Blow molding device

A technology of blow molding and preforms, applied in the direction of household components, applications, household appliances, etc., to achieve the effect of improving straightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments of the present invention will be illustrated and described in detail with reference to the drawings.

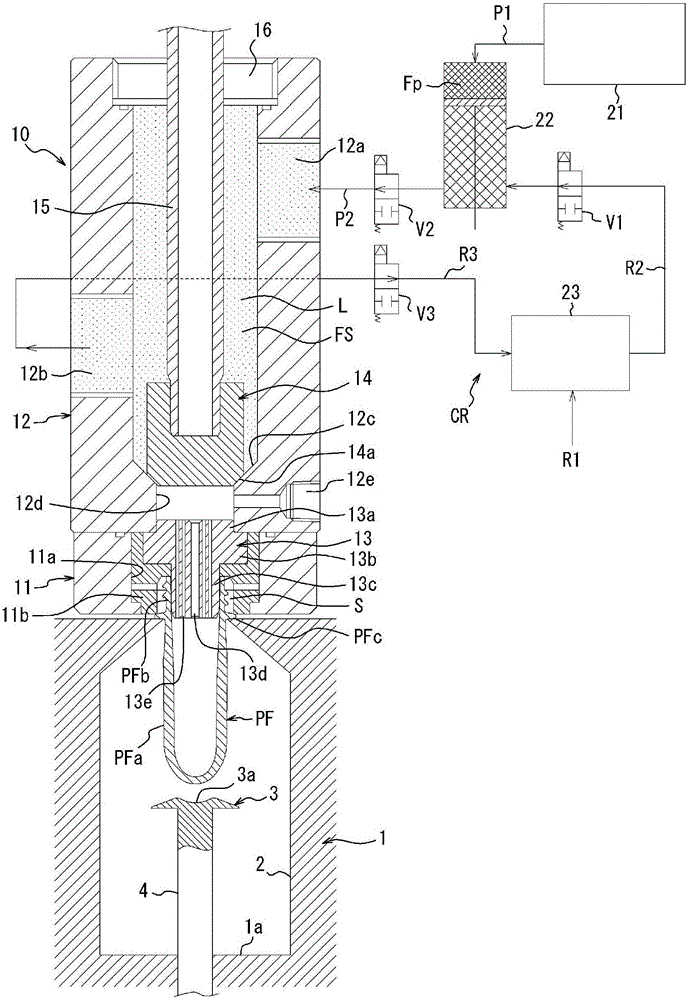

[0031] figure 1 The shown blow molding apparatus as one embodiment of the present invention has a mold 1 for blow molding. The cavity 2 of the mold 1 has an altar shape and opens upward on the upper surface of the mold 1 . Details are not shown, but the mold 1 can be opened left and right, and the molded product can be taken out from the mold 1 by opening the mold 1 .

[0032] A welcoming member (welcoming member) 3 is provided on the die 1 . The receiving member 3 is formed into a disc shape having a mountain-shaped cross-sectional shape with a concave portion 3 a on the central upper surface, and is supported by a support shaft 4 protruding from the center position of the bottom surface 1 a of the mold 1 and arranged in the cavity 2 of the mold 1 . Inside. The support shaft 4 is supported by the mold 1 so as to be movable vertically. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com