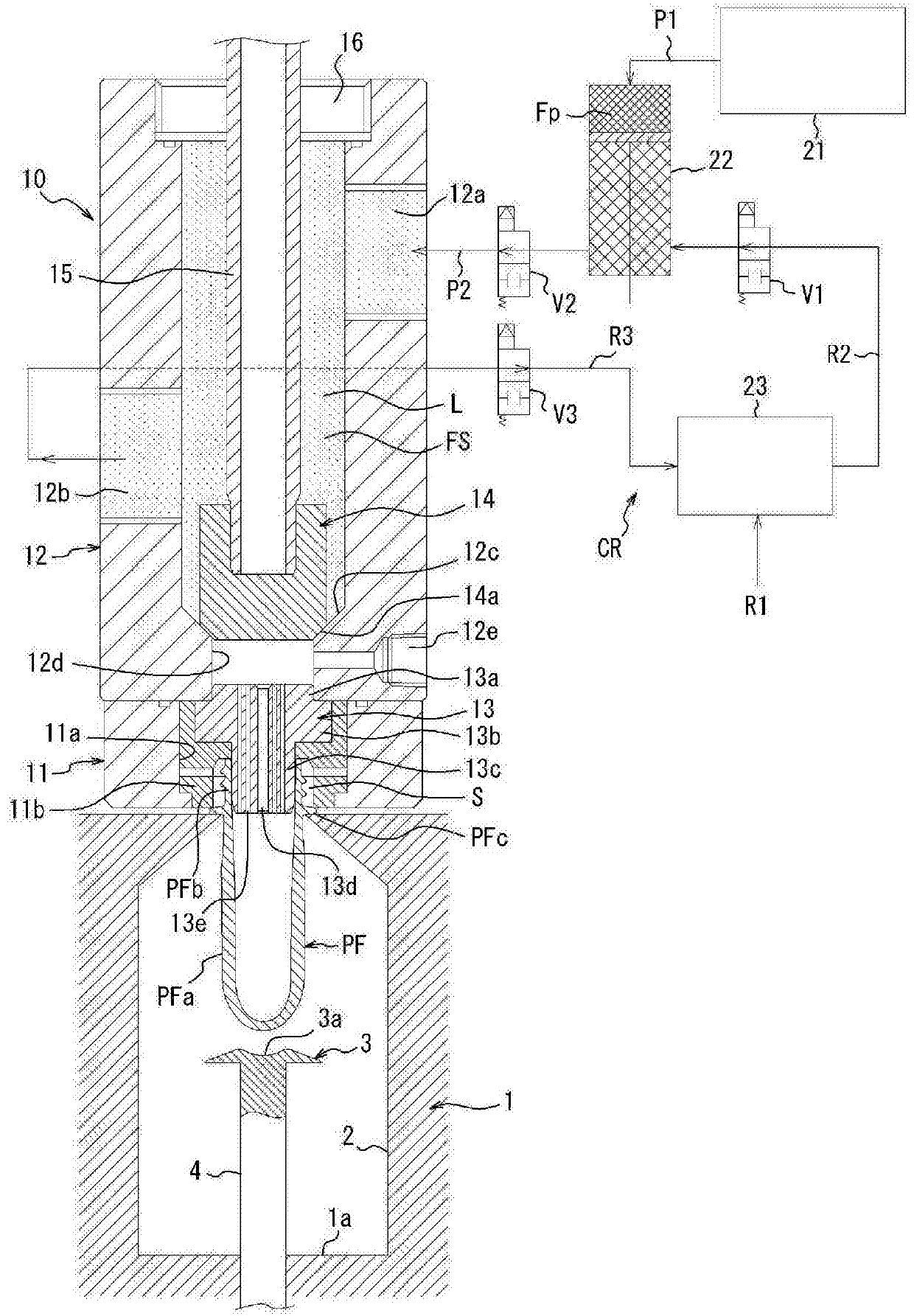

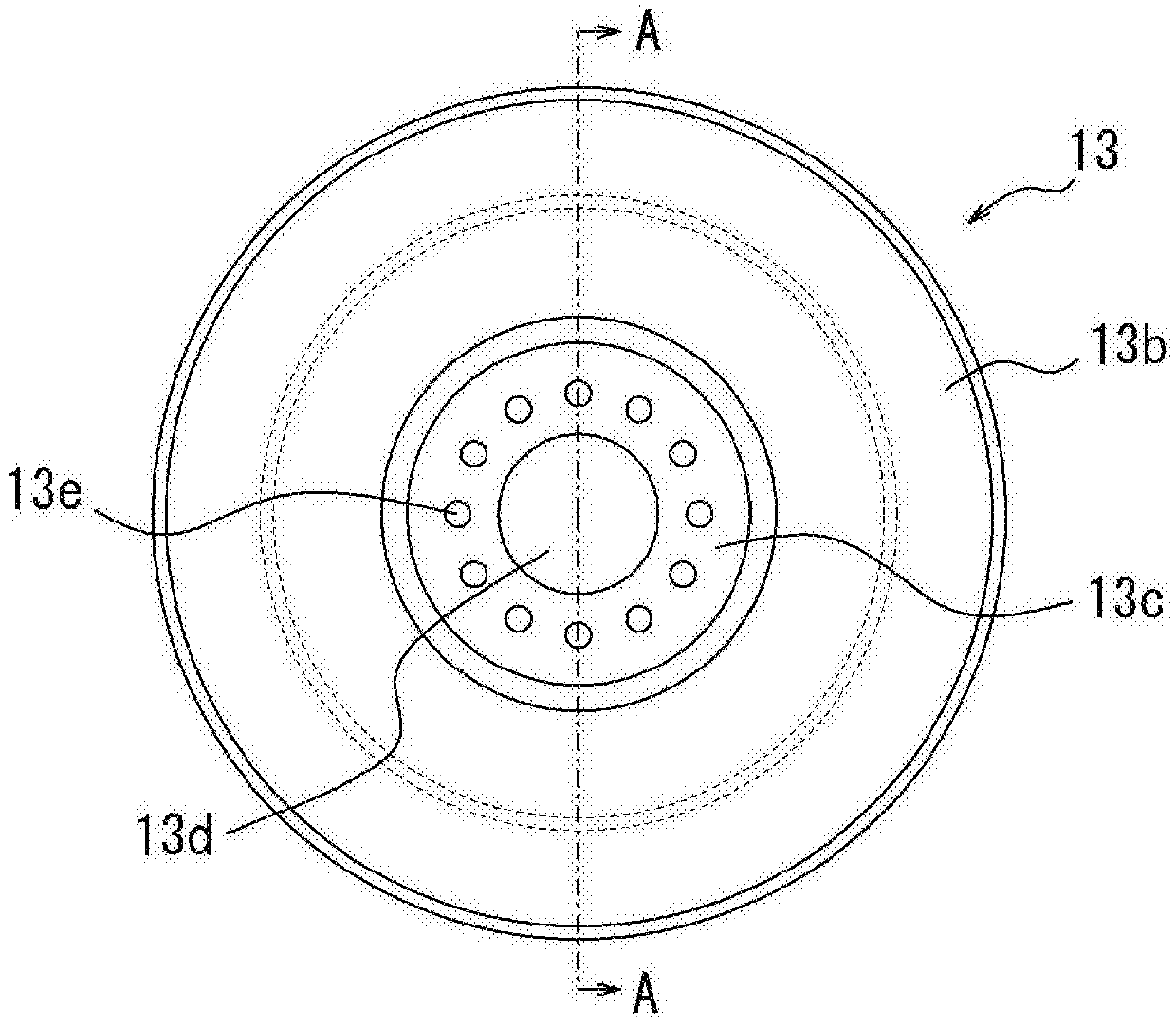

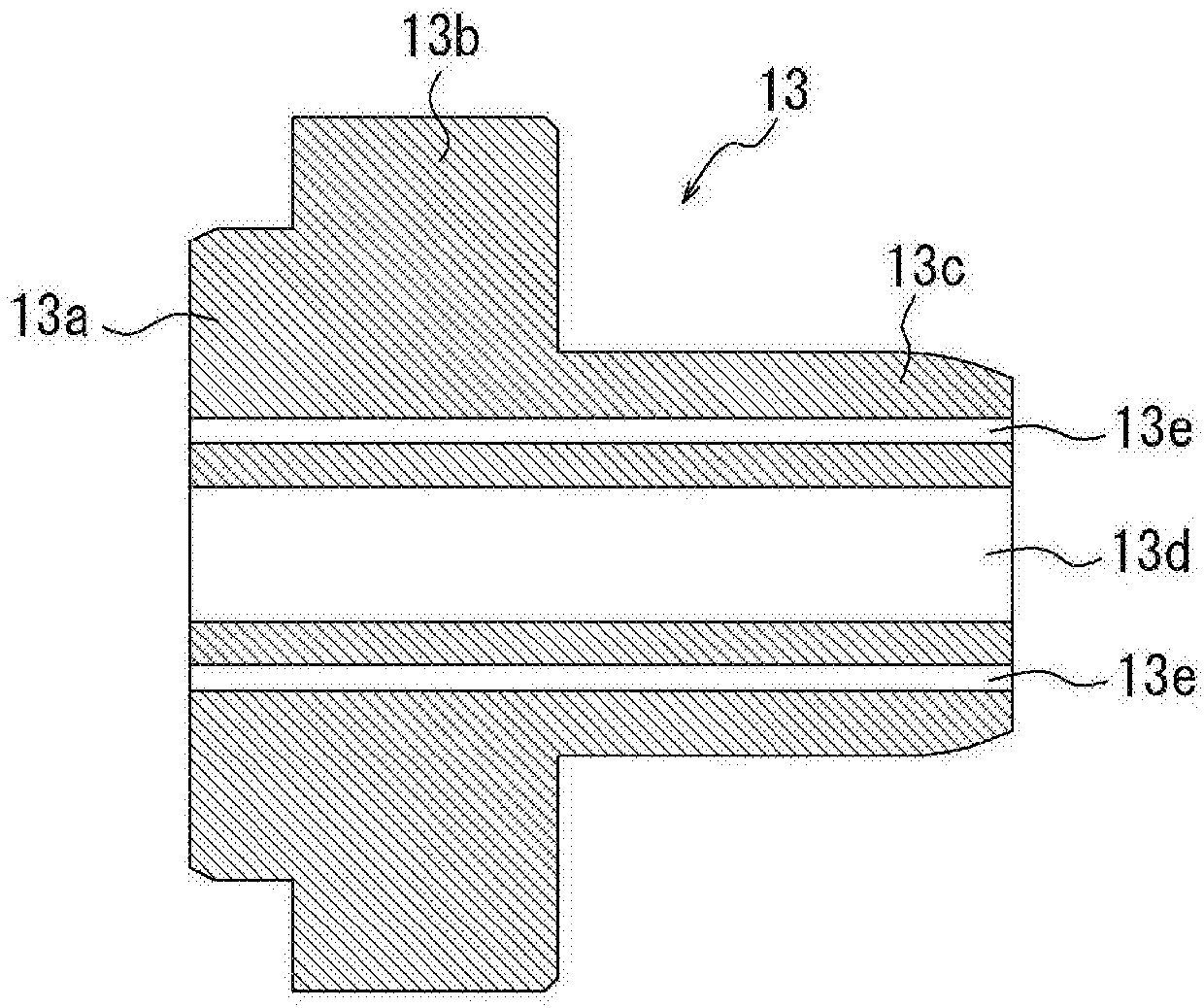

ActiveCN105682889B8Improve molding cycleInhibited DiffusionDomestic articlesBlow moldingBiomedical engineering

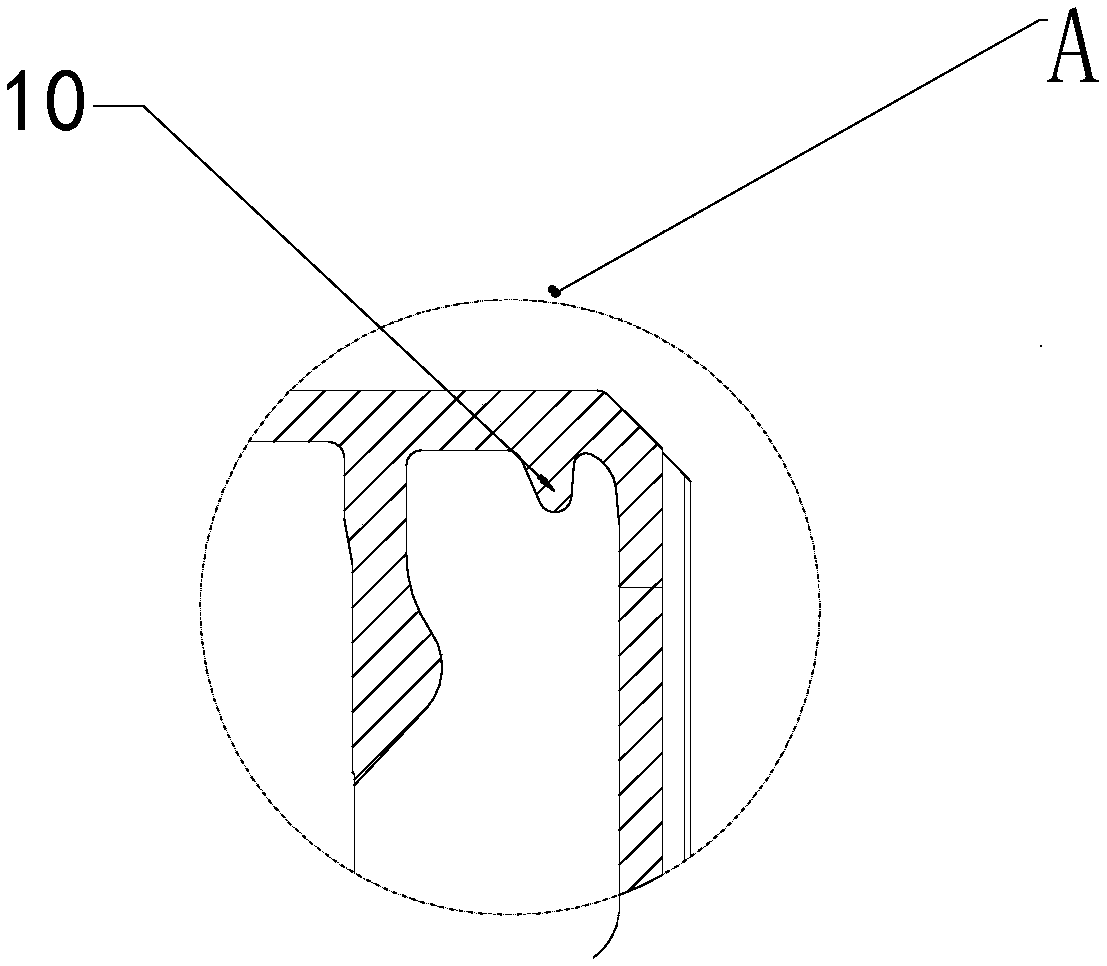

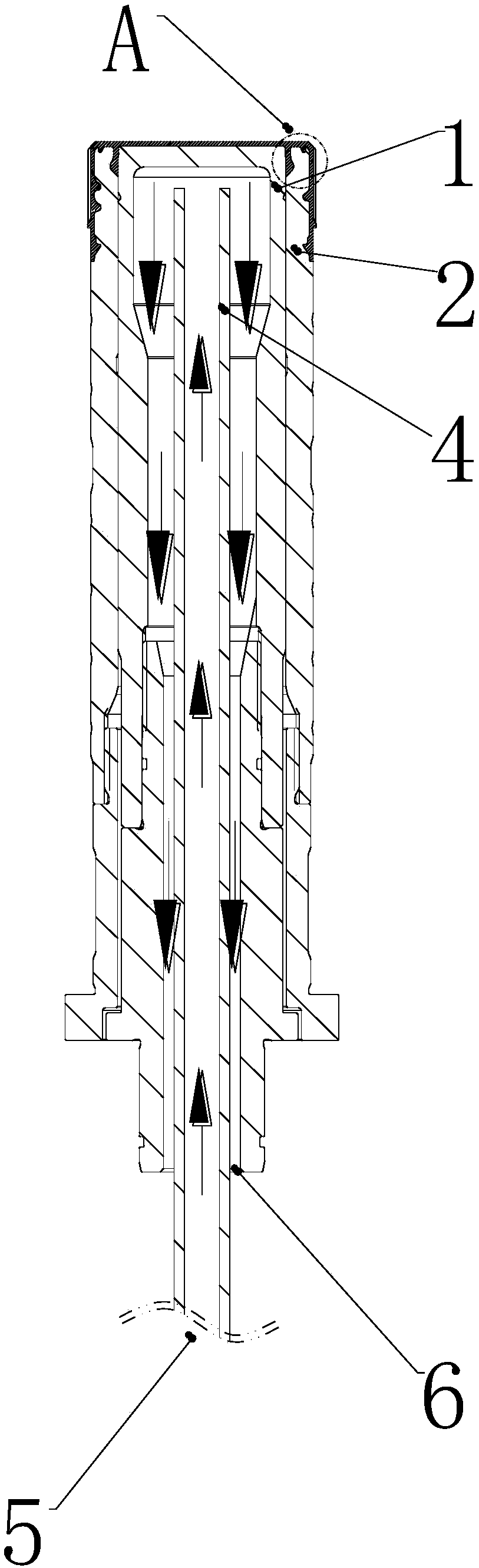

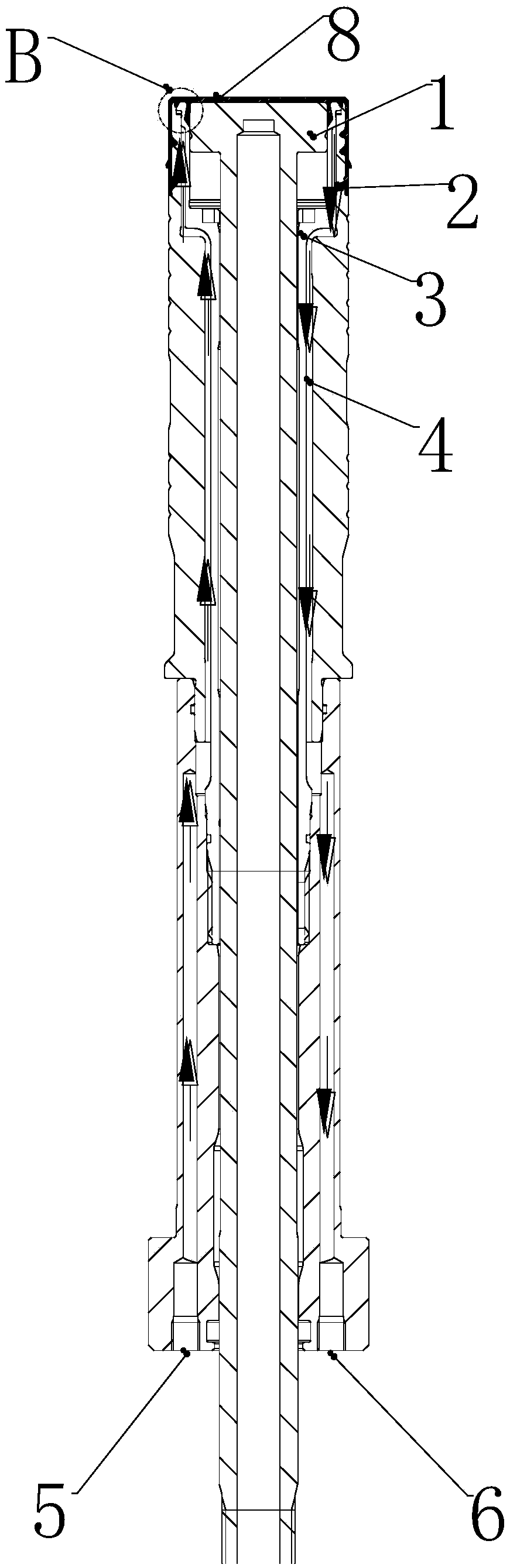

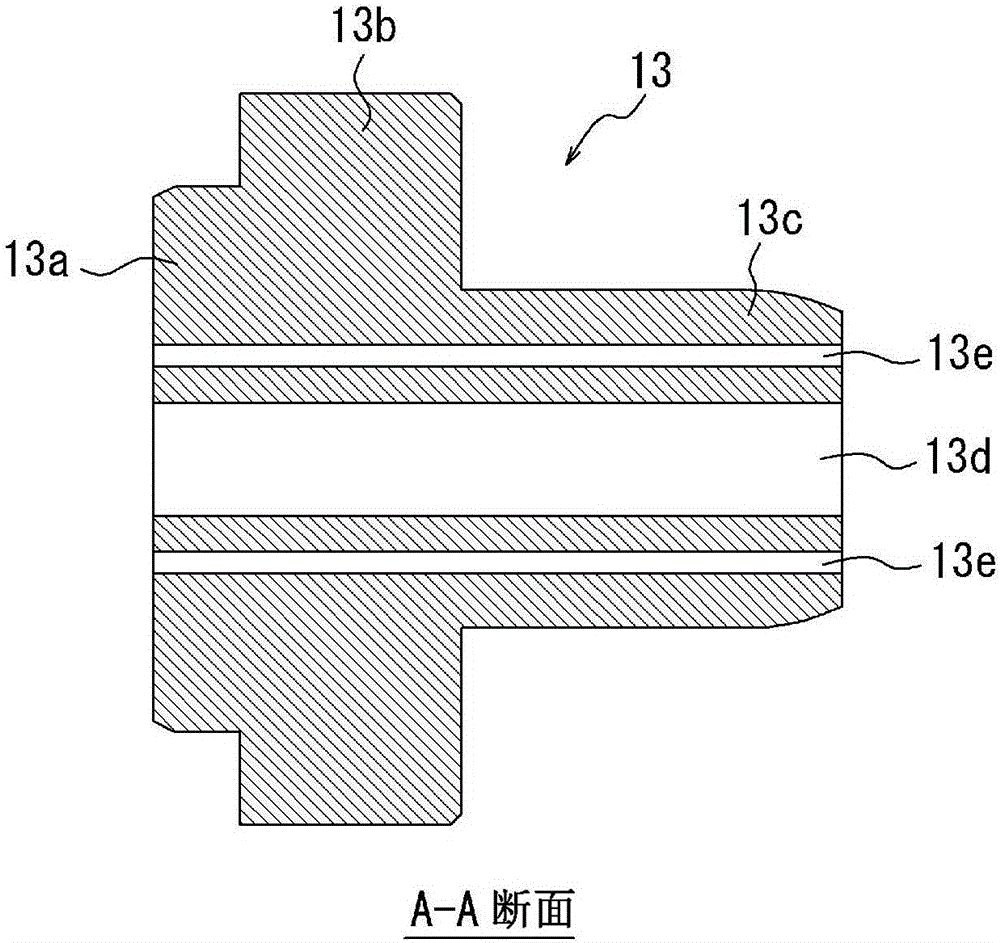

The blow molding device includes: a mold (1) for blow molding to which a bottomed cylindrical preform (PF) is mounted, and a mouthpiece fitted to the preform (PF) mounted on the mold (1) The blowing nozzle (13) in the part (PFb) and the pressurized liquid supply part (22) that supplies the pressurized liquid (L) to the blowing nozzle (13), and the liquid (L) is passed through the blowing nozzle ( 13) and filled into the preform (PF), so that the preform (PF) is molded into the shape of the cavity (2) according to the mold (1), characterized in that the blowing nozzle (13) has a configuration A center hole (13d) on its axis and a plurality of peripheral holes (13e) formed with an inner diameter smaller than the center hole (13d) and configured to surround the center hole (13d), through the center hole (13d) and A plurality of peripheral holes (13e) are used to fill the liquid (L) into the preform (PF).

Owner:DISCMA

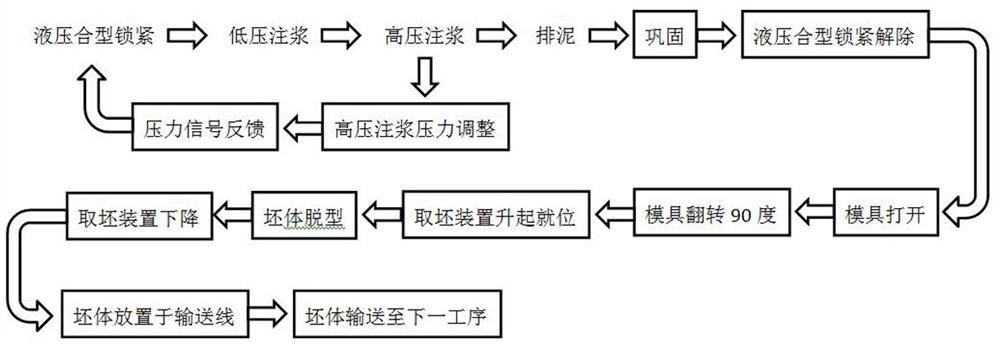

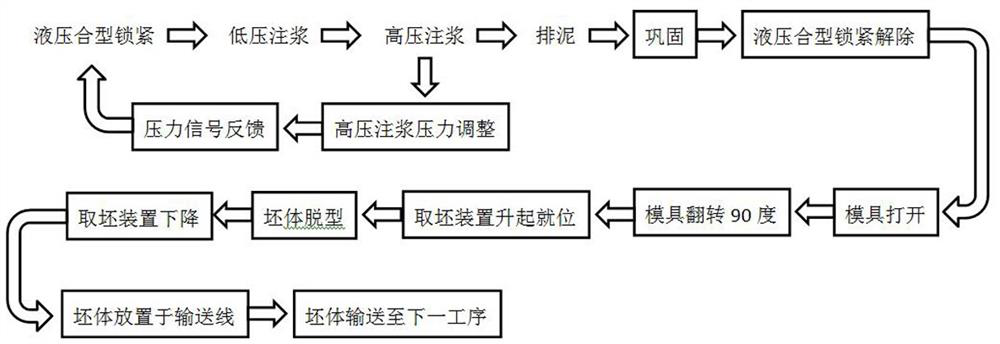

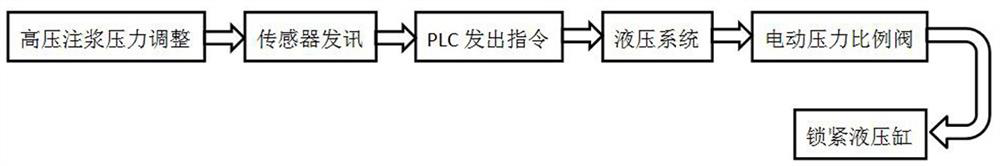

Multi-body high-pressure production process of fully automatic flip toilet ring

ActiveCN111605038BImprove yieldImprove molding cycleAuxillary shaping apparatusProcess engineeringMechanical engineering

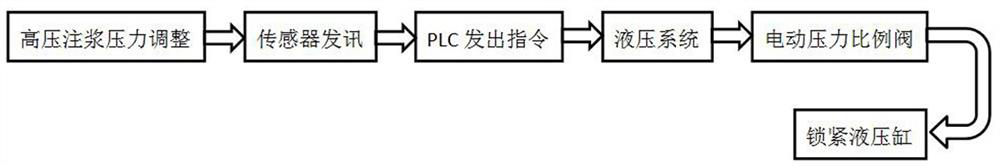

A fully-automatic high-pressure production process for multi-body toilet rings with overturning. During the high-pressure grouting process, a high-pressure grouting pressure adjustment process is added: during the high-pressure grouting process, the grouting pressure is adjusted, and a pressure sensor is installed in the mold for monitoring. ; After the grouting pressure is adjusted, the pressure sensor sends a pressure value signal to the PLC, and the PLC then transmits the command to the hydraulic pressure proportional valve in the hydraulic fitting and locking system; the pressure proportional valve adjusts the pressure to meet the pressure suitable for grouting Environment: Complete high-pressure grouting in a qualified pressure environment and enter the mud discharge process. The invention overcomes the disadvantages of the traditional high-pressure grouting process, and is more convenient to operate, with higher green body yield, more stable, and longer mold life, which greatly reduces the use cost of the mold and shortens the molding cycle of the entire green body. The production efficiency is greatly improved, the good product rate of the product is improved, the moisture content of the green body shortens the drying time of the green body, and the degree of environmental pollution is reduced.

Owner:TANGSHAN HEXIANG INDAL

Polyamide composite material as well as preparation method and application thereof

The invention provides a polyamide composite material which comprises the following components in parts by weight: 80-100 parts of short-carbon-chain polyamide; and 0.1-6 parts of an amide oligomer. In the repeating units of the short-carbon-chain polyamide, the number of carbon atoms on a main chain is smaller than or equal to 6. According to the polyamide composite material as well as the preparation method and application thereof, a small amount of amide oligomer is added, so that the injection molding property of the polyamide composite material can be obviously improved, the problems of mucous membrane, top bulge and the like in the production link are improved, the production efficiency is improved, and other properties such as mechanical properties of the polyamide composite material will not be obviously reduced.

Owner:KINGFA SCI & TECH CO LTD

A kind of environment-friendly plastic thrust bearing bush and its manufacturing method

The invention relates to an environmentally-friendly plastic thrust bearing bush and a production method thereof. The environmentally-friendly plastic thrust bearing bush comprises a steel bush base and a surface plastic layer, wherein the surface plastic layer is bonded on the steel bush base directly by a solvent-free adhesive to form the thrust bearing bush, a spring cushion does not need to be arranged between the steel bush base and the surface plastic layer, and brazed connection is also not required between the steel bush base and the surface plastic layer. Compared with the prior art, the environmentally-friendly plastic thrust bearing bush and the production method provided by the invention have the advantages of short molding cycle, outstanding environmental performance, uniform elastic modulus and the like.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

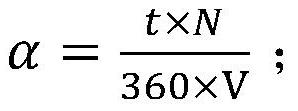

Glass bottle cold start-up rapid forming method

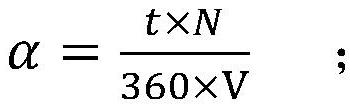

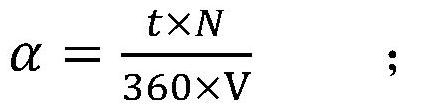

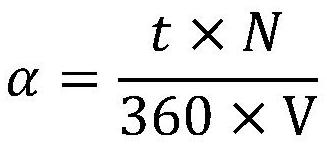

The invention belongs to the technical field of glass bottle production, and discloses a glass bottle cold start-up rapid forming method, which is used for a preheating production stage of a rank machine, the forming method comprises positive blowing, initial mold cooling and mold forming cooling, and the opening timing of the positive blowing is delayed by 70-90 units of periodicity from the opening timing during normal production; the opening timing of the primary mold cooling is delayed by 15-25 units of periodicity from the opening timing during normal production, and the stopping timing of the primary mold cooling is advanced by 50-70 units of periodicity from the stopping timing during normal production; the start timing of mold forming cooling is delayed by 60-80 units of periodicity from the start timing during normal production; wherein the periodicity of one unit is alpha, and alpha meets the following formula: alpha=(t*N) / (360*V). The rejection rate of the glass bottles is greatly reduced and the cost is reduced by delaying the start timing and stop timing of positive blowing, mold forming cooling and initial mold cooling and reducing the cooling air of the bottle conveying machine.

Owner:四川天马玻璃有限公司

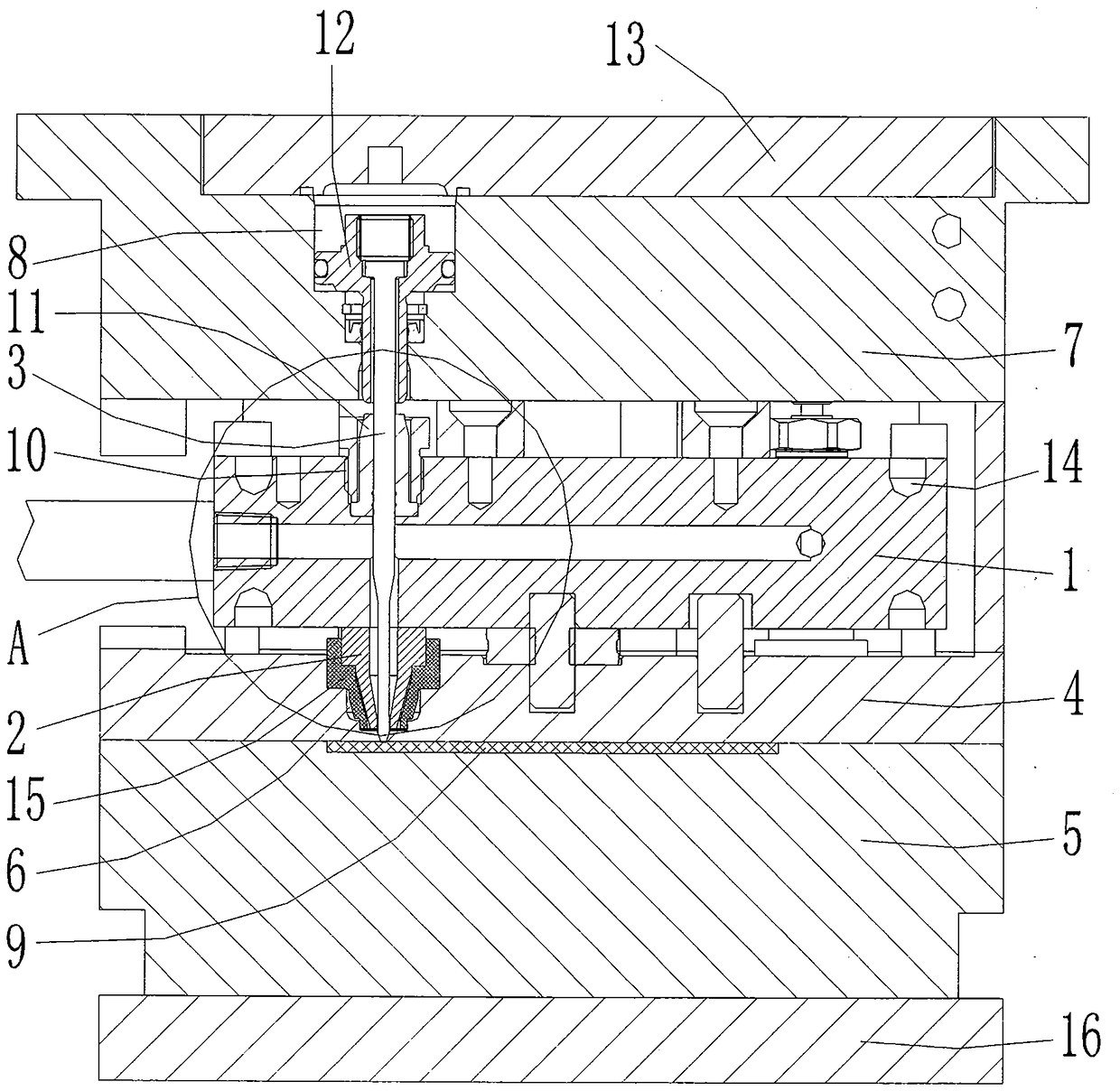

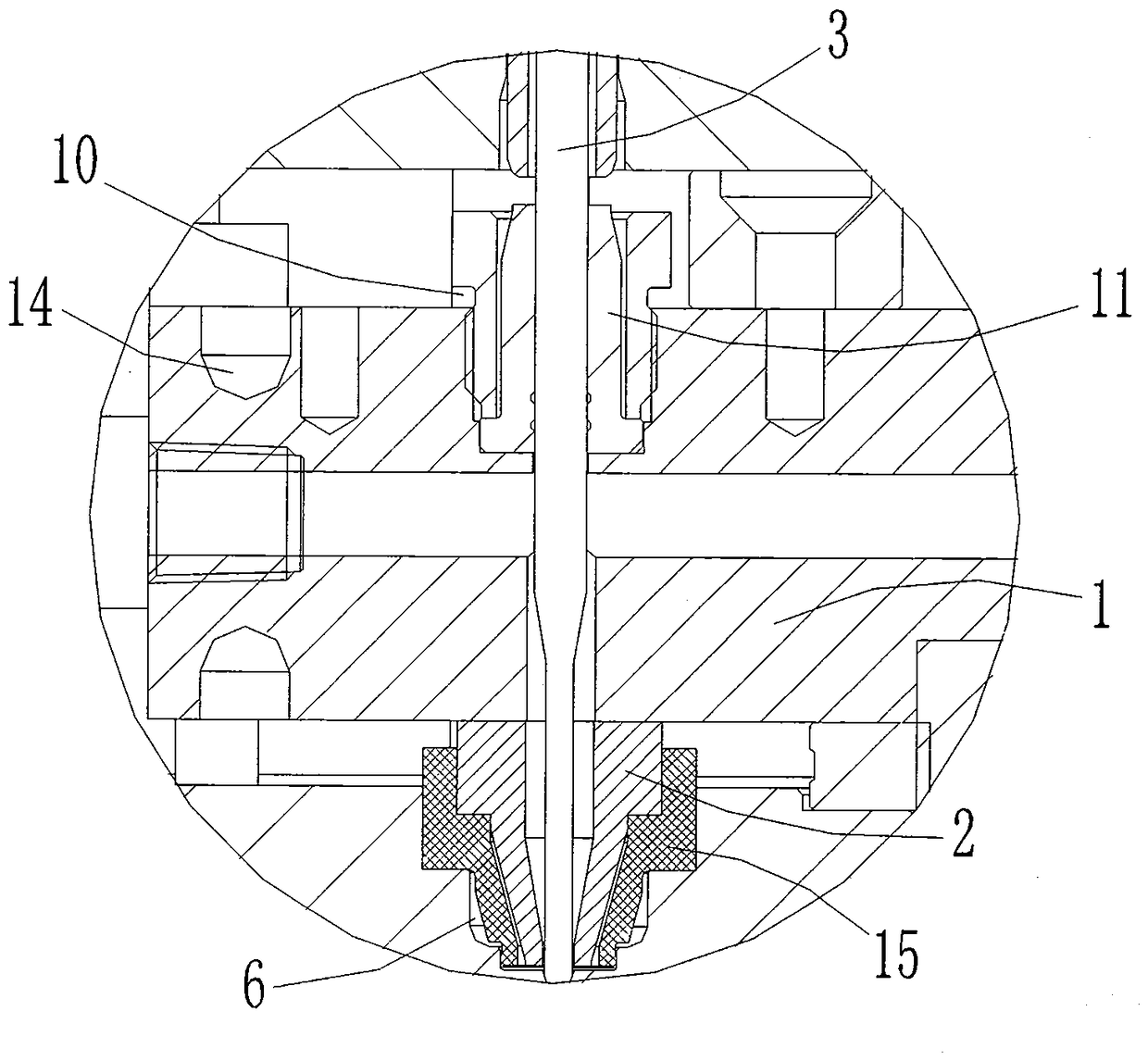

Low pressure non-runner glue injection device

The invention discloses a low pressure glue injecting device without flow channel. The glue injecting device comprises a glue injecting part and a mold part, wherein the glue injecting part comprises a glue gun with an internal hollow cavity, a gun nozzle which is communicated with the hollow cavity of the glue gun, a valve needle for controlling the glue from the gun nozzle and a driving part for driving the action of the valve needle, a glue out channel communicated with the internal hollow cavity is arranged on the glue gun, part of the valve needle is arranged in the gun nozzle and the glue out channel and a heating part is arranged on the outer part of the glue gun; the mold part comprises an upper mold and a lower mold which are used for clamping and positioning a packaging product, a positioning through hole is formed in the upper mold, the gun nozzle is arranged in the positioning through hole, the glue gun is arranged on the upper mold, a panel is arranged on the upper mold, and a glue outlet of the gun nozzle directs to the packaging product. The flow channel and a glue nozzle are not needed in the design, the glue injecting part is integrated on the mold part, so as to prevent the flow channel and the glue nozzle from affecting the technology effect, reduce the glue injection pressure and the glue injection temperature, and facilitate to increase the efficiency and yield.

Owner:SUZHOU KONIG ELECTRONICS TECH CO LTD

A kind of polyamide material with high friction coefficient and its preparation method and application

ActiveCN109943065BGood self-lubricating performanceImprove mechanical propertiesPolymer scienceSilanes

The invention discloses a polyamide material with high friction coefficient, its preparation method and application. It contains 60%-85% polyamide resin by weight, 5%-15% coated inorganic filler, 5%-25% toughening agent, 0.1%-0.2% silane coupling agent; 0.1%-0.5% antioxidant agent, 0.5%‑0.8% lubricant. The polyamide material with high friction coefficient has the characteristics of good wear resistance, high dynamic friction coefficient and excellent mechanical properties.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Fully biodegradable polyhydroxyalkanoate/polybutylene succinate blend gold

The invention discloses a completely biodegradable polyhydroxyalkanoate / polybutylene succinate blended alloy, which is characterized in that: the blended alloy is composed of polyhydroxyalkanoate, polybutylene succinate Alcohol esters, starch, fillers and other additives. The blended alloy of the present invention utilizes the heat resistance, good processability, high crystallinity, good tensile strength and impact toughness of polybutylene succinate to improve the heat resistance of polyhydroxyalkanoate materials Poor, severe viscosity during molding processing, slow crystallization, low mechanical strength and other defects, and reduce costs, expand the scope of application, the obtained blend alloy has good comprehensive properties, and can be used for blown film, extruded sheet, injection molding disposable environmental protection Supplies, medical and other fields.

Owner:山东省意可曼科技有限公司

A kind of carbon paper composite material and preparation method thereof for laser lamination

The invention provides a carbon paper composite material for laser lamination molding and a preparation method thereof, which is composed of the following raw materials in the following mass ratio: 5-20 parts of carbon paper, 80-95 parts of resin matrix, coupling agent 1-5 parts, 0.5-3 parts of antioxidant, 0.5-5 parts of heat stabilizer and 0.5-5 parts of lubricant. The carbon paper composite material for laser lamination prepared by the present invention has the characteristics of simple preparation process, high mechanical strength, fast forming speed and low water absorption rate, greatly shortens the production cycle and reduces costs, and can be directly applied and promoted in In the field of laser lamination manufacturing technology, it can be directly processed into structural parts.

Owner:HEFEI GENIUS NEW MATERIALS

u-shaped nylon oil filter mold

ActiveCN103753775BImprove filtering effectExtend the life cycleCoatingsProcess engineeringWear resistance

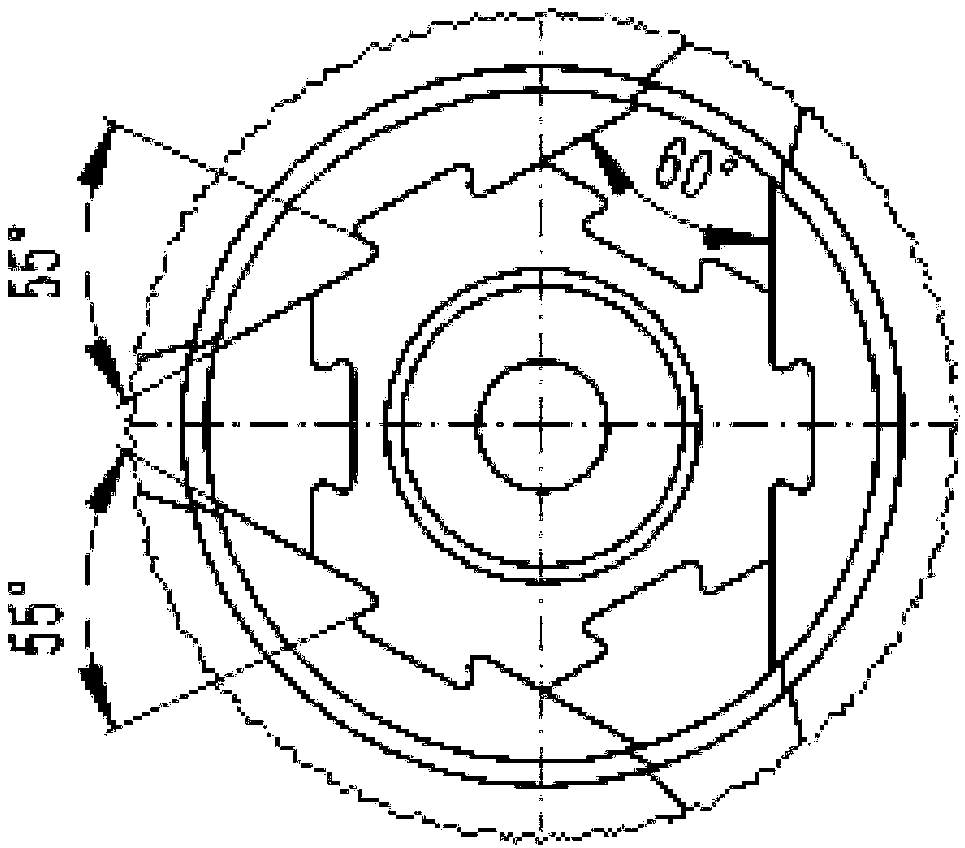

The present invention relates to A sort of U Shaped nylon oil filter mold, including front mold, back mold, mold core and slider, the front mold is fixed on the front mold fixing plate, and the front mold fixing plate is provided with a bottom hole; the outer peripheral surface of the mold core is provided with Horizontal stem grooves, vertical stem grooves, horizontal stem grooves and vertical stem grooves are interlaced, and bottom stem grooves are provided at the end of the mold core. Outer side of groove, vertical stem groove. The invention has simple processing structure and convenient cost, and is suitable for use by various small and medium-sized companies; the structure effectively avoids quality problems such as leaking screens and exposed bottoms; and the produced oil filter screen has good filtering effect, wear resistance, anti-corrosion, and long service life; The molding cycle is short and the production rate is high. Compared with the low production capacity of several hundred in the original technology, the existing technology can reach more than 6,000, which effectively improves the production efficiency; in addition, the external dimensions can be customized according to the drawings, and the applicability is wide.

Owner:SUZHOU HENGHUI TECH

High-speed mould threaded core cooling structure

The invention discloses a high-speed mould threaded core cooling structure which comprises an internal core and a threaded core. The high-speed mould threaded core cooling structure is characterized in that the threaded core is provided with a hollow cavity; an insert is arranged in the hollow cavity; a gap is reserved between the insert and the inner wall of the hollow cavity; and a cooling loopis formed by the gap. According to the high-speed mould threaded core cooling structure, the cooling loop is more balanced, the cooling on the forming part of a product is more direct and effective, the production efficiency is improved and the produced product meets the all requirements.

Owner:SUZHOU LIANKAI PRECISION MOLD

High-density polyethylene material and application thereof

ActiveCN102206374BReduce coefficient of frictionHigh surface glossFibre mechanical structuresPhosphoric Acid EstersPolymer science

The invention relates to a high-density polyethylene material and application thereof. The material comprises the components in percent by weight: 100% of high-density polyethylene, 5-80% of para-phthalic metal salt, 1-8% of silicone oil and 0.5-5% of antioxidant. The para-phthalic metal salt is selected from calcium terephthalate, magnesium terephthalate, zinc terephthalate, potassium terephthalate, sodium terephthalate, barium terephthalate, lead terephthalate, aluminum terephthalate, ferrum terephthalate or a mixture thereof. The silicone oil is selected from active silicone oil, dimethyl silicone oil, 201 methyl silicone oil or a mixture thereof. The antioxidant is selected from tris(2,4-ditert-butylphenyl) phosphate, pentaerythrite tetra [beta-(3,5-di-tert-butyl-4-hydroxyphenyl)-propionate], 2,6-di-tert-butyl-4-methylphenol, 2,2'-methylenebis[6-(1,1-dimethylethyl)-4-methyl-phenol or a mixture thereof. The polyethylene material provided by the invention has a small friction coefficient and favorable self-lubricity and can be used for manufacturing optical cable protection sleeves.

Owner:江苏爱特恩高分子材料有限公司

Carbon paper composite material used for laser laminating molding and preparation method thereof

The present invention provides a carbon paper composite material used for laser laminating molding and a preparation method thereof, and the carbon paper composite material comprises the following raw materials by weight ratio: 5 to 20 parts of carbon paper, 80 to 95 parts of a resin matrix, 1 to 5 parts of a coupling agent, 0.5 to 3 parts of an antioxidant, 0.5 to 5 parts of a heat stabilizer and 0.5 to 5 parts of a lubricant. The prepared carbon paper composite material used for laser laminating molding ahs the characteristics of simple preparation process, high mechanical strength, fast forming speed, low water absorption, and the like, can significantly shorten the production cycle and reduce cost, can be directly applied and promoted in laser laminating molding manufacturing technology, and can be directly processed into structural parts.

Owner:HEFEI GENIUS NEW MATERIALS

Fully automatic overturn-type toilet seat ring multi-green-body high-pressure production process

ActiveCN111605038AImprove yieldImprove molding cycleAuxillary shaping apparatusProcess engineeringForce sensor

Provided is a fully automatic overturn-type toilet seat ring multi-green-body high-pressure production process. In the high-pressure grouting process, a high-pressure grouting pressure adjustment process is added: the grouting pressure is adjusted in the high-pressure grouting process, and a pressure sensor is additionally installed in a mold for monitoring; after the grouting pressure is adjusted, the pressure sensor sends a pressure value signal to a PLC, the pressure value signal is processed by the PLC, and then a command is transmitted to a hydraulic pressure proportional valve in a hydraulic mold assembling locking system; the pressure proportional valve adjusts the pressure to meet a pressure environment adapting to the grouting; and high-pressure grouting is finished in the qualified pressure environment and the mud discharge process is started. The process overcomes the shortcomings of a traditional high-pressure grouting process, is more convenient to operate, has higher andmore stable green body yield, and longer mold life, greatly reduces the use cost of the mold, shortens the entire green body molding cycle, and greatly improves production efficiency and product yield. The moisture content of green bodies shortens the drying time of the green bodies, and the degree of environmental pollution is reduced.

Owner:TANGSHAN HEXIANG INDAL

Blow molding device

A blow molding device which: comprises a blow molding mold (1) in which a bottomed cylindrical preform (PF) is fitted, a blow nozzle (13) that is fitted together with the mouth tube section (PFb) of the preform (PF) fitted in the mold (1), and a pressurized liquid-supplying unit (22) for supplying a pressurized liquid (L) to the blow nozzle (13); and molds the preform (PF) into the shape that conforms to the cavity (2) of the mold (1) by filling the liquid (L) into the preform (PF) through the blow nozzle (13). The blow nozzle (13) is characterized in: having a central hole (13d) disposed at the shaft center thereof and multiple peripheral holes (13e) formed to have smaller internal diameters than the central hole (13d) and disposed so as to surround the central hole (13d); and the liquid (L) being filled through the central hole (13d) and the multiple peripheral holes (13e) into the preform (PF).

Owner:DISCMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com