Patents

Literature

62results about How to "Easy to anneal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

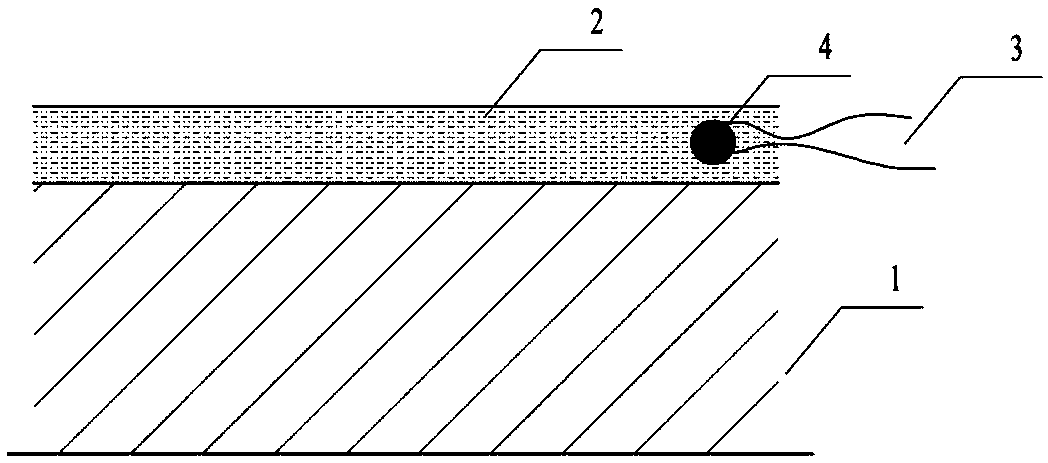

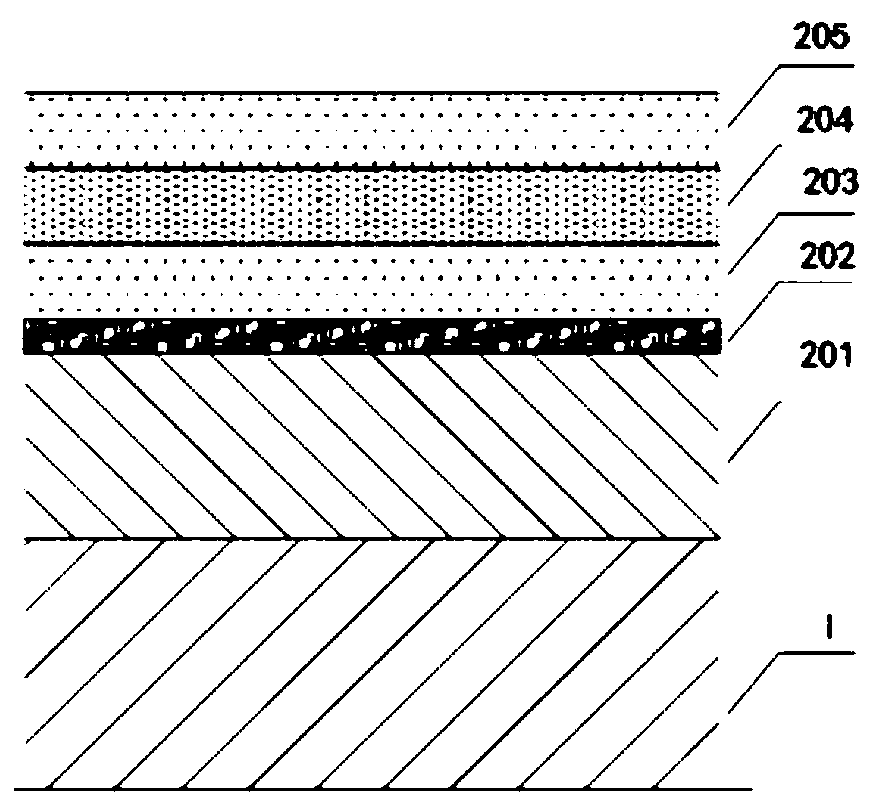

Film temperature sensor for turbine blades of aero-engine

ActiveCN109338290ASolve insulation problemsSolve sheddingMolten spray coatingThermometers using electric/magnetic elementsThin film sensorSputtering

The invention discloses a film temperature sensor for turbine blades of an aero-engine. The film temperature sensor comprises a transition layer, a thermal growing layer, an insulating layer and a thermocouple layer which are sequentially connected, wherein the thermocouple layer is formed by lapping a first thermocouple and a second thermocouple through one end part, and the lapping part forms athermal connecting point which is a measuring end; an outgoing conductor is a fine wire which has the same quality as the first thermocouple and the second thermocouple; and the outgoing conductor iscorrespondingly connected to the other end part of each of the first thermocouple and the second thermocouple through high-temperature conductive glue. According to the film temperature sensor for theturbine blades of the aero-engine, a film layer structure of the sensor is specially designed for the aero-engine in a high-temperature severe environment; the film sputtering, annealing and other preparation technologies are optimized; the ion deposition technology is carried out to directly deposit a plurality of layers of films on the surfaces of the turbine blades, and thus the function and structure integrated film sensor is obtained; the adhesion strength of the film layers is improved; the problems such as high-temperature insulating of the film layer, separating and signal exporting can be solved; and the total thickness of the film sensor is less than 25 microns, and the maximum measurement temperature is 1100 DEG C.

Owner:AVIC SHANGHAI AERONAUTICAL MEASUREMENT CONTROLLING RES INST

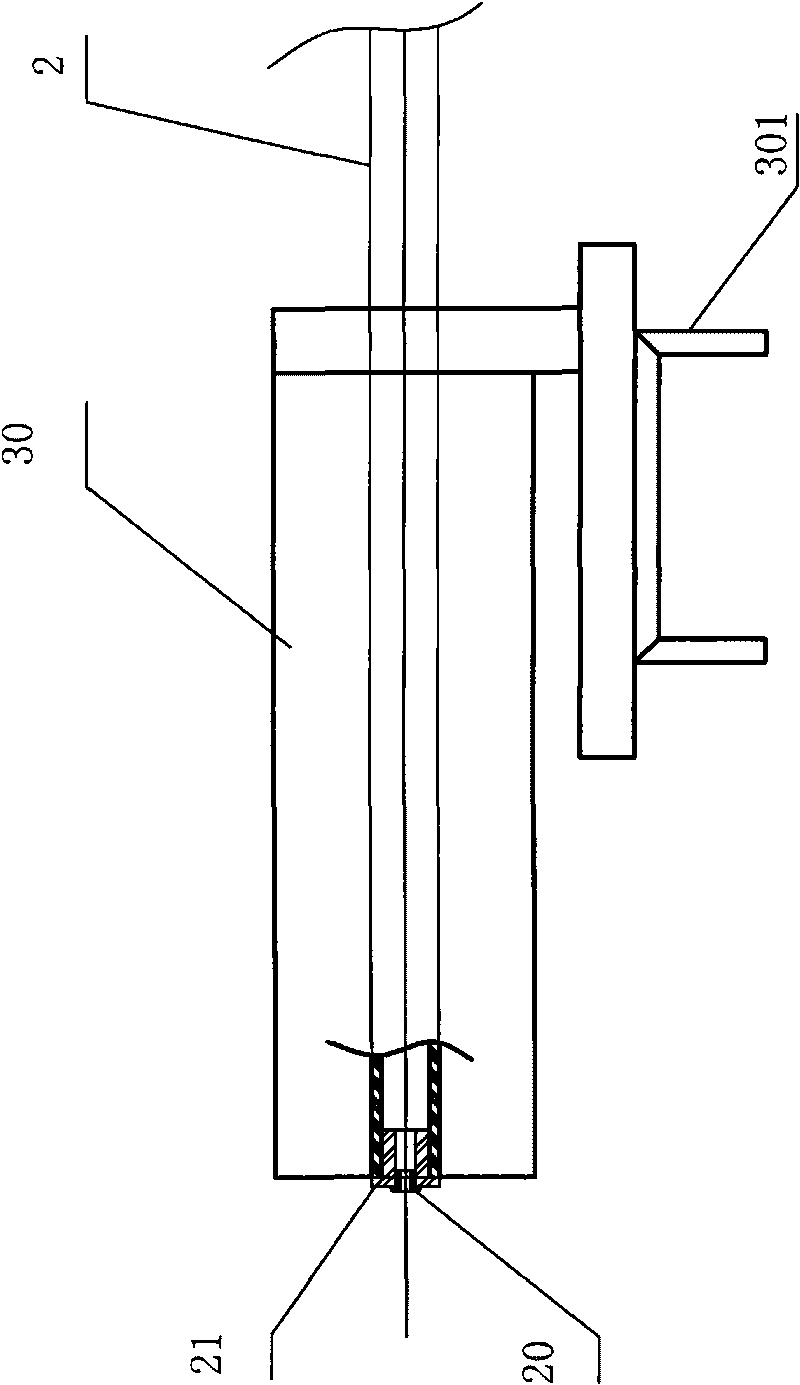

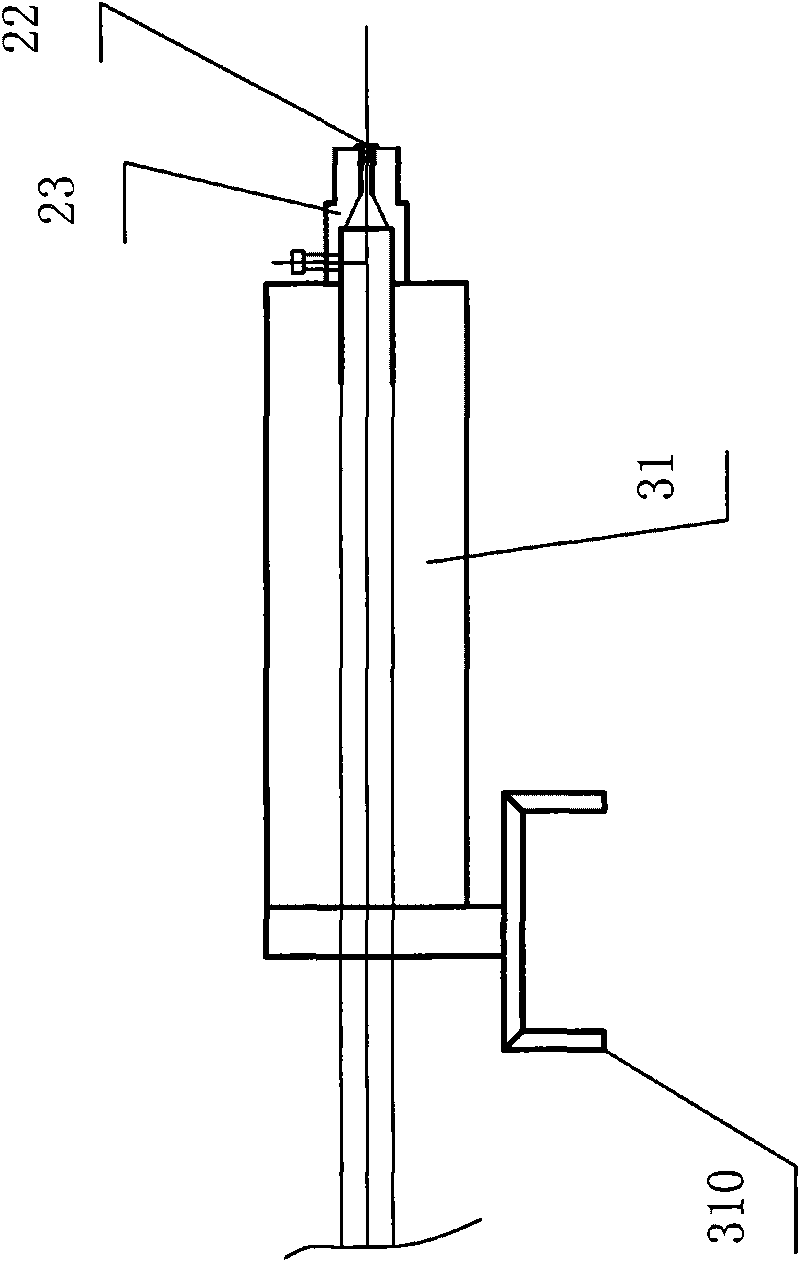

Wire annealing process and device thereof

InactiveCN101736143APrevent oxidationImprove performance and quality stabilityFurnace typesHeat treatment furnacesLiquid waterMetallurgy

The invention relates to the technical field of wire annealing, in particular to a wire annealing process and a device thereof, the wire annealing process mainly comprises three working procedures of heating treatment in a high temperature annealing region, cooling treatment in a steam cooling region and liquid water coating and cooling treatment in a liquid water coating and cooling region, wherein steam in the steam cooling region is low-temperature steam generated by a built-in steam generator, thereby realizing high cooling efficiency, having no problem of condensate and being applied in annealing of a variety of wires; furthermore, due to the working procedure of the liquid water coating and cooling treatment, the wire annealing process can not easily complete the wire cooling, but also better complete the tasks of coating of an antioxidant, coating a booster flux, cleaning the booster flux and the like. Therefore, the wire annealing process and the device thereof can avoid the oxidation of annealed wires, improve the performance and the quality stability of the wires after annealing, further realize the perfect coating of the antioxidant and the pretreatment of tin plating, have good energy-saving effect and be applied in the annealing of a variety of wires.

Owner:东莞市康汇聚线材科技有限公司

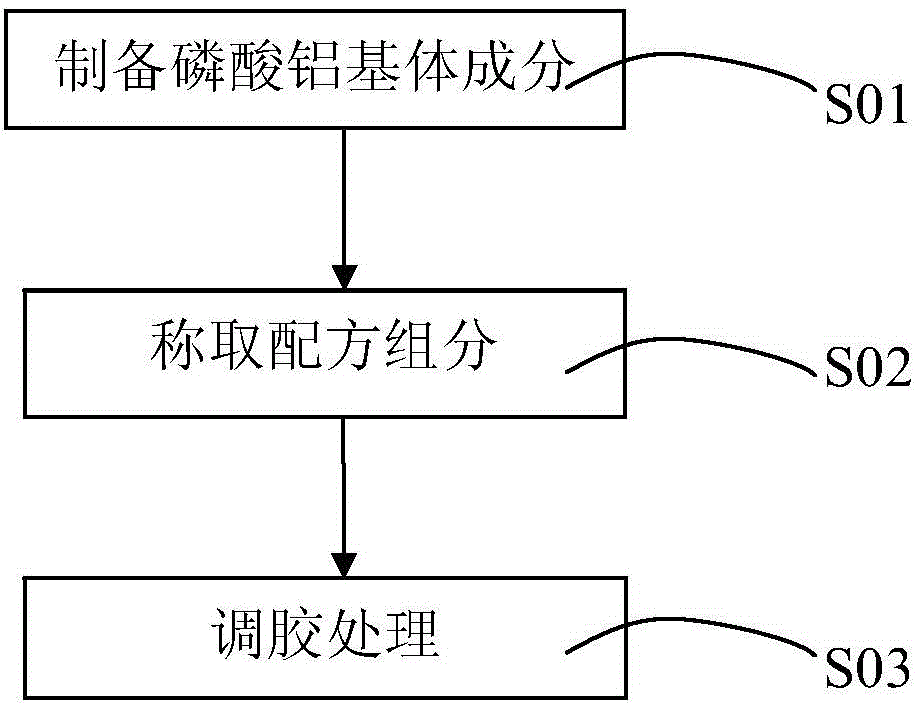

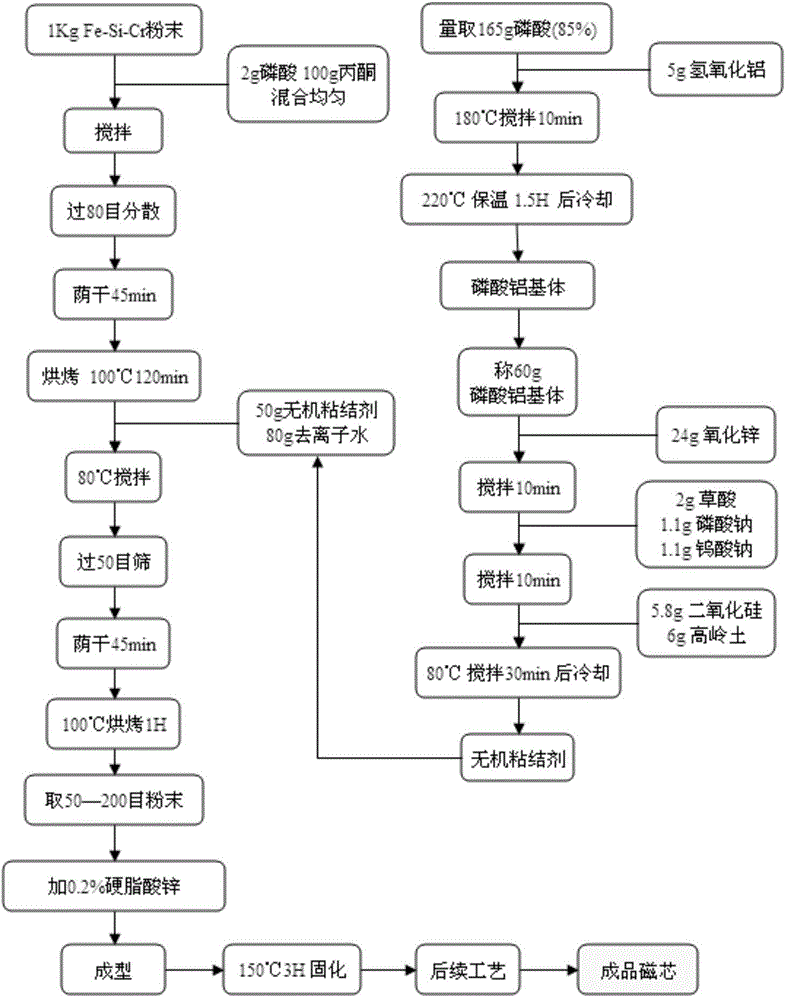

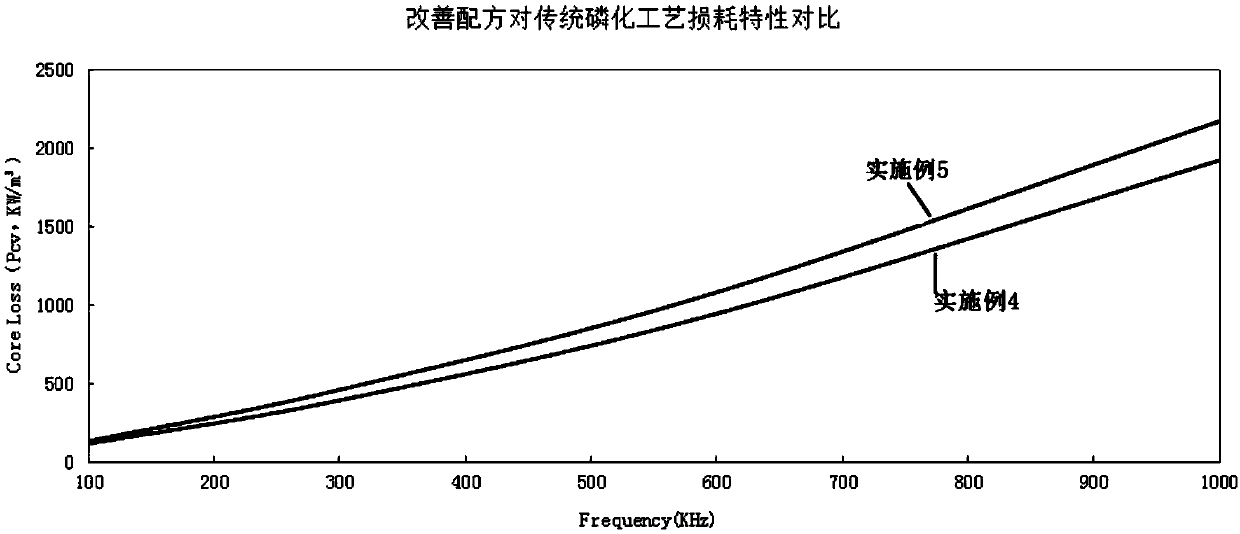

Inorganic binder used for metal soft magnetic powder core and metal soft magnetic powder core

ActiveCN105798284AImprove performanceStability is not affectedInorganic material magnetismTransformers/inductances detailsAging resistanceLow temperature curing

The invention is applicable to the field of metal powder alloy and provides an inorganic binder used for a metal soft magnetic powder core, the metal soft magnetic powder core and a preparation method of the metal soft magnetic powder core. The inorganic binder comprises the following formula components of, by the total weight of 100%, a matrix, a curing agent, a skeletal material and an additive, wherein the matrix is an aluminum phosphate matrix. The inorganic binder serves as the binder of the metal soft magnetic powder core. According to the inorganic binder provided by the invention, the binding effect is good, and meanwhile the requirements for the total inorganic performance, indecomposition of heat treatment, low-temperature curing, the ageing resistance and meeting of the ROSH standard are met.

Owner:SHENZHEN ZHENHUA FU ELECTRONICS

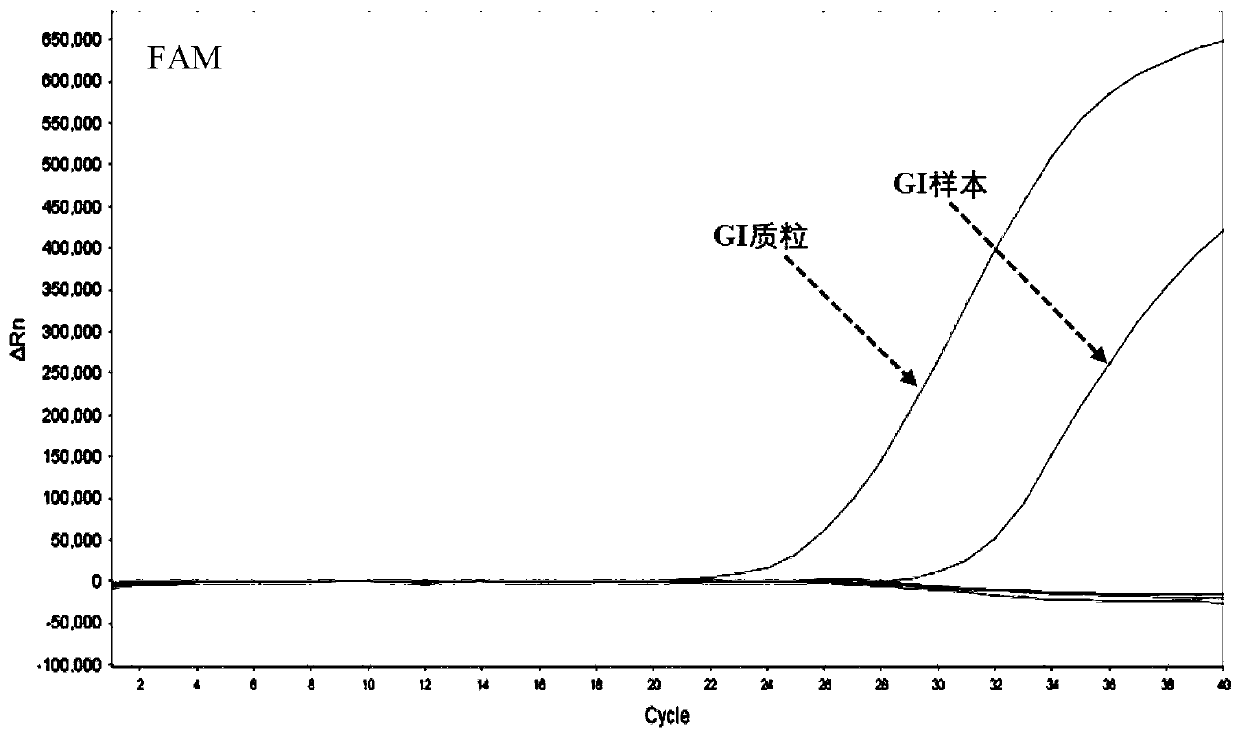

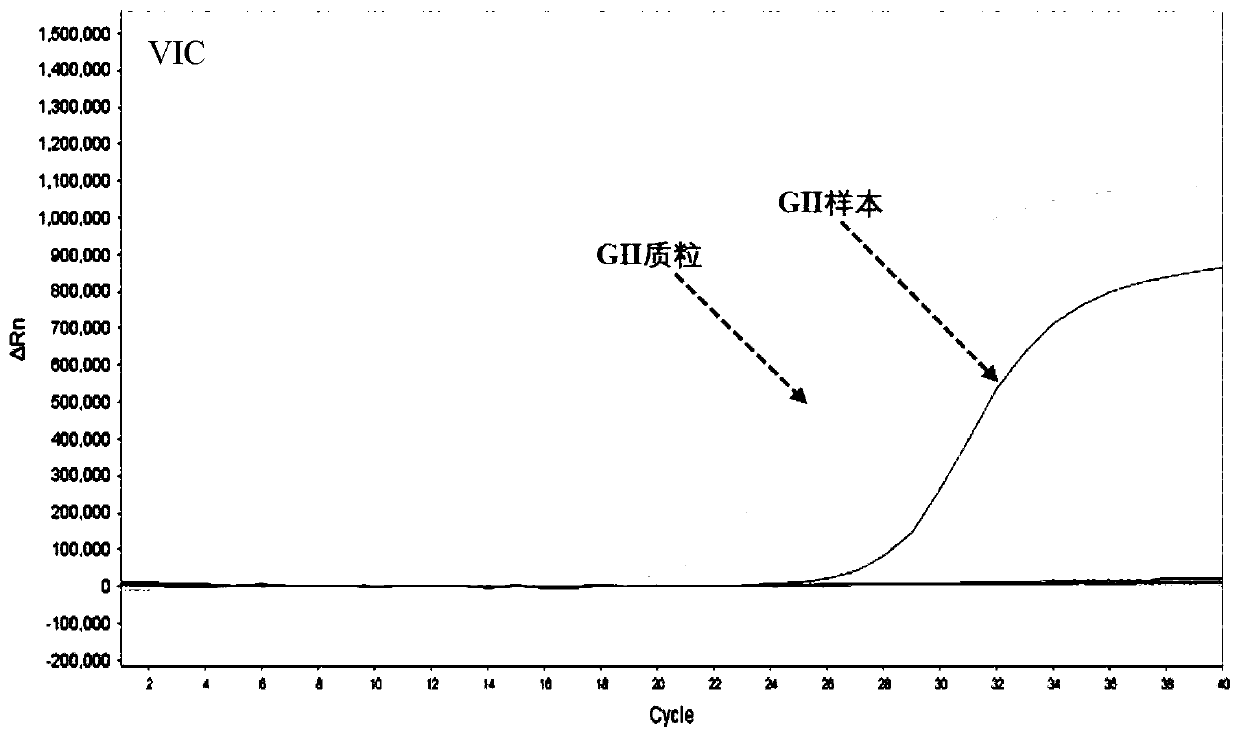

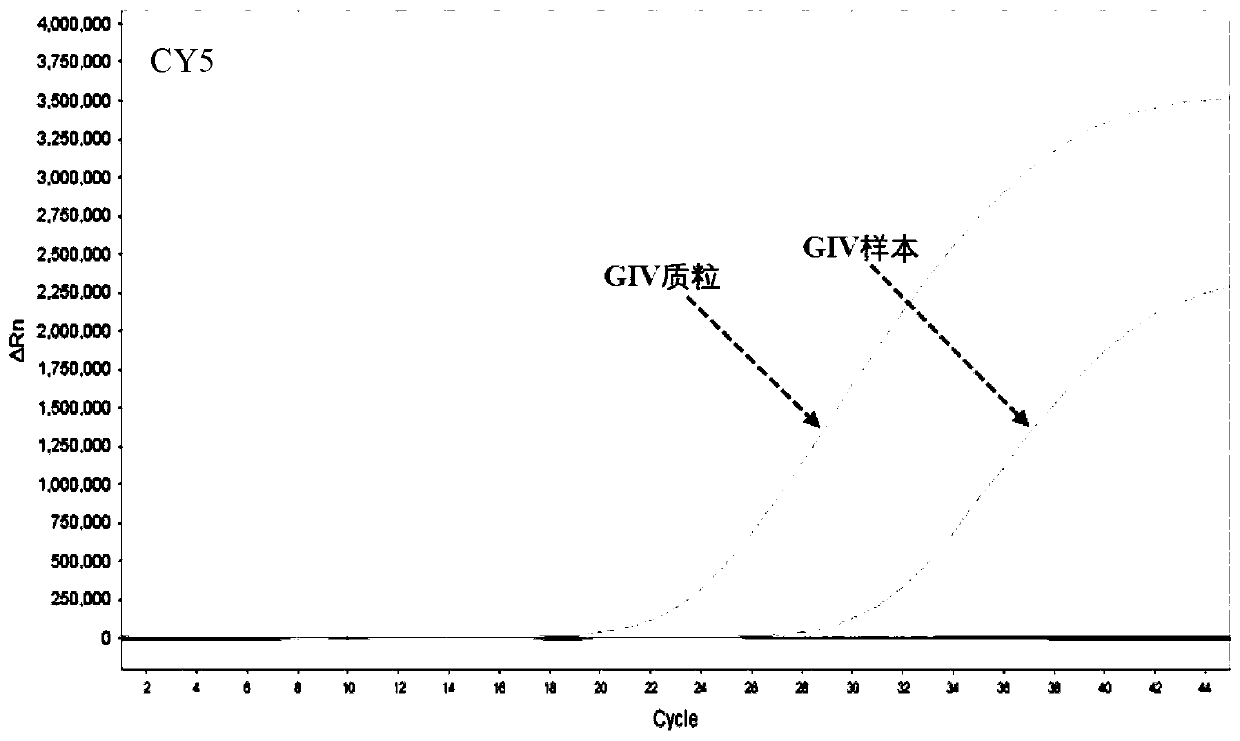

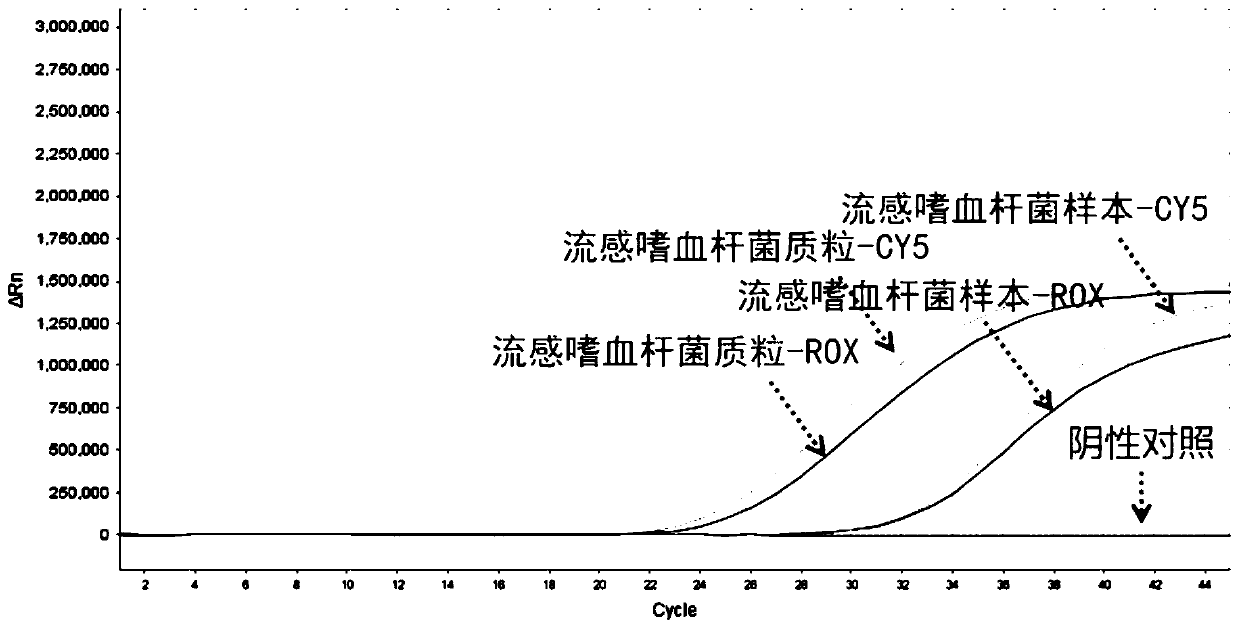

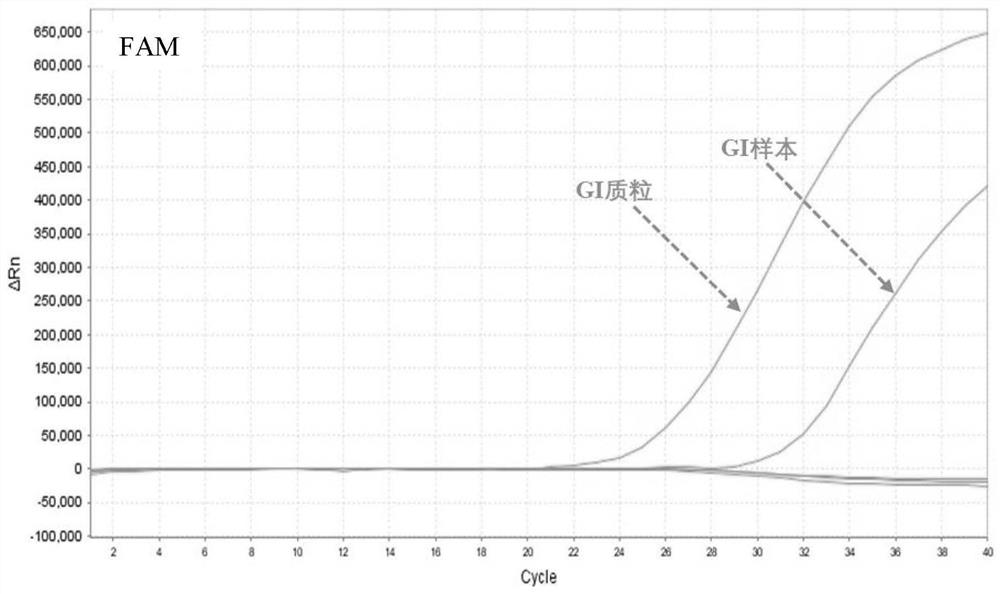

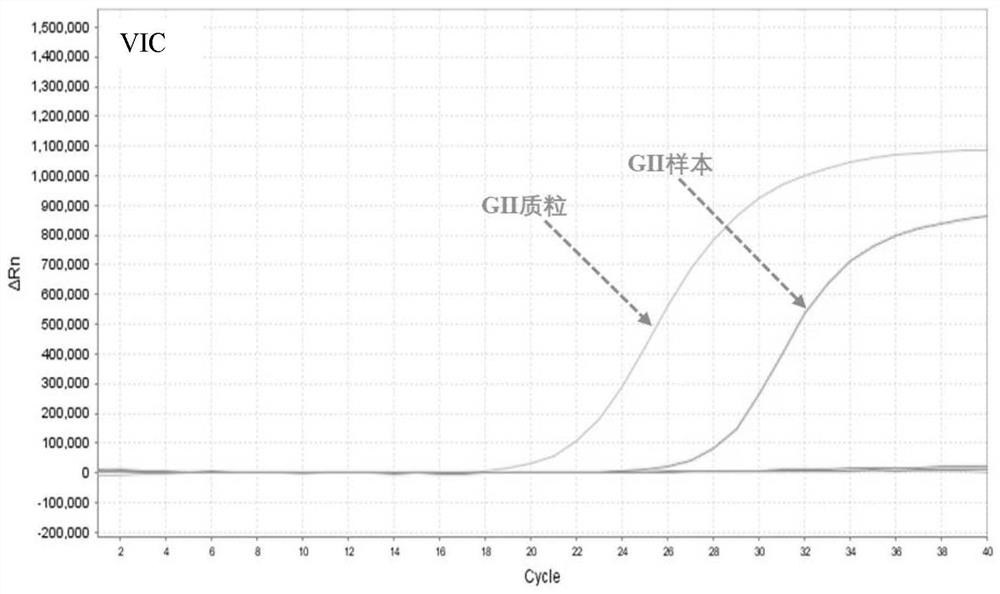

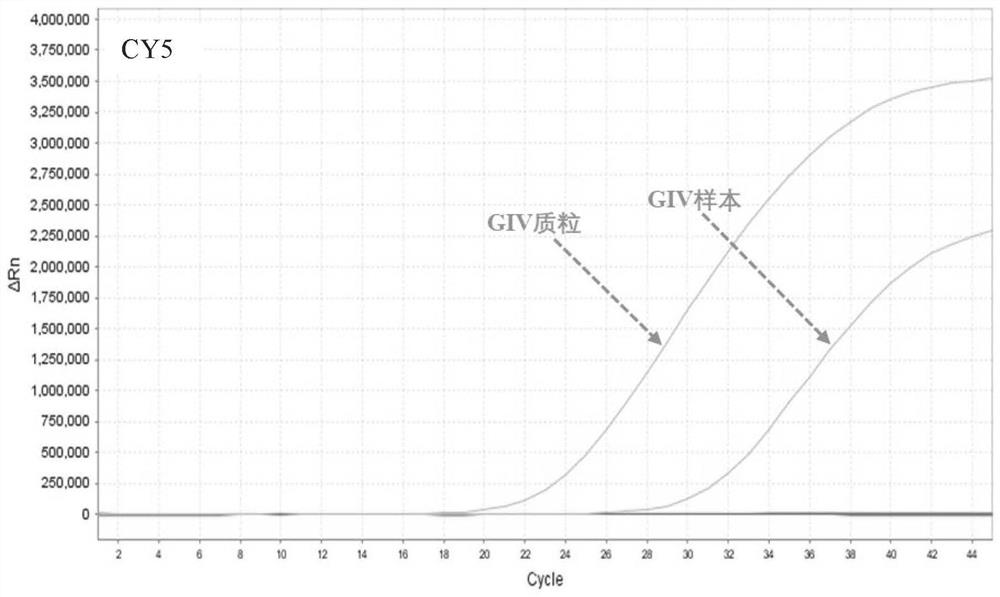

Norovirus GI, GII and GIV nucleic acid genotyping reagent kit and detection method

ActiveCN110273027AImprove detection efficiencyEffective crackingMicrobiological testing/measurementPositive controlNucleic acid detection

The invention discloses a Norovirus GI, GII and GIV nucleic acid genotyping reagent kit. The reagent kit comprises a viral nucleic acid quick extraction reagent, a PCR amplification reagent, PCR enzyme mixed liquor, a Norovirus GI, GII and GIV nucleic acid detection reagent, a positive control product, and a negative control product. The formula can be used for quick extraction of virus RNS, and the PCR detection efficiency is improved. The Norovirus GI, GII and GIV nucleic acid detection reagent comprises a Norovirus GI amplification primer F1, R1 and probe P1, a Norovirus GII amplification primer F2, R2 and probe P2 and a Norovirus GIV amplification primer F3, R3 and probe P3; and the sequence of the primer probe is created for the first time and unique in design, good in specificity and high in sensitivity. The invention further provides a Norovirus GI, GII and GIV nucleic acid genotyping detection method. According to the Norovirus GI, GII and GIV nucleic acid genotyping reagent kit and detection method disclosed by the invention, whether Norovirus GI, GII and GIV pathogens are contained in samples to be detected can be detected in a multichannel manner at the same time, quick and precise detection can be realized, viruses can be quantified, and application is convenient.

Owner:伯杰(青岛)医疗科技有限公司

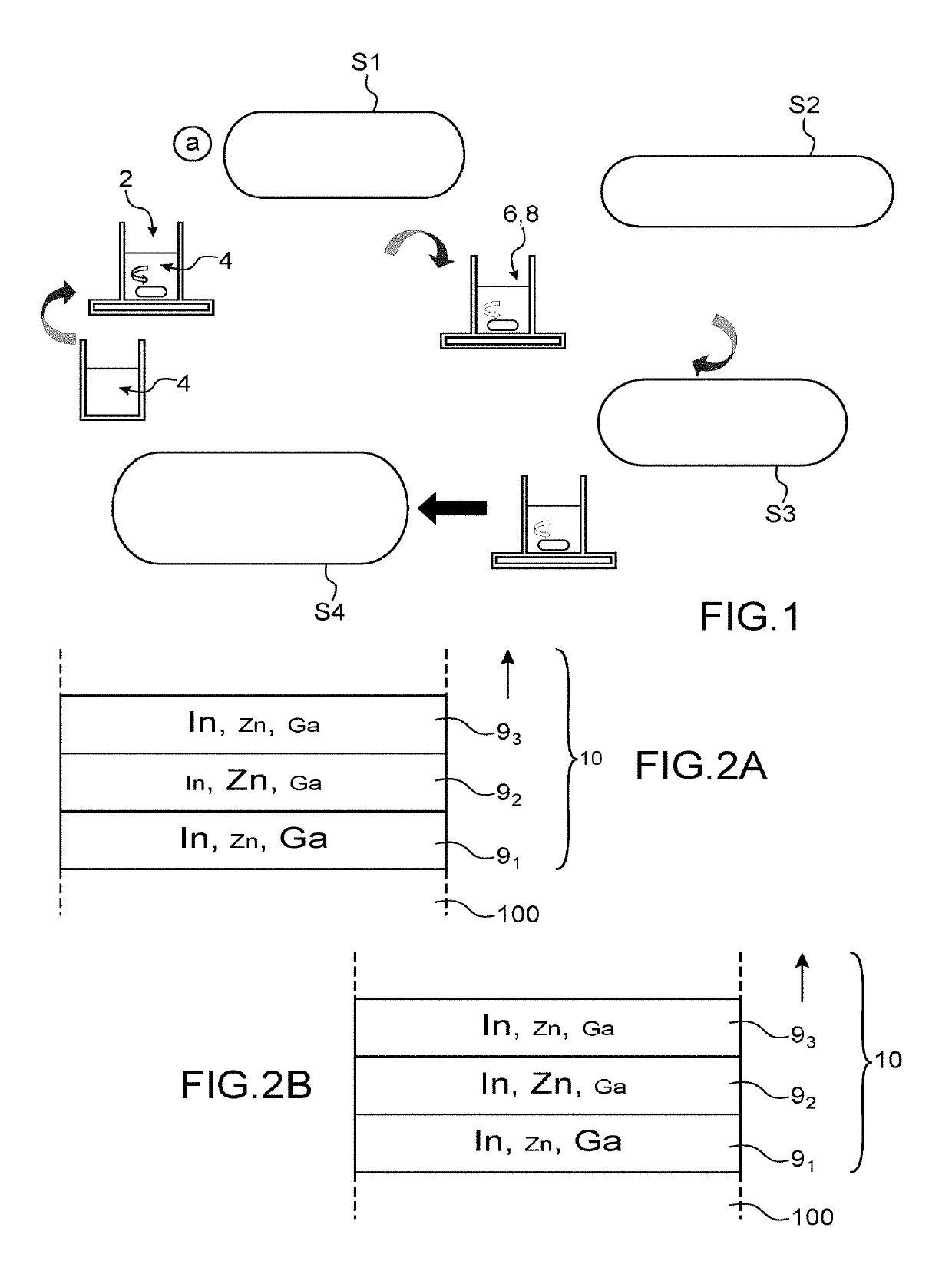

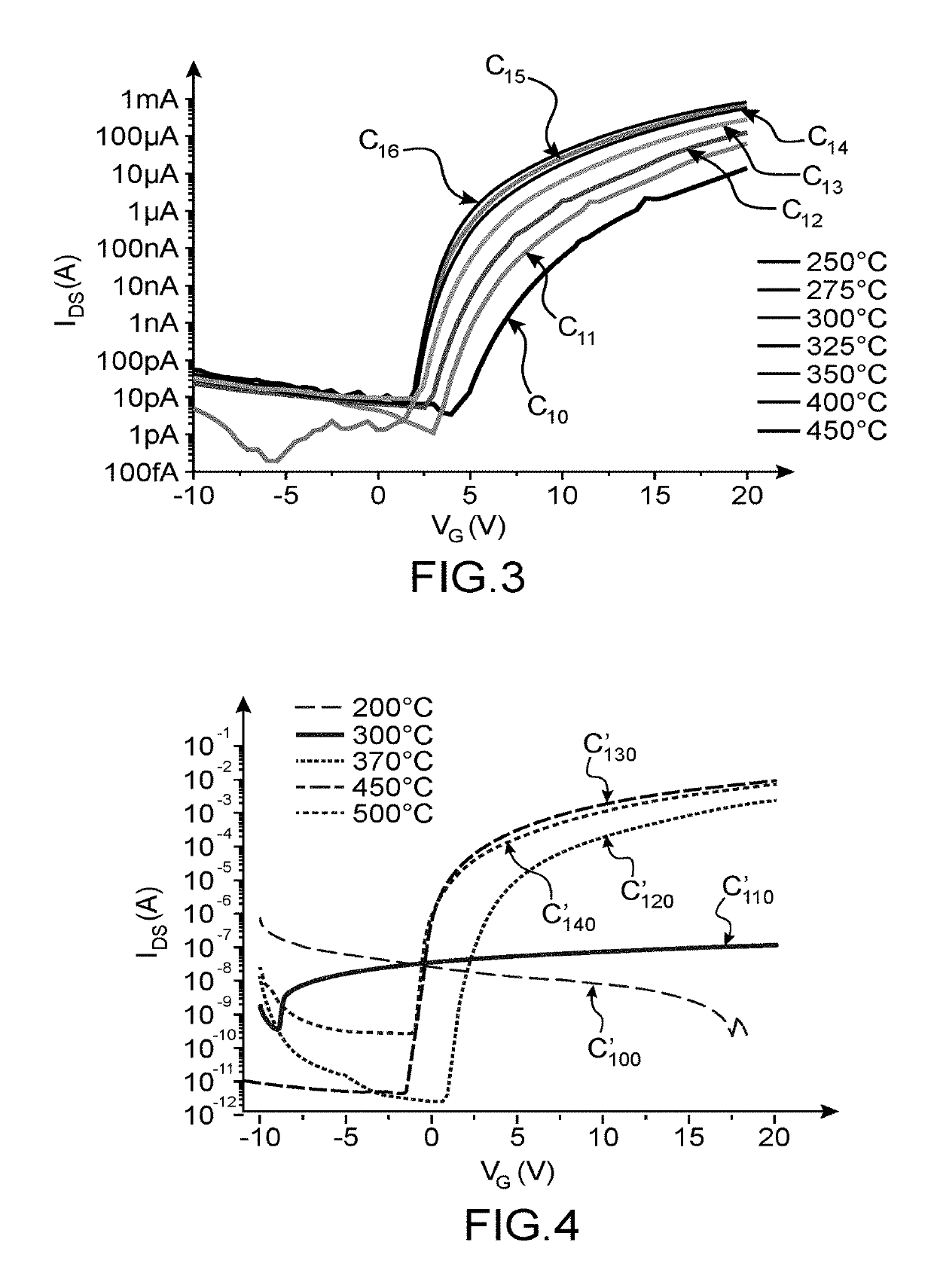

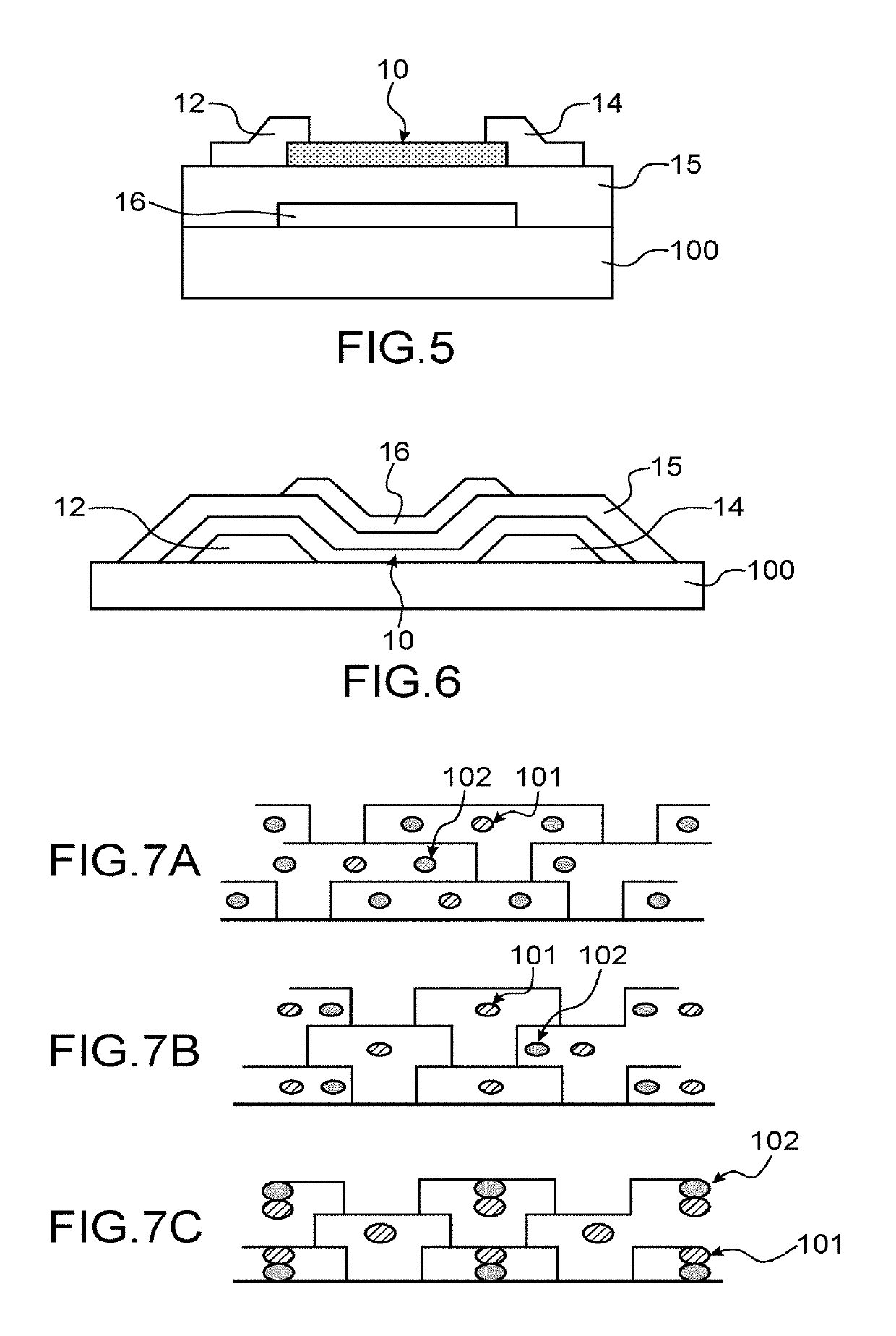

Reduction in the annealing temperature of an igzo layer obtained by sol gel

InactiveUS20180254185A1Reduce the temperatureEasy to annealTransistorSemiconductor/solid-state device manufacturingElectronic componentElectron

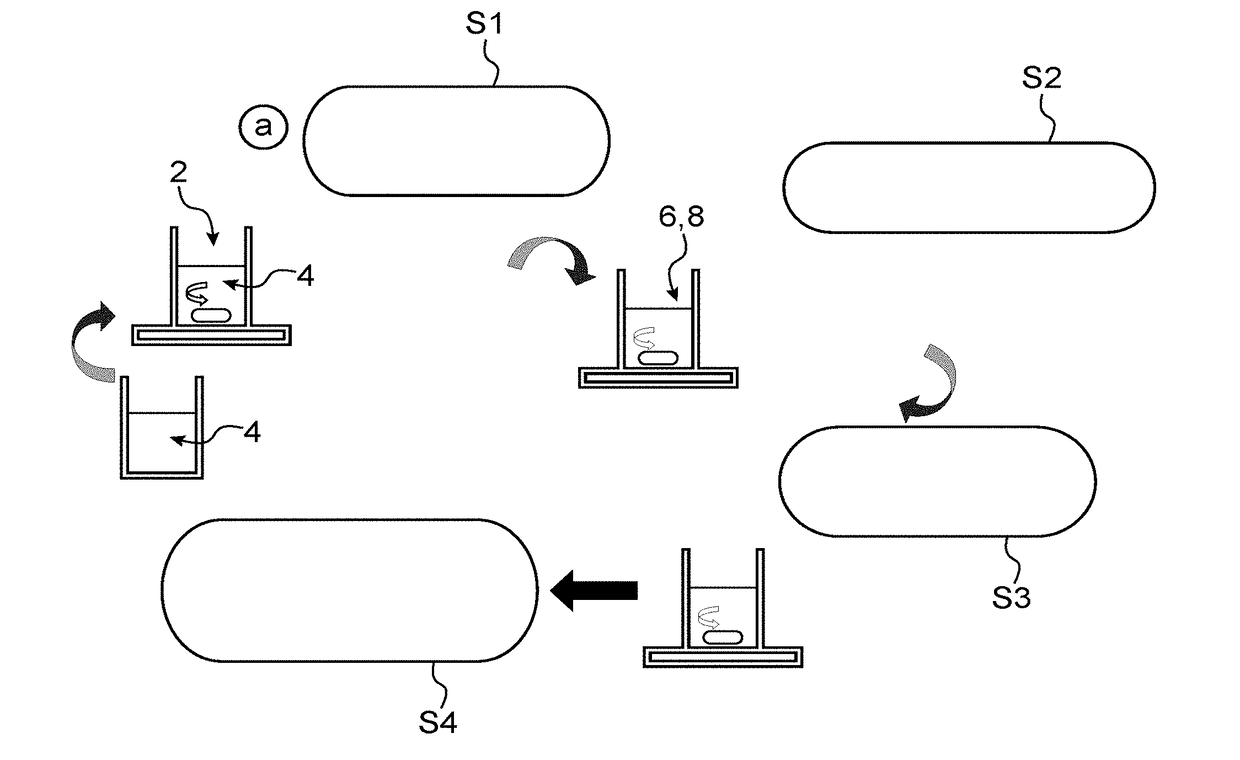

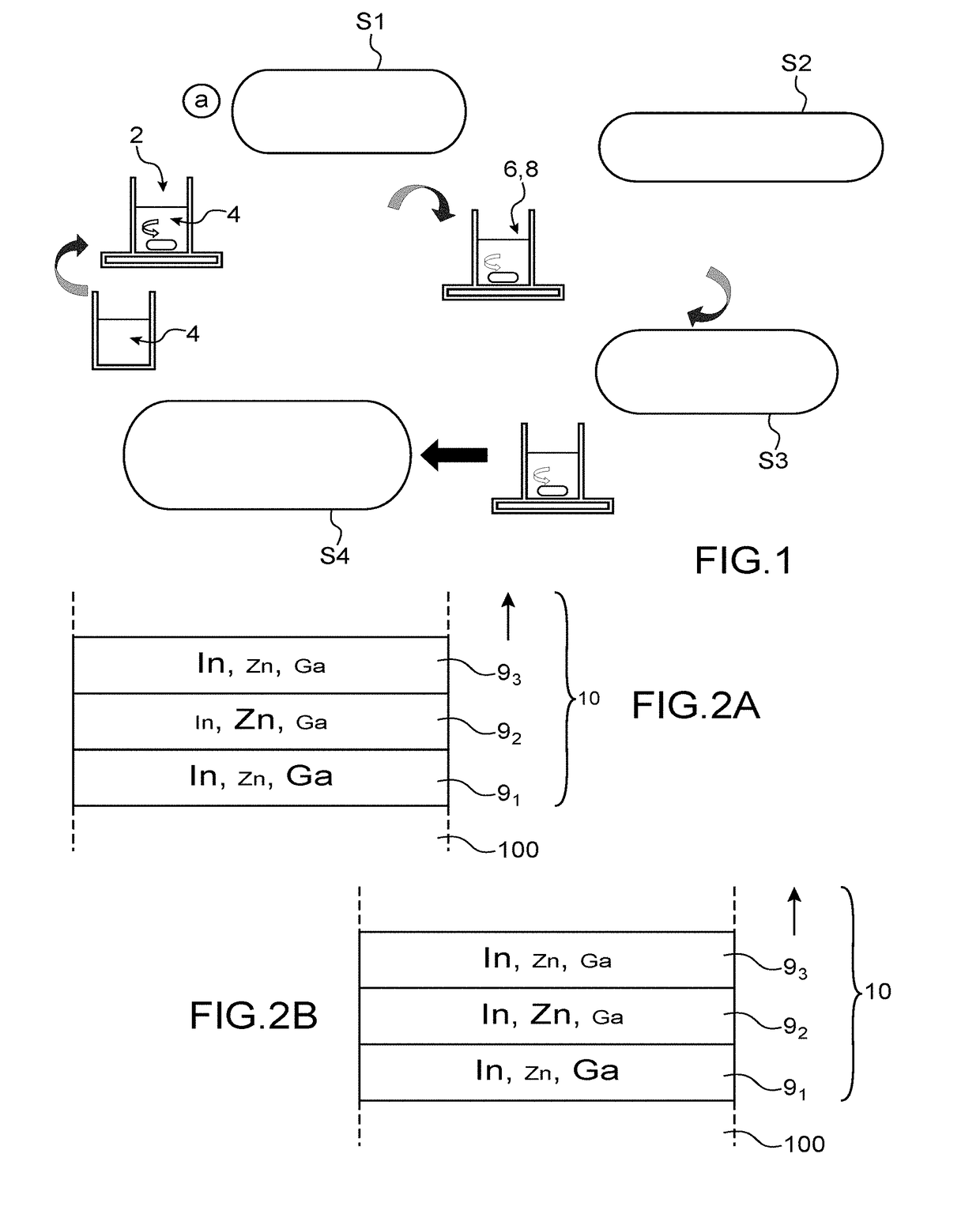

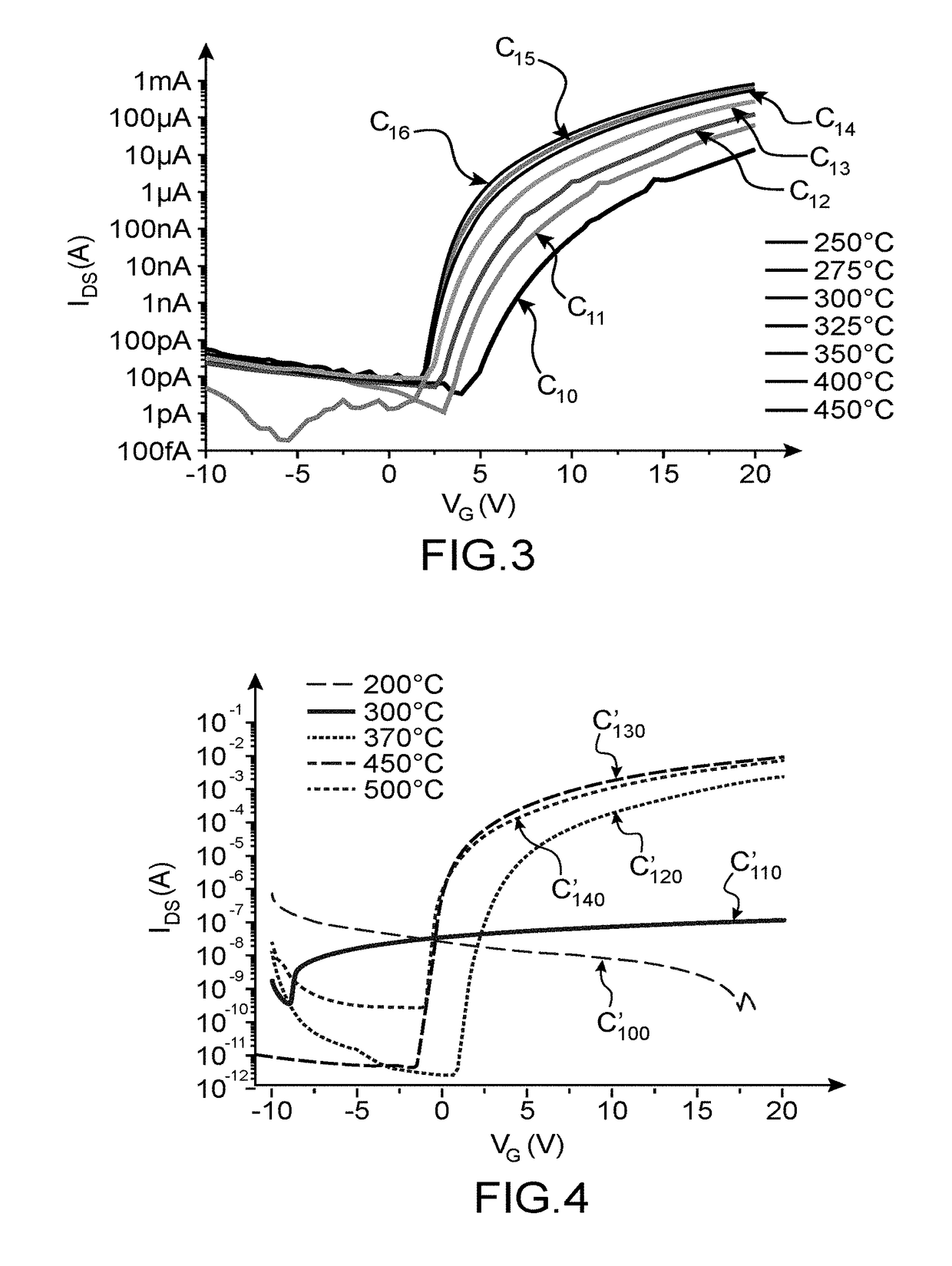

The present application relates to a method for forming an active zone of metal oxide for an electronic component including the formation of a stack of IXZO layers produced by liquid phase deposition on a substrate, the layers of said stack having different atomic fractions to each other in order to make it possible to reduce the annealing temperature enabling them to be made functional.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

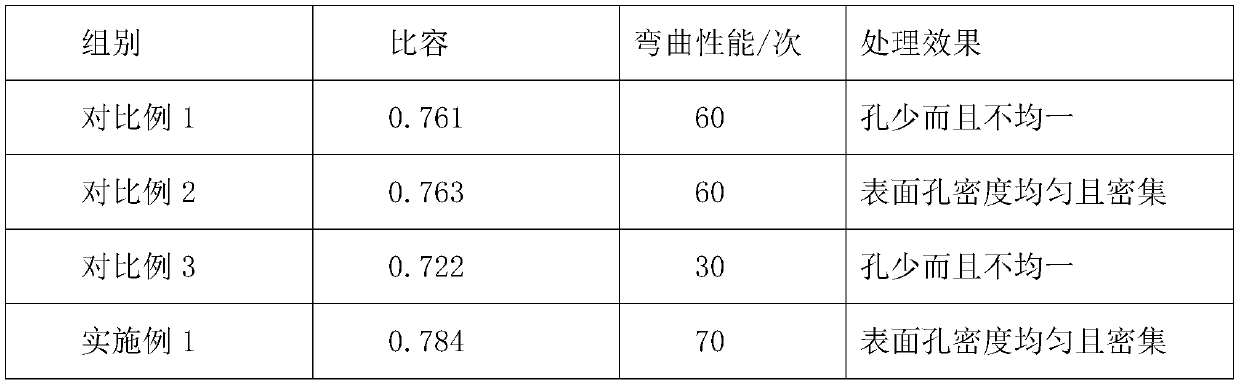

Manufacturing process for middle-high-voltage etched foil

InactiveCN109750346AStrong activation surfaceImprove bending performanceCapacitor manufactureAluminium electrolysisAluminum foil

The invention discloses a manufacturing process for middle-high-voltage etched foil, and relates to the technical field of production of etched foil. In order to solve the problem that etched foil isprone to deforming in the prior art, the manufacturing process comprises the steps of pretreatment, primary foaming corrosion, secondary foaming corrosion, third hole expansion corrosion and aftertreatment for high-purity aluminum foil; in the pretreatment, the aluminum plain foil is put into pretreatment liquid to be soaked for 40-50 seconds; then the aluminum plain foil is washed and then put into primary corrosion mixing liquid with the temperature of 80-90 DEG C, the foil is washed with pure water to be put into 2% of nitric acid liquid with the temperature of 70-80 DEG C, and direct current with the current density of 0.15 A / cm2 is applied for electrolytic corrosion for 500-600 seconds; and the aftertreatment adopts two-stage annealing heat treatment of different temperatures. The pretreatment process is simple, operation is convenient, deformation is avoided, the annealing process is improved in the aftertreatment, the two-stage annealing heat treatment of different temperaturesis adopted, and the bending performance of the etched foil for an aluminum electrolytic capacitor is greatly improved.

Owner:CENT SOUTH UNIV

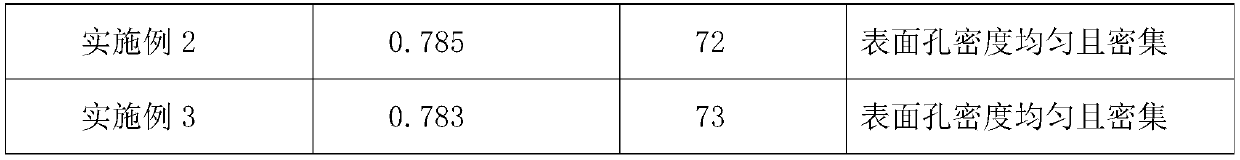

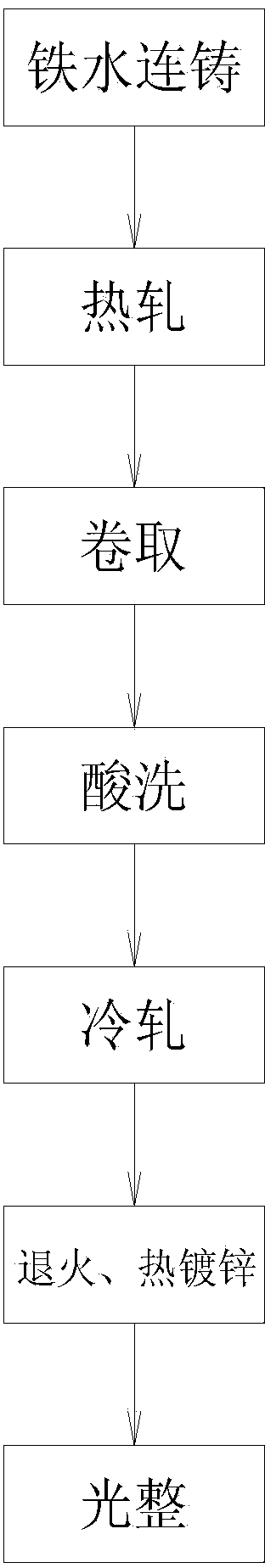

High-yield-ratio hot-galvanized micro-carbo/aluminum killed steel plate and production method thereof

InactiveCN104046890AEffective pinningHigh yield strengthHot-dipping/immersion processesSheet steelContinuous annealing

The invention relates to a high-yield-ratio hot-galvanized micro-carbo / aluminum killed steel plate and a production method thereof. The method comprises the following steps: carrying out desulphurization, bessemerizing, RH vacuum refining and continuous casting on molten iron so as to obtain a continuous casting sheet billet; carrying out hot rolling on the continuous casting sheet billet so as to obtain a hot rolled sheet billet; rolling the hot rolled sheet billet so as to obtain hot-rolled steel coil; carrying out uncoiling and acid pickling on the hot-rolled steel coil; carrying out cold rolling on the hot-rolled steel coil subjected to acid pickling so as to obtain a cold-rolled steel plate; carrying out annealing and hot galvanizing on the cold-rolled steel plate in a continuous annealing furnace; and carrying out finishing processing on the annealed cold-rolled steel plate. The high-yield-ratio hot-galvanized micro-carbo / aluminum killed steel plate produced according to the method has good forming properties and mechanical properties, and can satisfy the requirements of cargo trucks on the stamping formability of steel plates.

Owner:SHOUGANG CORPORATION

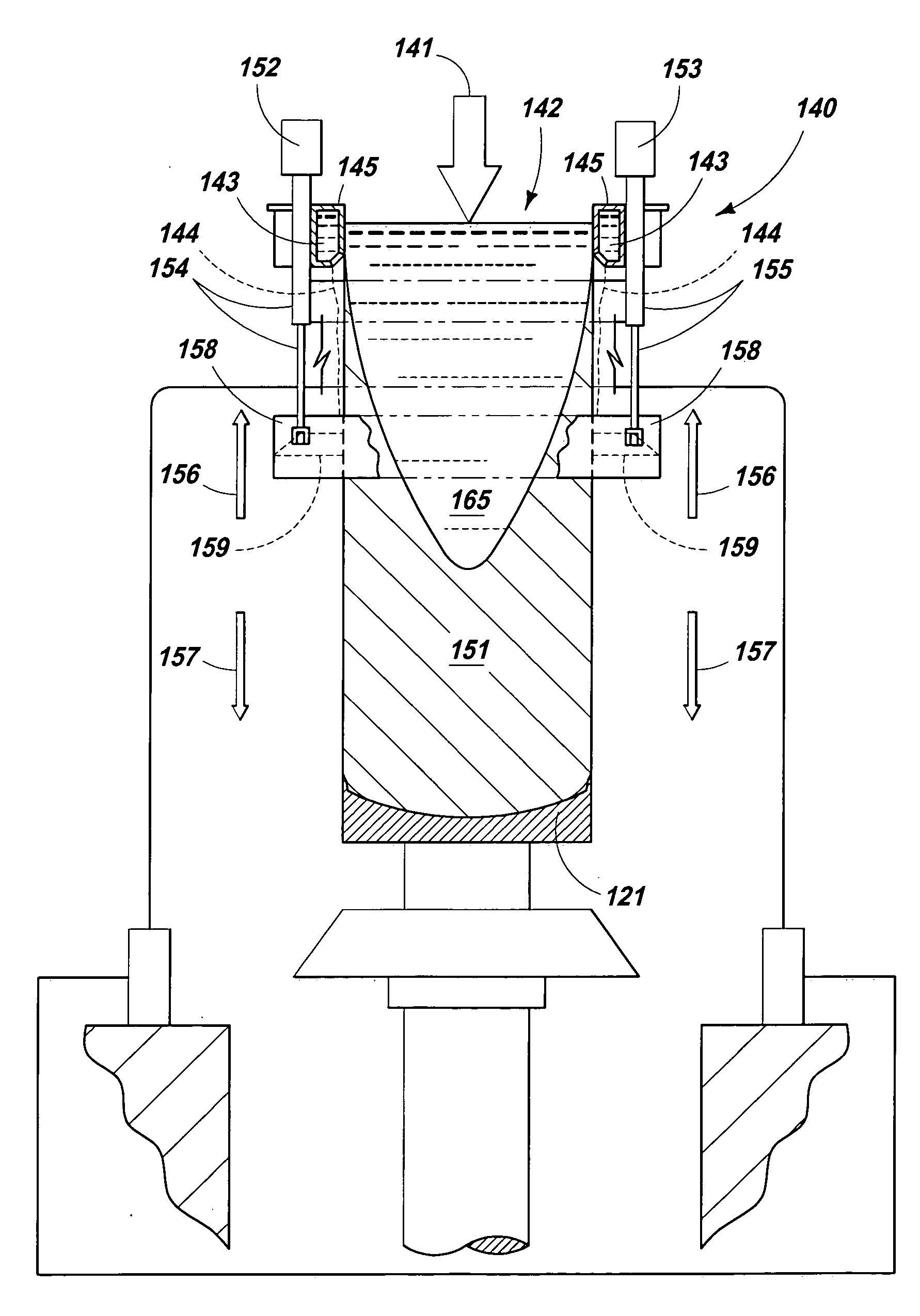

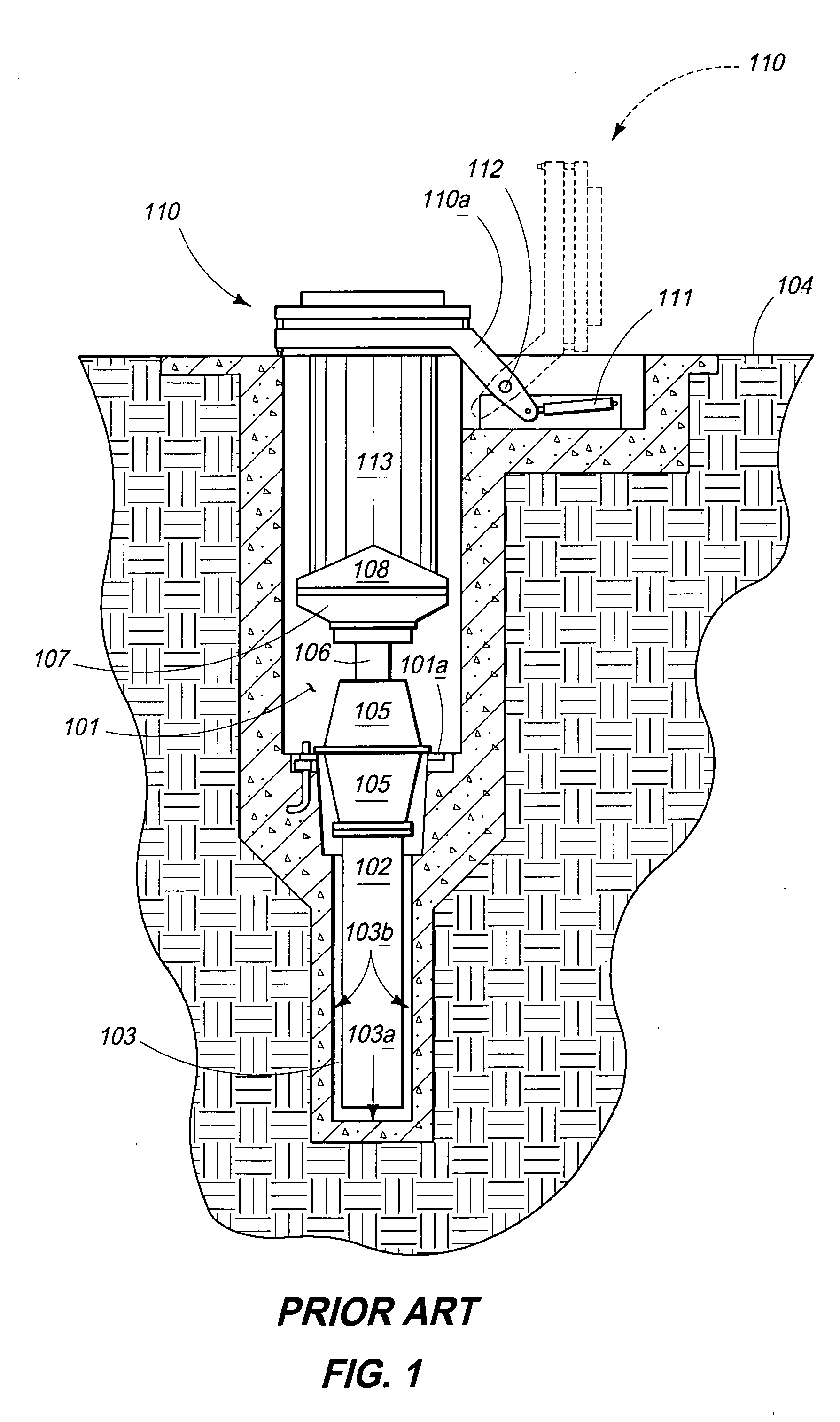

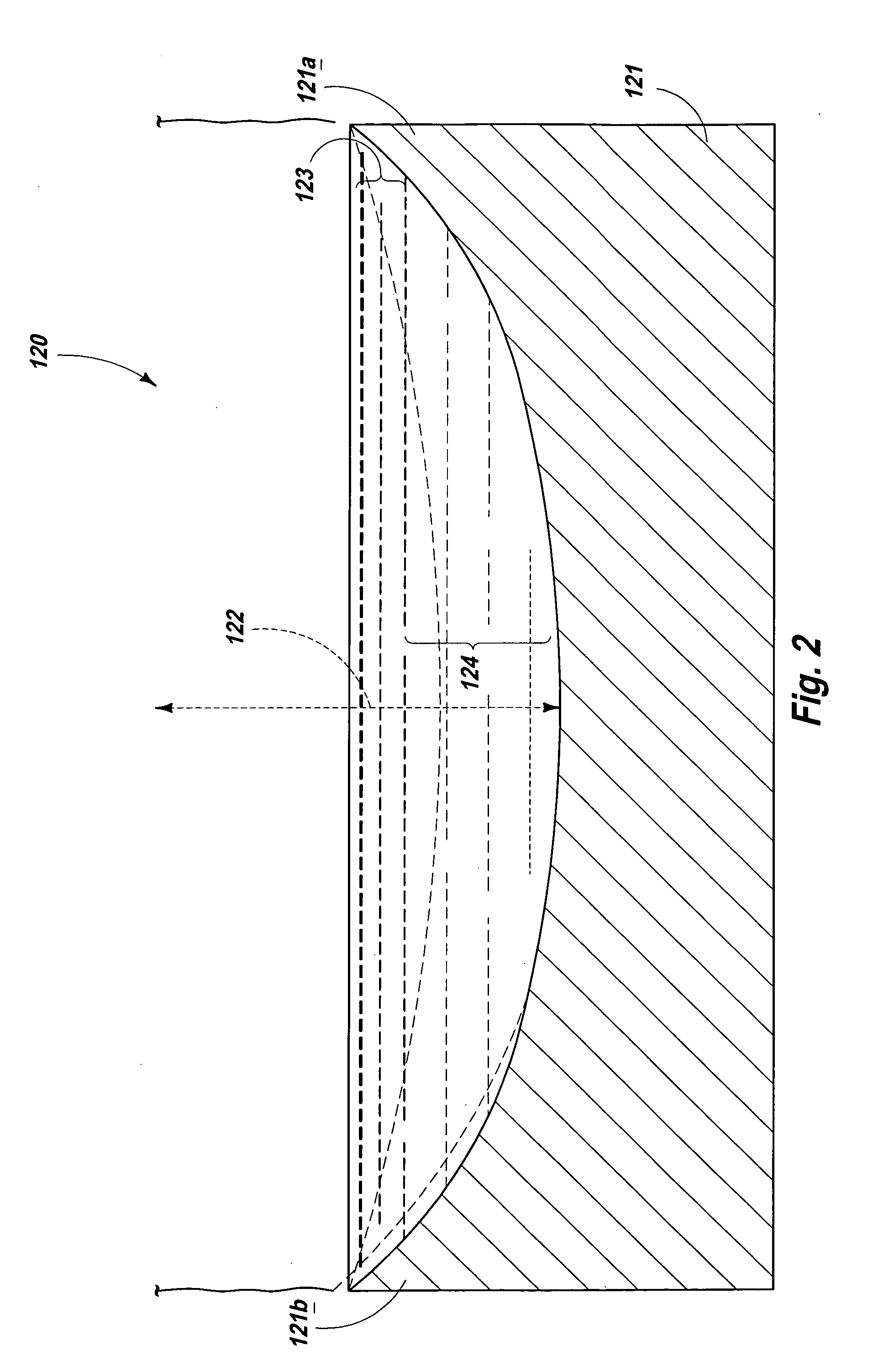

Coolant control and wiper system for a continuous casting molten metal mold

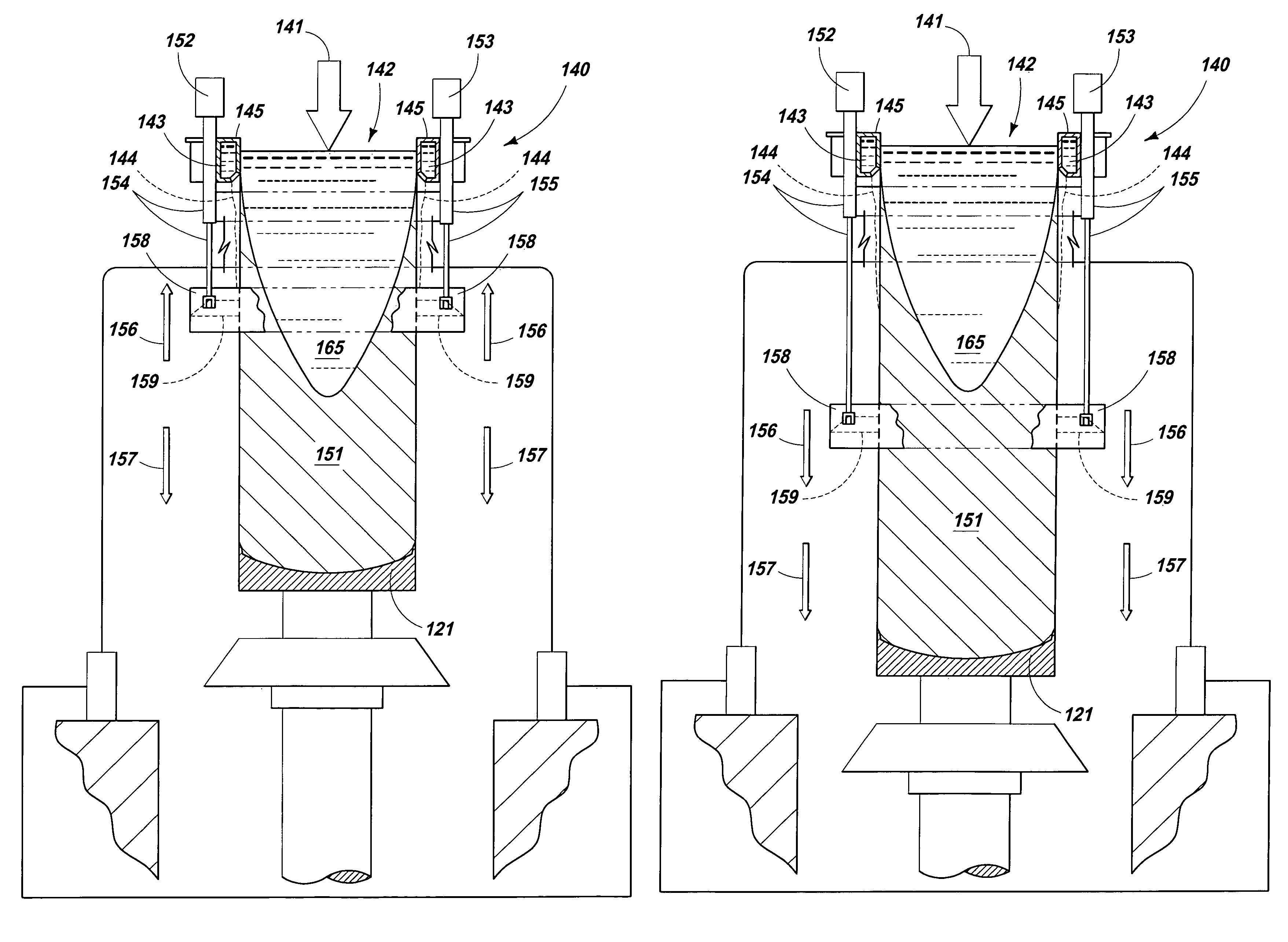

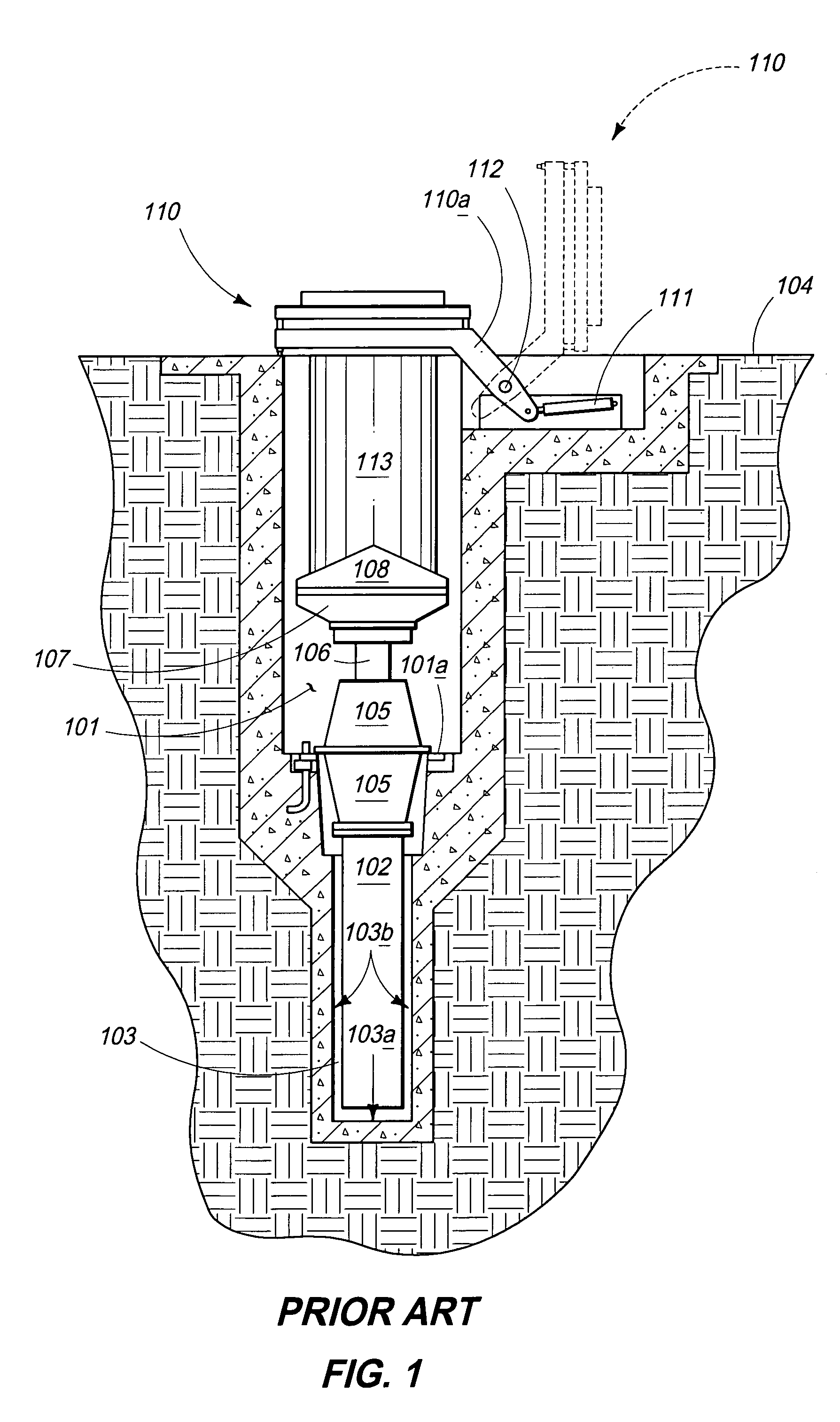

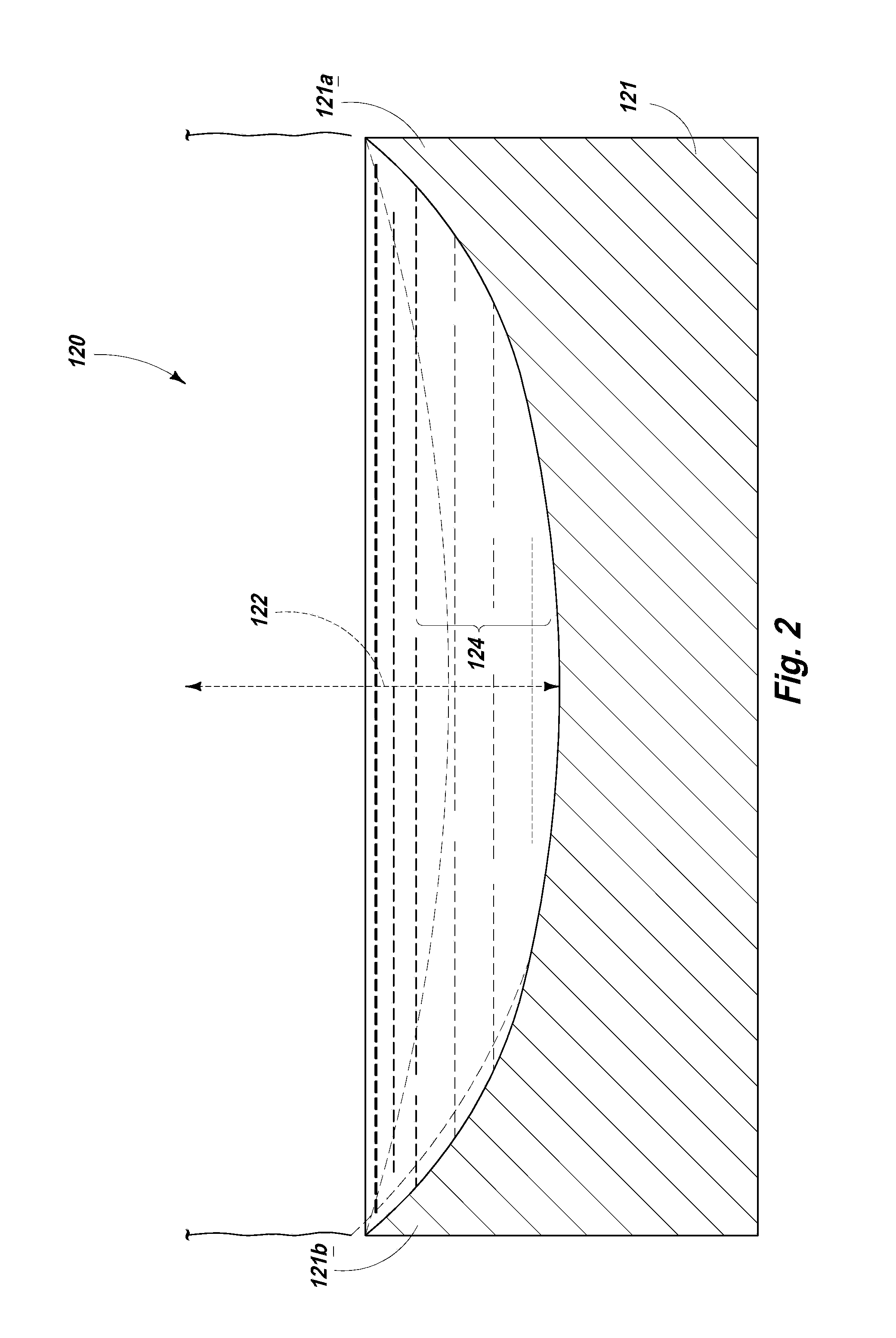

ActiveUS20120186773A1Easy to annealMinimizing capture and trappingIngot casting plantsControl systemMetal mold

A coolant or wiper control system for use in continuous casting mold for controlling and managing the coolants interaction with the castpart during casting. In some aspects of the process, the wiper framework is started sufficiently away from the bottom block so as not to interfere or cause / allow coolant to get into the bottom block; is then rapidly moved back to the emerging castpart during transient heat-up; and then moved away from the mold with the solidified castpart at a controlled rate to a predetermined steady state position or to a second transitory state of the casting.

Owner:WAGSTAFF INC

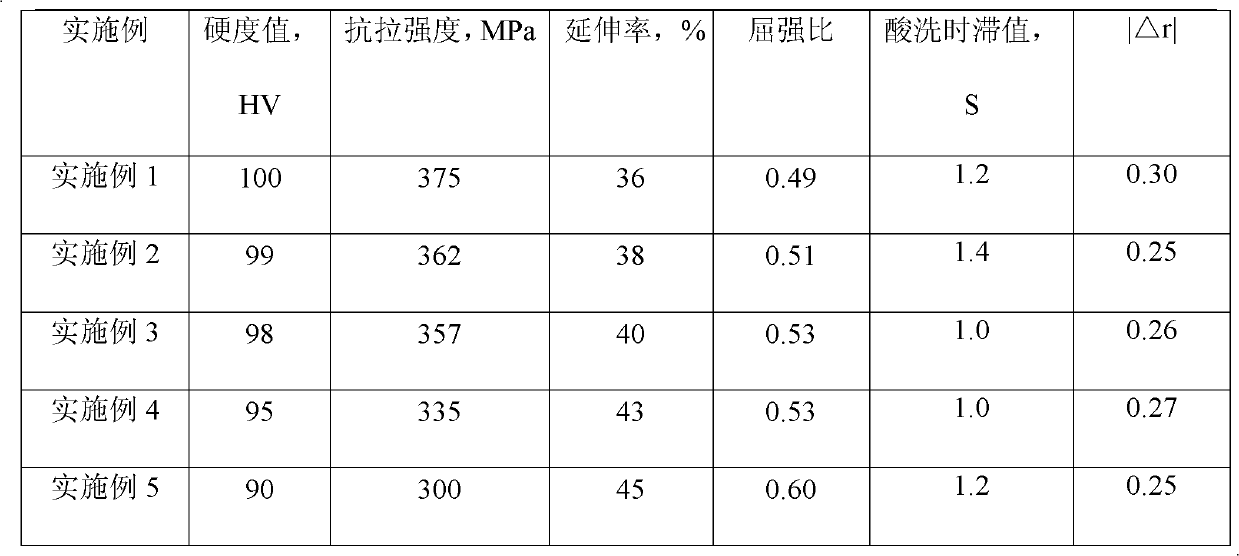

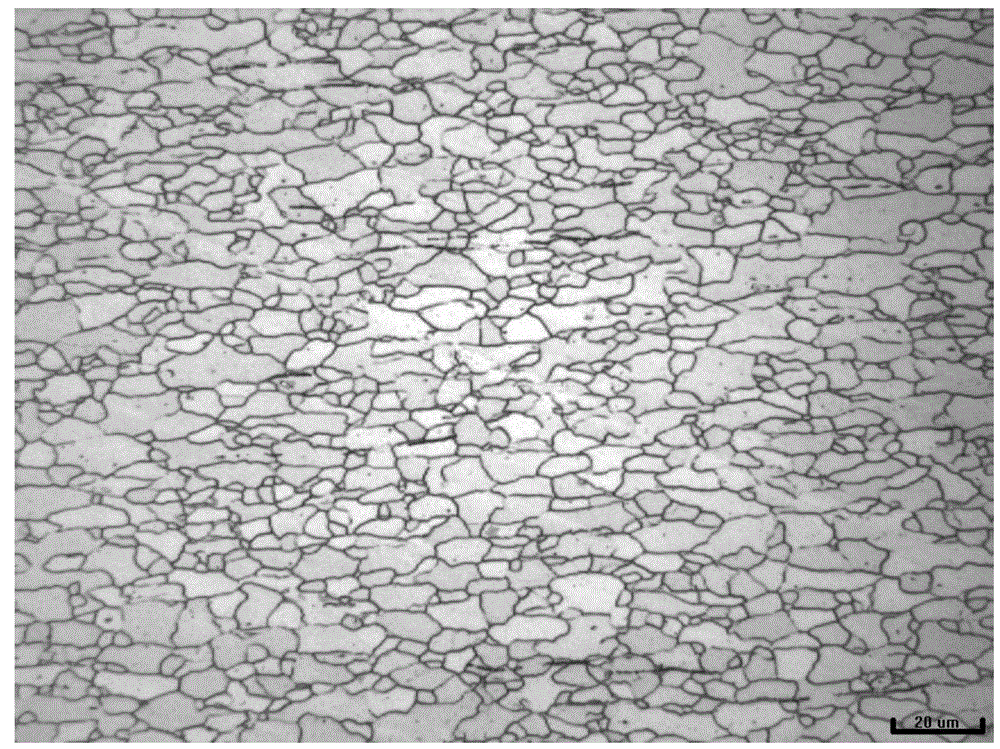

Corrosion-resistant steel with impact molding rate not smaller than 150 per minute for cell shell and preparation method thereof

The invention relates to steel capable of being subjected to rapid impact molding for a cell shell and a preparation method thereof. The steel comprises the components in percentage by weight: 0.0001-0.0050% of C, 0.10-0.20% of Mn, 0.010-0.050% of Al, 0.0001-0.0040% of N, 0.010-0.030% of Nb, not more than 0.020% of P, not more than 0.015% of S, not more than 0.05% of Cu, not more than 0.05% of Ni, not more than 0.08% of Cr, not more than 0.05% of Mo and not more than 0.020% of Si. The preparation method comprises the steps: smelting according to a pure steel process and carrying out continuous casting to obtain a blank; heating the continuous cast blank; carrying out rough rolling; carrying out finish rolling in a single-phase austenite region; coiling; pickling; carrying out cold rolling; degreasing; annealing in a full-hydrogen bell-type furnace; and leveling for later use. The finished product obtained in the invention has stable mechanical properties, hardness being 90-100, tensile strength being not lower than 300 MPa, elongation percentage being not lower than 36% and yield ratio being not more than 0.6; the impact-molded cell shell is not easy to crack and has good drum body shape fixity; and the finished product has high corrosion resistance.

Owner:武钢集团有限公司

Hot-dip galvanized steel sheet and production method thereof

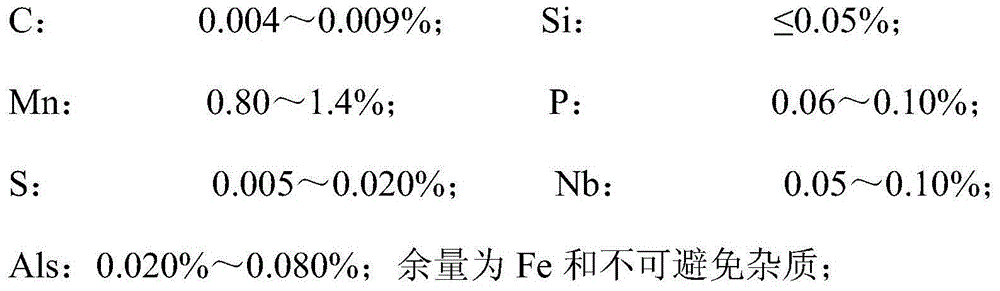

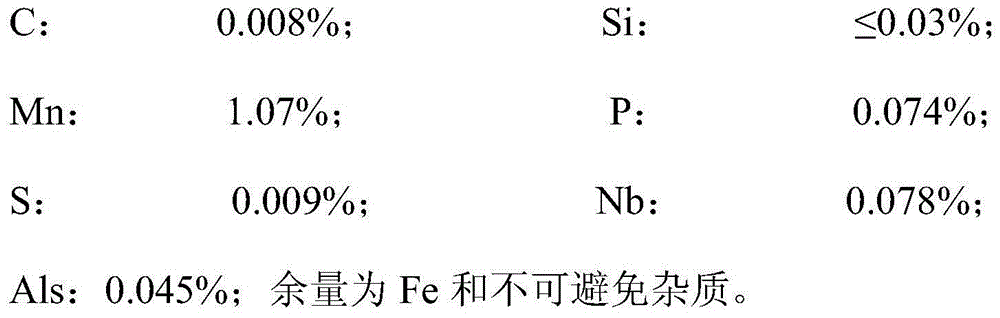

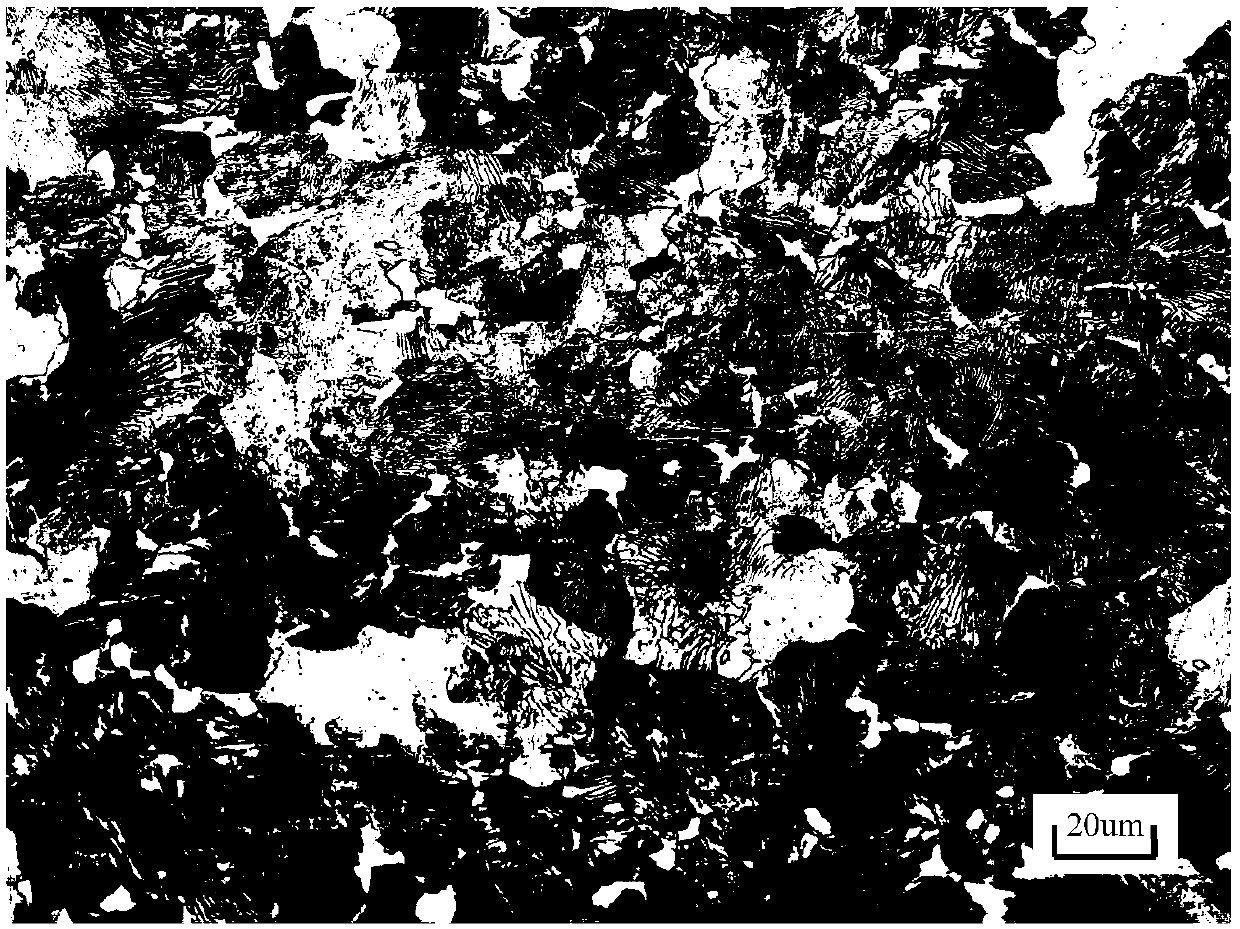

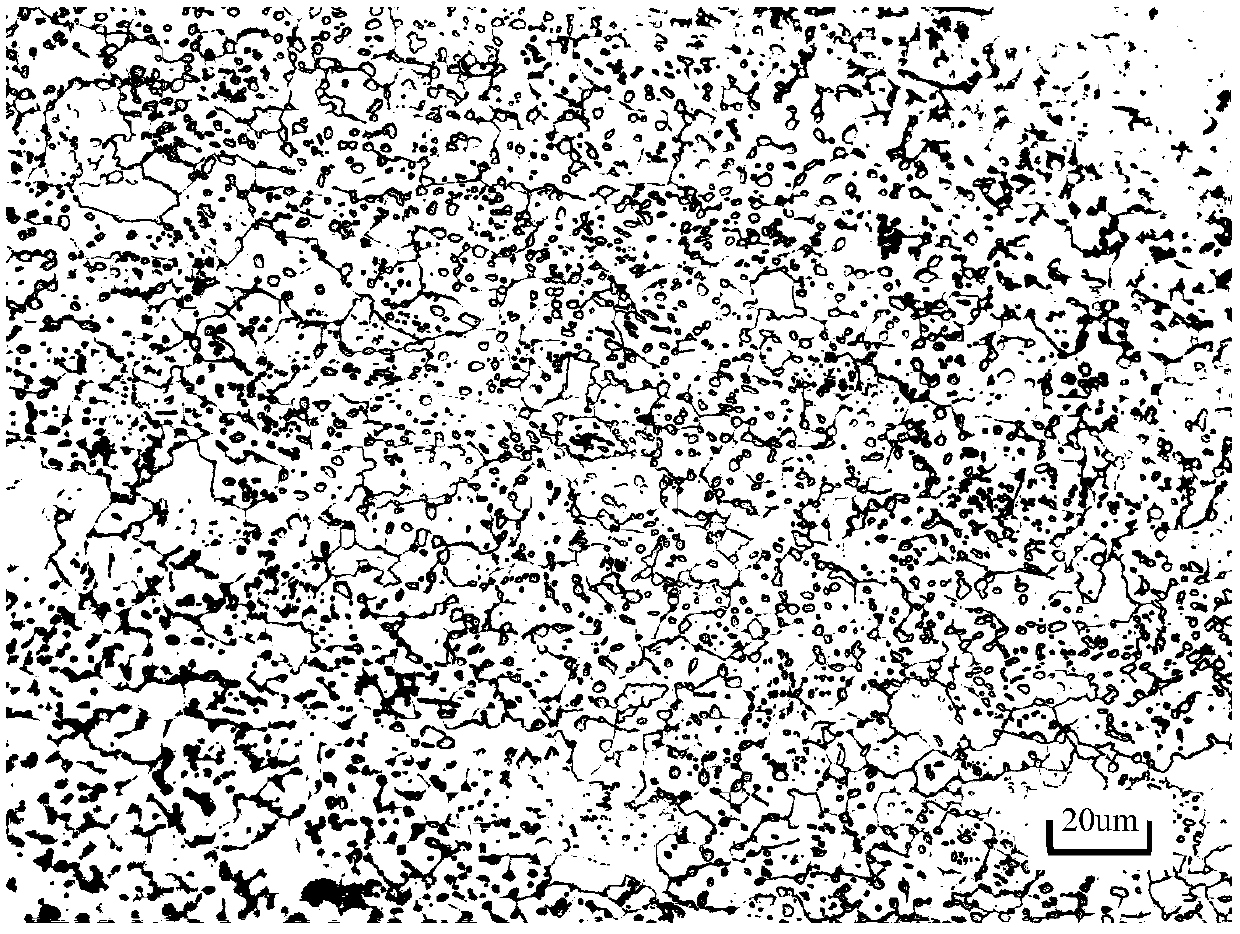

ActiveCN104674113AThe manufacturing process is less difficult to implementReduce the difficulty of implementationHot-dipping/immersion processesUltimate tensile strengthZinc

The invention discloses a hot-dip galvanized steel sheet for an automobile and a production method thereof. The hot-dip galvanized steel sheet consists of a base plate and a zinc coating on the base plate, wherein the chemical components of the base plate are as follows: 0.004-0.009% of C, 0-0.05% of Si, 0.80-1.4% of Mn, 0.06-0.10% of P, 0.005-0.020% of S, 0.05-0.10% of Nb, 0.020-0.080% of Als, and the balance of Fe and unavoidable impurities. The organization structure of the base plate is 100% of ferrite, wherein the grain fineness number is 9.0-11.0 and the grain size is 10.5-18.0mu m. The production method comprises the steps of casting the molten iron containing the components into blanks, performing rough rolling, fine rolling and cold rolling under a proper temperature, annealing to obtain the base plate, and galvanizing the base plate. The hot-dip galvanized steel sheet obtained from the invention has the following performances that the yield strength is 360-410 MPa, the tensile strength is 440-490 MPa, the ductility is 30.0-34.0%, the r90 is 1.6-2.0, and the n90 is 0.15-0.19. The hot-dip galvanized steel sheet has the characteristics of high strength, good forming property and corrosion resistance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Cold-roll steel plate used for precise punching of automobile safety belt buckles and manufacturing method of precise punching cold-roll steel plate

The invention discloses a cold-roll steel plate used for precise punching of automobile safety belt buckles and a manufacturing method of the precise punching cold-roll steel plate. The technical problems that an existing cold-roll steel plate used for precise punching of automobile safety belt buckles is high in hardness, low in ductility and not suitable for high-speed precise punching are solved. The cold-roll steel plate used for precise punching of automobile safety belt buckles comprises the chemical components including, by weight, 0.56%-0.64% of C, smaller than or equal to 0.20% of Si,0.3%-0.5% of Mn, 0.01%-0.04% of Al, 0.15%-0.25% of Cr, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S and the balance Fe and inevitable impurities. The yield strength RP 0.2 of the cold-roll steel plate is 300 MPa to 350 MPa, and the after-fracture elongation A 50 mm is 32% to 38%. The cold-roll steel plate is used for high-speed precise punching manufacturing of components such as automobile safety belt buckles.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Coolant control and wiper system for a continuous casting molten metal mold

ActiveUS8590596B2Easy to annealMinimizing capture and trappingIngot casting plantsControl systemMetal mold

A coolant or wiper control system for use in continuous casting mold for controlling and managing the coolants interaction with the castpart during casting. In some aspects of the process, the wiper framework is started sufficiently away from the bottom block so as not to interfere or cause / allow coolant to get into the bottom block; is then rapidly moved back to the emerging castpart during transient heat-up; and then moved away from the mold with the solidified castpart at a controlled rate to a predetermined steady state position or to a second transitory state of the casting.

Owner:WAGSTAFF INC

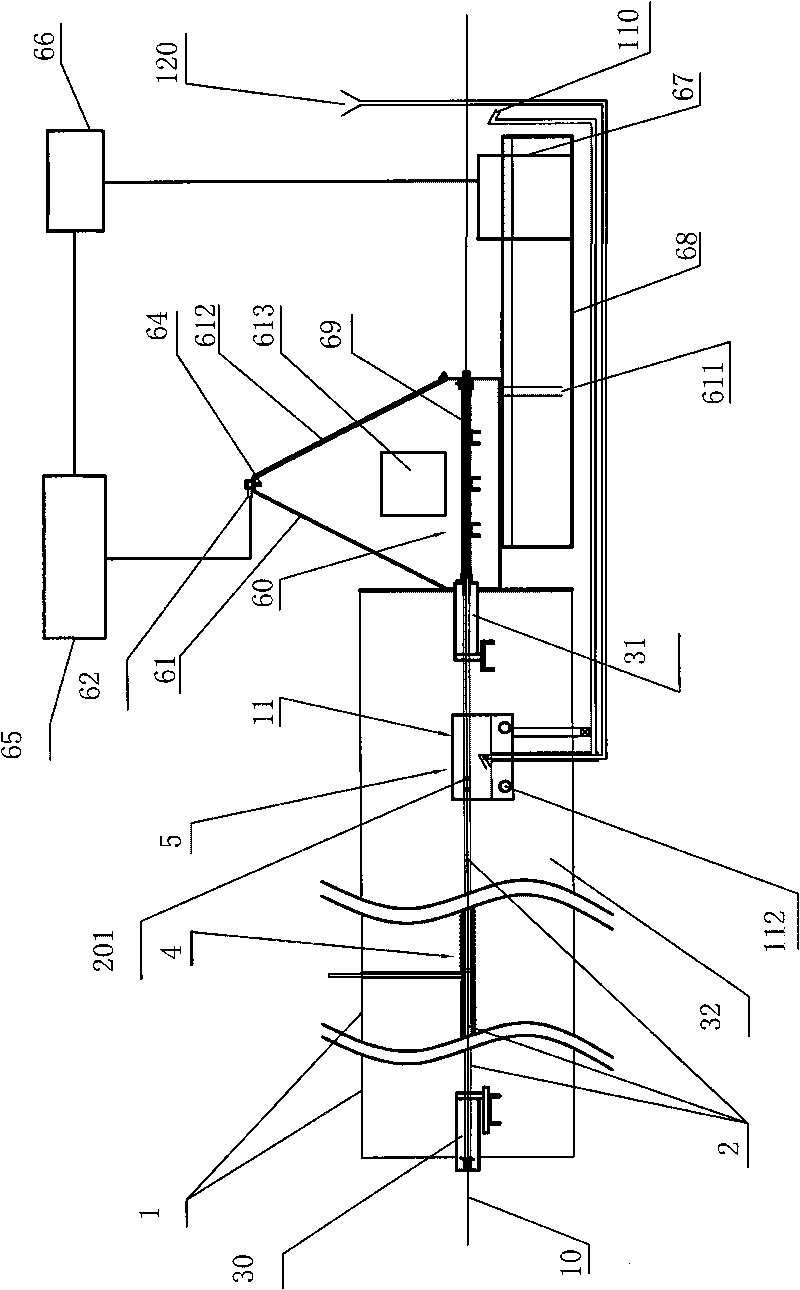

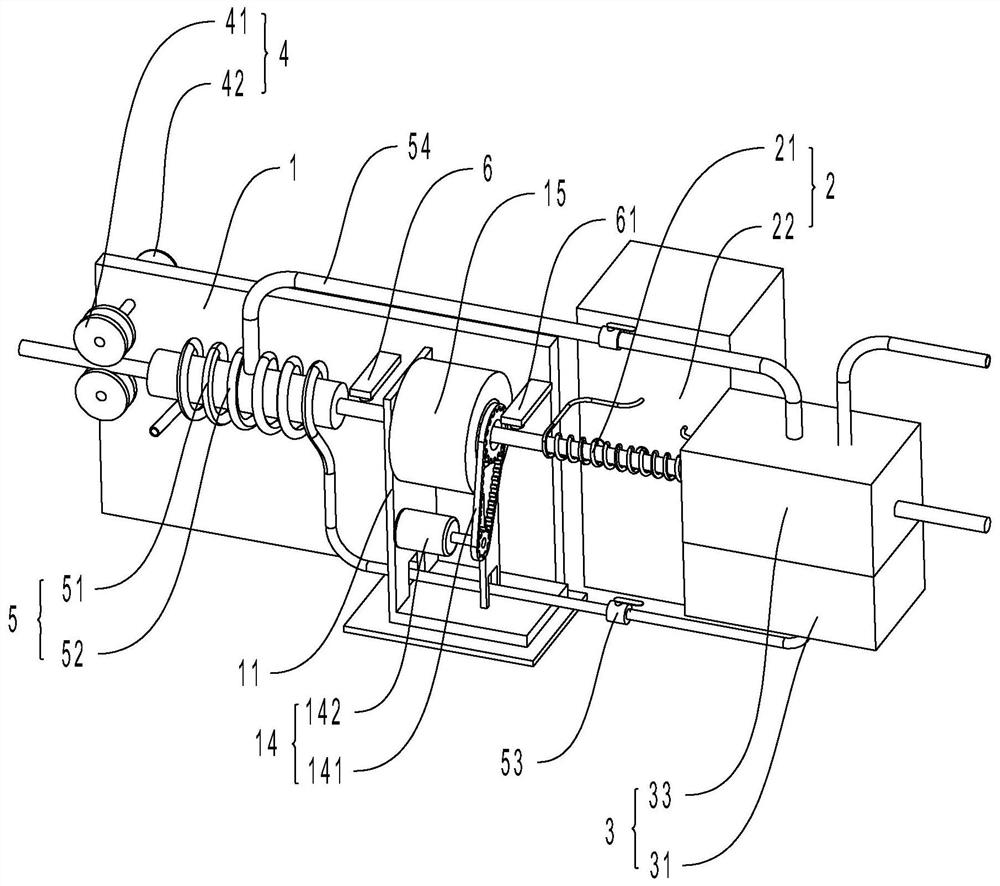

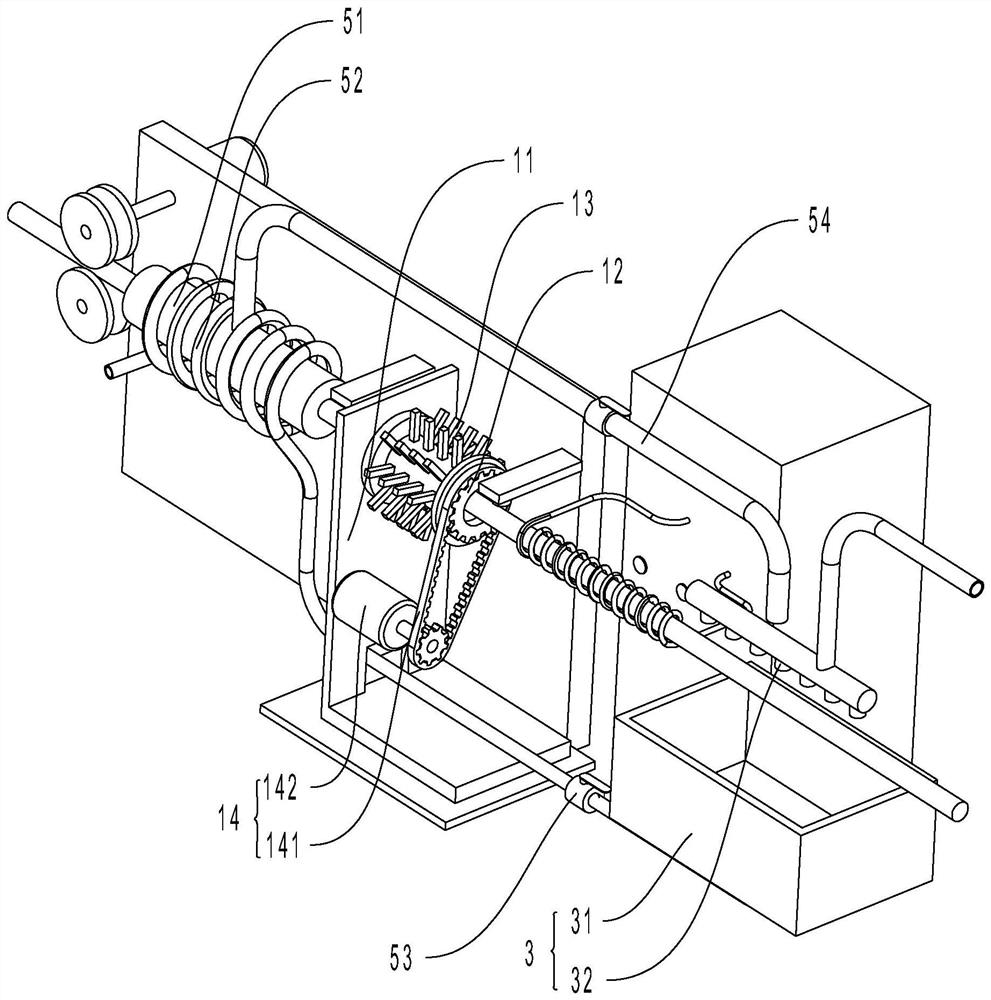

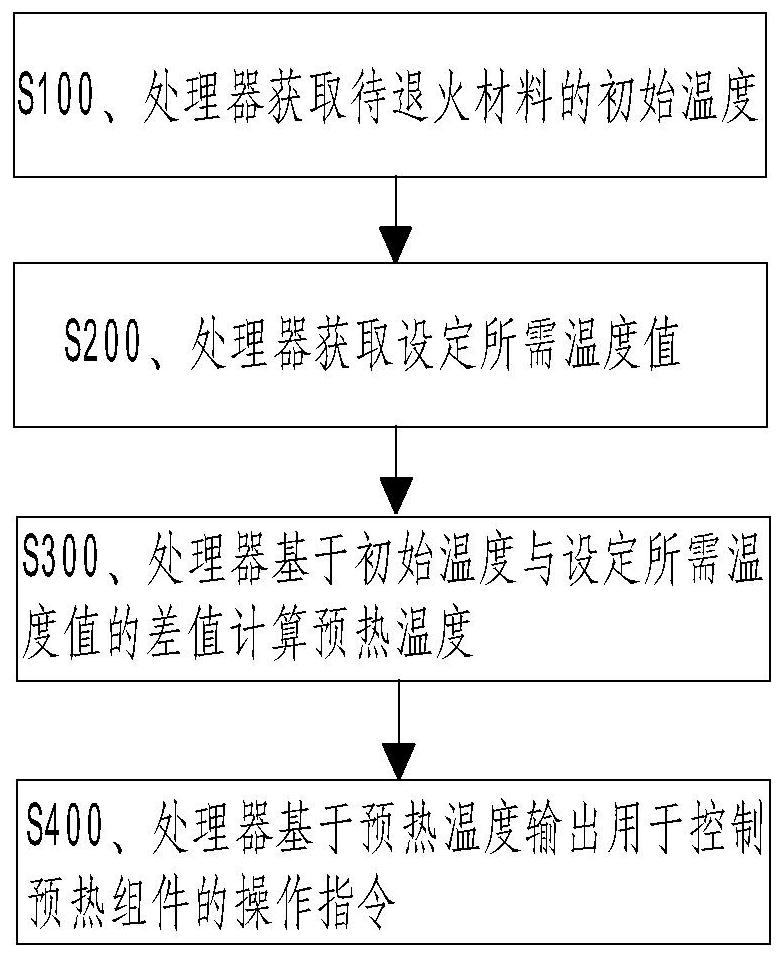

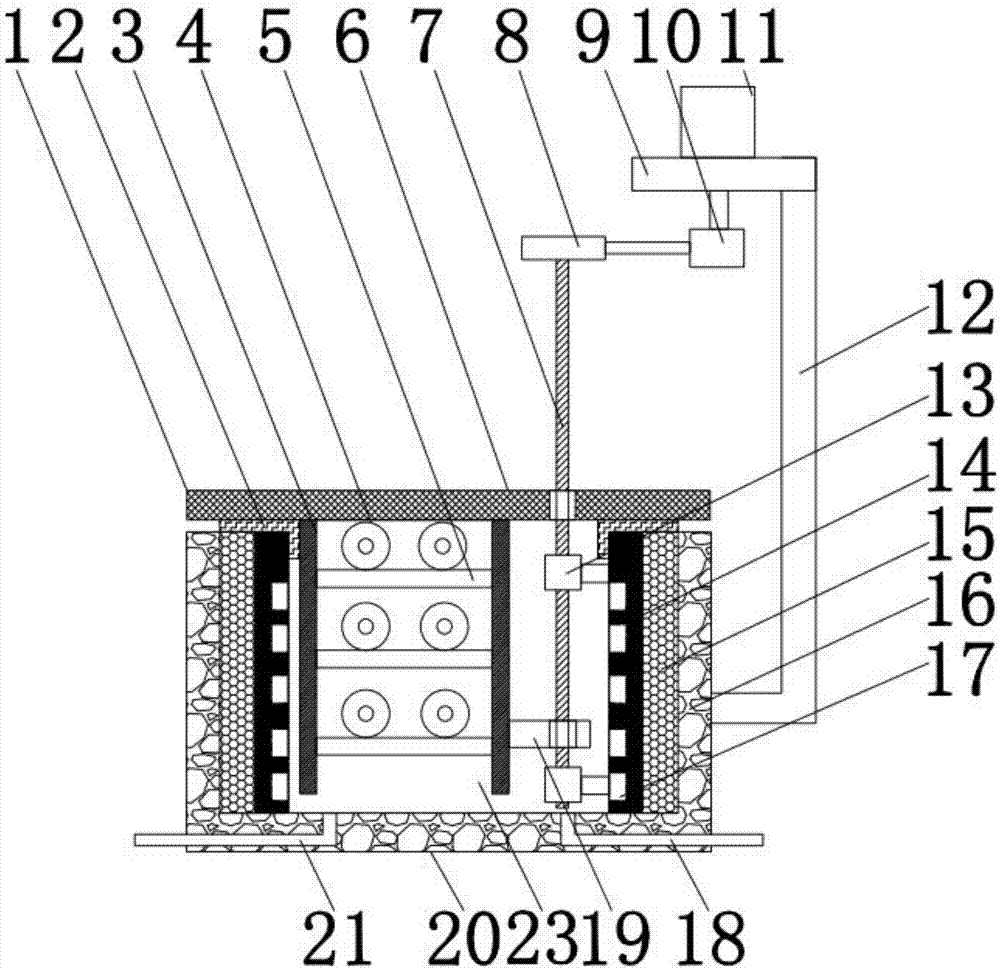

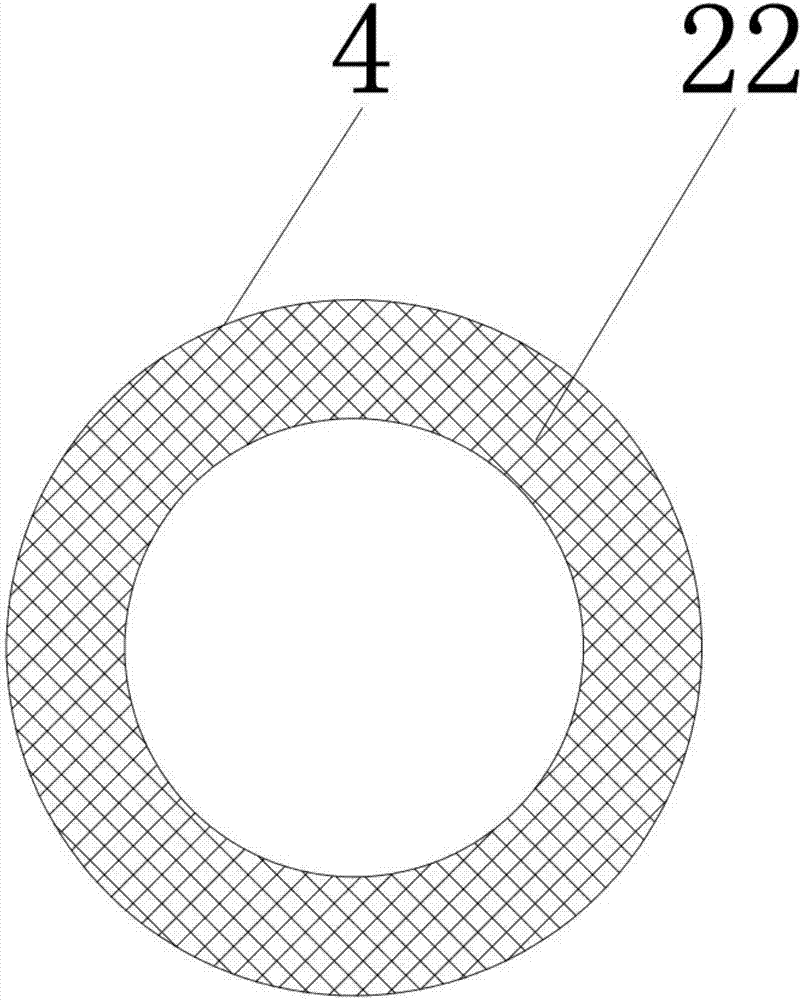

Intelligent copper pipe online annealing equipment and control method thereof

InactiveCN113088661AImprove the heating effectEasy to annealDrying solid materials without heatFurnace typesElectrical connectionEngineering

The invention relates to intelligent copper pipe online annealing equipment. The intelligent copper pipe online annealing equipment comprises a machine body and further comprises a heating device, a cooling device and a conveying device which are connected with the machine body, wherein the heating device comprises an eddy current coil and a power supply device electrically connected with the eddy current coil, and a heating channel for materials to pass through is formed in the eddy current coil; the conveying device is used for driving the materials to pass through the heating channel; a preheating tube and a preheating assembly are arranged on the portion, located on the feeding side of the eddy current coil, of the machine body, the preheating assembly is used for heating materials passing through the preheating tube, a temperature measuring sensor used for measuring the temperature of the materials is arranged on the side, away from the eddy current coil, of the preheating tube, and a controller used for receiving temperature signals of the temperature measuring sensor is connected to the temperature measuring sensor; and the controller is connected with the preheating assembly so as to respond to the temperature signal to control the preheating temperature of the preheating assembly. The intelligent copper pipe online annealing equipment has the effects of reducing the influences of the external temperature on the quality of an annealing material.

Owner:JIANGXI NAILE COPPER IND +1

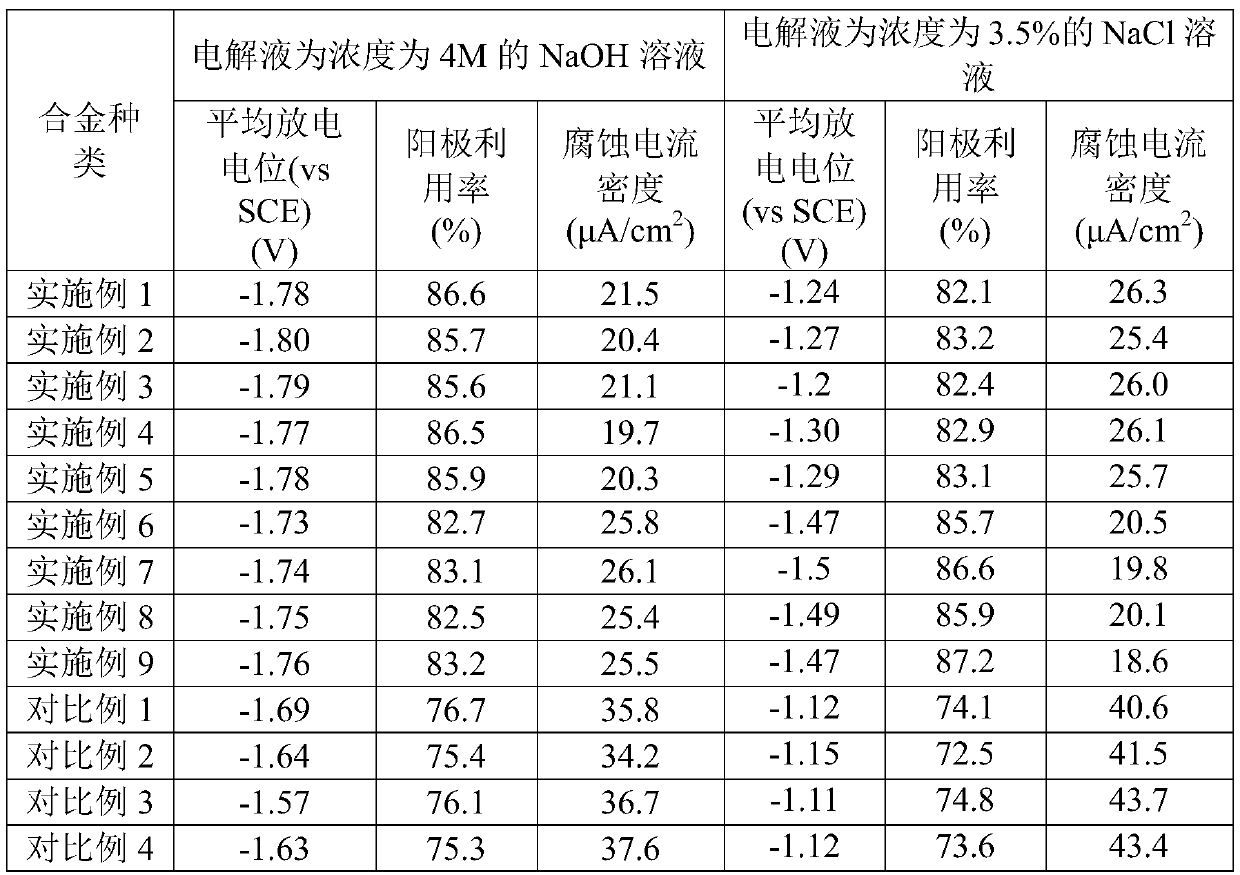

Anode alloy material, preparation method thereof, anode for aluminum-air battery and aluminum-air battery

ActiveCN111057914AInhibition of hydrogen evolution reactionIncrease profitFuel and secondary cellsCell electrodesMetallurgyBattery cell

The invention discloses an anode alloy material, a preparation method thereof, an anode for an aluminum-air battery and the aluminum-air battery, and relates to the field of anode materials for air batteries. The anode alloy material comprises aluminum and alloy elements added into the aluminum, wherein the alloy elements comprise, by mass, 0.01%-5.5% of Mg, 0.01%-3.0% of Sn, 0.01%-2.5% of Ce, 0.0001%-0.0010% of B and 0.01%-2.0% of Ti. The preparation method comprises the steps of preparing the anode alloy material from the raw materials according to the component matching ratio. The components of the anode alloy material are limited, the dosage of each component of the anode alloy material is adjusted, the optimal component dosage ratio is obtained, the hydrogen evolution reaction of thealuminum alloy anode material can be effectively inhibited, and the anode alloy material with negative average discharge potential and high anode utilization rate is developed.

Owner:GUANGDONG INST OF NEW MATERIALS

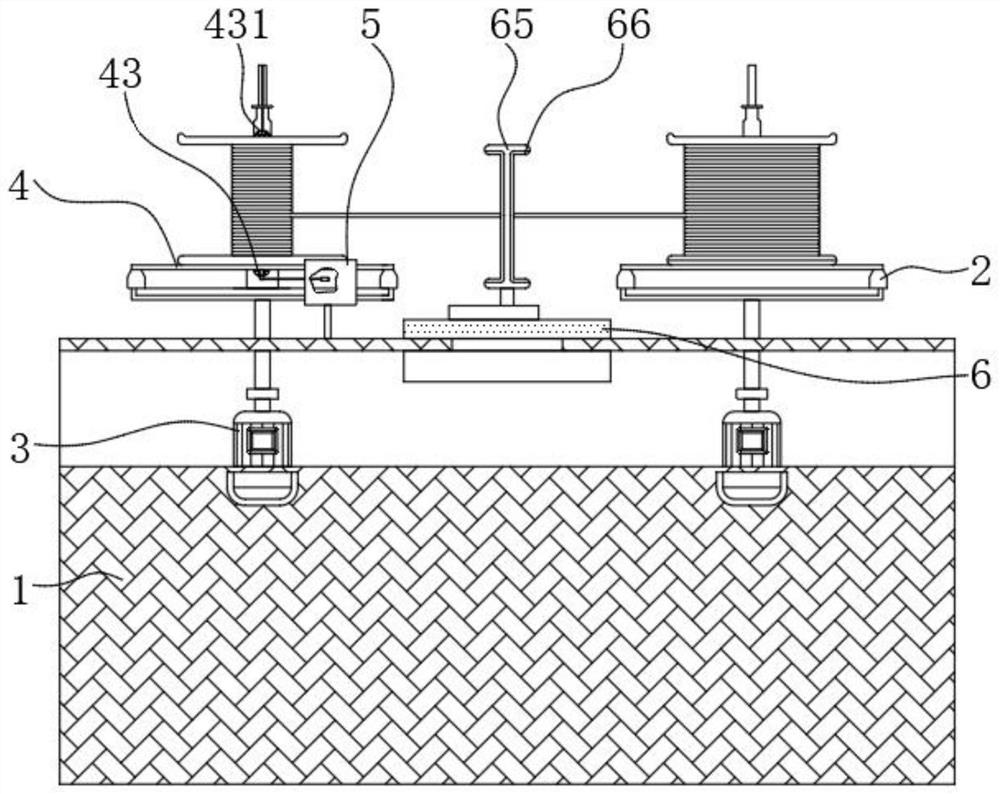

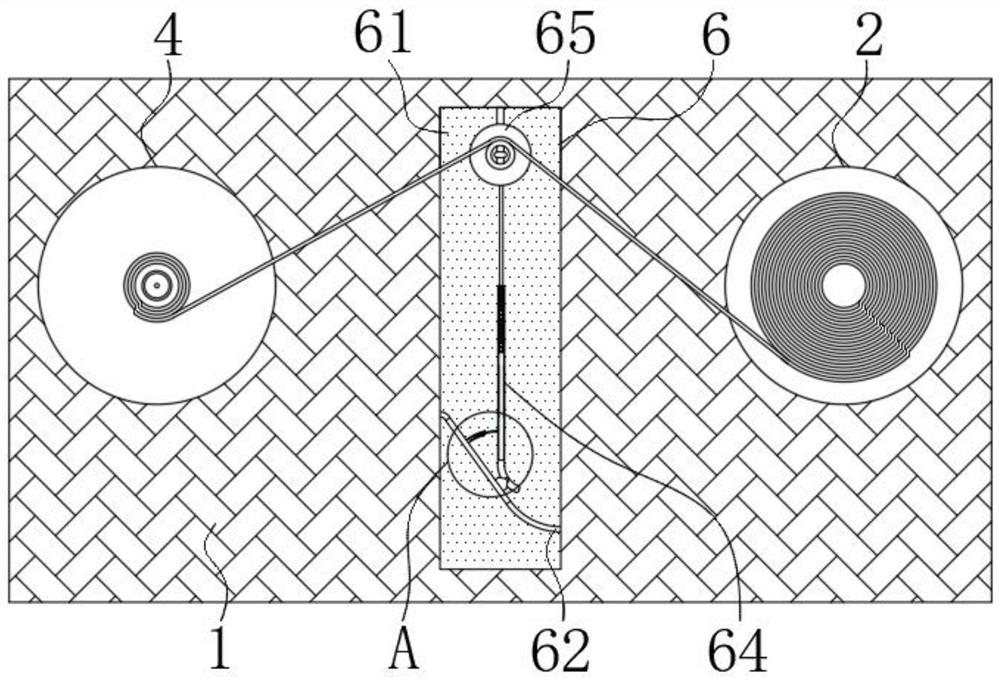

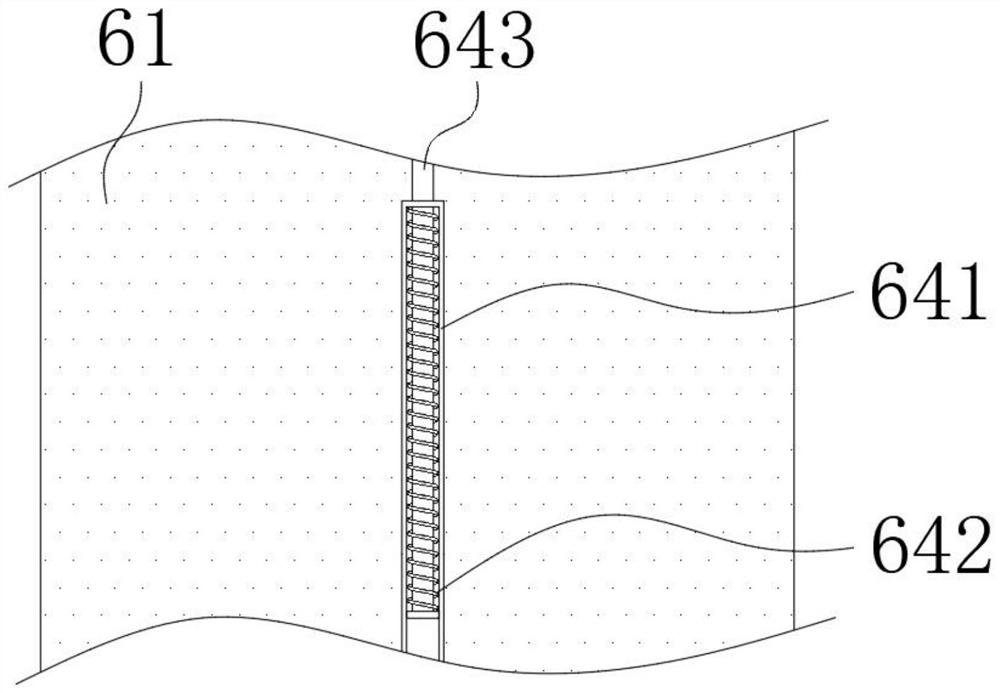

Varnished wire automatic processing equipment

ActiveCN112420279APrevent annealingImprove paint qualityApparatus for heat treatmentInsulating conductors/cablesAutomatic processingServo

The invention relates to the technical field of varnished wire processing, and discloses varnished wire automatic processing equipment which comprises a fixed table, the left side of the upper surfaceof the fixed table is movably sleeved with a take-up device, and the right side of the upper surface of the fixed table is movably sleeved with a wire outlet barrel. According to the varnished wire automatic processing equipment, through cooperation of a wire outlet barrel, a servo motor, a wire take-up device and a tension adjusting device, the pay-off tension can be kept, and the fixed-point movable connection of a vertical direction adjusting device and a fixed inclined rod in the tension adjusting device and the coincidence degree between an arc-shaped rod and an arc-shaped barrel in thehorizontal direction adjusting device are utilized, and the deviation angle of the vertical direction adjusting device is adjusted; when paying-off on the wire outlet barrel body is fast, the verticaldirection adjusting device is adjusted to drive a protective sleeve on a limiting barrel to do anticlockwise centrifugal motion, so that the paying-off comfort of the varnished wire automatic processing equipment is improved, and the working efficiency of the varnished wire automatic processing equipment during paying off is improved, and meanwhile, a wire is protected.

Owner:湘潭市霞城电工有限公司

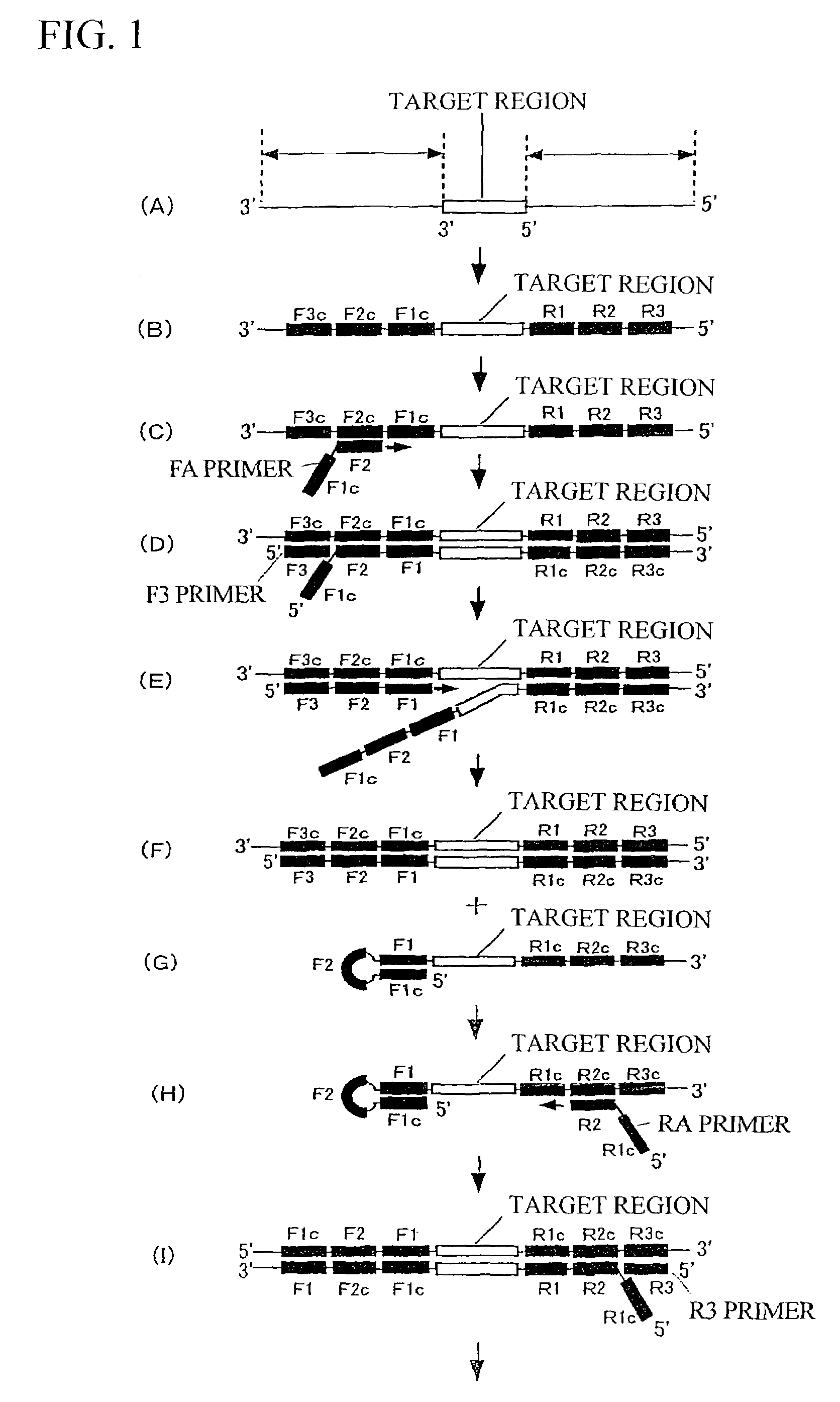

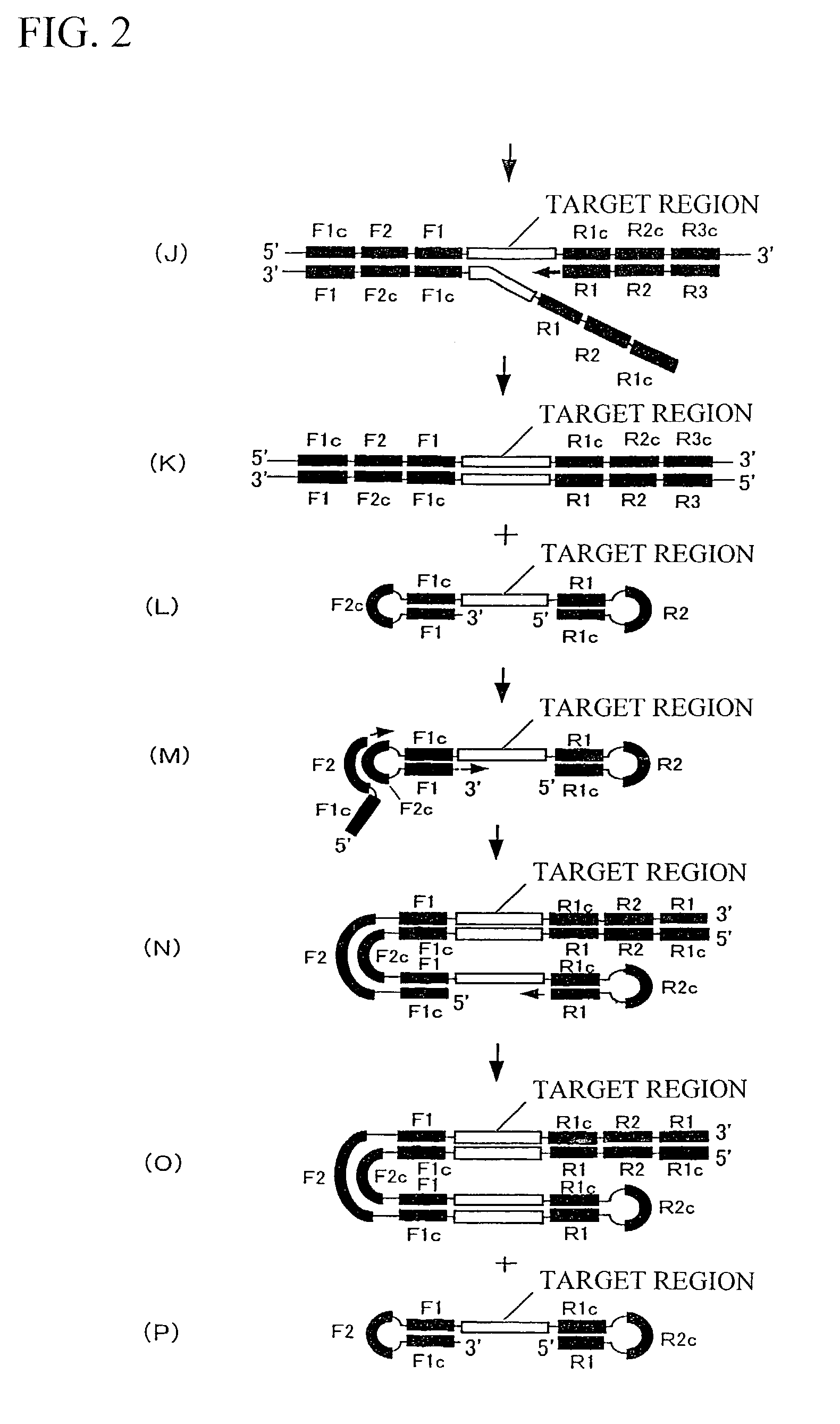

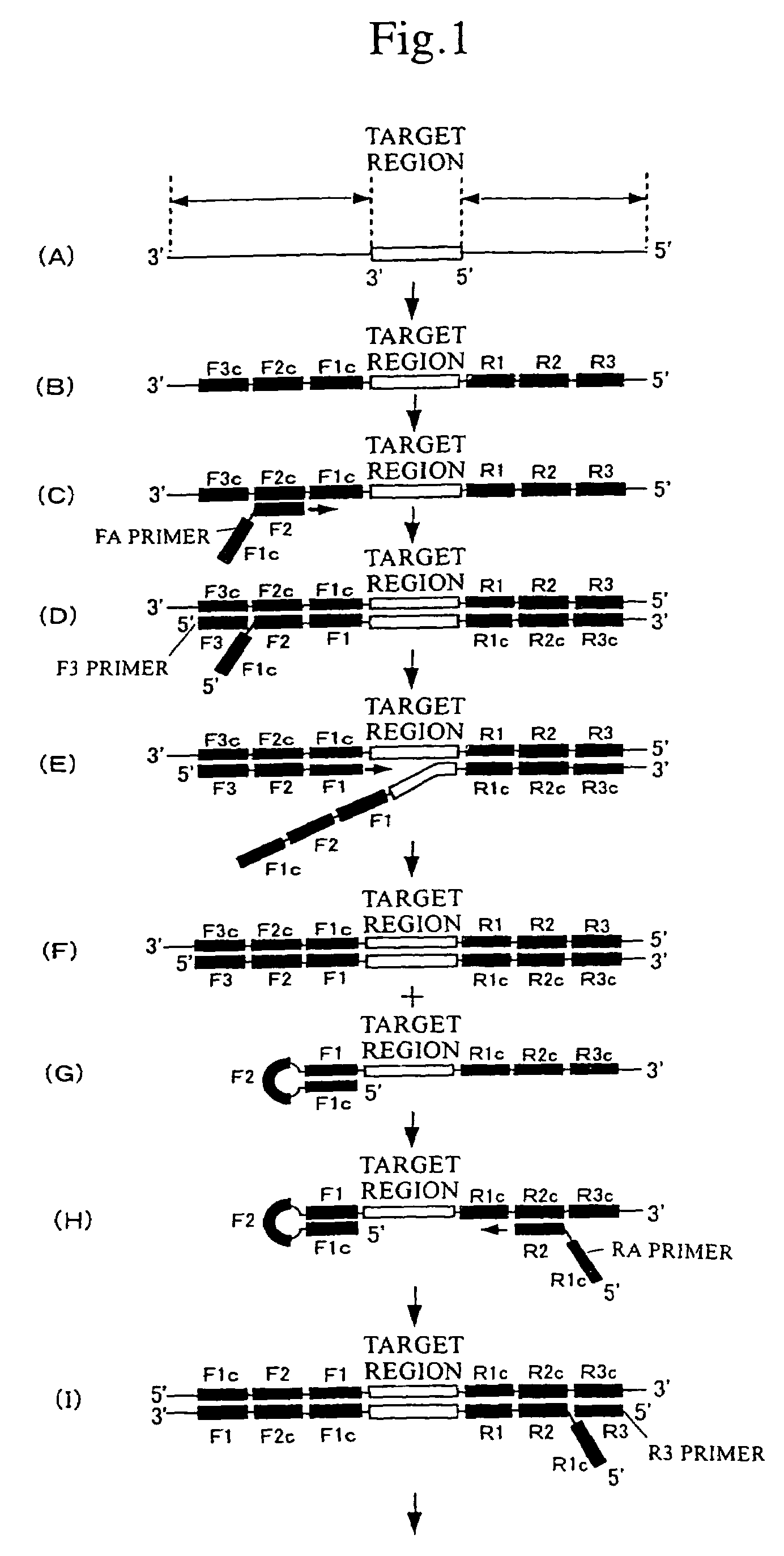

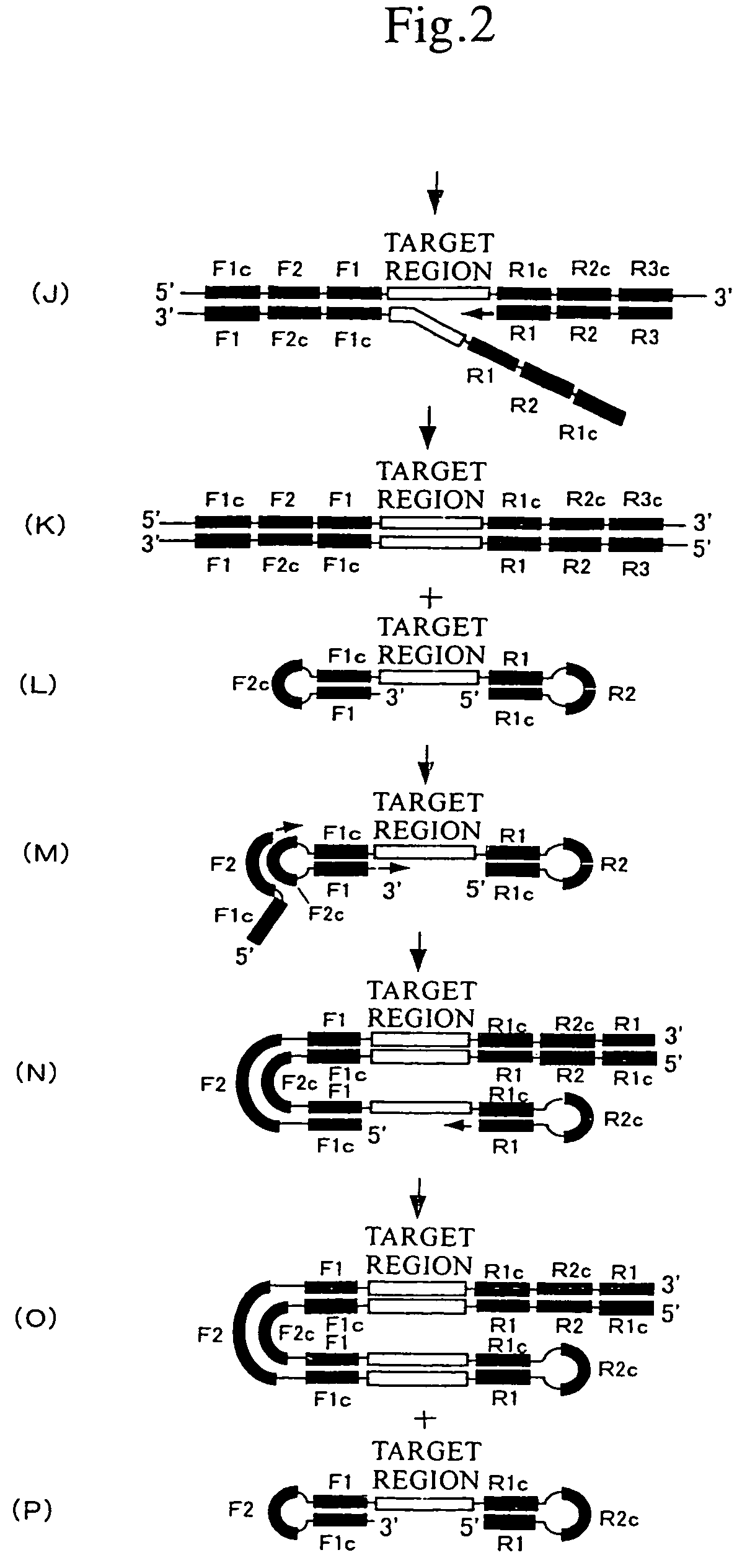

Method for detecting product of nucleic acid synthesizing reaction

InactiveUS7374879B2Increases precipitate yieldHigh detection sensitivityMicrobiological testing/measurementFermentationEnzymeNucleic acid

A method for detecting the occurrence of nucleic acid syntheses using an enzyme through the use of a generated insoluble substance as an indicator.

Owner:EIKEN KAGAKU

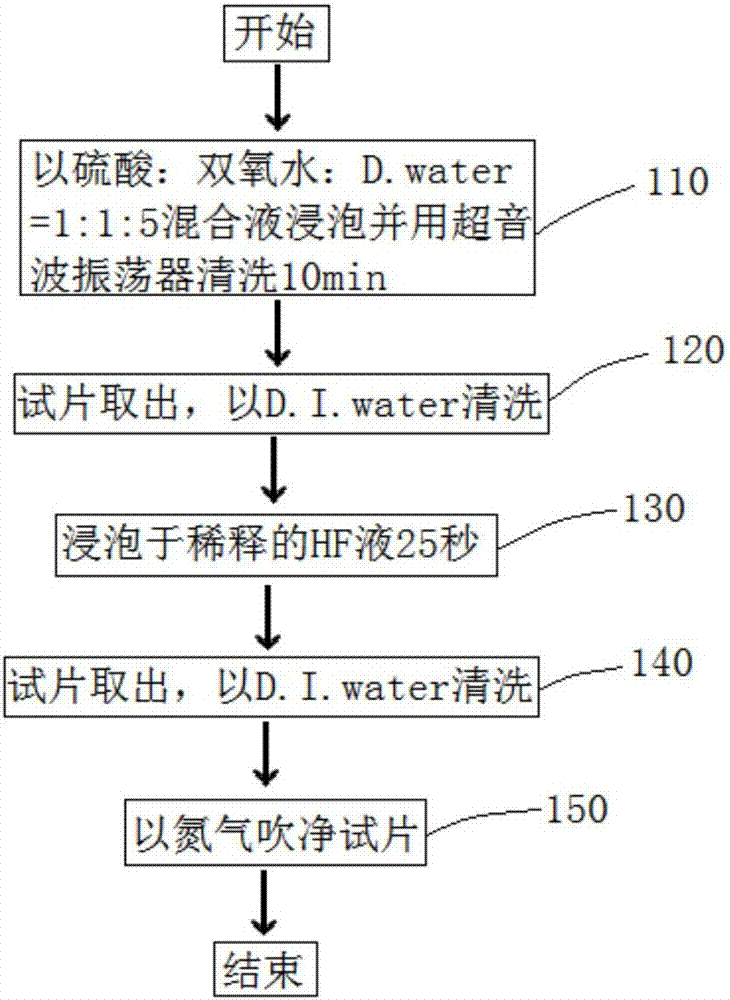

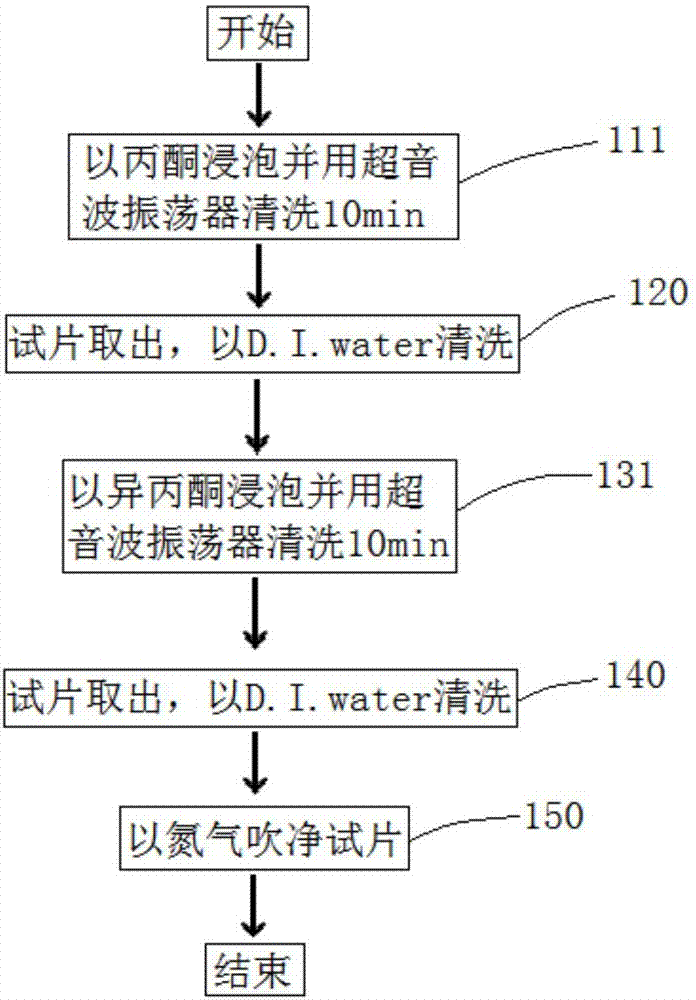

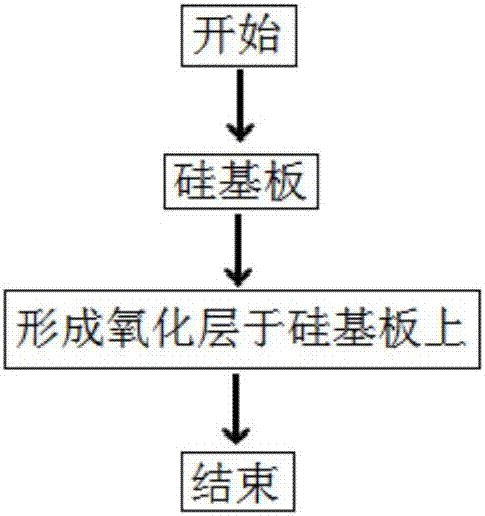

Method for forming carbon/metal double-layer structure and carbon/metal/carbon triple-layer structure on substrate

InactiveCN107419220AEasy to annealQuality improvementVacuum evaporation coatingSputtering coatingHydrogen atmospherePhysical chemistry

The invention discloses a method for forming a carbon / metal double-layer structure and a carbon / metal / carbon triple-layer structure on a substrate. The method comprises the steps of: 1) performing a nickel sputtering process, wherein a nickel target is bombarded with plasma so as to deposit a copper or nickel layer onto the substrate; 2) bombarding a carbon-containing reaction gas as well as a copper or a nickel target with plasma so as to form a copper, or nickel, and carbon mixed layer on the nickel layer; 3) performing a vacuum annealing process to form a (non)-crystalline-phase carbon / copper or nickel layer / (non)-crystalline-phase carbon / copper or nickel layer structure on the substrate. In another embodiment, the method includes the steps of: 1) pre-sputtering a nickel layer in a sputtering chamber; 2) simultaneously or successively bombarding a copper or nickel target and a graphite target with plasma and then performing annealing in a hydrogen-containing atmosphere so as to form a (non)-crystalline-phase carbon / copper or nickel layer / (non)-crystalline-phase carbon triple-layer structure.

Owner:NAT KAOHSIUNG UNIV OF SCI & TECH

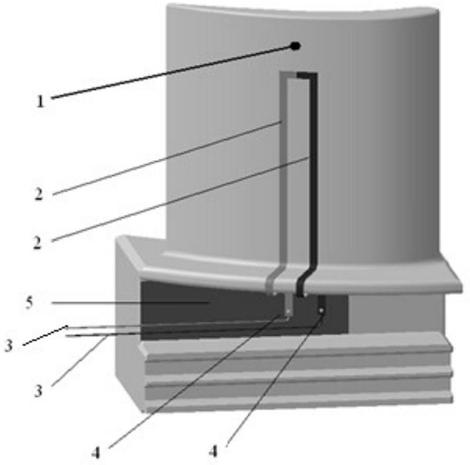

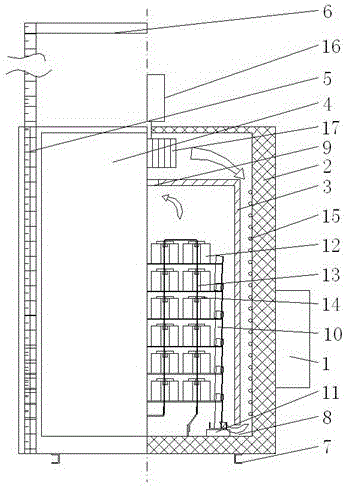

Amorphous annealing furnace

InactiveCN106702102AAdjustable sizeEasy to annealFurnace typesHeat treatment furnacesAutomatic controlNitrogen

The invention relates to an amorphous annealing furnace which comprises an instrument box, a furnace body and an iron stand group, wherein the furnace body comprises an outer furnace wall, an inner furnace wall and a door; a sealed chamber is formed between the outer furnace wall and the door; no bottom cover is arranged at the bottom of the inner furnace wall; a gap is reserved between the bottom of the inner furnace wall and the bottom of the outer furnace wall; a gas circulation port is formed at the top center of the inner furnace wall; the iron stand group is arranged in the inner furnace wall; amorphous iron cores are placed on the iron stand group; a conductive copper bar is arranged between the amorphous iron cores; a heating pipe is arranged on the inner wall of the outer furnace wall; the instrument box is fixed on one side of the exterior of the outer furnace wall and controls the annealing furnace; a motor is arranged at the top of the outer furnace wall and drives a fan; and the fan is positioned at the center between the outer furnace wall and the inner furnace wall. Compared with the prior art, the amorphous annealing furnace provided by the invention has the following advantages: with the addition of nitrogen, the iron cores become bright; the door is directly opened upward without occupying space; since the size of the iron stand is adjustable, the annealing of multi-size iron cores is facilitated; and through full-automatic control, the overall annealing efficiency of the amorphous alloy iron cores is effectively improved.

Owner:JIANGSU YANGDONG ELECTRIC

Reduction in the annealing temperature of an IGZO layer obtained by sol gel

InactiveUS10381220B2Reduce the temperatureEasy to annealTransistorSemiconductor/solid-state device manufacturingChemical physicsPhysical chemistry

The present application relates to a method for forming an active zone of metal oxide for an electronic component including the formation of a stack of IXZO layers produced by liquid phase deposition on a substrate, the layers of said stack having different atomic fractions to each other in order to make it possible to reduce the annealing temperature enabling them to be made functional.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

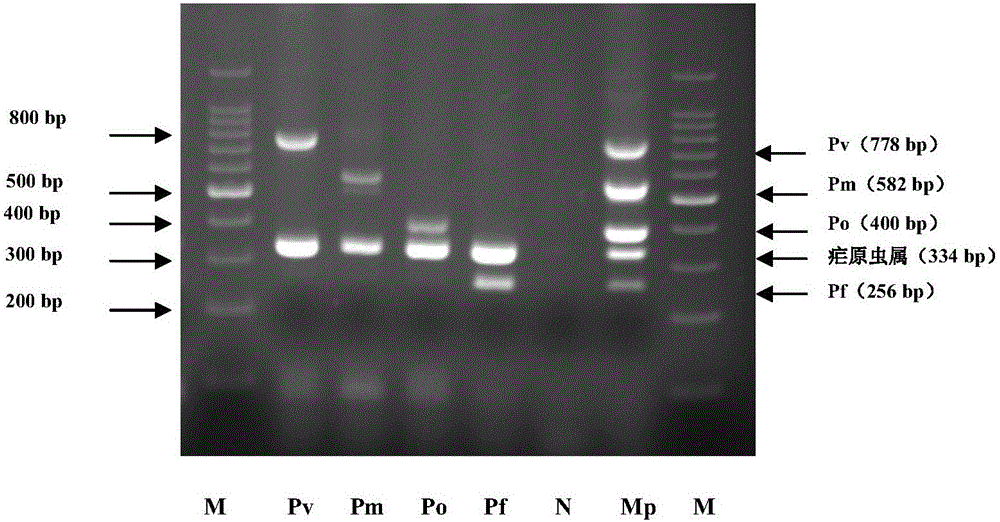

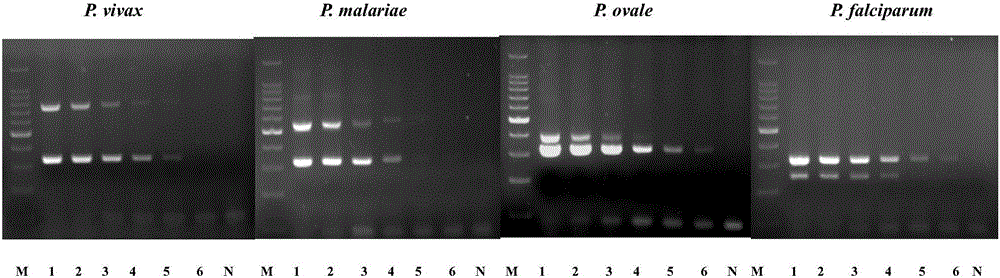

Chimeric primer multiple PCR molecular detection kit for malaria species-genera detection and detection method thereof

ActiveCN105695601ASure easyImprove accuracyMicrobiological testing/measurementAgainst vector-borne diseasesMicrobiologyMaterial resources

The invention relates to a chimeric primer multiple PCR molecular detection kit for malaria species-genera detection and a detection method thereof. The kit comprises a mixed primer combination, a 2*multiple PCR premix, a multiple PCR positive reference and a 100bp molecular weight Marker, wherein the mixed primer combination comprises a specific chimeric primers with sequences of SEQ No.1-SEQ ID No.10 and a universal primer with sequence of SEQ ID No.11; and the detection method comprises a multiple PCR amplification reaction, wherein the circulating temperature refers to three circulating annealing temperatures of 58 DEG C, 62 DEG C and 68 DEG C increasing step by step. By adopting the chimeric primer multiple PCR molecular detection kit for malaria species-genera detection and the detection method thereof, through the combination of the primer sequences shown by SEQ ID No.1-11, the gene segments of the specific species and genera in a malaria sample can be amplified at the same time by once PCR reaction, and four kinds of plasmodium can be identified and diagnosed according to the size and combination of the amplified segments. The time and human and material resources are saved, and the detection efficiency is improved.

Owner:SHANGHAI MUNICIPAL CENT FOR DISEASE CONTROL & PREVENTION

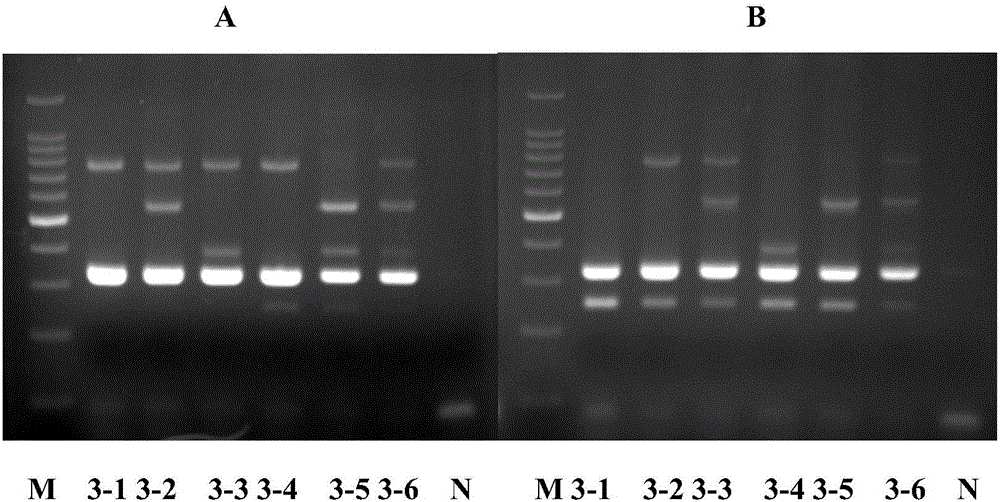

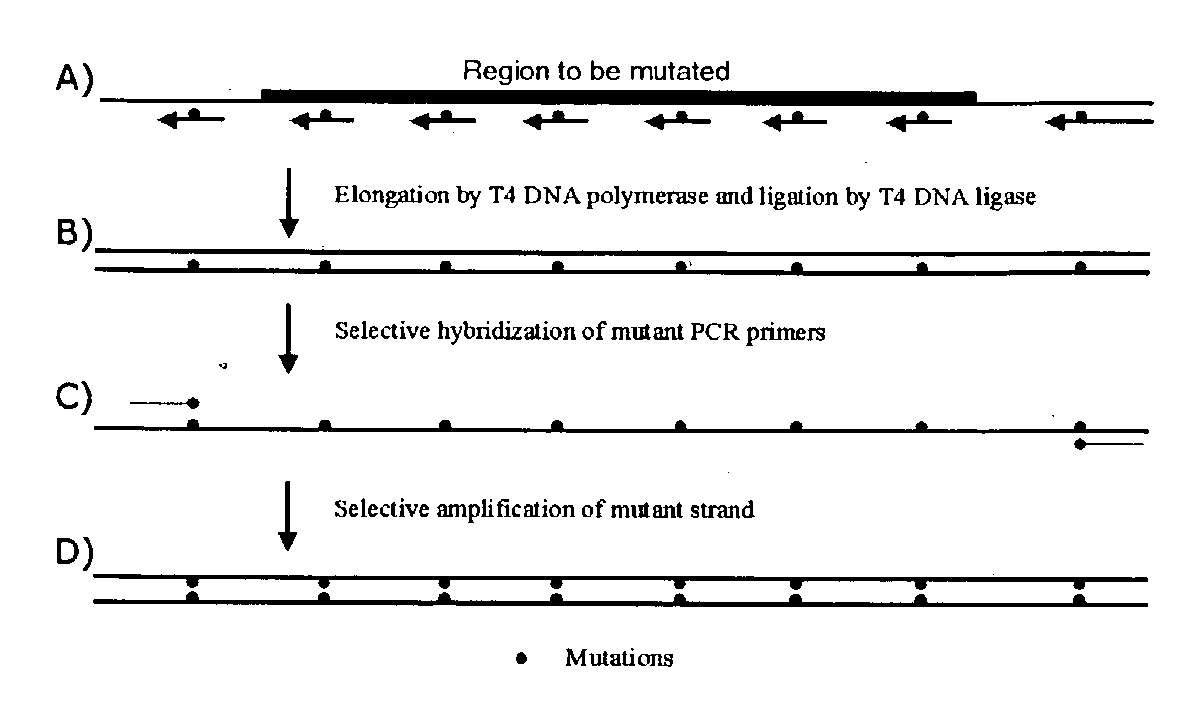

Method for site-directed mutagenesis

InactiveUS20030224492A1Highly efficient multiple site mutagenesisEfficient mutagenesisFermentationVector-based foreign material introductionGeneticsMolecular biology

A method for site-directed mutagenesis which achieves mutant strand selection by introducing two flanking mutagenic primers.

Owner:YOUNG LEI

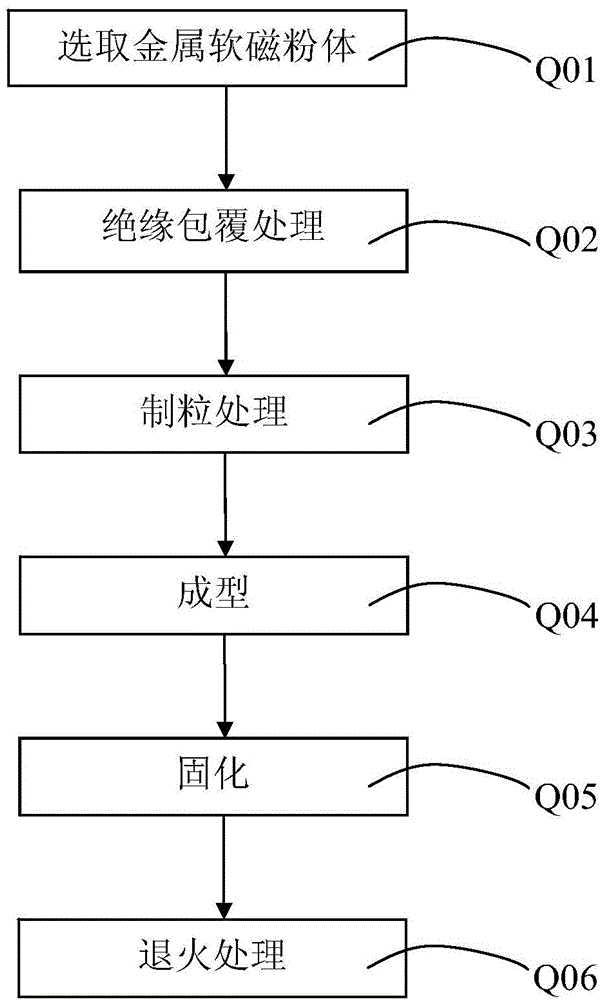

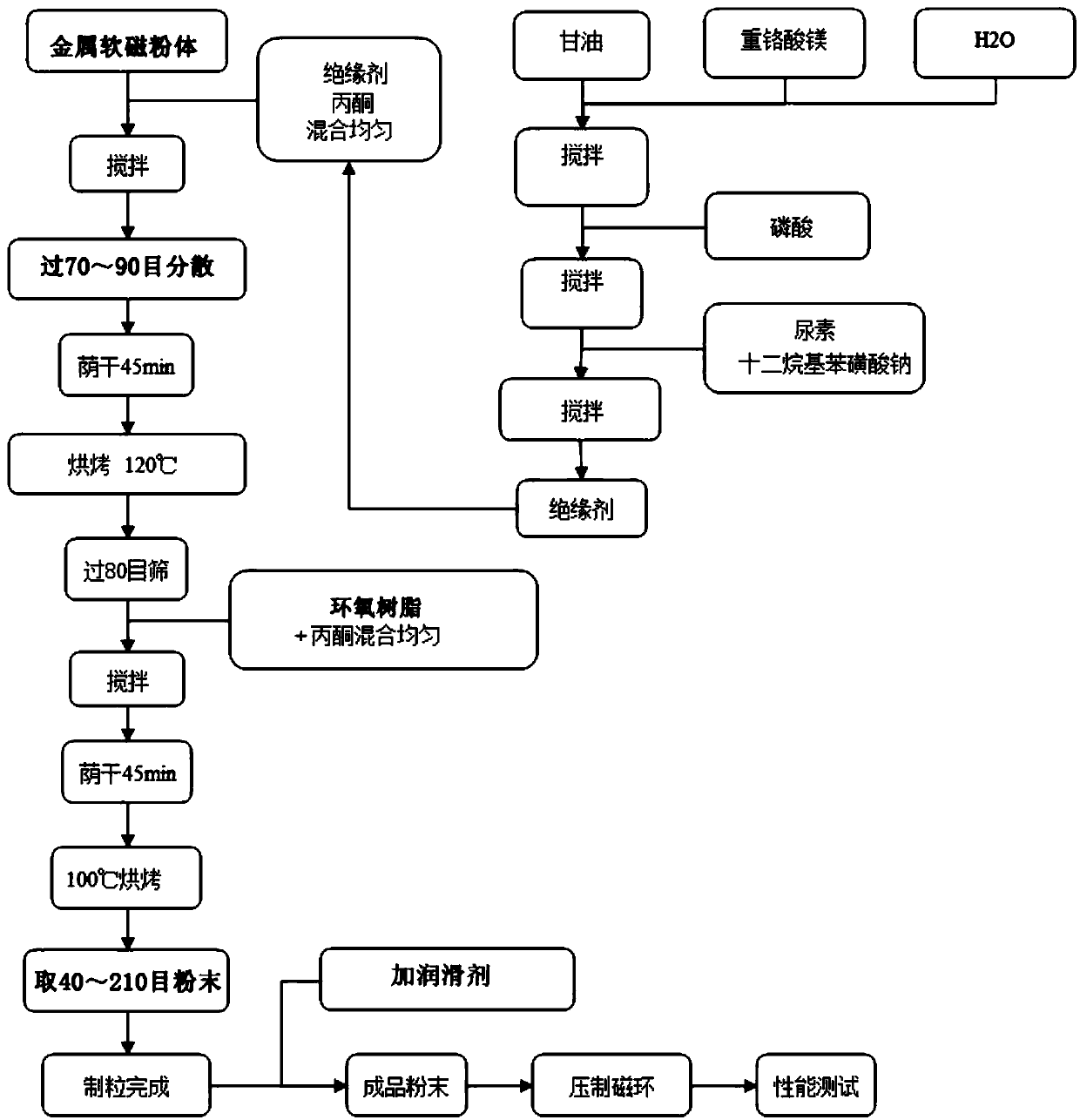

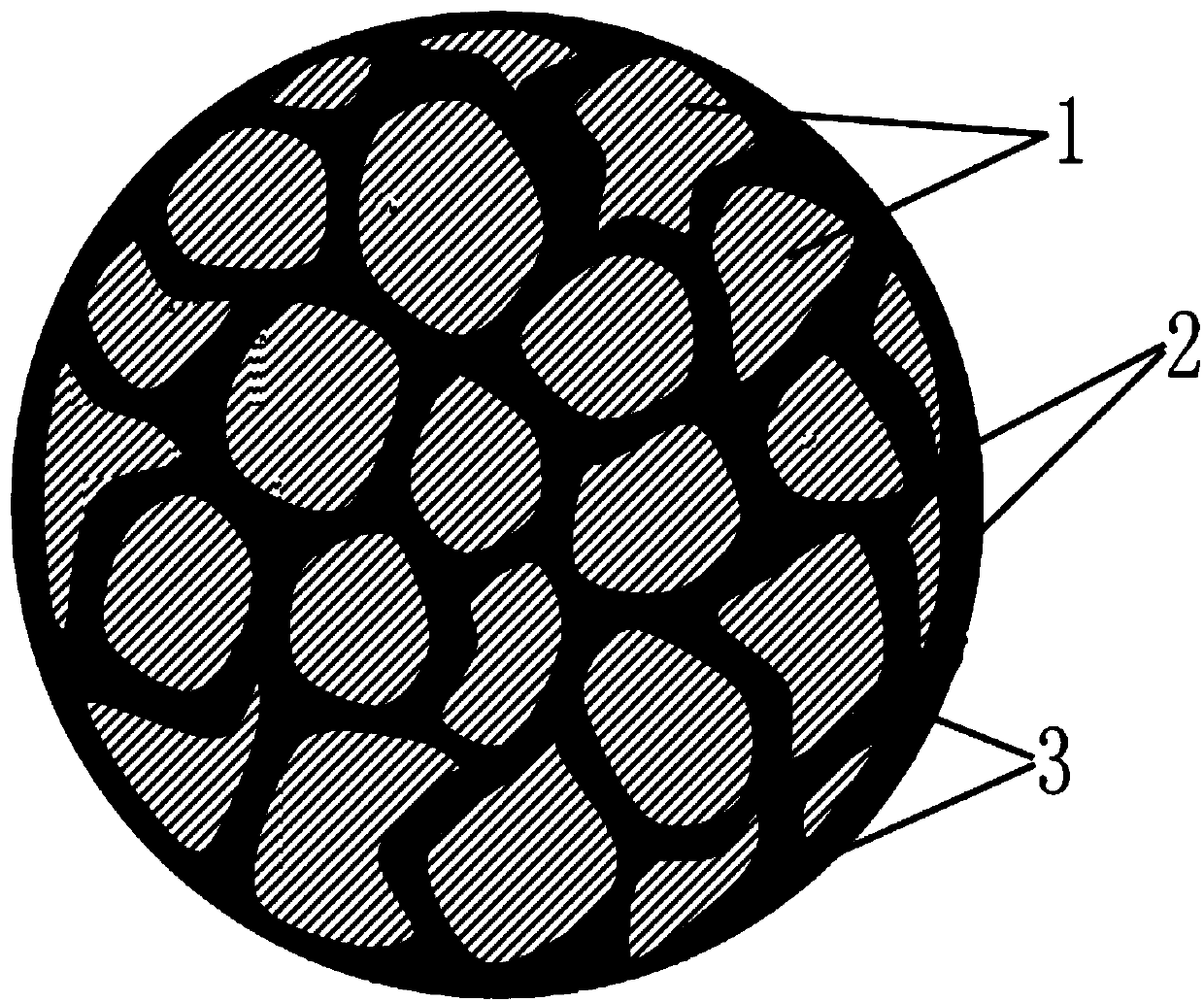

Manufacturing method for metal soft magnetic powder insulating particles

InactiveCN109663908AReduce eddy current lossHigh saturationTransportation and packagingMetal-working apparatusViscous liquidEpoxy

The invention discloses a manufacturing method for metal soft magnetic powder insulating particles. The manufacturing method comprises the following steps of adding magnesium dichromate in glycerol, performing stirring until a solution becomes viscous liquid with a uniform color, adding phosphoric acid for mixing, and adding urea and sodium dodecyl benzene sulfonate for mixing to prepare an insulating agent; (2) diluting the insulating agent with acetone, and adding metal soft magnetic powder in the insulating agent, performing stirring until a dry state, dispersing the powder with a sieve, drying the dispersed powder in a shallow, and performing baking to obtain primary processing powder; (3) diluting epoxy resin with the acetone, adding the diluted epoxy resin in the primary processing powder, performing screening, granulating, shadow drying and baking after stirring to obtain secondary processing powder; and (4) adding the secondary processing powder in a lubricant, and performing uniform mixing to obtain the metal soft magnetic powder insulating particles. A power inductor provided by the invention has high-saturation, large-current and low-eddy current loss power inductance performance; and compared with a traditional inductor, by adopting the method, the stability and the characteristics of a product are improved on the aspects of materials and processes.

Owner:深圳市迈翔科技有限公司

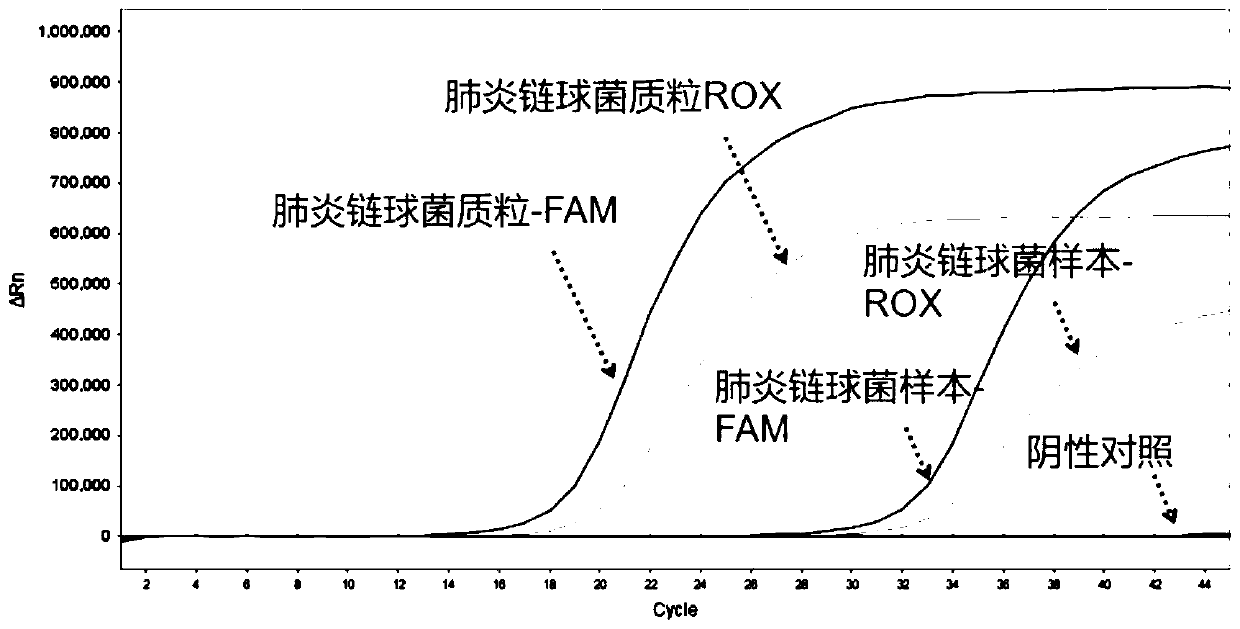

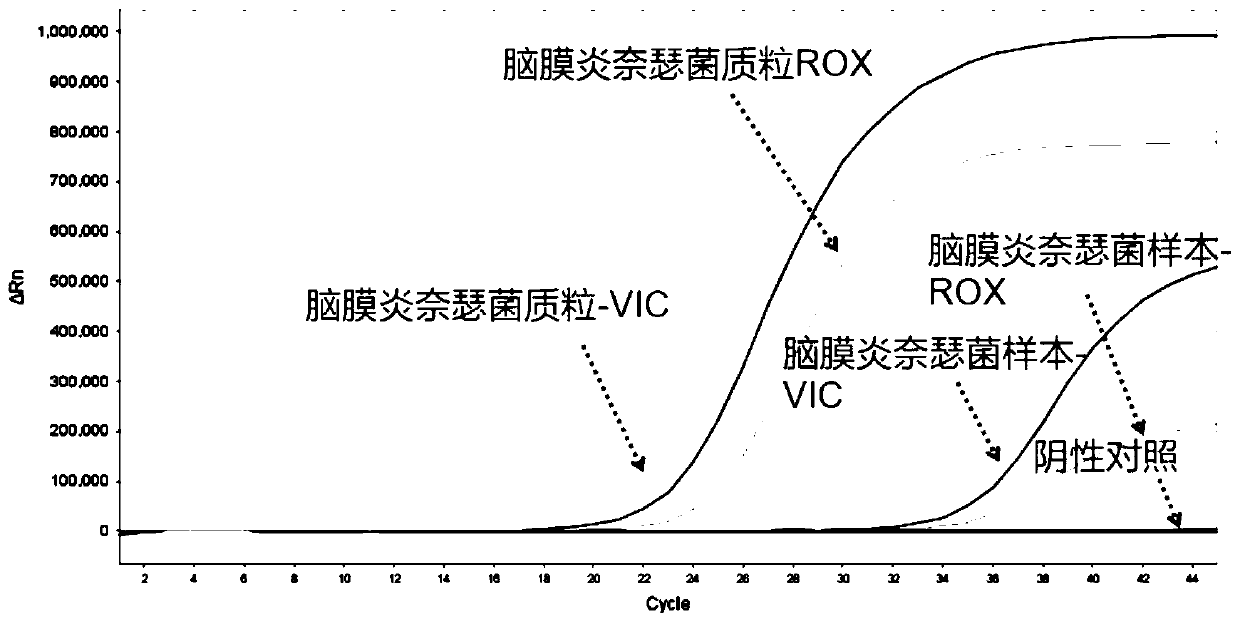

Nucleic acid typing detection kit for encephalitis and meningitis and detection method

PendingCN110904253ARapid diagnosisReduce workloadMicrobiological testing/measurementEncephalitis meningitisNeisseria meningitidis

The invention discloses a nucleic acid typing detection kit for encephalitis and meningitis. The kit comprises a nucleic acid rapid extraction reagent, a PCR amplification reagent, an encephalitis andmeningitis nucleic acid detection reagent, a positive reference substance and a negative reference substance. The encephalitis and meningitis nucleic acid detection reagent comprises an amplificationprimer and a probe of a streptococcus pneumoniae gene, an amplification primer and a probe of a neisseria meningitidis gene, an amplification primer and a probe of a haemophilus influenzae gene, andan amplification primer and a probe of an internal reference RNP gene. The invention further provides a nucleic acid typing detection method for encephalitis and meningitis. According to the invention, multi-channel primers and probes with encephalitis and meningitis specificity are introduced; the workload can be reduced; the problem that other detection methods are low in specificity and prone to missed diagnosis and misdiagnosis is solved; multiple simultaneous detection of three pathogens in the same system can be achieved, and primers and probes in all channels do not interfere with one another; the sensitivity is good; the specificity is high; accuracy and reliability are achieved; rapidness and convenience are achieved; and whether the three pathogens are infected or not is rapidlydiagnosed.

Owner:SHANGHAI BIOGERM MEDICAL TECH CO LTD

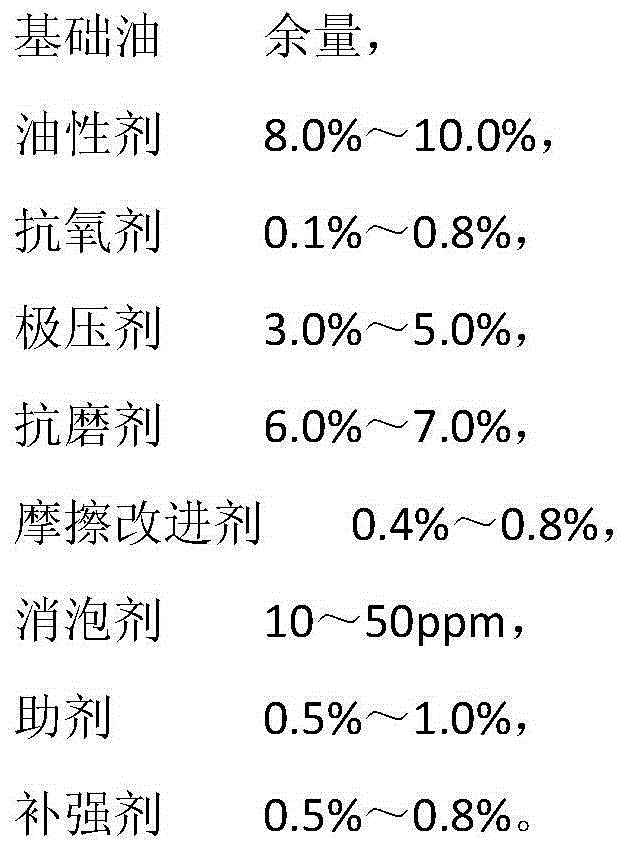

Lubricant composition for cold spinning of zirconium alloy pipe

The invention discloses a lubricant composition for cold spinning of a zirconium alloy pipe. The lubricant composition uses HVIS650 base oil as base oil and employs a plurality of cooperative additives including an oiliness agent, an anti-oxidant, an extreme pressure agent, an anti-wear agent, a friction improver, an antifoaming agent, an auxiliary agent and a strengthening agent. The lubricant composition provided by the invention has good cooling performance, lubricating performance, cleaning performance, diffusing performance, flowing performance, anti-wear performance, bearing capability, wettability and oil film toughness and is capable of reducing zirconium adhesion degree and friction coefficient, facilitating de-oiling, annealing and alkali-acid pickling and can reduce damage and surface defects caused by adhesion of the surface of the pipe.

Owner:GUANGXI UNIV

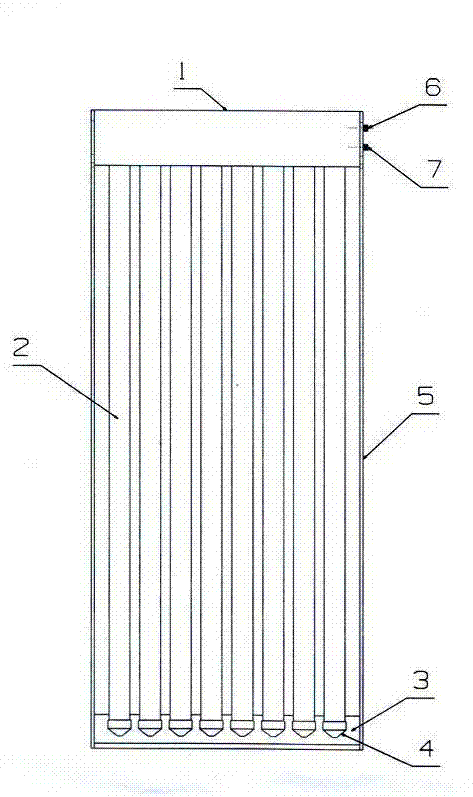

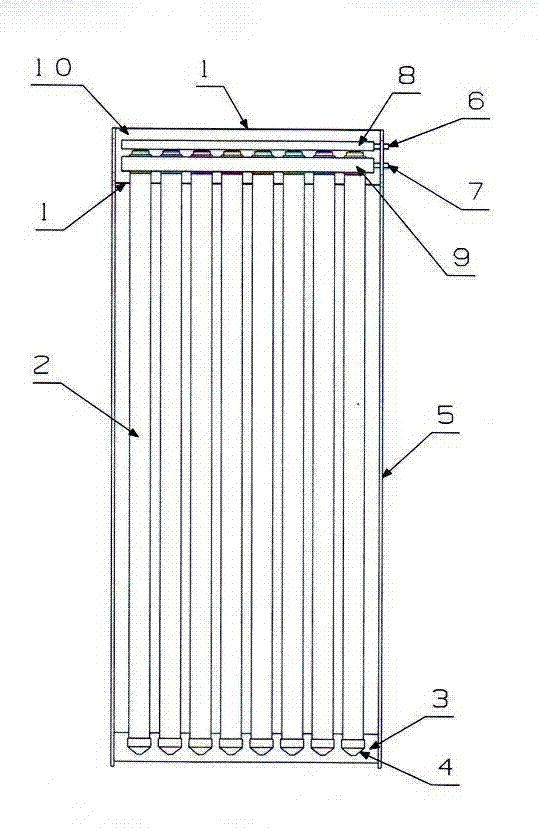

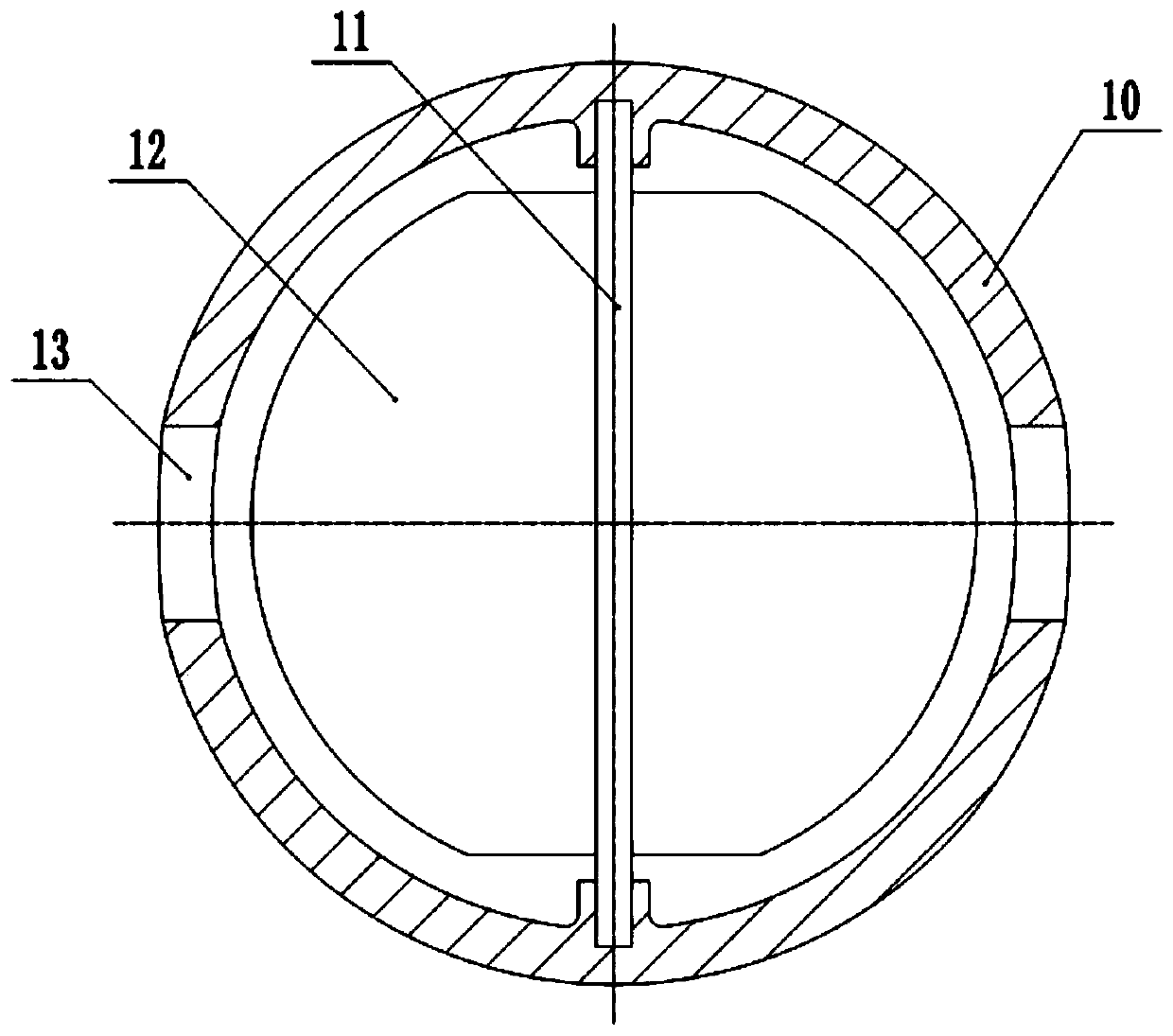

Side outlet type solar thermal collector

InactiveCN102889692ASimple processing technologyImprove product qualitySolar heating energySolar heat devicesThermal insulationCollector device

The invention discloses a side outlet type solar thermal collector which comprises a connecting box, an all-glass double-channel vacuum tube thermal collector, a vacuum tube bottom rack, a vacuum tube tail support and a bracket side plate, and is characterized in that an upper water collector pipe and a lower water collector pipe are horizontally fixed in the connecting box through a polyurethane thermal insulation layer; a water outlet of the upper water collector pipe and a water inlet of the lower water collector pipe serving as exchange ports of the collector and a heat exchanger are formed at one side or two sides of the connecting box; the all-glass double-channel vacuum tube thermal collector consists of an outer glass tube, a thermal absorption glass tube, an isolating glass tube and an inner glass tube; and the all-glass double-channel vacuum tube thermal collector, the connecting box, the vacuum tube bottom rack, the vacuum tube tail support and the bracket side plate form the solar thermal collector which is applied to the all-glass double-channel vacuum tube thermal collector. The side outlet type solar thermal collector has the advantages that the production difficulty is reduced, the breakage resistance of products is ensured during transport, the yield and perfectness ratio of the products are improved and the production cost is reduced, and is suitable for mass production and easy to mount and maintain.

Owner:吴艳频 +1

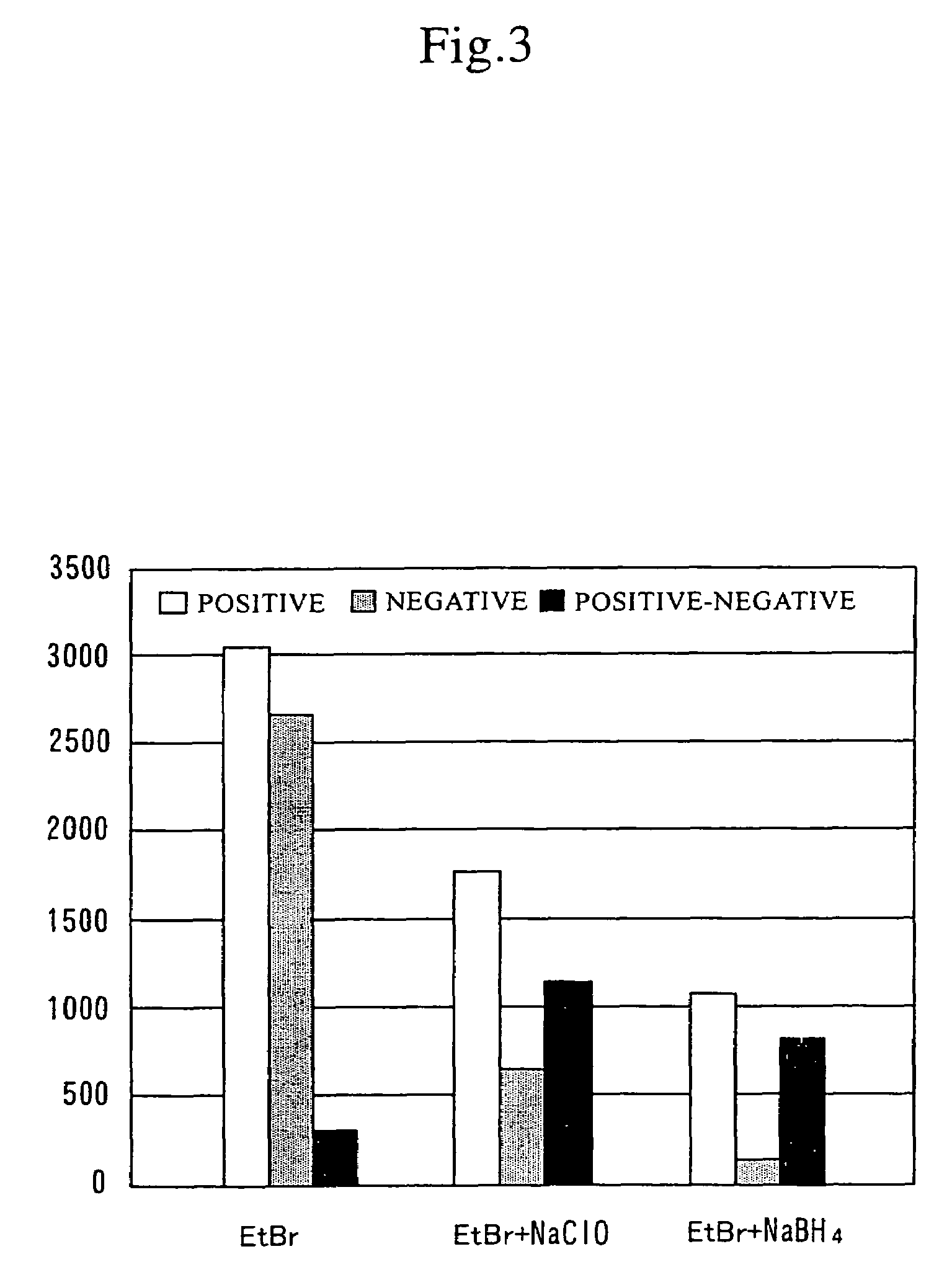

Method of efficiently detecting double-stranded nucleic acid

ActiveUS7316901B2Easy to annealMaintain activityMicrobiological testing/measurementFermentationSingle strandDouble strand

This invention relates to a method for efficiently detecting double-stranded nucleic acids. More particularly, this invention relates to a method for reducing signals derived from an intercalator bound to a single-stranded nucleic acid, wherein a compound that reacts more preferentially with an intercalator bound to a single-stranded nucleic acid than with an intercalator bound to a double-stranded nucleic acid or a compound that is bound to a single-stranded nucleic acid more strongly than an intercalator and is bound to a double-stranded nucleic acid more weakly than an intercalator is added to a mixture comprising double-stranded and single-stranded nucleic acids both having intercalators bound thereto, thereby reducing signals derived from an intercalator bound to a single-stranded nucleic acid.

Owner:EIKEN KAGAKU +2

Zirconium alloy having excellent corrosion resistance and creep resistance and method of manufacturing the same

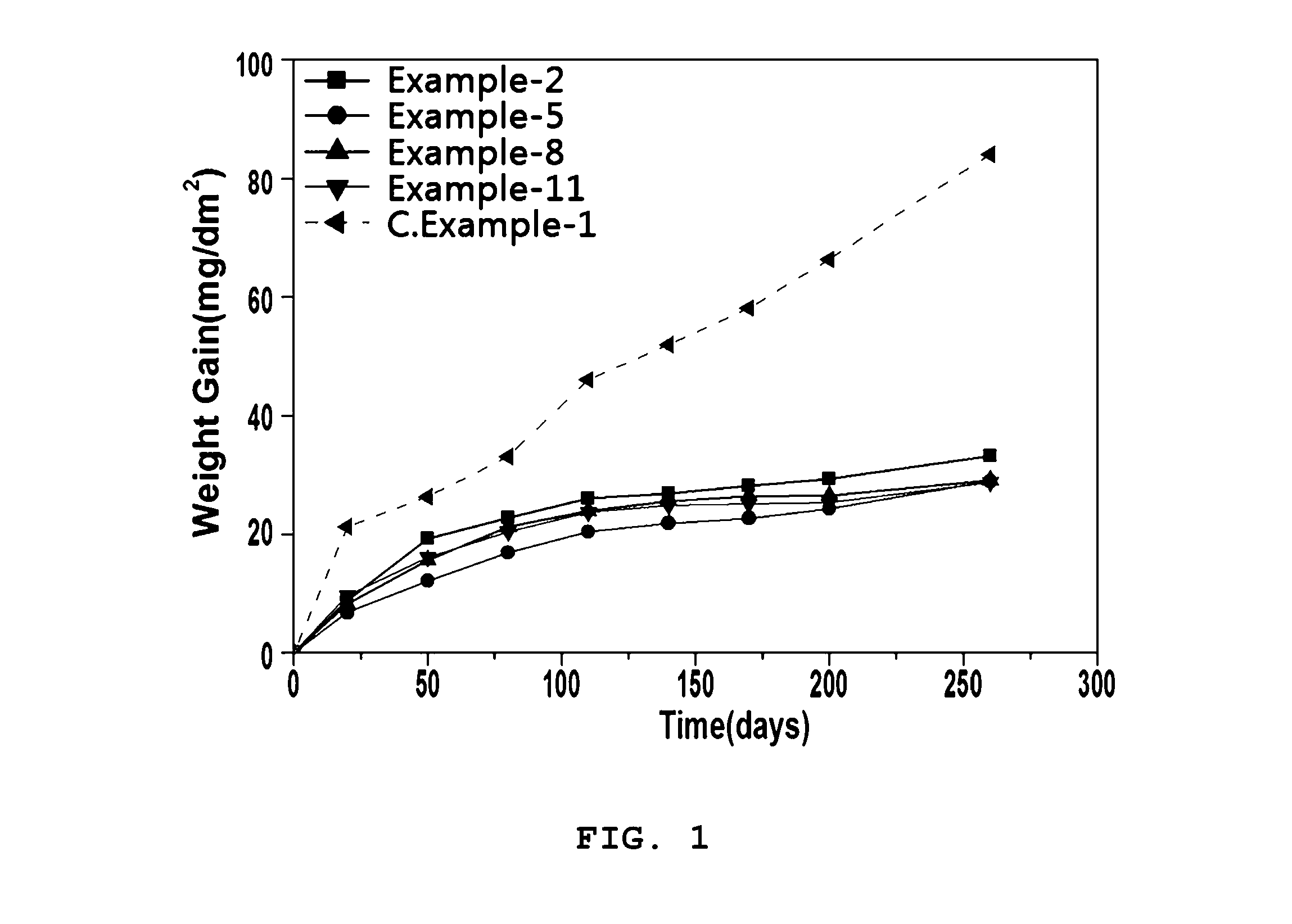

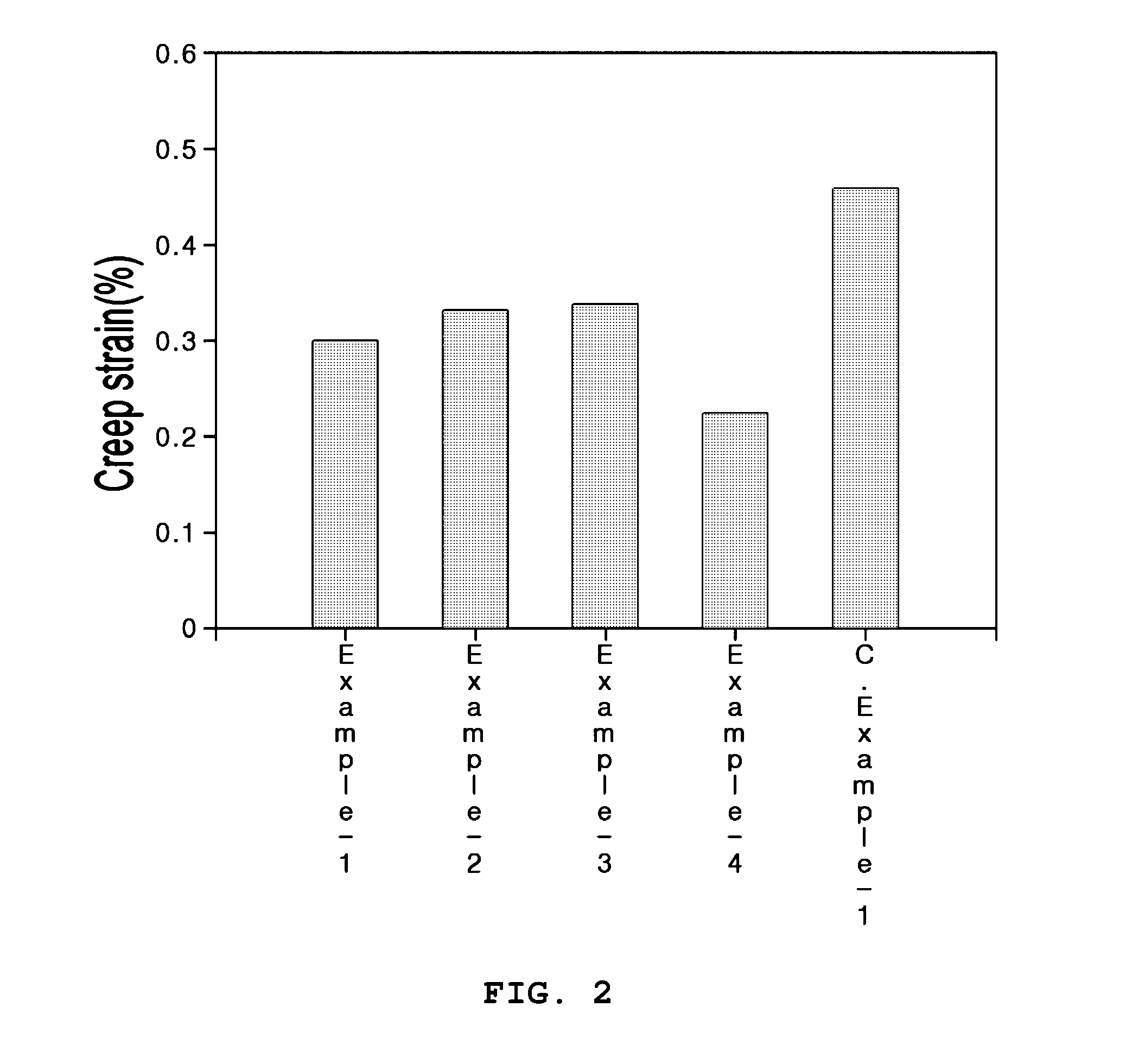

InactiveUS20160304991A1Optimizing corrosion resistanceOptimizing resistance creepZirconium alloyVacuum annealing

A zirconium alloy is manufactured through melting; solution heat treatment at 1,000 to 1,050° C. for 30 to 40 min and β-quenching using water; preheating at 630 to 650° C. for 20 to 30 min and hot rolling at a reduction ratio of 60 to 65%; primary intermediate vacuum annealing at 570 to 590° C. for 3 to 4 hr and primarily cold-rolled at a reduction ratio of 30 to 40%; secondary intermediate vacuum annealing at 560 to 580° C. for 2 to 3 hr and secondarily cold-rolled at a reduction ratio of 50 to 60%; tertiary intermediate vacuum annealing at 560 to 580° C. for 2 to 3 hr and tertiarily cold-rolled at a reduction ratio of 30 to 40%; and final vacuum annealing at 440 to 650° C. for 7 to 9 hr.

Owner:KEPCO NUCLEAR FUEL CO LTD

Aluminum wire annealing furnace

InactiveCN107385160AEasy to annealAnnealing achievedFurnace typesHeat treatment furnacesMetallurgyHeating efficiency

The invention discloses an aluminum wire annealing furnace, which comprises an aluminum wire pipeline, a motor, a loading device, a furnace body, a furnace chamber, a screw rod, a driving pulley and a driven pulley, and the aluminum wire pipeline is used for placing the aluminum wire; The aluminum wire is placed in the aluminum wire pipe, thus ensuring the uniform heating of the aluminum wire and improving the heating efficiency, thereby improving the effect of annealing the aluminum wire and improving the practicability of the equipment. After the annealing of the aluminum wire is completed, the motor Rotate forward to raise the loading device, which is convenient for the operator to remove the annealed aluminum wire in the cavity. When the aluminum wire needs to be annealed, place the aluminum wire in the aluminum box pipe in the cavity, and further use the Reverse to put the loading device into the furnace cavity to realize the annealing of the aluminum wire, without manual lifting of the loading device, the operation is convenient and fast.

Owner:JIANGSU SUFENG MECHANICAL DEV CO LTD

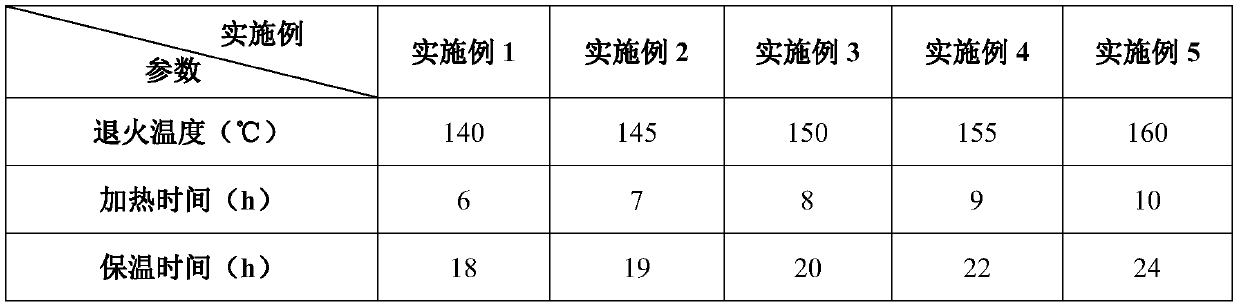

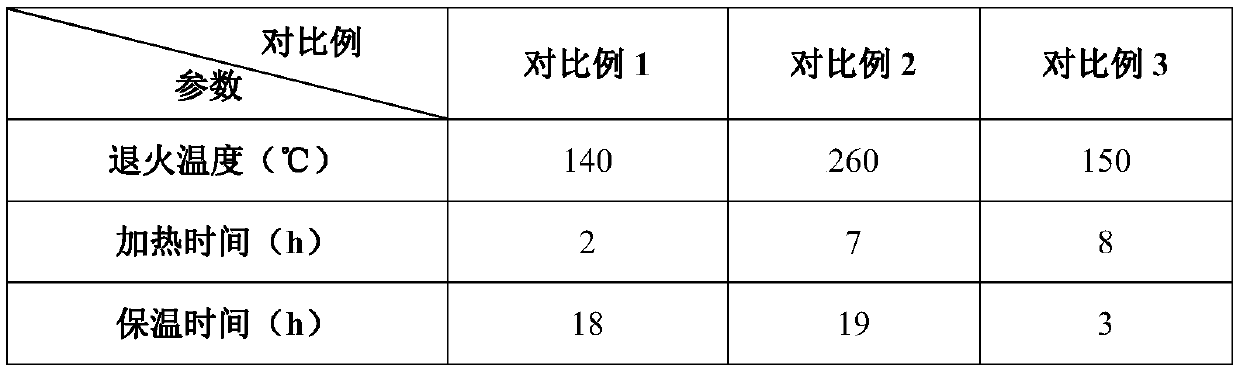

Method for eliminating surface unevenness of aluminum alloy roll

ActiveCN110777309AImprovement of unevennessBump removalFurnace typesHeat treatment furnacesHeat conservationAlloy

The invention relates to the technical field of preparation of aluminum rolls, and particularly discloses a method for eliminating surface unevenness of an aluminum alloy roll. The method comprises the step that after being coiled, the aluminum roll is placed in an aluminum roll annealing furnace so as to be annealed, wherein the annealing temperature is 140-160 DEG C, the heating temperature is 6-10h, and the heat preservation time is 18-24h. According to the method, aluminum alloy is tempered or annealed repeatedly in the rolling process; the rolling reduction, the components of rolling oil,an rolling oil spraying system and the temperature are generally adjusted in the industry to reduce or eliminate the surface unevenness of the coiled aluminum roll, but the measures cannot effectively reduce or eliminate the surface unevenness of the aluminum roll; and according to the technical scheme of the invention, after being coiled, the aluminum roll is placed into the annealing furnace tobe annealed again, so that the surface unevenness of the aluminum roll is effectively reduced and eliminated.

Owner:陇西西北铝铝箔有限公司

Norovirus gⅰ, gⅱ and gⅳ type nucleic acid typing detection kit and detection method

ActiveCN110273027BImprove detection efficiencyEffective crackingMicrobiological testing/measurementNucleic acid detectionViral type

The invention discloses a norovirus GI, GII and GIV type nucleic acid typing detection kit, the kit includes viral nucleic acid rapid extraction reagents, PCR amplification reagents, PCR enzyme mixture, norovirus GI, GII and GIV types Nucleic acid detection reagents, positive control substances, and negative control substances. This formula can be used for rapid extraction of viral RNA and improve the efficiency of PCR detection; Norovirus GⅠ, GⅡ and GIV nucleic acid detection reagents include: Norovirus GⅠ amplification primer F1 , R1 and probe P1, norovirus GII amplification primers F2, R2 and probe P2, norovirus GIV amplification primers F3, R3 and probe P3; the primer probe sequence is the first and unique design, Good specificity and high sensitivity. The invention also provides a detection method for norovirus GⅠ, GII and GIV type nucleic acid typing. The invention can simultaneously detect through multiple channels whether norovirus GⅠ, GII and GIV pathogens are contained in the specimen to be tested, realize rapid and accurate detection and quantify the virus, and the application is extremely convenient.

Owner:伯杰(青岛)医疗科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com