Method of melting aluminum ash to prepare brown aluminum oxide

A technology of brown corundum and aluminum ash, which is applied in the field of solid waste resource utilization in the metallurgical industry, can solve the problems of high alumina bauxite resource depletion, small equipment investment, etc. , Improve the effect of particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

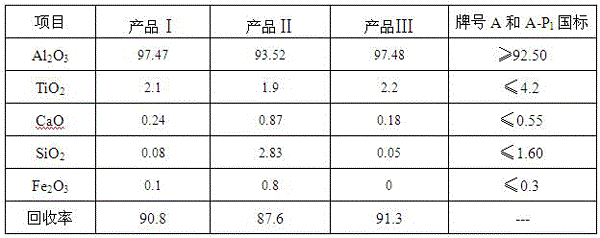

Examples

Embodiment 1

[0026] A method for preparing brown corundum by smelting aluminum ash. Firstly, aluminum ash and water are uniformly mixed in a weight ratio of 0.5:1 to make aluminum mortar, and then the aluminum mortar is subjected to acidification treatment and alkalization treatment in sequence, and then solid-liquid Separation, the filtrate obtained after solid-liquid separation is used to prepare aluminum mortar, and the aluminum ash obtained by solid-liquid separation is dehydrated at a temperature of 300°C, calcined at a high temperature of 1150°C for 2.0h, and then cooled at a rate of 300°C / min Rapid cooling, after it is completely cooled, it is mixed with iron filings and coke for smelting to obtain brown corundum products. During smelting, the calcined aluminum ash, iron filings and coke are mixed according to the weight ratio of 100:3:8. Melting at high temperature for 2 hours, then cooling to produce brown corundum products;

[0027] The acidification treatment is to add acid to t...

Embodiment 2

[0032] A method for preparing brown corundum by smelting aluminum ashes. Firstly, aluminum ashes and water are uniformly mixed in a weight ratio of 2:1 to make aluminum mortar, and then the aluminum mortar is subjected to acidification treatment and alkalization treatment in sequence, and then solid-liquid Separation, the filtrate obtained after solid-liquid separation is used to prepare aluminum mortar, and the aluminum ash obtained by solid-liquid separation is dehydrated at a temperature of 120°C, calcined at a high temperature of 1300°C for 0.5h, and then cooled at a rate of 400°C / min Rapid cooling, after it is completely cooled, it is mixed with iron filings and coke for smelting to obtain brown corundum products. During smelting, the calcined aluminum ash, iron filings and coke are mixed according to the weight ratio of 100:4:13. Melting at high temperature for 3 hours, then cooling to produce brown corundum products;

[0033] The acidification treatment is to add acid t...

Embodiment 3

[0038] A method for preparing brown corundum by smelting aluminum ash. Firstly, aluminum ash and water are uniformly mixed at a weight ratio of 1:1 to make aluminum mortar, and then the aluminum mortar is subjected to acidification treatment and alkalization treatment in sequence, and then solid-liquid Separation, the filtrate obtained after solid-liquid separation is used to prepare aluminum mortar, and the aluminum ash obtained by solid-liquid separation is dehydrated at a temperature of 210°C, calcined at a high temperature of 1220°C for 1.5h, and then cooled at a rate of 350°C / min Rapid cooling, after it is completely cooled, it is mixed with iron filings and coke for smelting to obtain brown corundum products. During smelting, the calcined aluminum ash, iron filings and coke are mixed according to the weight ratio of 100:3.5:10.5. Melting at high temperature for 2.5 hours, then cooling to produce brown corundum products;

[0039] The acidification treatment is to add acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com