Normal temperature low-pressure seawater desalination system based on ejection cavitation technology

A normal temperature, low pressure technology, applied in seawater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., to achieve stable performance, quick results, and eliminate the need for device cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

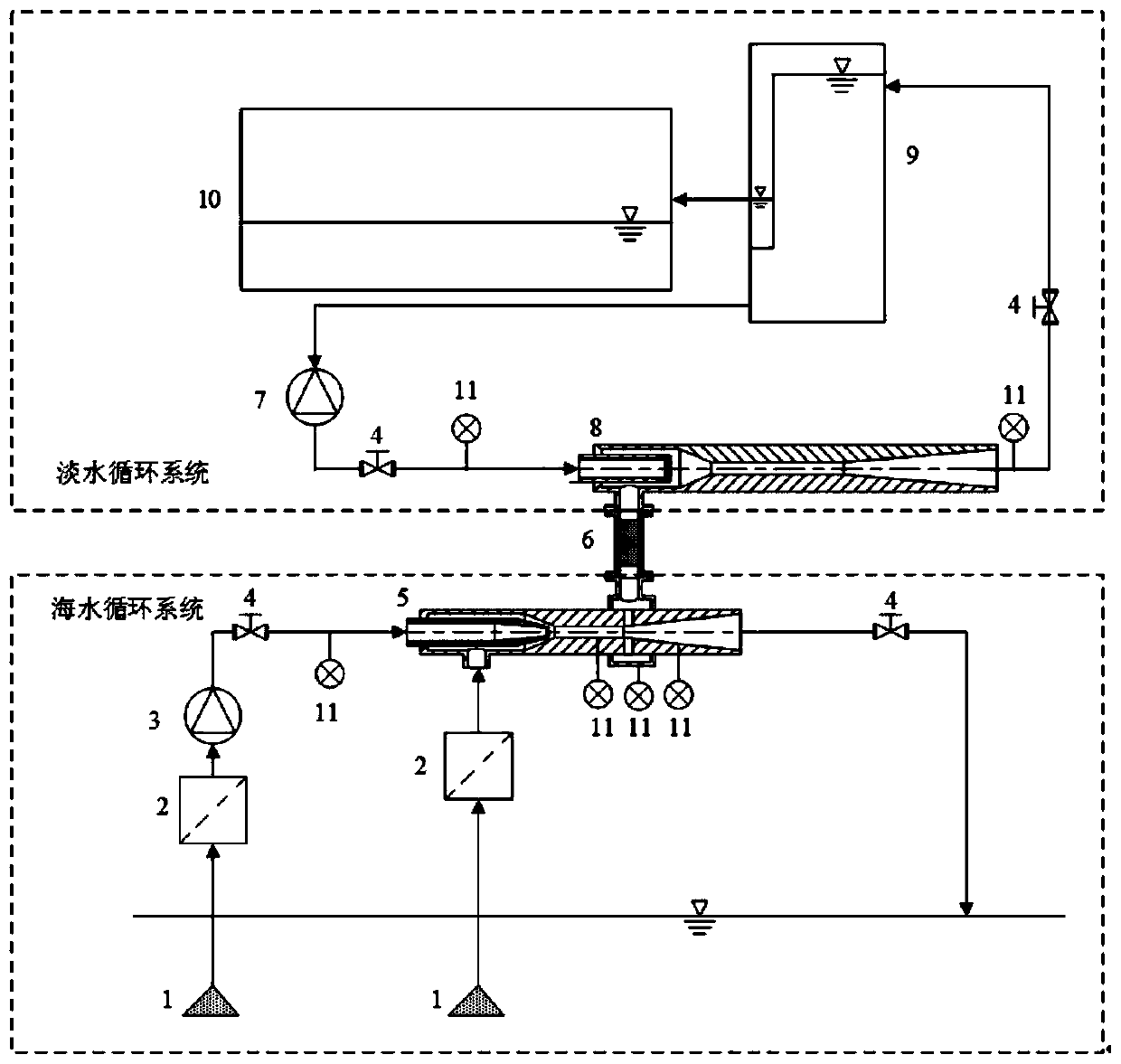

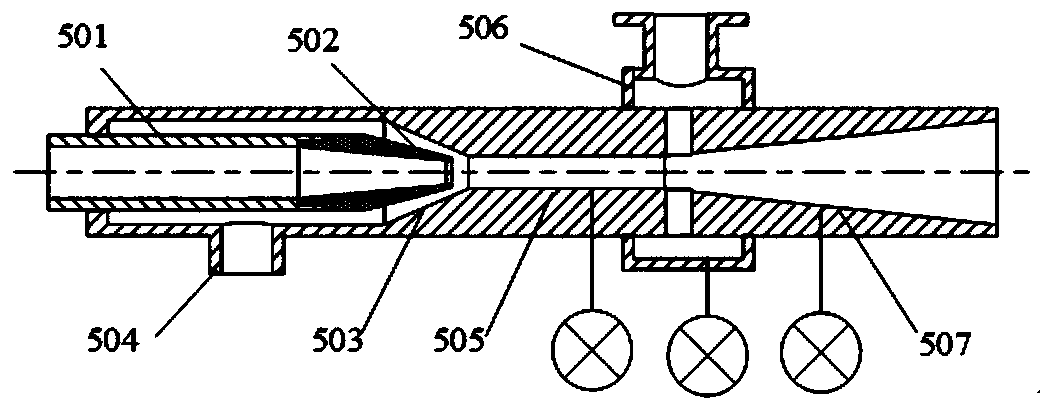

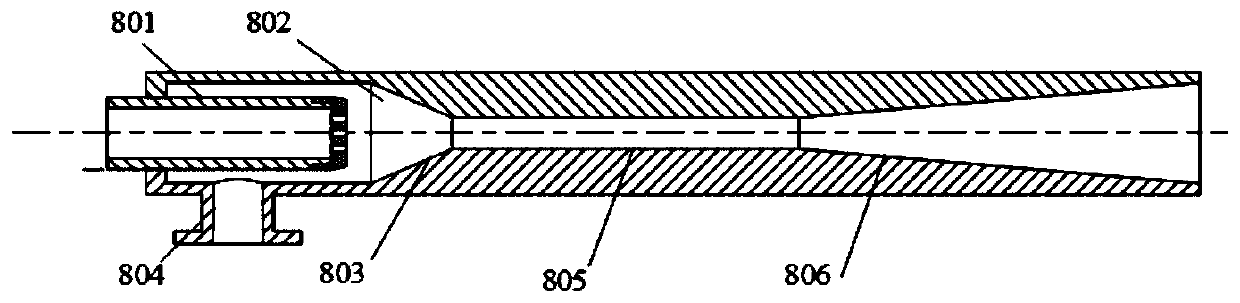

[0028] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-3As shown, in the seawater circulation system, seawater passes through the water suction device 1 and the coarse filter device 2, is pressurized by the seawater working pump 3, enters the inlet pipe A501 of the ejector cavitation generator 5, and is accelerated by the nozzle A502 to form a high-speed jet flow into the suction Chamber A503, the high-speed jet forms a low pressure in the suction chamber A503, and sucks seawater through the secondary suction pipe A504, the coarse filter device 2 and the water suction device 1, and the two fluids are violently mixed and sheared in the throat steam chamber A505, At the same time, accompanied by a high flow rate, the pressure in the throat steam chamber A505 is lower than the saturated steam pressure at this time, cavitation occurs and a large amount of cavitated water vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com