Preparing method for SiC particle enhanced aluminum-base composite material

A composite device and feeding device technology, applied in the development and application of new materials, can solve the problems of enhancing the bonding force between particles and substrates, being unsuitable for mass production, and difficult to remove air films, avoiding harmful interface reactions, The effect of improved binding force and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

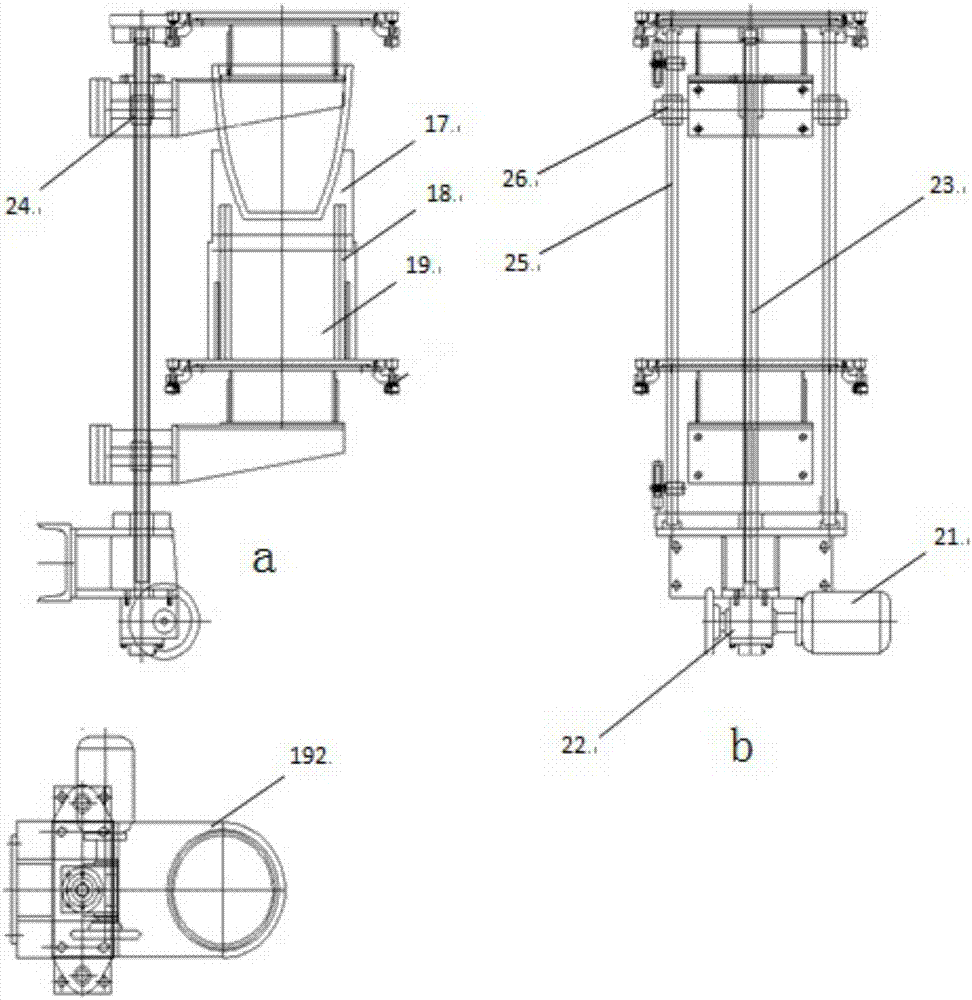

Method used

Image

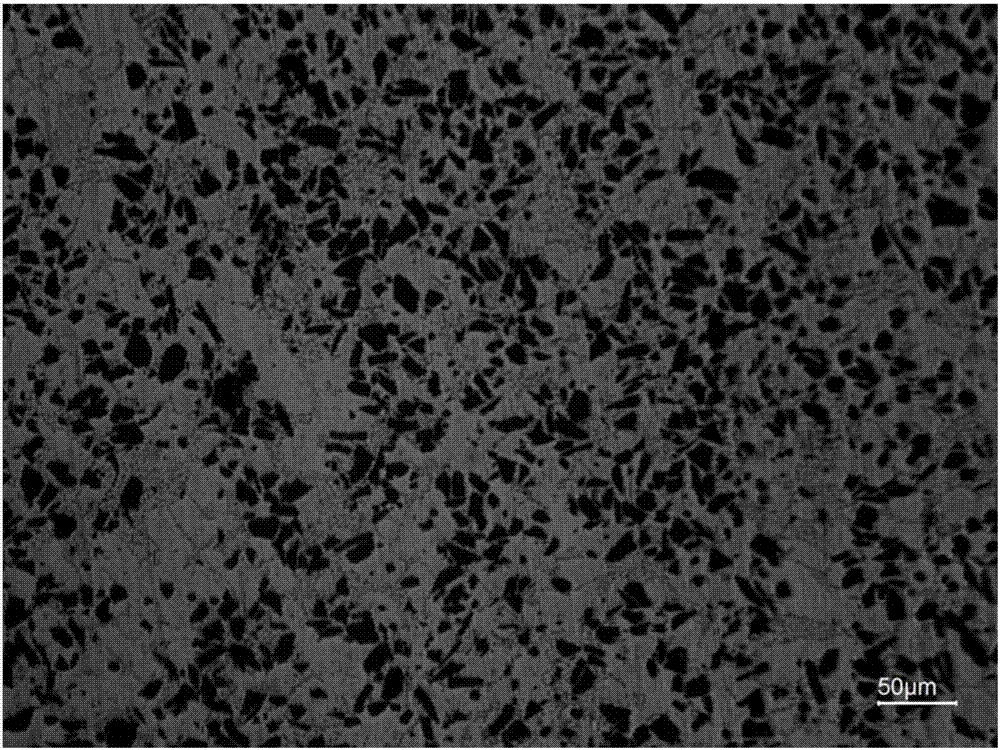

Examples

Embodiment 1

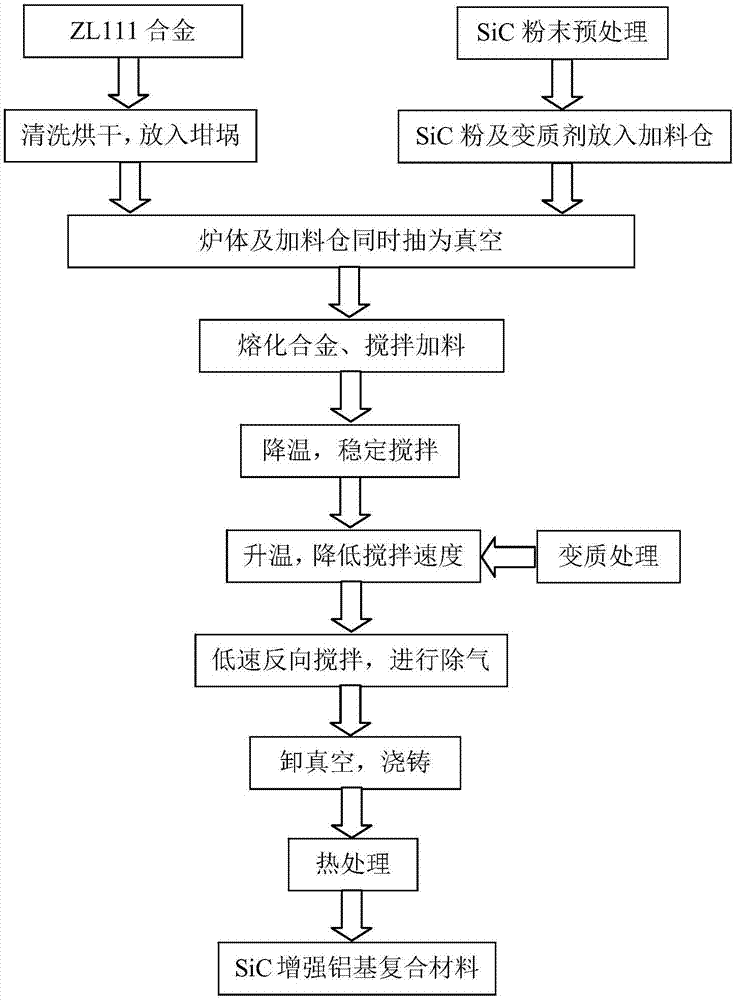

[0055] 1. Preparation process of SiC particle reinforced aluminum matrix composites

[0056] 1.1 Principle of vacuum stirring casting

[0057] Vacuum stirring casting to prepare SiC particle-reinforced composite materials is to use the rotating motion of the stirring paddle under vacuum conditions to make the aluminum alloy liquid surface rotate and generate a vortex, so that SiC particles enter the aluminum alloy matrix. Due to the vacuum and high temperature environment in the feeding bin, the surface layer of SiC particles no longer absorbs the air film, and at the same time, it does not wrap air into the aluminum alloy melt. During the feeding process, according to the Bernoulli principle of the fluid, there will be a pressure difference between the fluids with different moving speeds. During the stirring process of the stirring paddle, due to the influence of the paddle member, the viscosity of the aluminum alloy liquid and the friction of the crucible wall, Different po...

Embodiment 2

[0106] Adopt the same special equipment of embodiment 1, according to the same equipment operation mode of embodiment 1, complete the following process preparation of the present embodiment:

[0107] The composition of the matrix ZL111 alloy (which already belongs to the prior art) is shown in Table 1, and the SiC particle size is 10-20 μm.

[0108] Table 1 ZL111 alloy composition

[0109]

[0110] Included steps are:

[0111] Step 1: Put 1000g of ZL111 alloy into a graphite crucible, add 250g of SiC powder and 4g of Al-Sr intermediate alloy modifier prepared in advance into the feeding bin, seal the furnace body and the feeding bin and vacuumize it.

[0112] The pre-preparation of SiC powder in this embodiment 2 is the surface modification process. The process is: 1) add HF acid solution with a volume fraction of 9% in the SiC, and magnetically stir for 2.5 hours; Filter the SiC powder, wash it with distilled water until the pH is 7, and then filter; 3) Add anhydrous eth...

Embodiment 3

[0123] Adopt the same special equipment of embodiment 1, according to the same equipment operation mode of embodiment 1, complete the following process preparation of the present embodiment:

[0124] The composition of the matrix ZL111 alloy is the same as in Example 2.

[0125] The preparation method comprises the steps of:

[0126] Step 1: Put 1000g of ZL111 alloy into the graphite crucible, add 350g of SiC powder and 7g of Al-Sr intermediate alloy modifier prepared in advance into the feeding bin, seal the furnace body and the feeding bin and evacuate them into a vacuum.

[0127] The pre-preparation of the SiC powder in Example 3, that is, the surface modification process, is as follows: 1) add an HF acid solution with a volume fraction of 9% in the SiC, and stir it magnetically for 3 hours; 2) add the acid solution to the SiC Filter the washed SiC powder, wash it with distilled water until the pH is 6-7.2, and then filter; 3) Add absolute ethanol solution to the powder af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com