Mould requiring no thimble to participate in molding process

A thimble and mold technology, which is applied in the field of injection molds, can solve the problems of large labor costs, affecting product quality, and low production efficiency, and achieve the effects of reducing labor costs, reducing manpower input, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

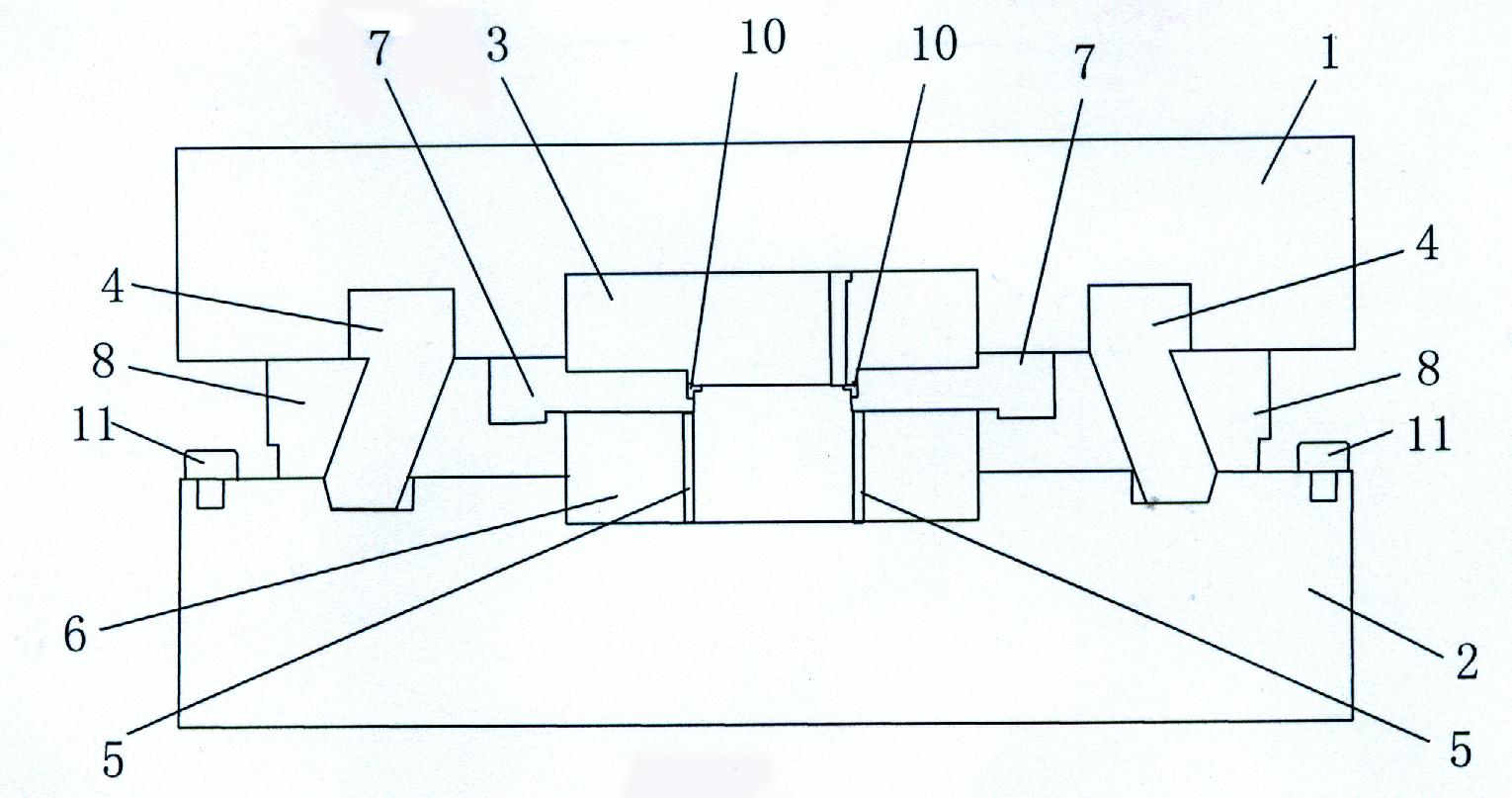

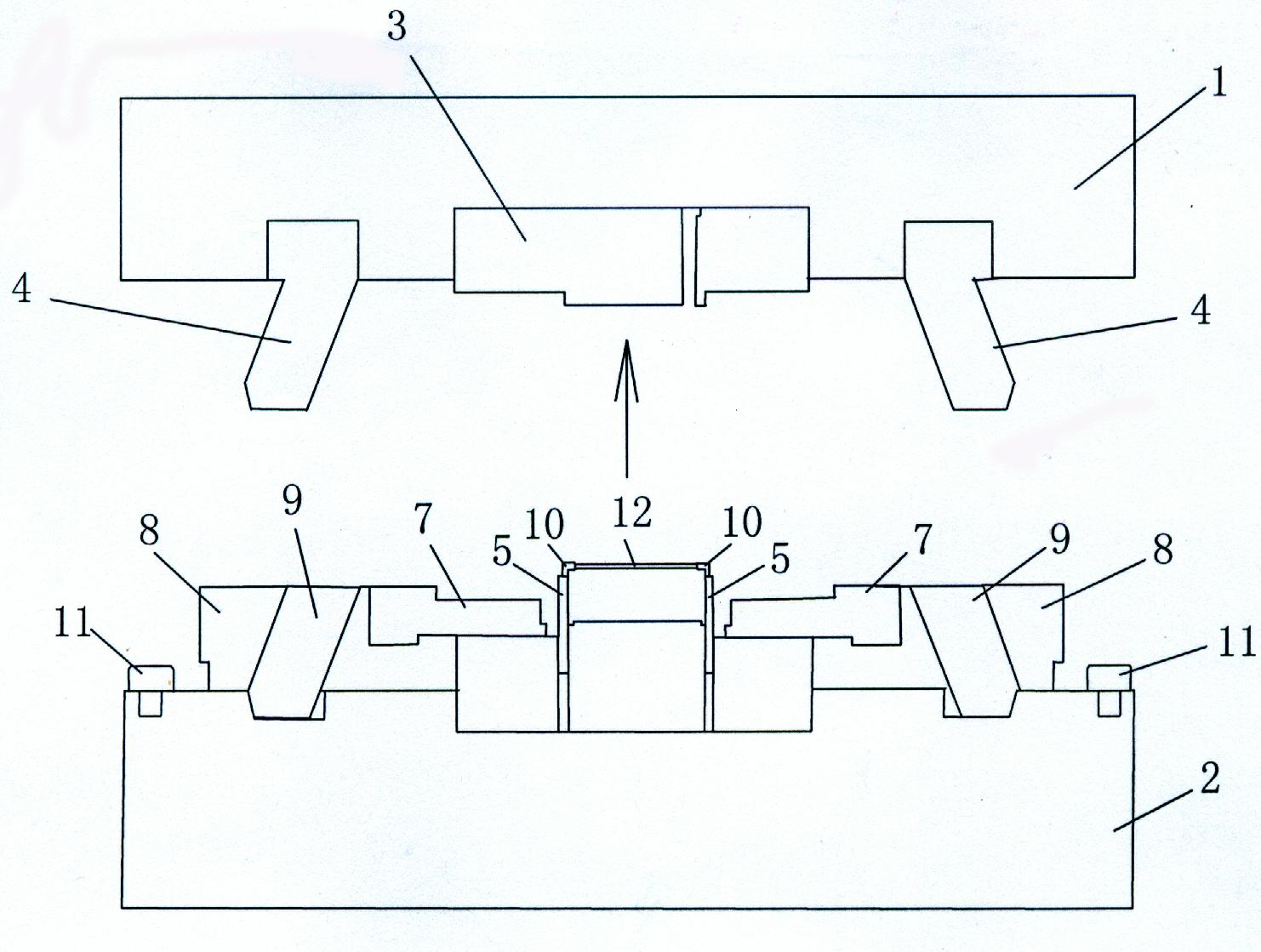

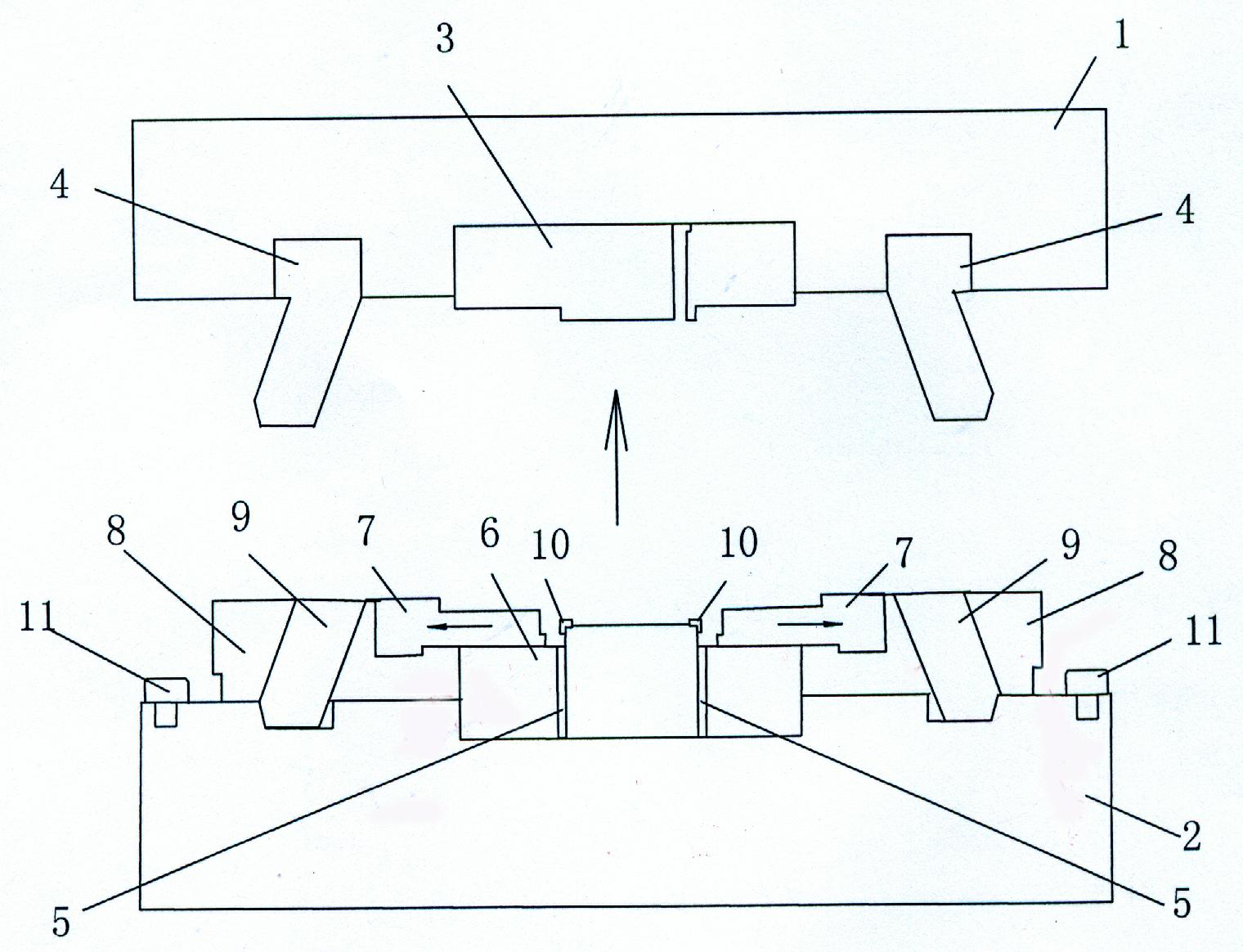

[0025] Below, in conjunction with the accompanying drawings, the specific implementation manners of the present invention will be introduced.

[0026] Such as figure 1 , figure 2 and image 3 As shown, a mold in which the thimble does not participate in the molding of the present invention includes a movable mold 1 located above and a fixed mold 2 located below;

[0027] The front mold core 3 is set on the movable mold 1, and the slider beam blocks 4 are arranged symmetrically on the dynamic mold 1 on the left and right sides of the front mold core 3, and the slider bundle pieces 4 on the left protrude downward and extend downward from top to bottom. The left side is inclined, and the slider beam block 4 on the right protrudes downward and is inclined from top to bottom to the right.

[0028] A product cavity is set on the fixed mold 2, and thimbles 5 are symmetrically arranged on the left and right sides of the product cavity, and the product cavity and the symmetrically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com