Preparation method of stannous oxide polycrystalline film

A stannous oxide and thin film technology is applied in the field of preparation of stannous oxide polycrystalline thin films, which can solve the problems of high preparation requirements, complex preparation methods or processes, and increased preparation costs, and achieves reduced preparation difficulty and substrate pre-processing. The effect of simple processing technology and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In this embodiment, quartz glass is used as the substrate to realize the preparation of the SnO polycrystalline thin film, including the following steps.

[0025] First, a quartz glass substrate is provided. The quartz glass substrate provided in this step is a non-single crystal substrate.

[0026] The quartz glass substrate is then cleaned. The specific method of cleaning may be to use acetone, ethanol and deionized water to perform ultrasonic cleaning on the quartz glass substrate for 15 minutes each.

[0027] Next, the cleaned quartz glass substrate and SnO 2 The ceramic sintering evaporation material is placed at the corresponding position of the electron beam evaporation coating equipment. The electron beam evaporation coating equipment can be, for example, the electron beam evaporation coating equipment of the model MUE-ECO of Japan ULVAC Company.

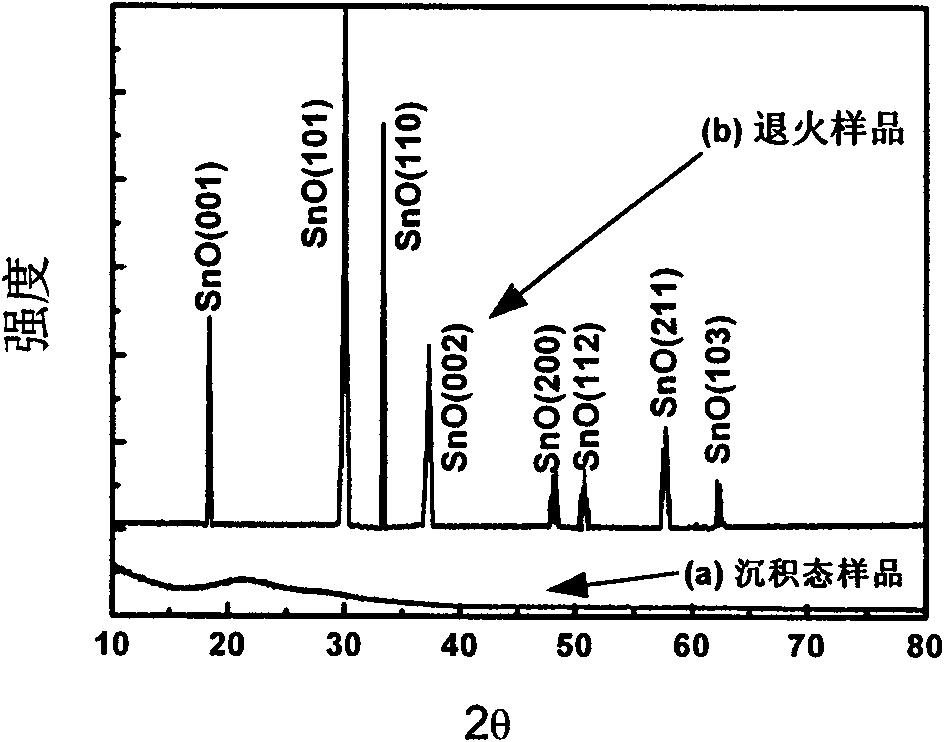

[0028] Heat the quartz glass substrate to 350°C, and set the background vacuum to 5×10 -6 Pa. Electron beam b...

Embodiment 2

[0032] In this embodiment, the substrate is changed to a single crystal sapphire substrate, while other process steps and process parameters are the same as in Embodiment 1.

[0033] In this example, the prepared SnO x The film sample is called (c) as-deposited sample, and the prepared SnO polycrystalline film sample is called (d) annealed sample.

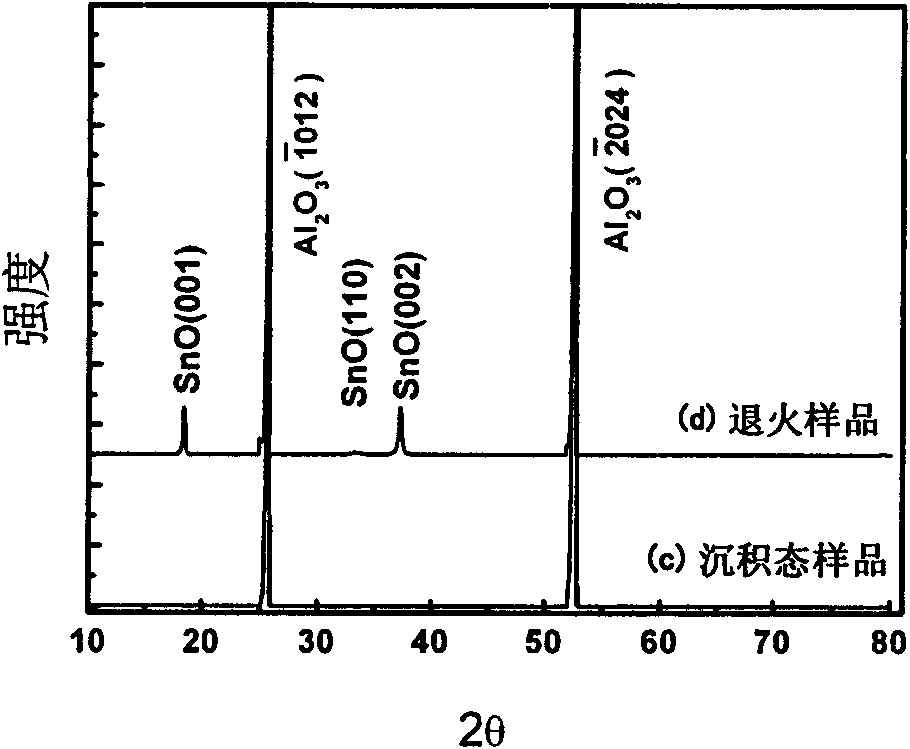

[0034] The above (c) as-deposited sample and (d) annealed sample were characterized by X-ray diffraction spectrum (XRD), and the results are as follows: figure 2 shown. figure 2 SnO is not observed in the XRD spectrum of the (c) deposited state sample on the sapphire substrate of the present embodiment X Any diffraction peaks of (1 figure 2 In the XRD spectrum of the (d) annealed sample on the sapphire substrate in this embodiment, the diffraction peaks of SnO are observed, and all peaks can be found in the XRD standard card (06-0395) of SnO corresponding to the diffraction peaks , that is to say, the annealed sapphire film in t...

Embodiment 3

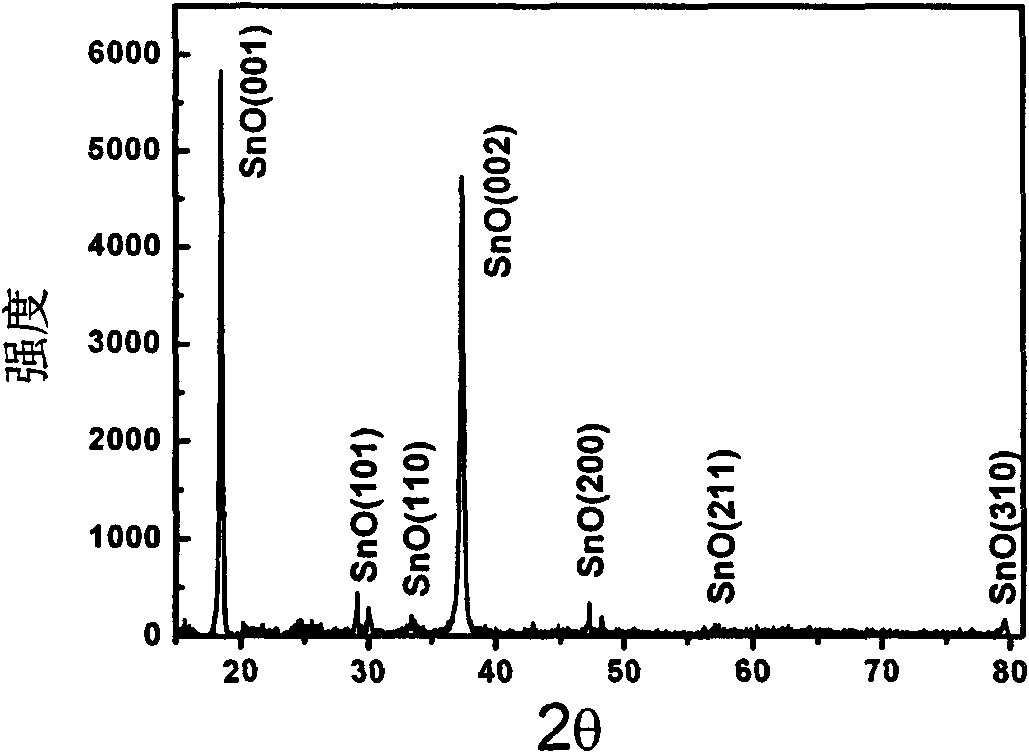

[0041] In this example, SnO x The thin film deposition step is carried out at a vacuum degree of 2×10 -4 It is carried out in a vacuum environment of Pa, and the deposition rate is 0.04nm / s. For SnO x The film was thermally annealed at a vacuum of 2×10 -4 Pa vacuum environment. Other processing steps and conditions are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com