Manufacturing process for middle-high-voltage etched foil

A medium and high voltage corroded foil and manufacturing process technology, which is applied in capacitor manufacturing, electrical components, circuits, etc., can solve the problems of corroded foil's easy deformation, surface color difference, etc., and achieve ideal effect, convenient operation and improved bending performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

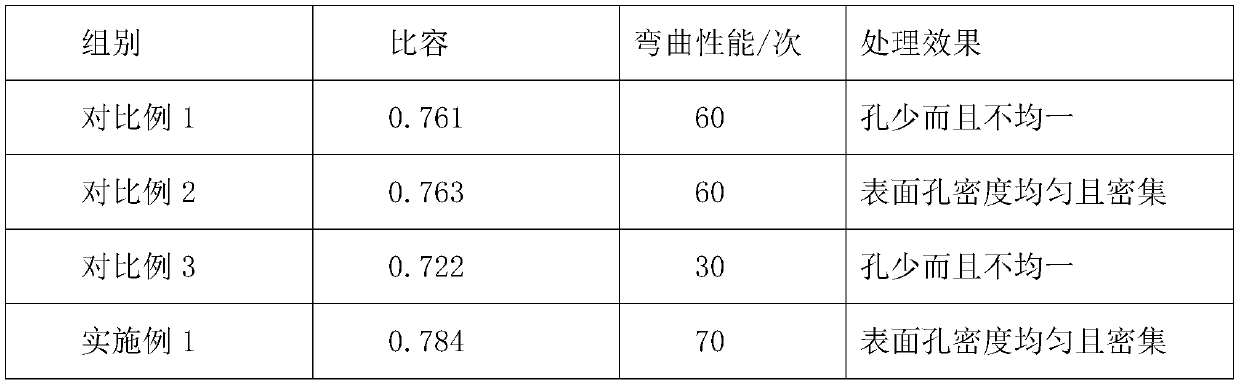

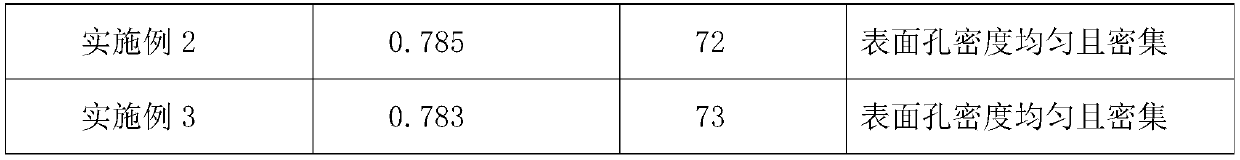

Embodiment 1

[0017] In the embodiment of the present invention, a manufacturing process of medium and high pressure corrosion foil includes five steps of pretreatment, primary pore corrosion, secondary pore corrosion, tertiary expansion corrosion and post-treatment on high-purity aluminum foil. The pre-treatment is to put the aluminum foil in the pre-treatment solution and soak for 40s; after that, it is cleaned and placed in the primary corrosion mixture at a temperature of 80℃, and a direct current with a current density of 0.8A / cm2 is applied for electrolytic corrosion for 50s. Clean the pure water and put it into a bath containing 2% nitric acid at a temperature of 70°C, and apply a direct current with a current density of 0.15A / cm2 for electrolytic corrosion for 500s; finally, clean the pure water and put it in a bath with a temperature of 200°C Drying in an oven is sufficient. The post-treatment is to enter the corroded foil that has completed the third-stage expansion corrosion into t...

Embodiment 2

[0025] In the embodiment of the present invention, a manufacturing process of medium and high pressure corrosion foil includes five steps of pretreatment, primary pore corrosion, secondary pore corrosion, tertiary expansion corrosion and post-treatment on high-purity aluminum foil. The pre-treatment is to immerse the aluminum foil in the pre-treatment solution for 45s; then clean it and place it in the primary corrosion mixture at a temperature of 85°C, apply a direct current with a current density of 0.8A / cm2 for electrolytic corrosion for 55s. Clean the pure water and put it into a bath containing 2% nitric acid at a temperature of 75°C, and apply a direct current with a current density of 0.15A / cm2 to perform electrolytic corrosion for 550s; finally, clean the pure water and put it in a temperature of 210°C Drying in an oven is sufficient. The post-treatment is to enter the corroded foil that has completed the third-stage expansion corrosion into the heating stage, the starti...

Embodiment 3

[0033] In the embodiment of the present invention, a manufacturing process of medium and high pressure corrosion foil includes five steps of pretreatment, primary pore corrosion, secondary pore corrosion, tertiary expansion corrosion and post-treatment on high-purity aluminum foil. The pre-treatment is to immerse the aluminum foil in the pre-treatment solution for 50s; then clean it and place it in the primary corrosion mixture at a temperature of 90℃, apply a direct current with a current density of 0.8A / cm2 for electrolytic corrosion for 60s. Clean the pure water and put it in a bath containing 2% nitric acid at a temperature of 80℃, and apply a direct current with a current density of 0.15A / cm2 for electrolytic corrosion for 600s; finally, clean the pure water and put it in a temperature of 220℃ Drying in an oven is sufficient. The post-treatment is to enter the corroded foil that has completed the third-stage expansion corrosion into the heating stage, the starting temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com