High-friction-coefficient polyamide material and preparing method and application thereof

A high friction coefficient, polyamide technology, applied in the field of wear-resistant materials, can solve the problems of small friction damping, increased damping and energy dissipation capacity, and complexity of side bearing wear plates, and achieve good wear resistance and high dynamic friction coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

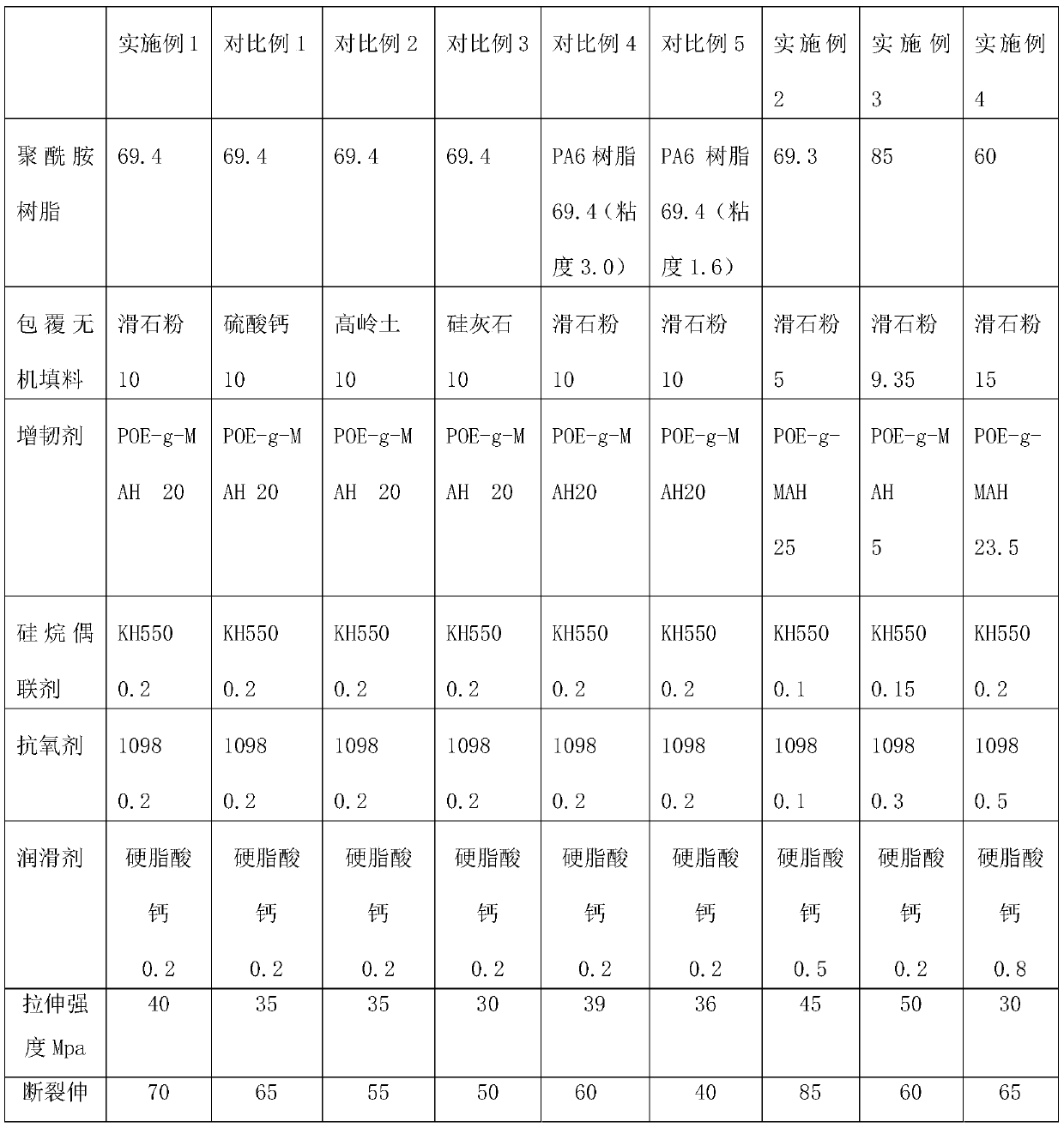

[0035] Embodiment 1: Preparation of high friction coefficient polyamide material

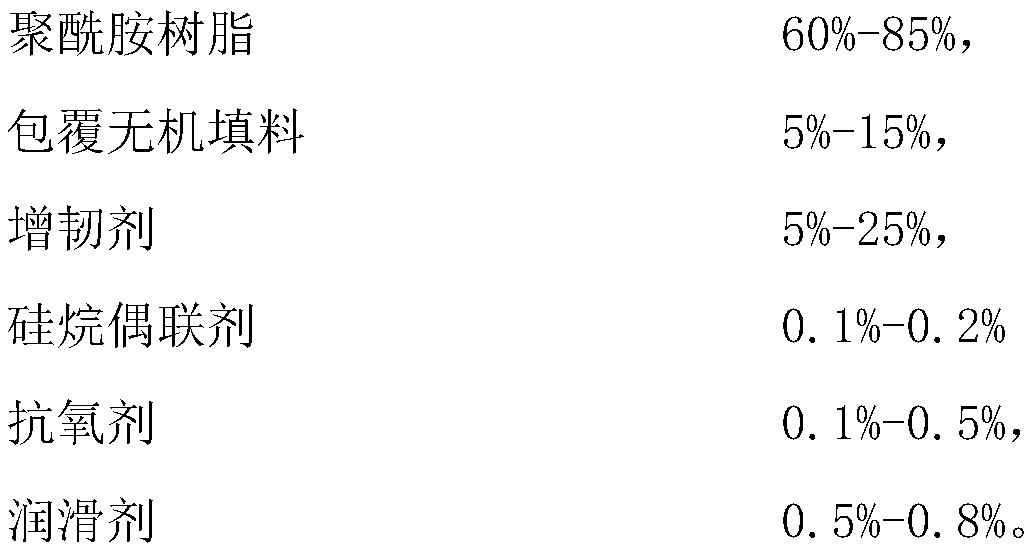

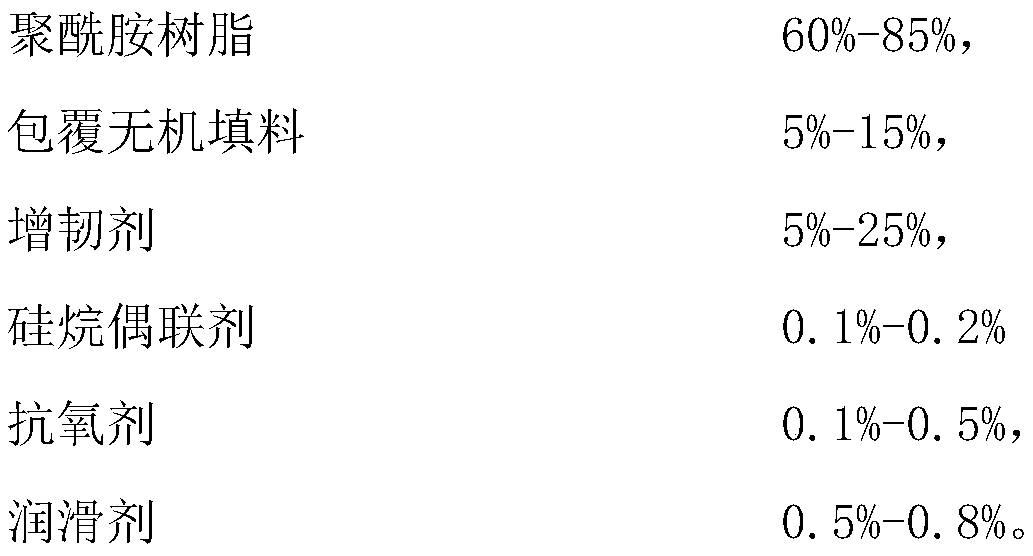

[0036] Raw materials: see Table 1

[0037] Preparation method: Add PA6 resin, coated inorganic filler, toughening agent, antioxidant and lubricant into a high-speed mixer for stirring

[0038] The mixture obtained above is granulated through a co-rotating intermeshing twin-screw extruder to prepare a polyamide material with a high coefficient of friction.

[0039] The obtained polyamide material with high friction coefficient was injection molded into a flat plate, and the basic mechanical properties were measured by proofing. The static friction coefficient test was carried out according to the ISO8295 standard, as shown in Table 1.

Embodiment 2

[0040] Embodiment 2: Preparation of high friction coefficient polyamide material

[0041] Raw materials: see Table 1

[0042] Preparation method: with embodiment 1

[0043] The obtained polyamide material with high friction coefficient was injection molded into a flat plate, and the basic mechanical properties were measured by proofing. The static friction coefficient test was carried out according to the ISO8295 standard, as shown in Table 1.

Embodiment 3

[0044] Embodiment 3: Preparation of high friction coefficient polyamide material

[0045] Raw materials: see Table 1

[0046] Preparation method: with embodiment 1

[0047] The obtained polyamide material with high friction coefficient was injection molded into a flat plate, and the basic mechanical properties were measured by proofing. The static friction coefficient test was carried out according to the ISO8295 standard, as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com