Rapid measurement method of residual amounts of two photoinitiators in paper packaging material

A paper-based packaging material and photoinitiator technology, applied in the direction of measuring devices, material separation, and analysis materials, can solve the problems of daily inspection and screening of unfavorable samples, complex analysis process, long analysis time, etc., and achieve detection sensitivity and accuracy High reliability, rapid analysis, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1. Reagents and instruments:

[0040] Analytical standards 4,4-bis(dimethylamino)benzophenone (purity >98%) and 4,4-bis(diethylamino)benzophenone (purity >98%) were purchased from Tokyo Chemical Industry Co., Ltd.; acetonitrile (HPLC grade), purchased from Fisher Scientific; laboratory water is ultrapure water.

[0041]American Millipore ultra-pure water device; Waters Acquity ultra-high performance liquid chromatography (with PDA detector), binary solvent manager and Empower2 chromatographic workstation (Waters, USA); AE163 electronic balance, sensitivity: 0.0001g (Mettler, Switzerland) ); Kunshan Shumei KQ-700DB desktop CNC ultrasonic instrument (Kunshan Ultrasonic Instrument Co., Ltd.); SHA-BA water bath constant temperature oscillator (Jiangsu Jintan Zhongda Instrument Factory); needle filter, 13mm×0.22μm (Shanghai An Pu Scientific Instrument Co., Ltd.).

[0042] 2. Sample handling:

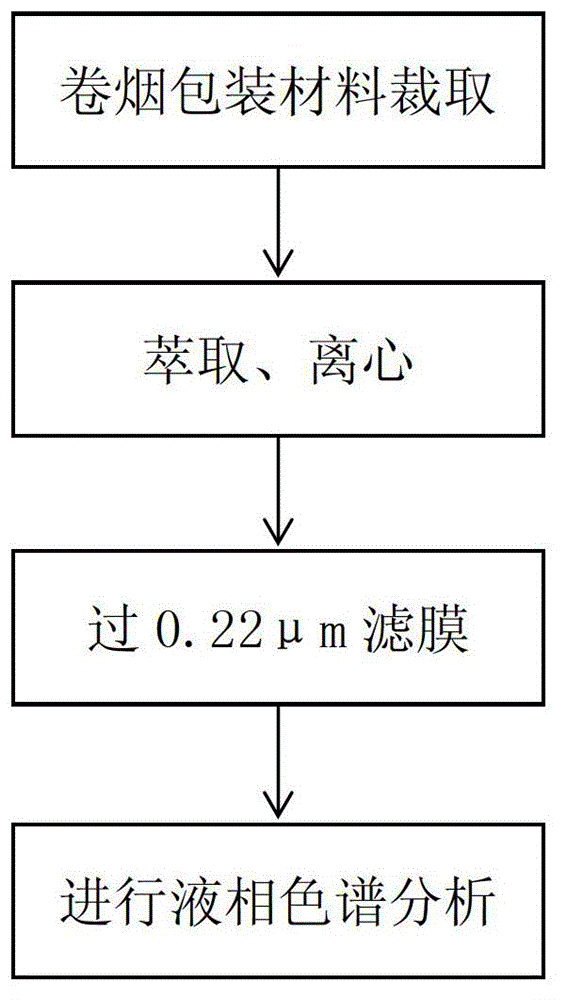

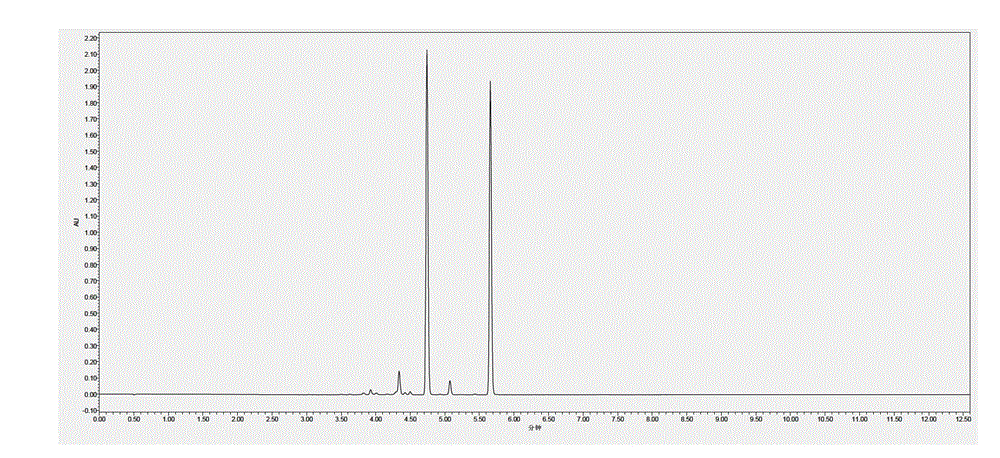

[0043] Such as figure 1 Shown, accurately cut 0.5dm 2 Paper printed and pac...

Embodiment 2

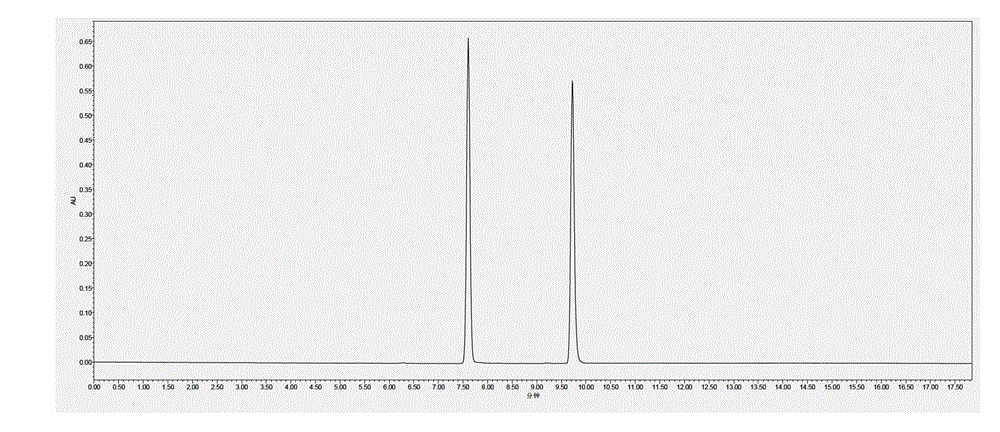

[0055] Repeat Example 1 with the following differences: adopt Luna PFP (2) (3μm, 150x4.6mm) from Chromatographic column, column temperature: 30°C; mobile phase A: water; mobile phase B: acetonitrile; column flow rate: 0.5mL / min; injection volume: 10μL; gradient: binary solvent mobile phase gradient as shown in Table 2: detection Detector: ultraviolet detector; detector mode: 2D; detect ultraviolet wavelength 372nm. Referring to this condition, the sample detection can be completed within 7 minutes, and the typical chromatogram is as follows image 3 , where the chromatographic peak at 7.65 minutes corresponds to 4,4-bis(dimethylamino)benzophenone, and the chromatographic peak at 9.75 minutes corresponds to 4,4-bis(diethylamino)benzophenone.

[0056] Table 2 Gradient elution program

[0057]

[0058] The test evaluation results show that the detection limit of 4,4-bis(diethylamino)benzophenone and 4,4-bis(dimethylamino)benzophenone in paper packaging materials is 1.0mg / m ...

Embodiment 3

[0060] The same paper packaging material sample was analyzed by the methods of Examples 1-2, and the experimental results are shown in Table 3. It can be seen from Table 3 that under the two liquid chromatography analysis conditions, the experimental data have good consistency, which is suitable for the combination of 4,4-bis(diethylamino)benzophenone and 4,4 in paper packaging materials. - Fast and accurate analysis of bis(dimethylamino)benzophenone.

[0061] Table 3 Comparison of actual sample analysis results

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com