Jet forming system and method

An injection molding and molding surface technology, which is applied in the field of injection molding systems with rapid heating and cooling, can solve the problems of prolonged molding cycle, unfavorable rapid heating, affecting the heating effect of molds, etc., to improve production efficiency, facilitate temperature control, shorten The effect of the molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solution will be further described in detail below in conjunction with the accompanying drawings.

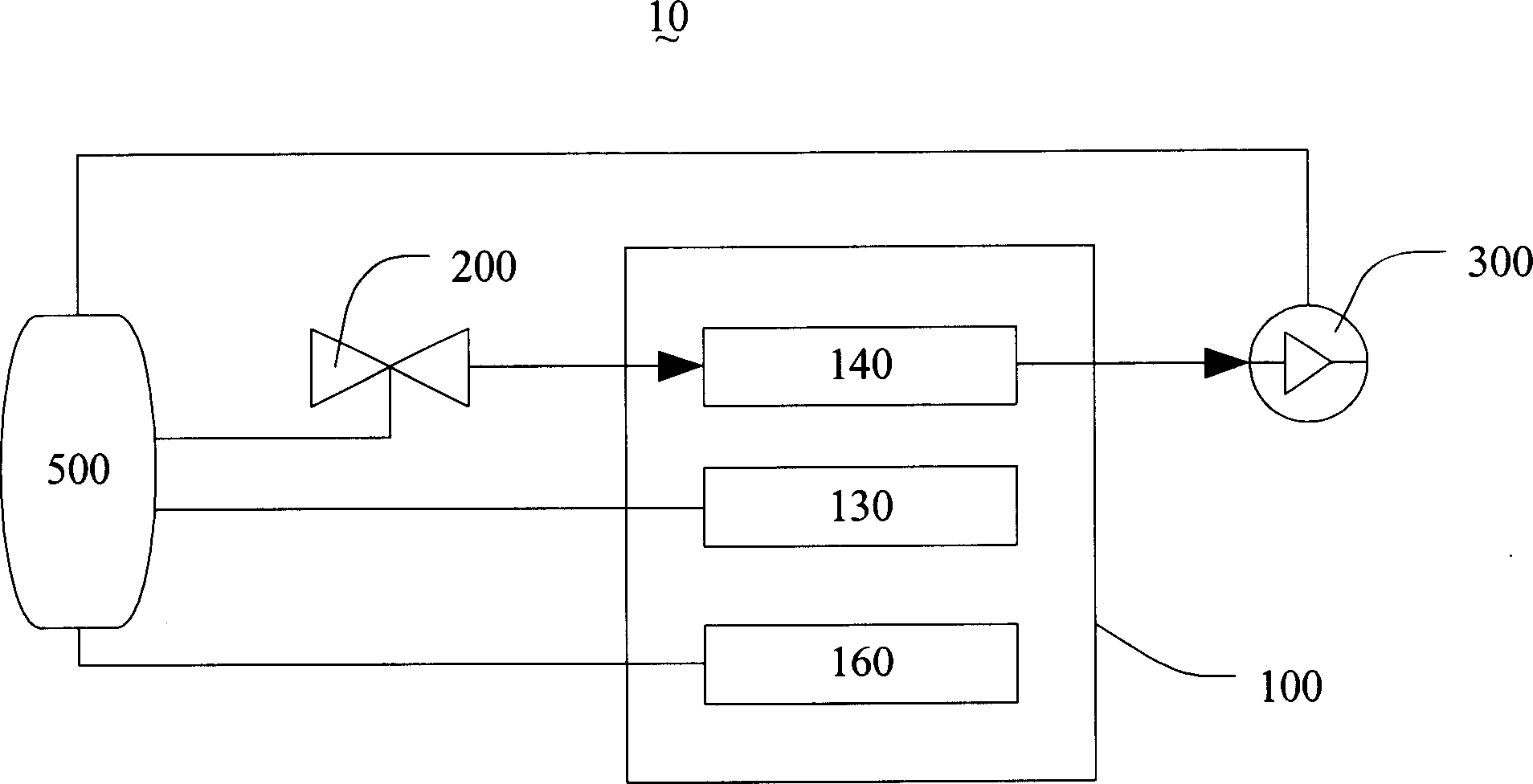

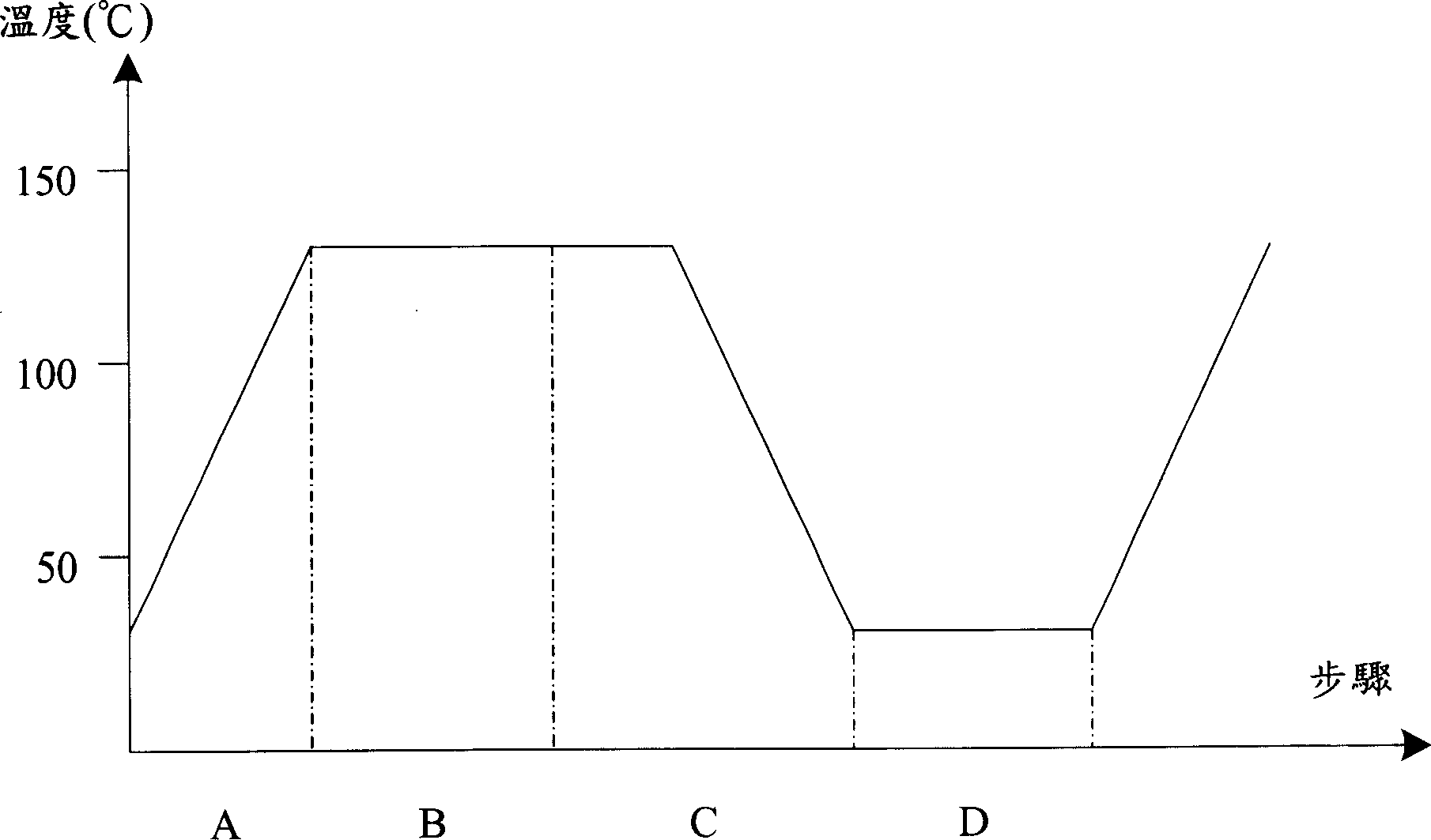

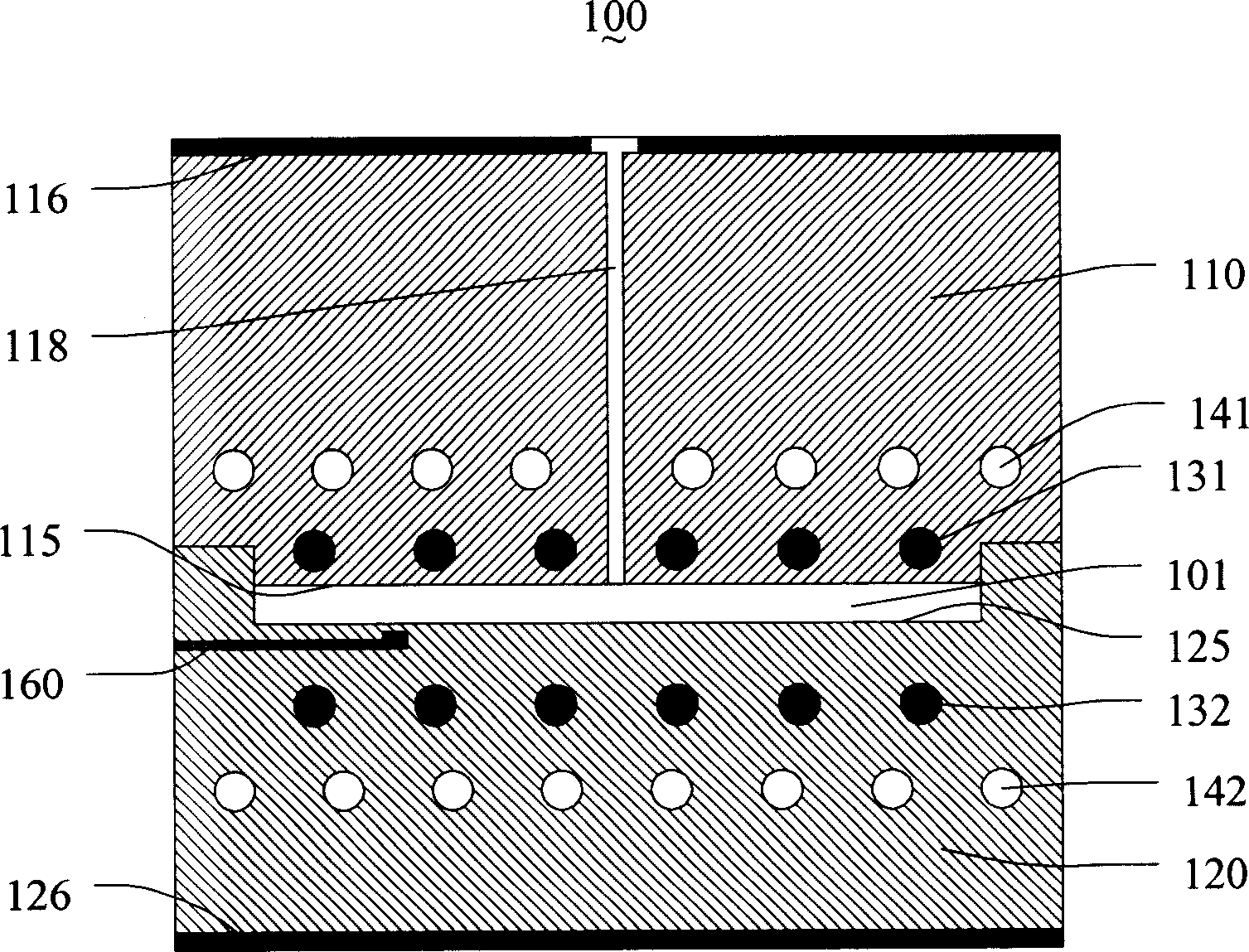

[0037] Please also refer to figure 1 and image 3 The present embodiment provides an injection molding system 10, which includes a molding mold 100 with a heating device 130, a cooling channel 140, and a temperature sensing device 160 inside; one end of the cooling channel 140 is connected to a valve device 200, The other end is connected with a negative pressure device 300 ; and a control device 500 connected with the heating device 130 , the temperature sensing device 160 , the valve device 200 and the negative pressure device 300 . The heating device 130 can use an electric heating device or a high-frequency induction heating device, such as an electric heating rod, an electric heating plate, a high-frequency oscillation sensor, etc., to heat up the forming mold 100 through heating. The cooling channel 140 can be a plurality of parallel through holes or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com