Zr alloying Ti-8Si alloy and preparing method thereof

An alloying and alloying technology, applied in the field of materials, can solve the problem that the overall performance of the titanium-silicon alloy cannot meet the requirements of use, and achieve the effects of easy realization, excellent economy, oxidation resistance and friction and wear performance improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

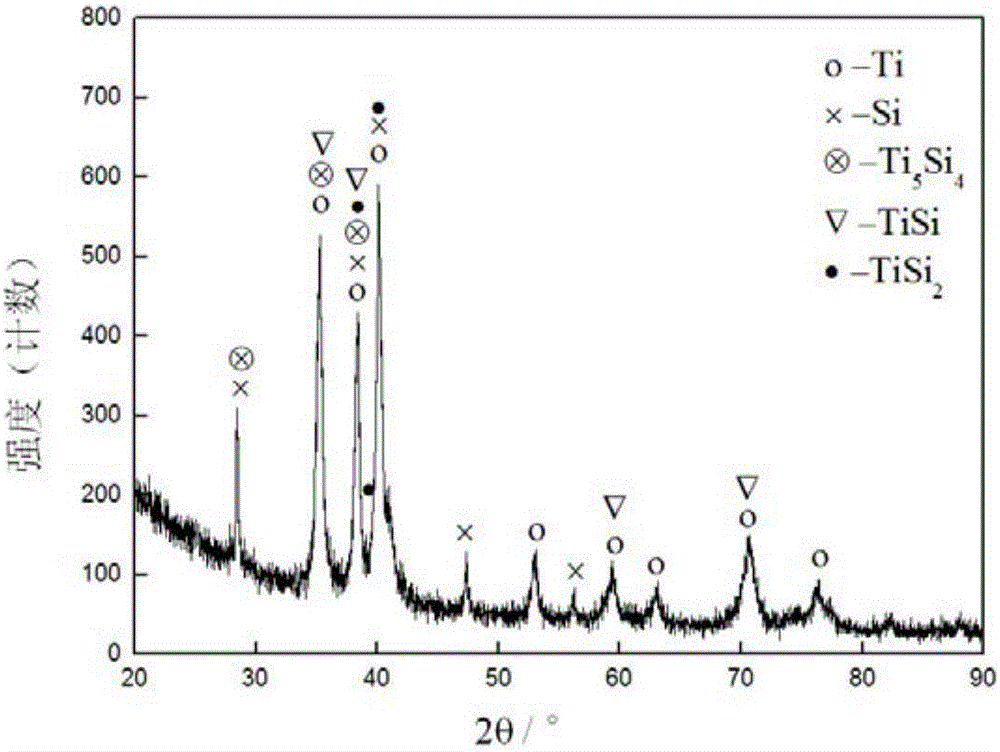

[0034] Such as figure 1 , 2 , 5, and 6.

[0035] A Zr alloyed Ti-8Si alloy Ti-8Si-0.7Zr, which is prepared by the following steps:

[0036] First, prepare 30g of Ti, Si, Zr elemental mixed powder, wherein Ti powder 91.3wt.% (27.39g), Si powder 8wt.% (2.4g), Zr powder 0.7wt.% (0.21g), the mixed powder Place in a beaker and stir well;

[0037] Secondly, first weigh 240g of agate balls and place them in a 500ml nylon ball mill jar according to the ball-to-material ratio of 8:1, then place the weighed and evenly mixed mixed powder in a nylon ball mill jar, and seal it with a cover;

[0038] Then, install the ball milling jar on the planetary ball mill, start ball milling, the ball milling parameter is set to 300r / min, stop 15min every 1h of ball milling, after ball milling for 48h, take out the powder in the ball milling jar;

[0039] Further, pass the mixed powder taken out through a 300-mesh sieve to obtain a powder with uniform particle size, and place it in a vacuum drying...

Embodiment 2

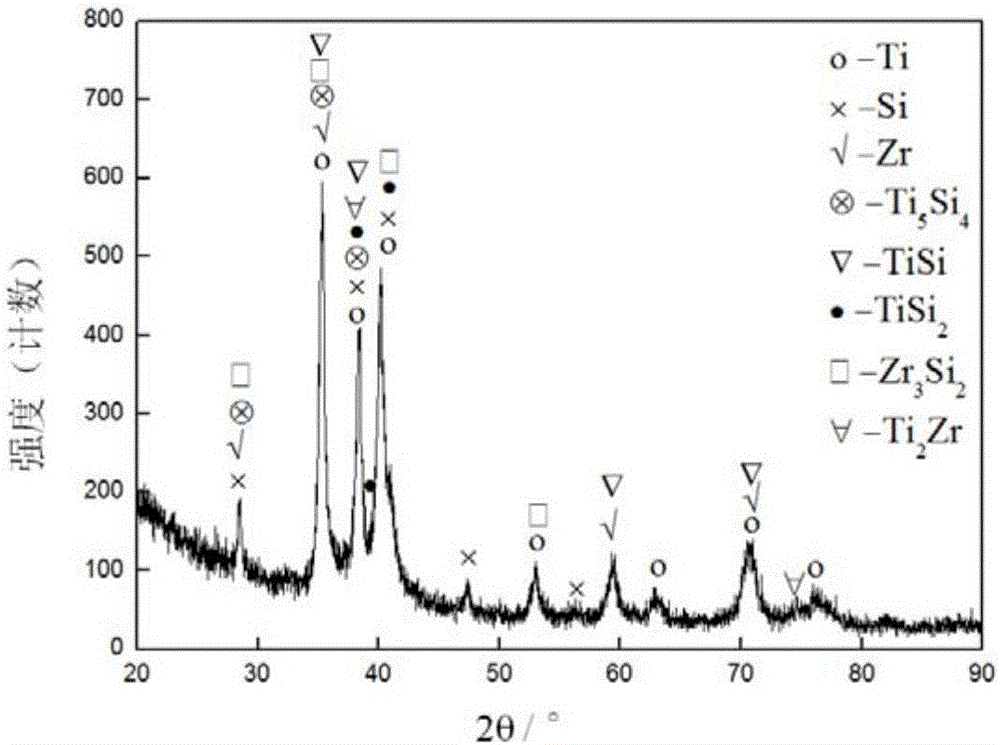

[0045] Such as figure 1, 3 , 5, and 7.

[0046] A Zr alloyed Ti-8Si alloy Ti-8Si-1.4Zr, its preparation method is basically the same as that of Example 1, except that the mass fraction of Zr powder is increased to 1.4wt from 0.7wt.% (0.21g) .% (0.42g), correspondingly, the mass fraction of Ti powder decreased from 91.3wt.% (27.39g) to 90.6wt.% (27.18g).

[0047] The mechanical alloying phenomenon of Ti-8Si-0.7Zr mixed powder prepared by the above steps is obvious, image 3 It is the XRD diffraction pattern of the Ti-8Si-1.4Zr powder obtained after high-energy ball milling in this example. After analysis, except for the detection of Ti 5 Si 4 , TiSi and TiSi 2 The formation of three titanium silicon compounds, and Ti 2 Zr, and Zr 3 Si 2 and other compounds; Figure 7 It is the XRD diffraction pattern of the Ti-8Si-1.4Zr alloy obtained after vacuum pressureless sintering. 5 Si 4 、TiSi 2 、Ti 2 Zr or Zr 3 Si 2 In addition to the phase of matter, there is also a new ...

Embodiment 3

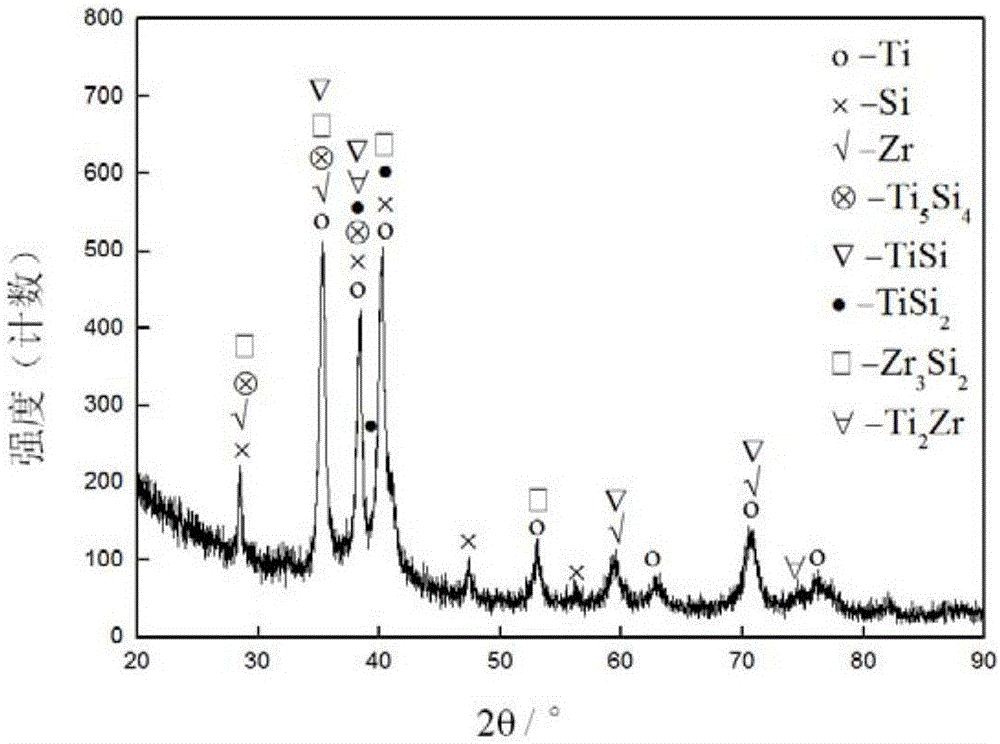

[0049] Such as figure 1 , 4 , 5, and 8.

[0050] A kind of Zr alloyed Ti-8Si alloy Ti-8Si-2.8Zr, its preparation method is basically the same as embodiment one, the difference is that the mass fraction of Zr powder is increased to 2.8wt by 0.7wt.% (0.21g) .% (0.84g), correspondingly, the mass fraction of Ti powder decreased from 91.3wt.% (27.39g) to 89.2wt.% (26.76g).

[0051] The mechanical alloying phenomenon of Ti-8Si-2.8Zr mixed powder prepared by the above steps is obvious, Figure 4 It is the XRD diffraction pattern of the Ti-8Si-1.4Zr powder obtained after high-energy ball milling in this example. After analysis, except for the detection of Ti 5 Si 4 , TiSi and TiSi 2 The formation of three titanium silicon compounds, and Ti 2 Zr, and Zr 3 Si 2 and other compounds; Figure 8 It is the XRD diffraction pattern of the Ti-8Si-1.4Zr alloy obtained after vacuum pressureless sintering. 5 Si 4 、TiSi 2 、Ti 2 Zr or Zr 3 Si 2 In addition to the phase of matter, ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com