Glass bottle cold start-up rapid forming method

A forming method and rapid technology, applied in glass forming, glass blowing, glass manufacturing equipment, etc., can solve problems such as failure to open machine bottles normally, broken glass bottles, waste of materials, etc., and achieve good market promotion and application prospects, convenient The effect of adaptation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment provides a cold start-up rapid forming method for glass bottles, which is used in the preheating production stage of the line machine. The forming method includes forward blowing, blank mold cooling and mold cooling, and the opening timing of the forward blowing is controlled by The opening timing during normal production is delayed by a period of 70 units; the opening timing of the primary mold cooling is delayed by a period of 15 units from the opening timing during normal production, and the stop timing of primary mold cooling is determined by normal production. The stop timing of the time is advanced by the cycle degree of 50 units; the opening timing of the mold cooling is delayed by the cycle degree of 60 units from the opening timing of normal production; the stop timing of positive blowing and mold cooling The stop timing during normal production remains unchanged;

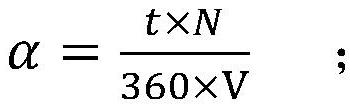

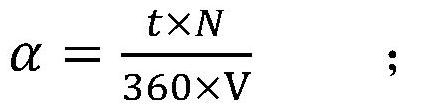

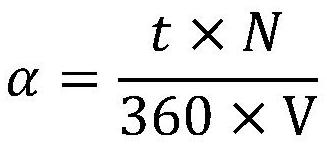

[0027] Among them, the periodicity of a unit is α, and α satisfies the following...

Embodiment 2

[0038] This embodiment provides a cold start-up rapid forming method for glass bottles, which is used in the preheating production stage of the line machine. The forming method includes forward blowing, blank mold cooling and mold cooling, and the opening timing of the forward blowing is controlled by The opening timing during normal production is delayed by a period of 80 units; the opening timing of the cooling of the primary mold is delayed by a period of 20 units from the opening timing of normal production, and the stop timing of the primary mold cooling is determined by normal production. The stop timing of the time is advanced by the cycle degree of 60 units; the opening timing of the mold cooling is delayed by the cycle degree of 70 units from the opening timing of normal production; The stop timing during normal production remains unchanged.

[0039] Among them, the periodicity of a unit is α, and α satisfies the following formula:

[0040]

[0041] Wherein, the m...

Embodiment 3

[0050]This embodiment provides a cold start-up rapid forming method for glass bottles, which is used in the preheating production stage of the line machine. The forming method includes forward blowing, blank mold cooling and mold cooling, and the opening timing of the forward blowing is controlled by The opening timing during normal production is delayed by a period of 90 units; the opening timing of the initial mold cooling is delayed by a period of 25 units from the opening timing during normal production, and the stop timing of the initial mold cooling is determined by normal production. The stop timing of the time is advanced by the cycle degree of 70 units; the opening timing of the mold cooling is delayed by the cycle degree of 80 units during normal production; the stop timing of positive blowing and mold cooling is the same as The stop timing during normal production remains unchanged.

[0051] Among them, the periodicity of a unit is α, and α satisfies the following f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com