System and method for superheated steam and hot air combined drying of prawns as well as application of system and method

A superheated steam, combined drying technology, applied in the application, dry preservation of meat/fish, meat/fish preservation, etc., can solve the problem of affecting the color and nutritional composition of food materials, affecting the overall quality of shrimp drying, affecting the color and luster of shrimp. Nutrient composition and other issues, to achieve the effect of easy peeling and eating, saving drying time, and individual plumpness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

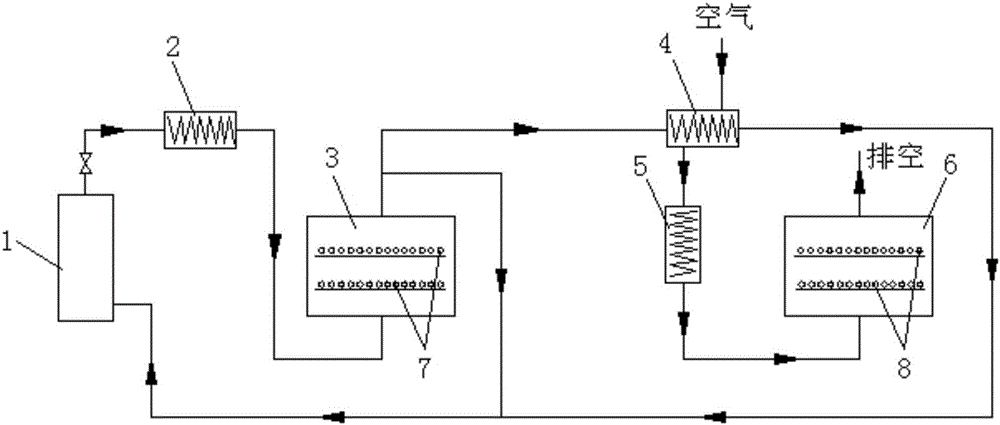

[0037] A method for drying prawns in combination with superheated steam and hot air, comprising the steps of:

[0038] 1) Pickle the fresh prawns according to taste requirements after cleaning;

[0039] 2) Put the pretreated prawns into the superheated steam drying box 3, and the steam generated by the steam generator 1 enters the steam heater 2 to be heated to become superheated steam at 130°C, and then enters the superheated steam drying box 3 to dry the pretreated prawns 7 , the flow velocity of the superheated steam is 1.5m / s, and the moisture content of the prawns is reduced to 45%;

[0040] 3) Put the dried prawns after the superheated steam into the hot air drying box 6, a part of the superheated steam in the superheated steam drying box 3 heats the cold air through the heat exchanger 4, and the heated cold air enters the electric heater 5 for further heating, Heating to 55° C., hot air enters the hot air drying box 6 to carry out secondary drying to the prawns, and th...

Embodiment 2

[0043] A method for drying prawns in combination with superheated steam and hot air, comprising the steps of:

[0044] 1) Pickle the fresh prawns according to taste requirements after cleaning;

[0045] 2) Put the pretreated prawns into the superheated steam drying box 3, and the steam generated by the steam generator 1 enters the steam heater 2 to be heated to become superheated steam at 160°C, and then enters the superheated steam drying box 3 to dry the pretreated prawns 7 , the flow velocity of the superheated steam is 2.5m / s, and the moisture content of the prawns is reduced to 50%;

[0046] 3) Put the dried prawns after the superheated steam into the hot air drying box 6, a part of the superheated steam in the superheated steam drying box 3 heats the cold air through the heat exchanger 4, and the heated cold air enters the electric heater 5 for further heating, Heating to 50°C, hot air enters the hot air drying box 6 to carry out secondary drying to the prawns, the flow...

Embodiment 3

[0049] A method for drying prawns in combination with superheated steam and hot air, comprising the steps of:

[0050] 1) Pickle the fresh prawns according to taste requirements after cleaning;

[0051] 2) Put the pretreated prawns into the superheated steam drying box 3, and the steam generated by the steam generator 1 enters the steam heater 2 to be heated to become superheated steam at 150°C, and then enters the superheated steam drying box 3 to dry the pretreated prawns 7 , the flow velocity of the superheated steam is 2.2m / s, the moisture content of the prawns is reduced to 47%;

[0052] 3) Put the dried prawns after the superheated steam into the hot air drying box 6, a part of the superheated steam in the superheated steam drying box 3 heats the cold air through the heat exchanger 4, and the heated cold air enters the electric heater 5 for further heating, Heating to 53° C., hot air enters the hot air drying box 6 to carry out secondary drying on the prawns, and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com