A kind of Cu-alloyed Ti-8Si alloy and preparation method thereof

An alloying and ti-8si technology, applied in the field of materials, can solve the problems of low overall performance of titanium-silicon alloys, and achieve the effects of excellent economy, simple operation, and improved friction and wear properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

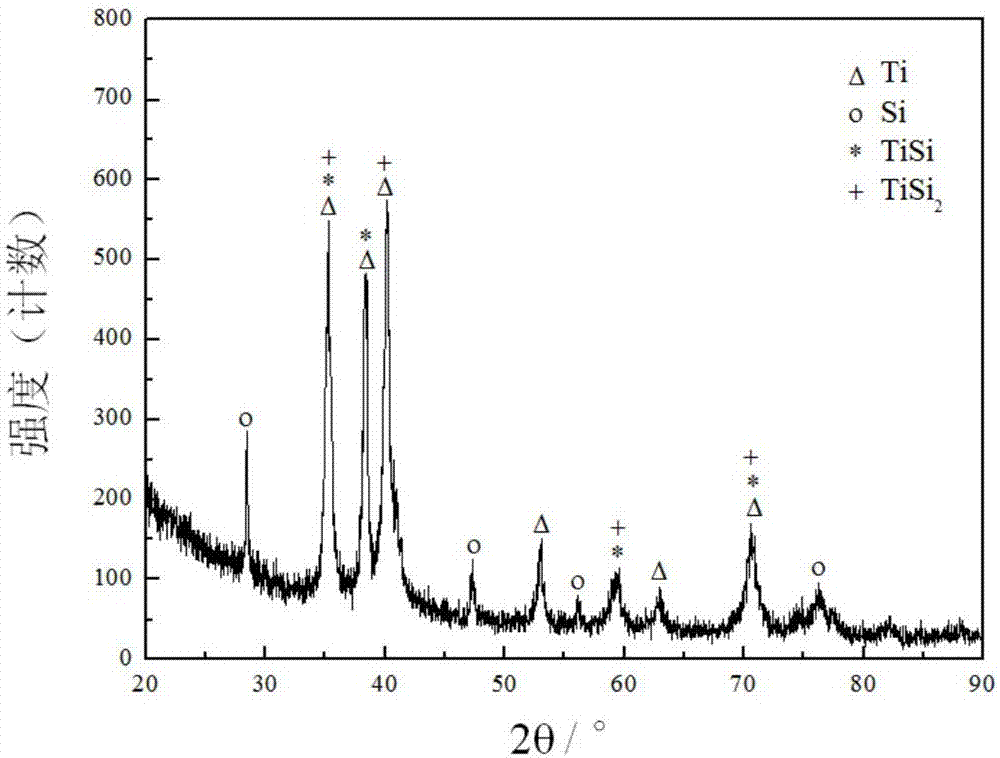

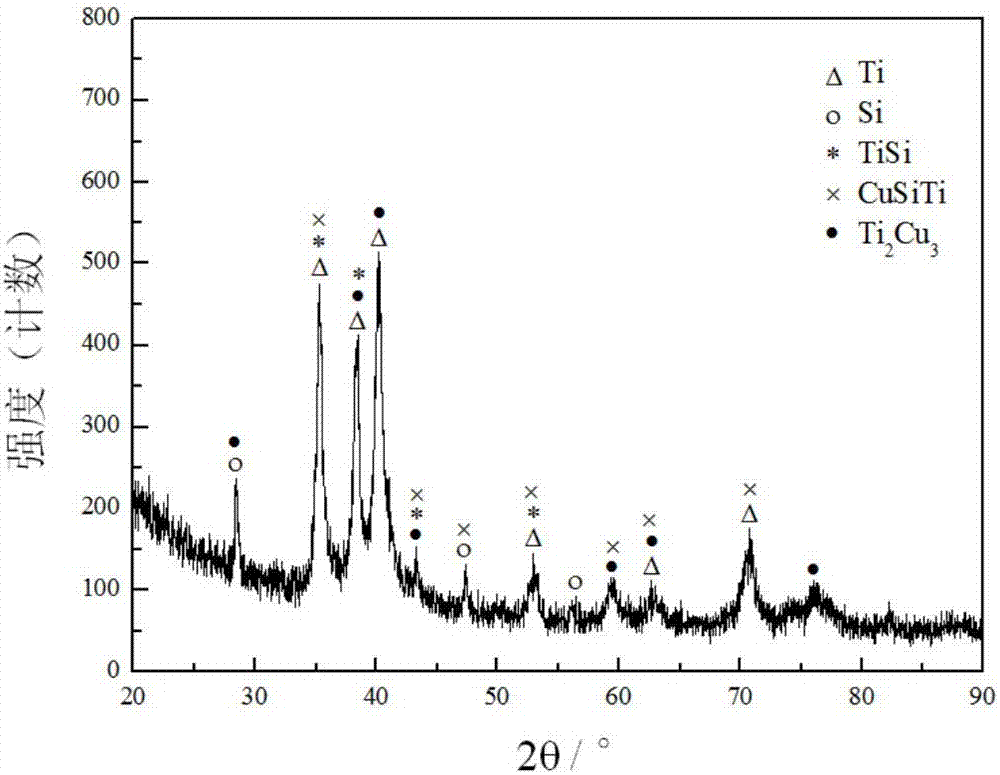

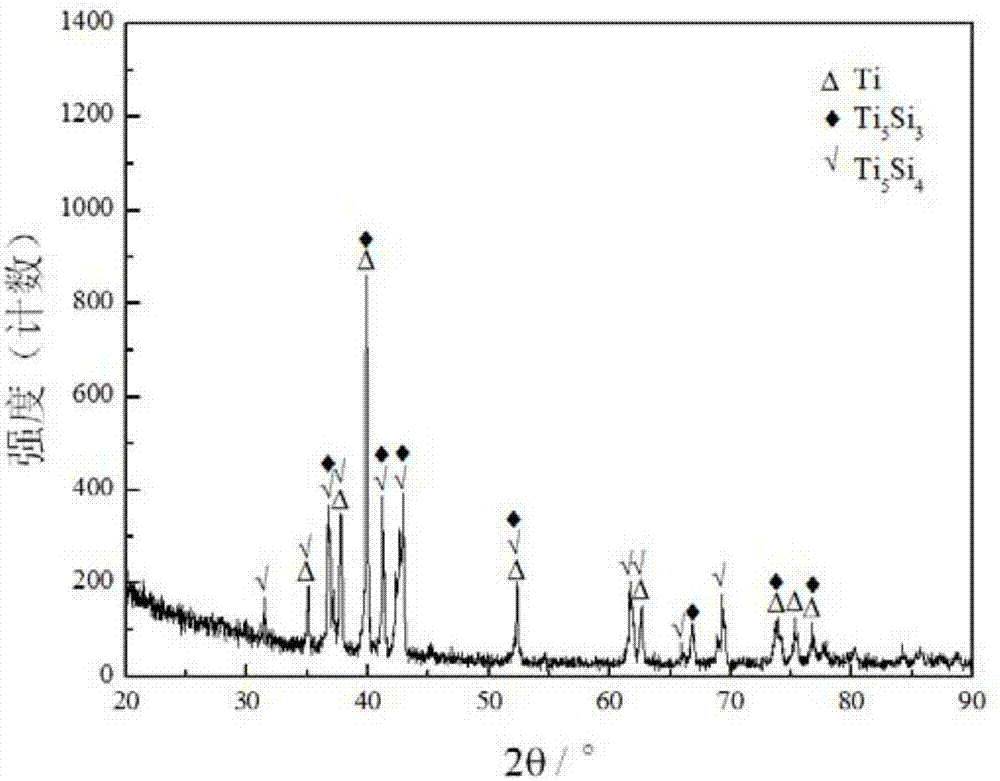

[0030] Such as Figure 1~4 shown.

[0031] A preparation method of Cu-alloyed Ti-8Si alloy Ti-7.6Si-5Cu:

[0032] First, prepare 30g of Ti, Si, Cu single substance mixed powder, wherein Ti powder 87.4wt.% (26.22g), Si powder 7.6wt.% (2.28g), Cu powder 5wt.% (1.5g), the mixed powder Place in a beaker and stir well;

[0033] Secondly, first weigh 240g of agate balls and place them in a 500ml nylon ball mill jar according to the ball-to-material ratio of 8:1, then place the weighed and evenly mixed mixed powder in a nylon ball mill jar, and seal it with a cover;

[0034] Then, install the ball mill jar on the planetary ball mill, start the ball mill, the ball mill parameter is set to 300r / min, the ball mill stops for 10 minutes after 30 minutes, and after grinding for 48 hours, take out the powder in the ball mill jar;

[0035] Further, put the mixed powder taken out in a vacuum drying oven, heat it up to 60°C with the drying oven, keep it warm for more than 4 hours, and pass ...

Embodiment 2

[0046] A preparation method of Cu-alloyed Ti-8Si alloy Ti-7.2Si-10Cu:

[0047] First, prepare 30g of Ti, Si, Cu single substance mixed powder, wherein Ti powder 24.84g, Si powder 2.16g, Cu powder 3g), the mixed powder is placed in a beaker and stirred evenly;

[0048] Secondly, first weigh 300g of agate balls and place them in a 500ml nylon ball mill jar according to the ball-to-material ratio of 10:1, then place the weighed and evenly mixed mixed powder in the nylon ball mill jar, and seal it with a cover;

[0049] Then, install the ball milling jar on the planetary ball mill, start ball milling, the ball milling parameter is set to 350r / min, every ball milling 30min stop 10min, after ball milling 50h, take out the powder in the ball milling jar;

[0050] Further, put the mixed powder taken out in a vacuum drying oven, heat the drying oven to at least 60°C for 4 hours, and pass through a 300-mesh sieve to obtain the desired powder;

[0051] After that, the obtained powder is...

Embodiment 3

[0056] A preparation method of Cu-alloyed Ti-8Si alloy Ti-6.4Si-20Cu:

[0057] First, prepare 30g of Ti, Si, Cu simple substance mixed powder, wherein Ti powder 22.08g, Si powder 1.92g, Cu powder 6g), the mixed powder is placed in a beaker and stirred evenly;

[0058] Secondly, first weigh 360g of agate balls and place them in a 500ml nylon ball milling jar according to the ball-to-material ratio of 12:1, then place the weighed and evenly mixed mixed powder in a nylon ball milling jar, cover and seal;

[0059] Then, install the ball milling jar on the planetary ball mill, start ball milling, the ball milling parameter is set to 400r / min, the ball milling is 30min and stop for 10min, after ball milling for 55h, take out the powder in the ball milling jar;

[0060] Further, put the mixed powder taken out in a vacuum drying oven, heat the drying oven to at least 60°C for 4 hours, and pass through a 300-mesh sieve to obtain the desired powder;

[0061] Afterwards, the obtained po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com