Synchronous ring for synchronizer and method for manufacturing synchronous ring

A manufacturing method and technology of synchronous rings, applied in the direction of manufacturing tools, clutches, mechanically driven clutches, etc., can solve the problems of insufficient dynamic friction coefficient, poor anti-overload ability, low material utilization rate, etc., and achieve low cost, no machining, and materials The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

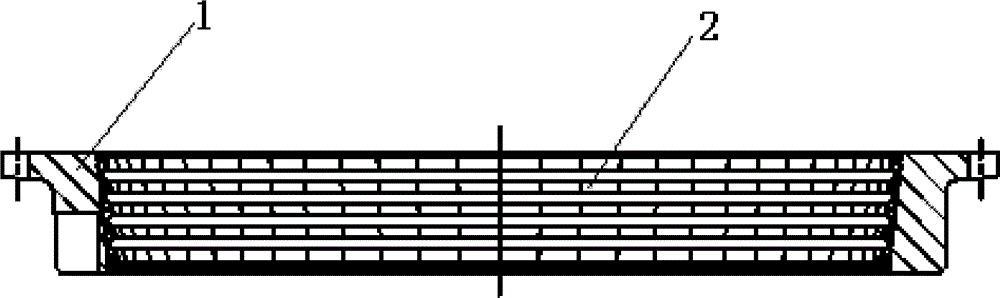

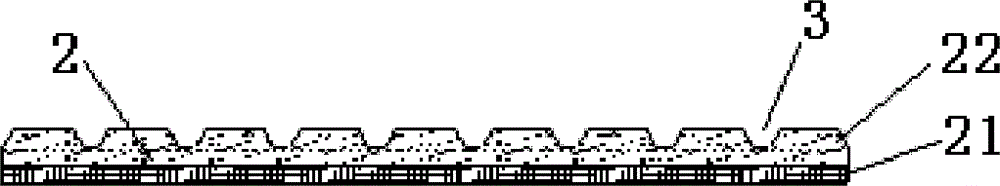

[0029] Embodiment 1: A synchronous ring for a synchronizer is provided, including a synchronous ring base 1 , and a friction plate 2 is provided inside the synchronous ring base 1 , and the friction plate 2 is composed of a soft base layer 21 and a friction layer 22 . By replacing the existing hard friction layer structure with the combined structure of the soft base layer 21 and the friction layer 22, the anti-overload performance of the synchronous ring is improved. The surface of the friction layer 22 is provided with an oil discharge groove 3 . The thickness of the friction plate 2 is 0.5mm˜1mm.

[0030] A method for manufacturing a synchronizer ring for a synchronizer, comprising the following steps:

[0031] (1) Mix artificial graphite and friction additive with resin powder evenly to make a friction layer mixture, wherein the mass ratio of artificial graphite is 45% to 63%, the mass ratio of friction additive is 25% to 42%, and the resin powder The mass ratio of the f...

Embodiment 2

[0036] Embodiment 2: A synchronous ring for a synchronizer is provided, including a synchronous ring base 1 , and a friction plate 2 is provided inside the synchronous ring base 1 , and the friction plate 2 is composed of a soft base layer 21 and a friction layer 22 . By replacing the existing hard friction layer structure with the combined structure of the soft base layer 21 and the friction layer 22, the anti-overload performance of the synchronous ring is improved. The surface of the friction layer 22 is provided with an oil discharge groove 3 . The thickness of the friction plate 2 is 0.5mm˜1mm.

[0037] A method for manufacturing a synchronizer ring for a synchronizer, comprising the following steps:

[0038] (1) Mix artificial graphite and friction additive with resin powder evenly to make a friction layer mixture, wherein the mass ratio of artificial graphite is 45% to 63%, the mass ratio of friction additive is 25% to 42%, and the resin powder The mass ratio of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com