Intelligent copper pipe online annealing equipment and control method thereof

A technology for annealing equipment and copper tubes, applied in the field of intelligent copper tube online annealing equipment and its control, can solve the problems of material annealing quality decline, material quality decline, large initial temperature difference, etc., to improve energy utilization and reduce energy waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

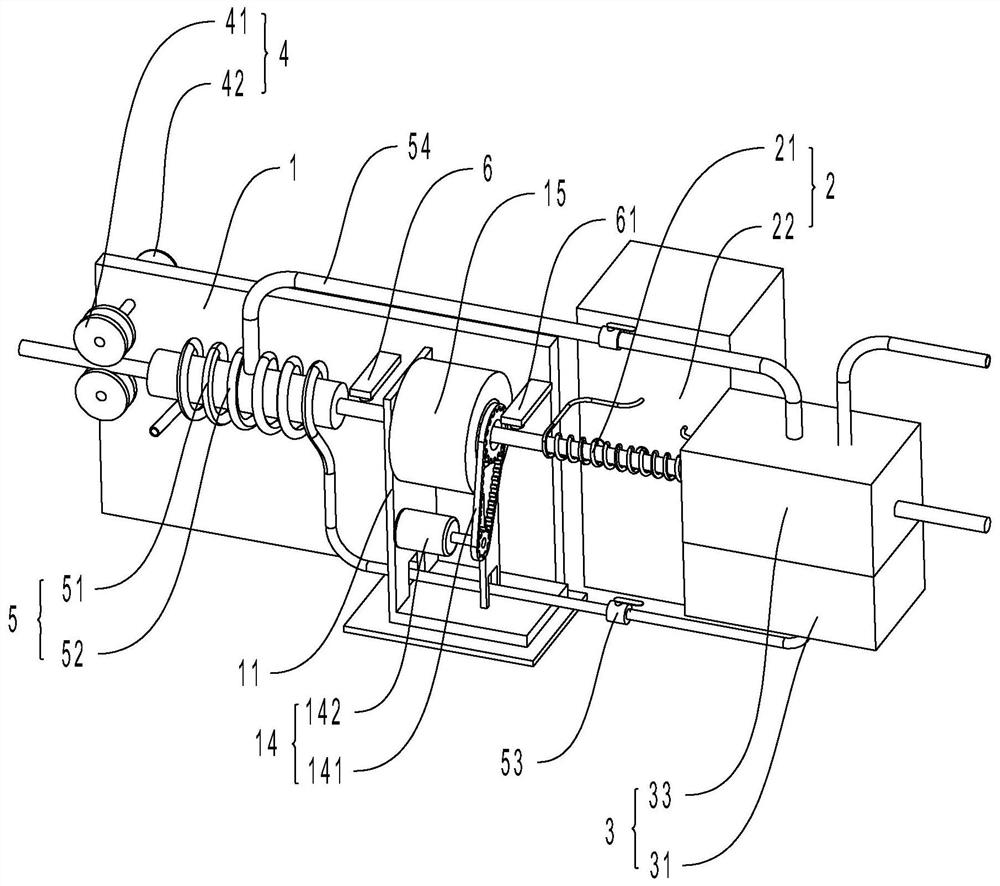

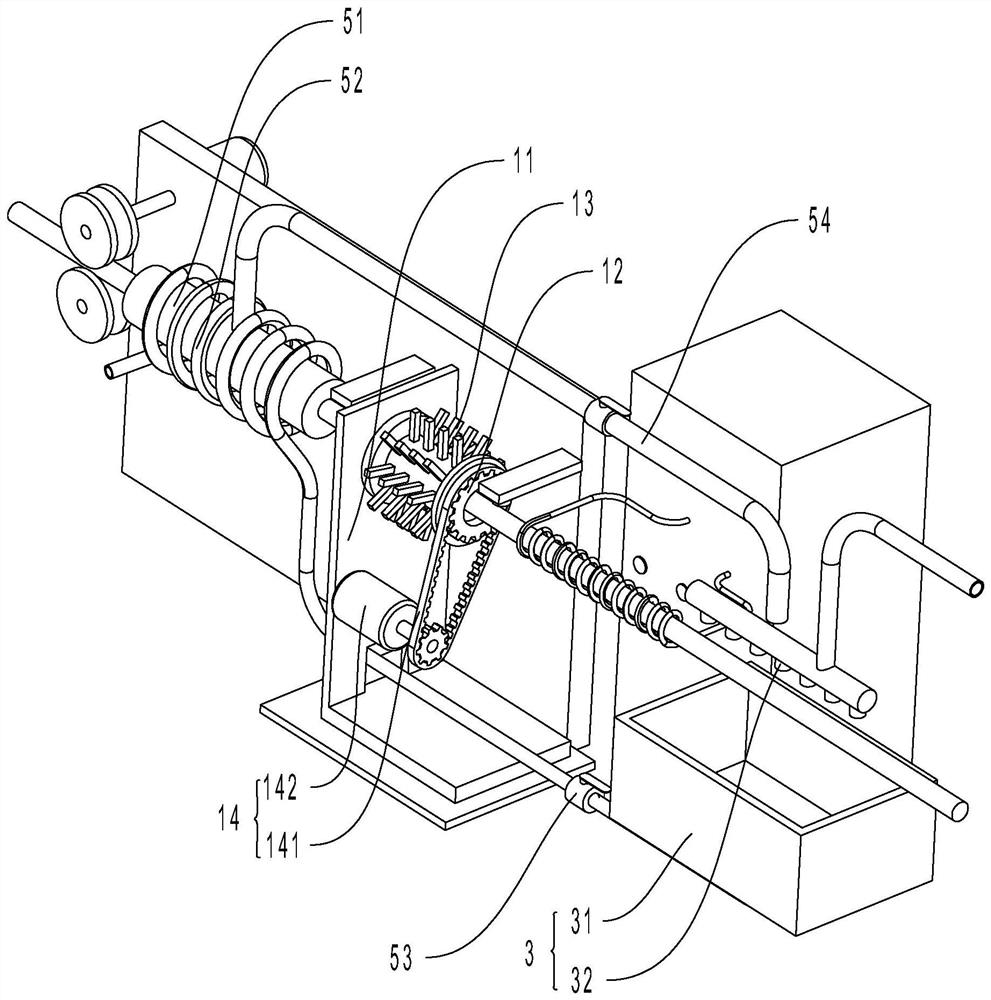

[0041] The application will be described in further detail below in conjunction with all the accompanying drawings.

[0042] The embodiment of the present application discloses an intelligent copper pipe online annealing device and a control method thereof. The material in this embodiment is preferably a copper tube.

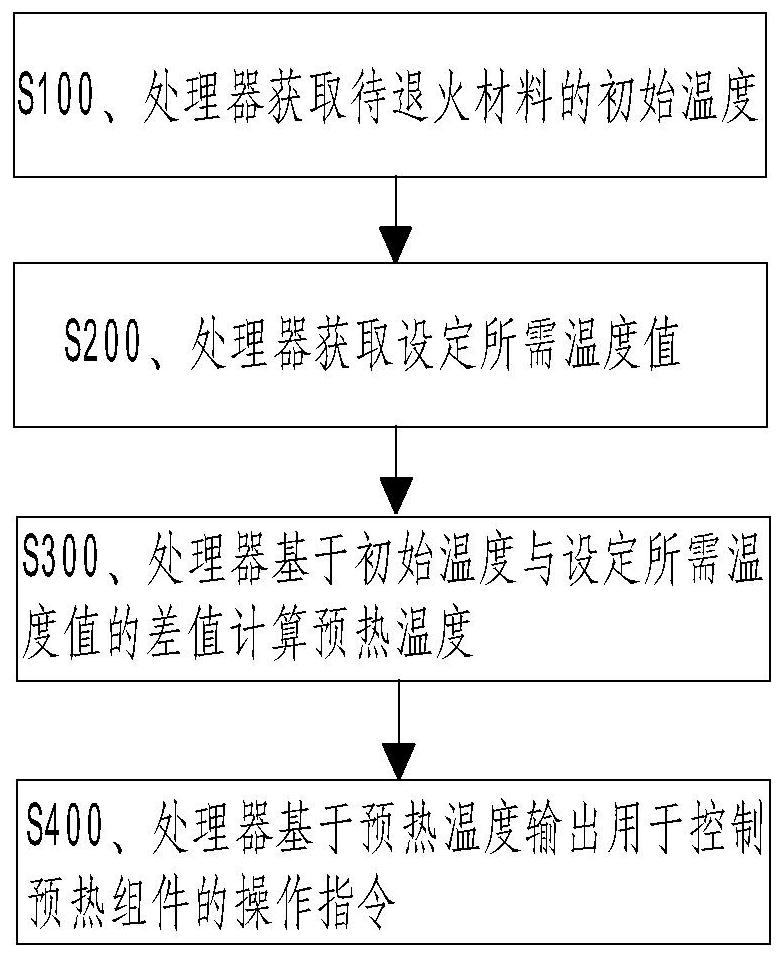

[0043] refer to figure 1 , the intelligent copper pipe online annealing equipment includes a body 1, and also includes a heating device 2 connected to the body 1, a cooling device 3 and a transmission device 4, and the side of the heating device 2 away from the cooling device 3 is provided with a preheating pipe 51 and a preheating assembly 5. The preheating assembly 5 is used to heat the preheating pipe 51 to raise its temperature, so that the temperature of the copper pipe to be passed through the preheating pipe 51 is raised, and the temperature after preheating of the copper pipes with different initial temperatures is controlled in a targeted manner. , s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com