Carbon fiber conductive enhanced PET/polyester alloy and preparation method thereof

A technology of polyester alloy and conductive enhancement, which is applied in the field of carbon fiber conductive reinforced PET/polyester alloy and its preparation, can solve the problems of carbon fiber reinforcement and conductive effect not fully exerted, and unsatisfactory mechanical properties, so as to achieve enhanced mechanical properties and improve Mechanical properties, the effect of high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

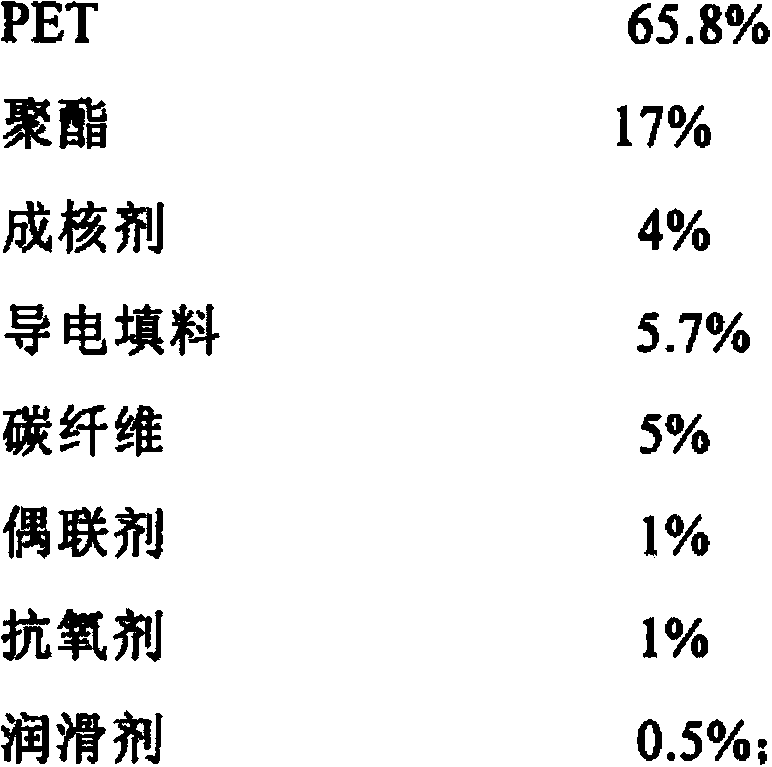

[0058] A conductive carbon fiber reinforced PET / polyester alloy, calculated by weight percentage, the composition and content of its raw materials are as follows:

[0059]

[0060] PET is polyethylene terephthalate with a viscosity of 0.8-0.9dl / g;

[0061] The polyester is polyethylene-2,6-naphthalate;

[0062] The nucleating agent is Surlyn8920;

[0063] The conductive filler may be one or a mixture of more than one of natural flake graphite powder, artificial graphite powder, expanded graphite, carbon black, and conductive metal powder;

[0064] The carbon fiber has a tensile strength of 5200MPa, and the carbon fiber grade is T700;

[0065] Coupling agent is silane coupling agent KH-570;

[0066] Antioxidant is a mixture of antioxidant 168 and antioxidant 1010 in a ratio of 3:7;

[0067] The lubricant is paraffin wax.

[0068] The above-mentioned preparation method of conductive carbon fiber reinforced PET / polyester alloy specifically includes the following steps:

[0069] (1) Put 34.8% PE...

Embodiment 2

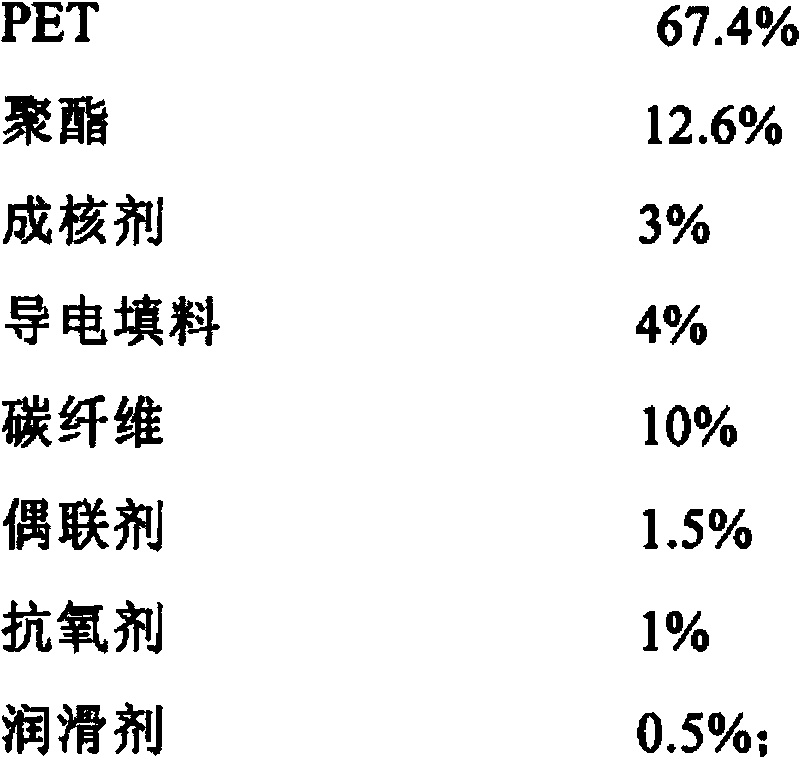

[0073] A conductive carbon fiber reinforced PET / polyester alloy, calculated by weight percentage, the composition and content of its raw materials are as follows:

[0074]

[0075] PET is polyethylene terephthalate with a viscosity of 0.8-0.9dl / g;

[0076] The polyester is polytrimethylene terephthalate;

[0077] The nucleating agent is Surlyn8920;

[0078] The conductive filler may be one or a mixture of more than one of natural flake graphite powder, artificial graphite powder, expanded graphite, carbon black, and conductive metal powder;

[0079] The carbon fiber has a tensile strength of 5200MPa, and the carbon fiber grade is T700;

[0080] Compatibilizer is silane coupling agent KH-570;

[0081] Antioxidant is a mixture of antioxidant 168 and antioxidant 1010 in a ratio of 3:7;

[0082] The lubricant is polyethylene wax.

[0083] The above-mentioned preparation method of conductive carbon fiber reinforced PET / polyester alloy specifically includes the following steps:

[0084] (1) Put 37...

Embodiment 3

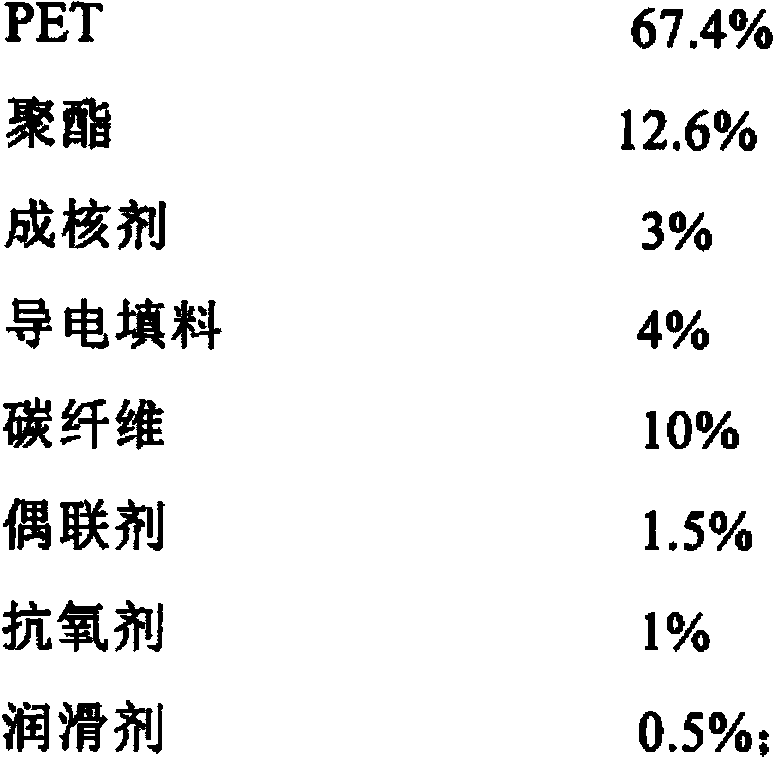

[0088] A conductive carbon fiber reinforced PET / polyester alloy, calculated by weight percentage, the composition and content of its raw materials are as follows:

[0089]

[0090] PET is polyethylene terephthalate with a viscosity of 0.8-0.9dl / g;

[0091] The polyester is polybutylene terephthalate;

[0092] The nucleating agent is Surlyn8920;

[0093] The conductive filler may be one or a mixture of more than one of natural flake graphite powder, artificial graphite powder, expanded graphite, carbon black, and conductive metal powder;

[0094] The carbon fiber has a tensile strength of 5200MPa, and the carbon fiber grade is T700;

[0095] Compatibilizer is silane coupling agent KH-570;

[0096] Antioxidant is a mixture of antioxidant 168 and antioxidant 1010 in a ratio of 3:7;

[0097] The lubricant is polyethylene wax.

[0098] The above-mentioned preparation method of conductive carbon fiber reinforced PET / polyester alloy specifically includes the following steps:

[0099] (1) Put 37.4% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com