Fixed efficient vibration static-pressure forming machine

A molding machine, fixed technology, applied in ceramic molding machines, supply devices, unloading devices, etc., can solve the problems of low mixing amount, strength and compactness difficult to meet the requirements of building standards, etc., to improve the molding cycle, Guarantee the effect of targeted release and utilization and product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1 (being commonly called as whole body product)

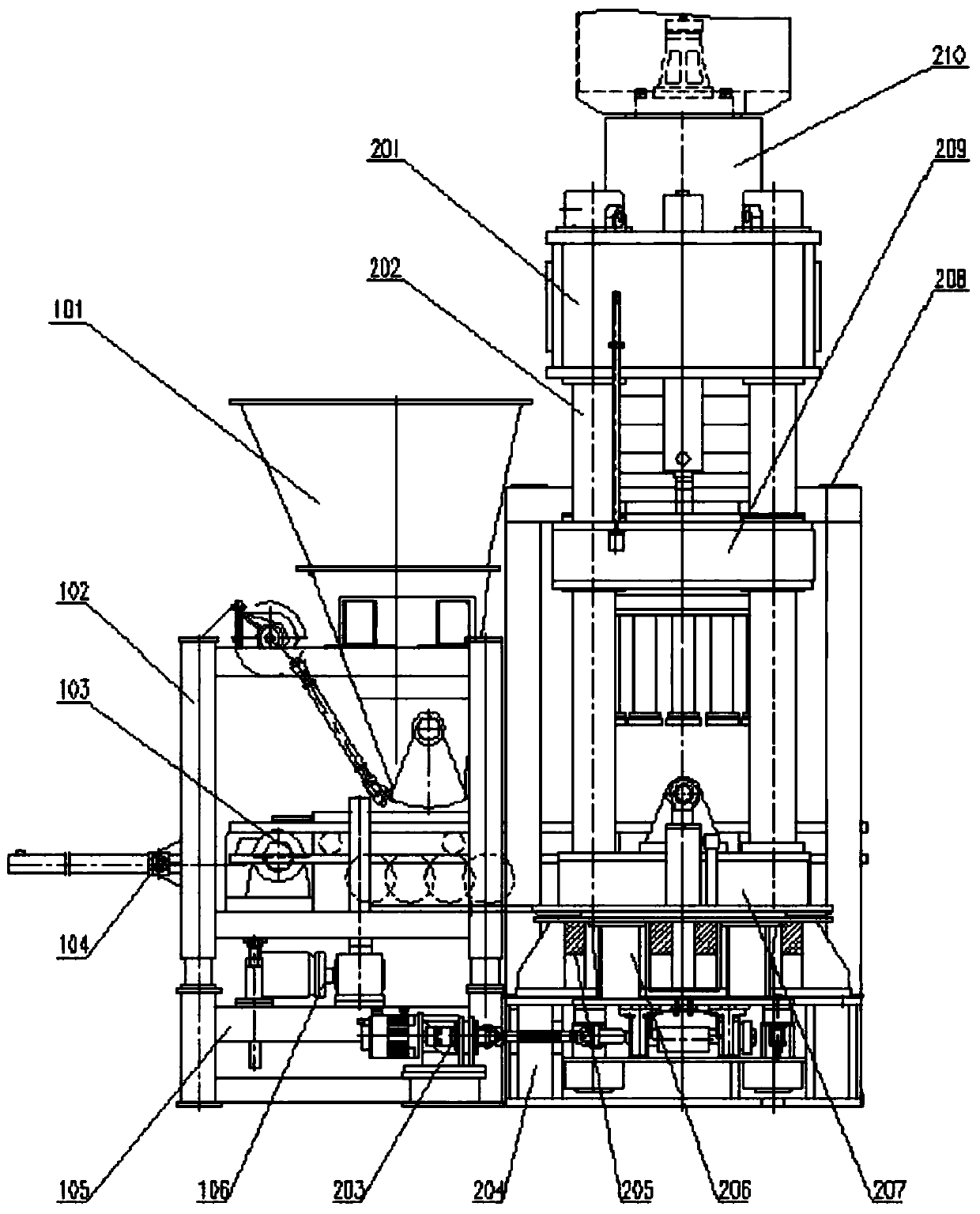

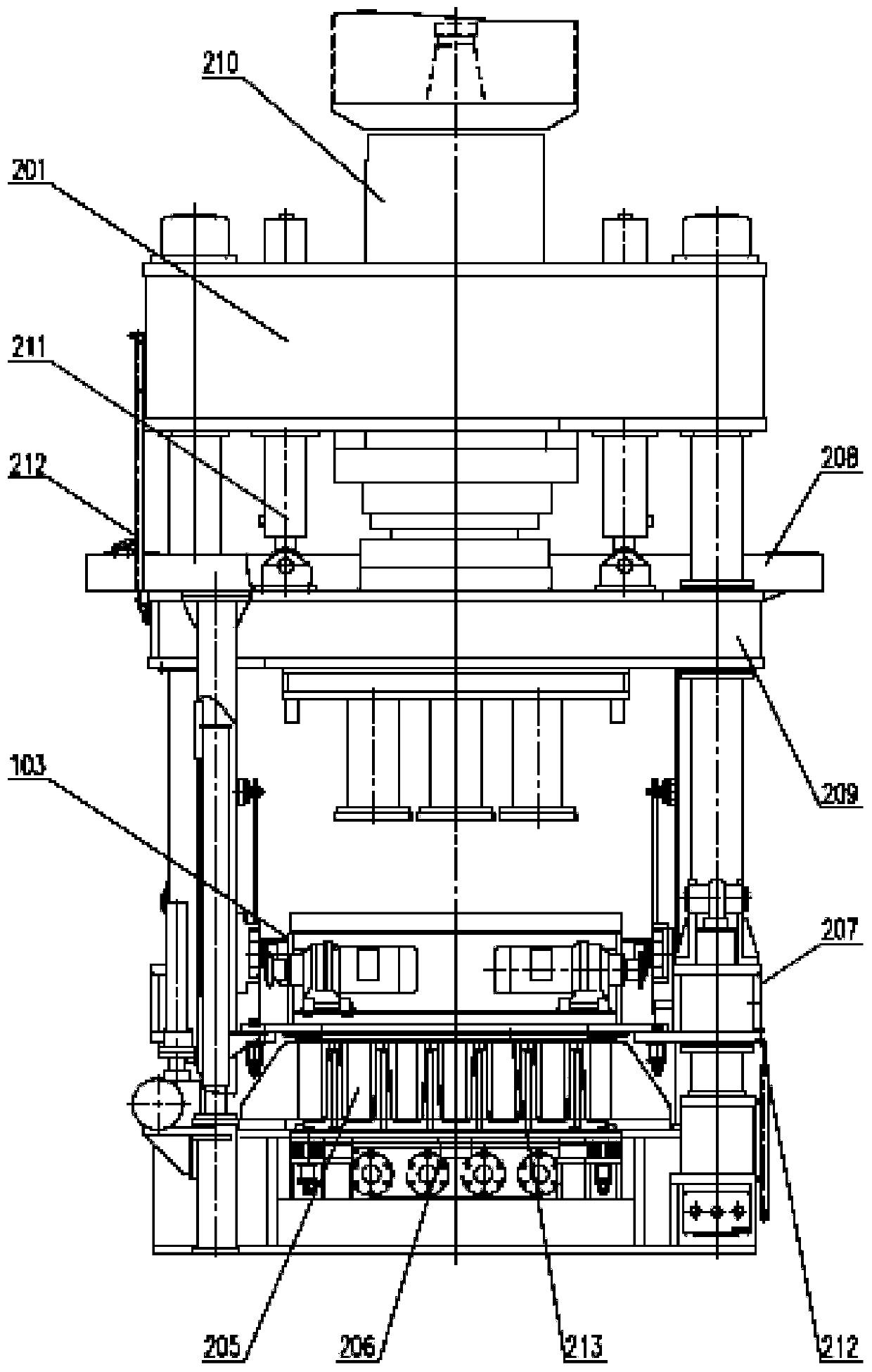

[0046] Such as figure 1 with figure 2 As shown, the fixed high-efficiency vibratory static pressure forming machine in this embodiment includes a material distribution system and a vibratory static pressure system.

[0047] The distributing system is used to fill the blank material into the mold box of the vibratory static pressure system;

[0048] The vibratory static pressure system is used to pre-vibrate the material and vibrate the material in the mold box;

[0049] When the vibrated material in the mold box reaches the preset value, the vibratory static pressure system continues to vibrate and simultaneously pressurizes the material in the mold box until it reaches the predetermined height value set by the material, and the finished product is demoulded.

[0050] As preferably, the material distribution system in this embodiment is a bottom material distribution system, and the bottom material distrib...

Embodiment 2

[0070] Embodiment 2 (being commonly called as containing surface layer product)

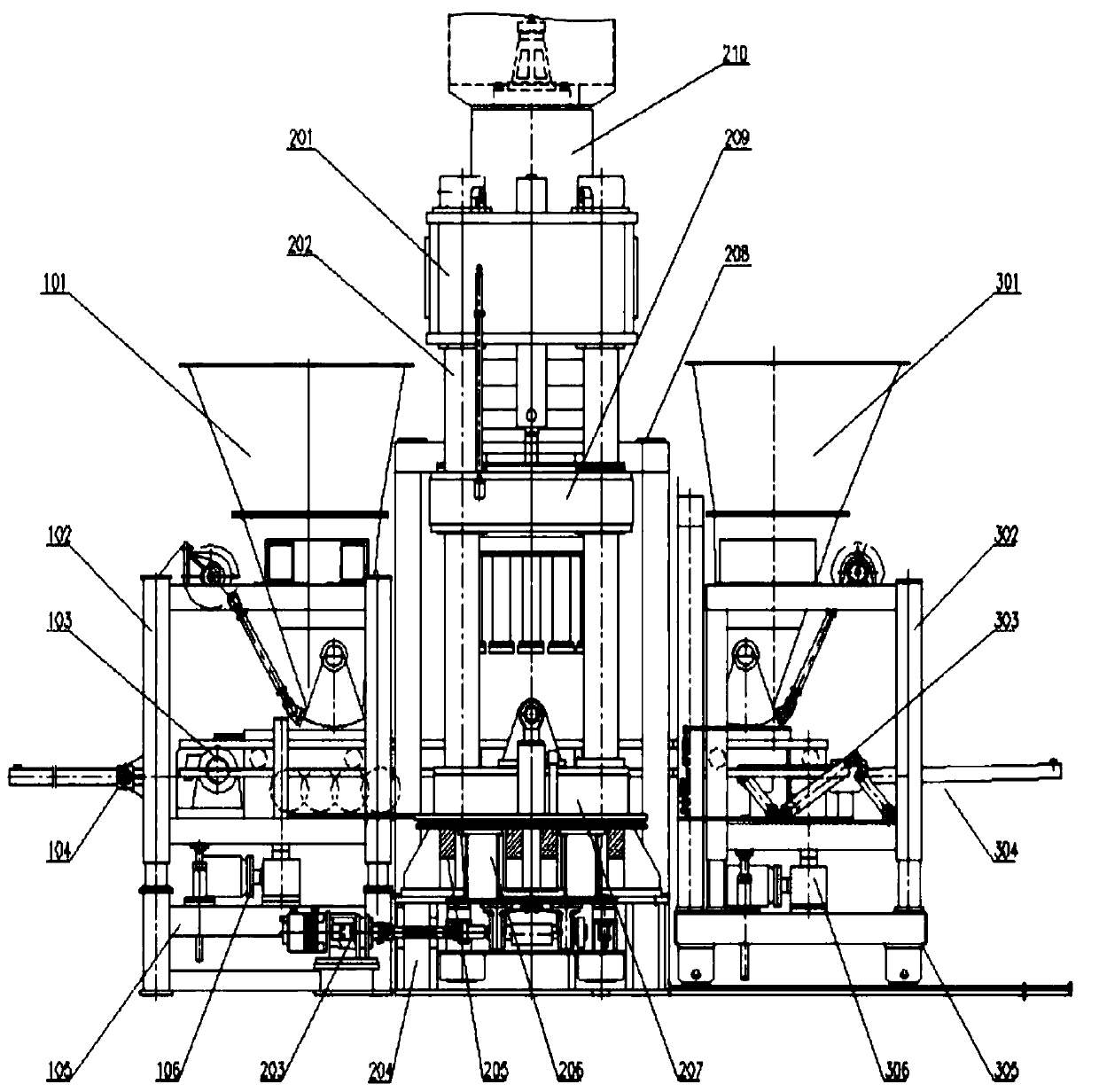

[0071] Such as figure 2 with image 3 As shown, the fixed high-efficiency vibratory static pressure forming machine in this embodiment includes a material distribution system and a vibratory static pressure system.

[0072] The distributing system is used to fill the blank material into the mold box of the vibratory static pressure system;

[0073] The vibratory static pressure system is used to pre-vibrate the material and vibrate the material in the mold box;

[0074] When the vibrated material in the mold box reaches the preset value, the vibratory static pressure system continues to vibrate and simultaneously pressurizes the material in the mold box until it reaches the predetermined height value set by the material, and the finished product is demoulded.

[0075] As a preference, the cloth system in this embodiment includes a bottom material cloth system and a fabric cloth system, the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com