A kind of rapid prototyping method of glass bottle cold machine

A molding method and fast technology, applied in glass molding, glass blowing, glass manufacturing equipment, etc., can solve problems such as unfavorable glass bottle molding, glass bottle breakage, waste of materials, etc., to speed up the rapid molding cycle and avoid material waste , The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a method for rapid prototyping of glass bottles with cold start-up, which is used in the preheating production stage of an inline machine. The molding method includes positive air blowing, preliminary mold cooling, and mold cooling. The opening timing of normal production is delayed by 70 units of cycle; the opening timing of the initial mold cooling is delayed by 15 units of the cycle from the opening timing of normal production, and the stopping timing of initial mold cooling is delayed by normal production. The stop timing is 50 units ahead of time; the mold cooling start timing is delayed 60 units of the cycle from the normal production start timing; the positive blowing and mold cooling stop timings are the same as The stop timing of normal production remains unchanged;

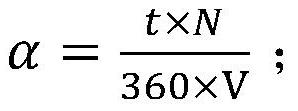

[0027] Among them, the periodicity of one unit is α, and α satisfies the following formula:

[0028]

[0029] The meaning of each symbol in the formula is as fo...

Embodiment 2

[0038] The present embodiment provides a method for rapid prototyping of glass bottles with cold start-up, which is used in the preheating production stage of an inline machine. The molding method includes positive air blowing, preliminary mold cooling, and mold cooling. The opening timing during normal production is delayed by 80 units of the cycle; the opening timing of the initial mold cooling is delayed by 20 units of the cycle from the opening timing during normal production, and the stopping timing of the initial mold cooling is delayed by normal production. The stop timing is 60 units ahead of time; the mold cooling start timing is delayed by 70 units from the normal production start timing; the positive blowing and mold cooling stop timings are the same as The stop timing during normal production remains unchanged.

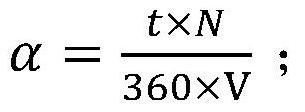

[0039] Among them, the periodicity of one unit is α, and α satisfies the following formula:

[0040]

[0041] The meaning of each symbol in the formul...

Embodiment 3

[0050]The present embodiment provides a method for rapid prototyping of glass bottles with cold start-up, which is used in the preheating production stage of an inline machine. The molding method includes positive air blowing, preliminary mold cooling, and mold cooling. The opening timing during normal production is delayed by 90 units of cycle; the opening timing of the initial mold cooling is delayed by 25 units of the cycle during normal production, and the stopping timing of initial mold cooling is delayed by normal production. The stop timing is 70 units ahead of time; the mold cooling start timing is delayed by 80 units from the normal production start timing; the positive blowing and mold cooling stop timings are the same as The stop timing during normal production remains unchanged.

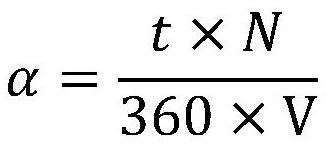

[0051] Among them, the periodicity of one unit is α, and α satisfies the following formula:

[0052]

[0053] The meaning of each symbol in the formula is as follows:

[0054] α: Tak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com