Patents

Literature

67results about How to "Avoid oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for the purification of marigold xanthophylls

Description of a process to extract, saponify and purify lutein and zeaxantine contained in Marigold flowers free from any genetic manipulation, which have been harvested by hand and dried upon weather so that it neither contains epoxicarotenoids or cis-carotenoids. Fatty acids are removed as its metallic salts and carotenoids are recovered using a polar solvent.

Owner:POBLETE VIDAL ALFONSO MR

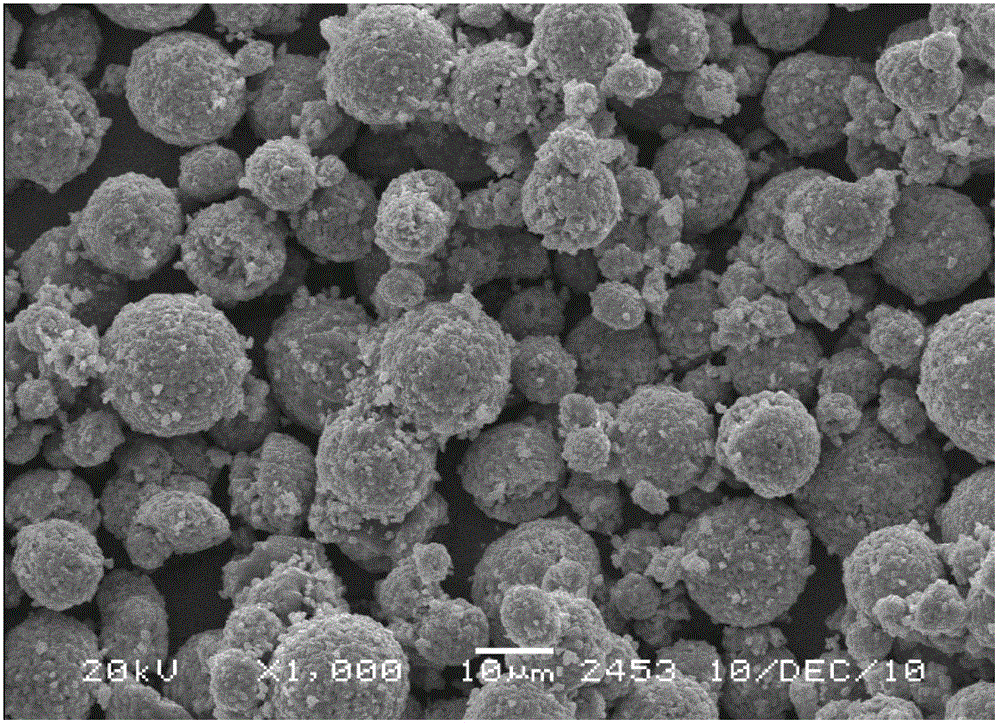

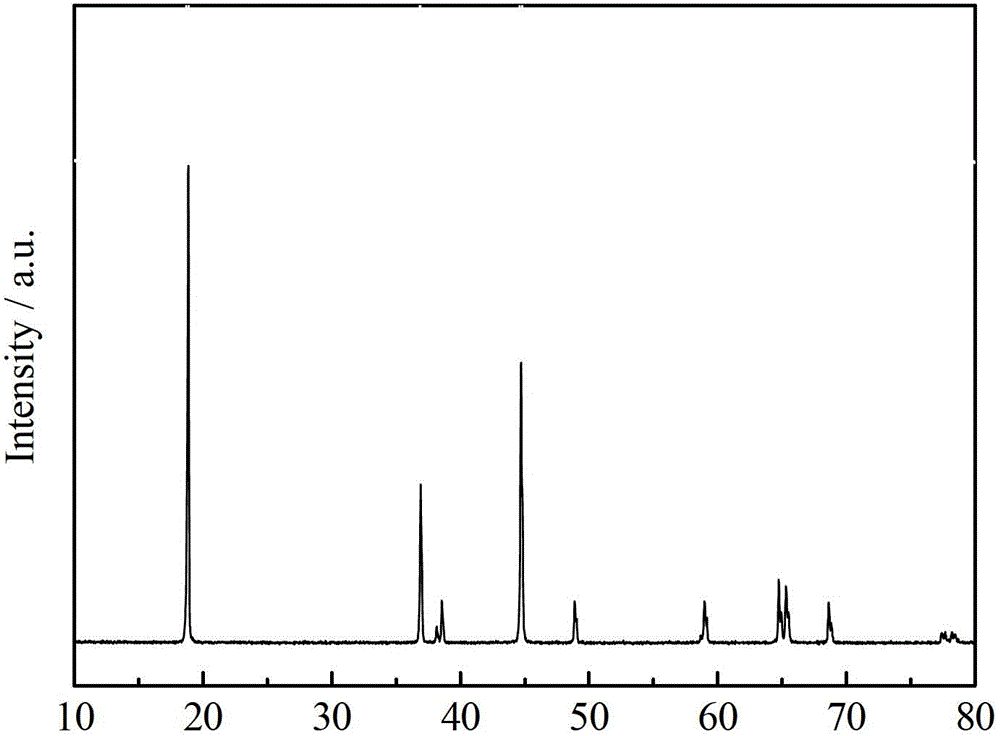

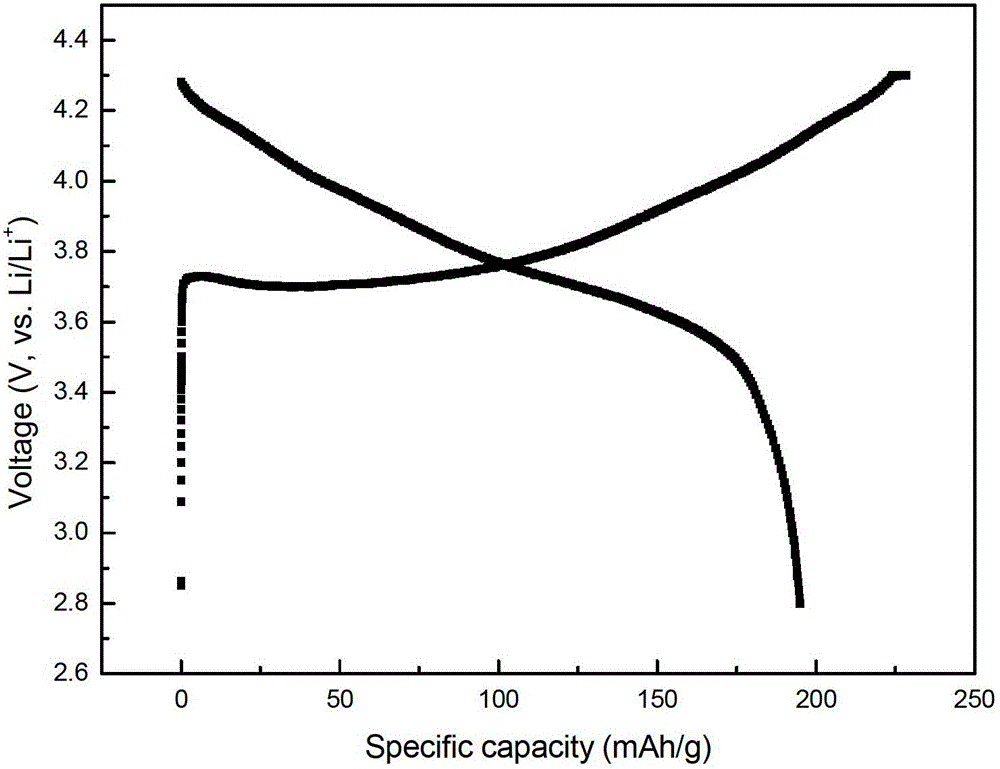

Preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries

ActiveCN103066257ASolve the problem of complete oxidationPrevent "cation mixing" phenomenonCell electrodesLithium hydroxideOxygen

The invention provides a preparation method of lithium-nickel-cobalt-aluminum oxide for anode materials of lithium ion batteries. The method comprises: step 1, using a nickel-cobalt-aluminum precursor prepared through a coprecipitation method and doped with mixed ions as raw materials, putting the raw materials into a sealed hearth of a pressure furnace, continuously introducing oxygen until a fixed pressure value is formed, then heating to a pre-burning temperature and keeping warm for a period of time, and cooling to obtain an oxidized precursor; and step 2, adding measured lithium salt or lithium hydroxide into the oxidized precursor, ball milling and uniformly mixing; heating the uniformly mixed raw materials to a certain temperature and keeping warm for a period of time, and meanwhile continuously introducing oxygen to complete a sintering process, thereby obtaining the finish product. According to the invention, through a hyperbaric oxygen atmosphere, the oxygen are enabled to fully infiltrate into particles of the raw materials which has a certain accumulation thickness, thereby preventing situations that only surface materials are oxidized under a normal pressure, and ensuring a full conversion of Ni<2+> to Ni<3+> by a full pre-oxidation.

Owner:GUANGZHOU LIBODE NEW MATERIAL

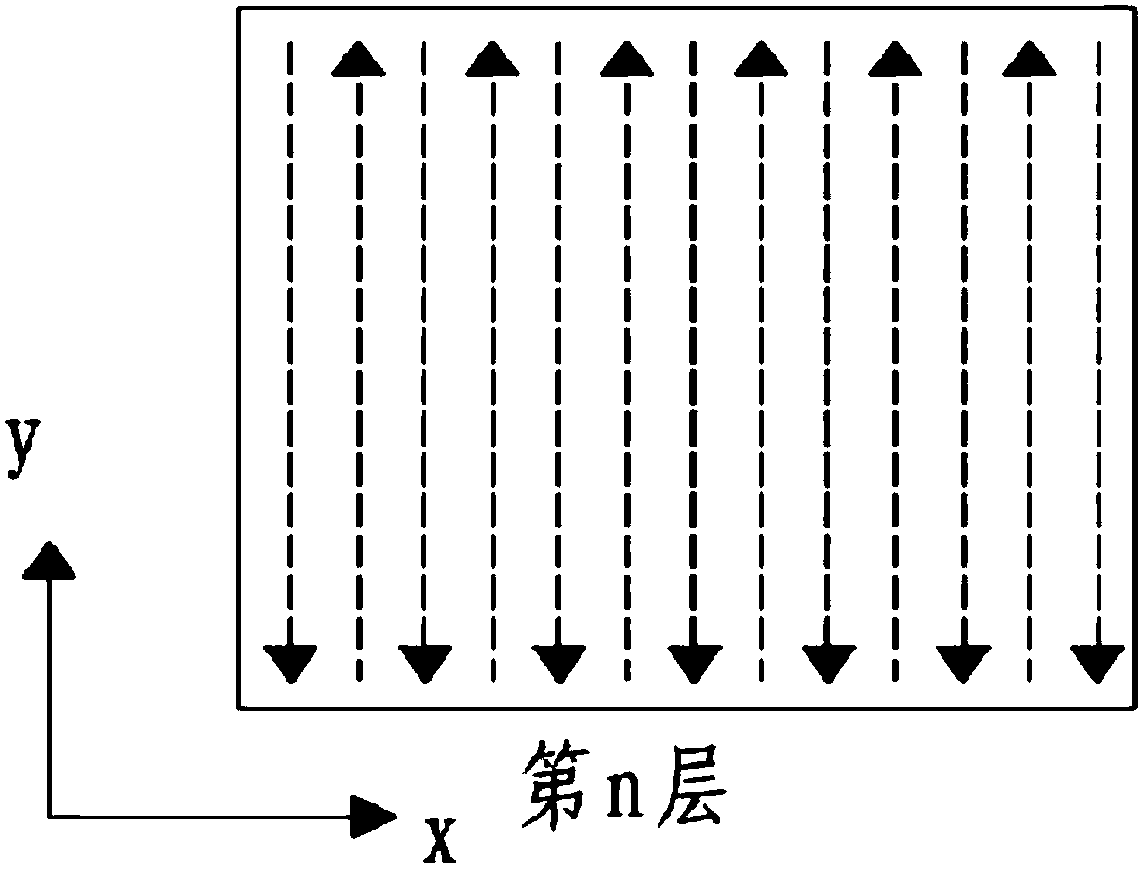

Method for preparing porous tantalum medical implant material based on electron beam selective melting technology

ActiveCN107598166AAvoid oxidationImproved biostability and biocompatibilityAdditive manufacturing apparatusIncreasing energy efficiencyThree dimensional modelPorous tantalum

The invention provides a method for preparing a porous tantalum medical implant material based on an electron beam selective melting technology. The method comprises the steps that firstly, software is utilized for reconstructing a two-dimensional medical CT image or MRI data, and a three-dimensional model of the porous tantalum medical implant material is obtained after structure optimization andsupporting addition processing are conducted on a three-dimensional rough model; and secondly, selective melting is conducted on tantalum powder by adopting electron beams according to shearing-layerdata of the three-dimensional model of the porous tantalum medical implant material, and then the porous tantalum medical implant material is obtained. According to the method for preparing the porous tantalum medical implant material based on the electron beam selective melting technology, the tantalum powder is melted and formed under the vacuum condition, and no additive is contained in the tantalum powder, so that the oxidation phenomenon after heating of tantalum is avoided, contamination of impurity elements such as carbon and oxygen is reduced, the requirement of the customized poroustantalum medical implant material is met, and meanwhile biological stability and biological compatibility of the porous tantalum medical implant material are improved. Post-processing processes such as sintering and annealing do not need to be conducted on the obtained porous tantalum medical implant material, and the method is convenient and efficient.

Owner:广州赛隆增材制造有限责任公司

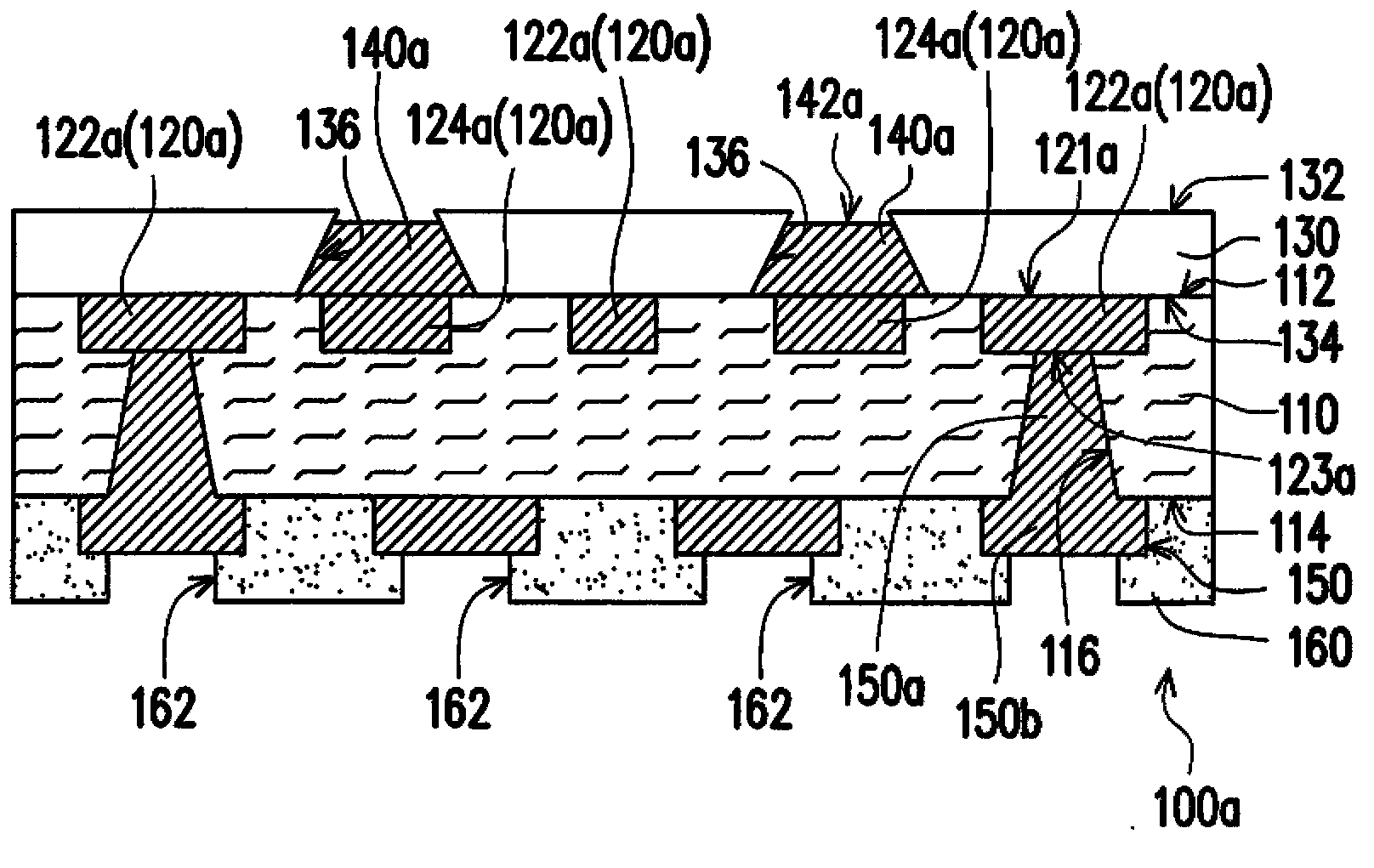

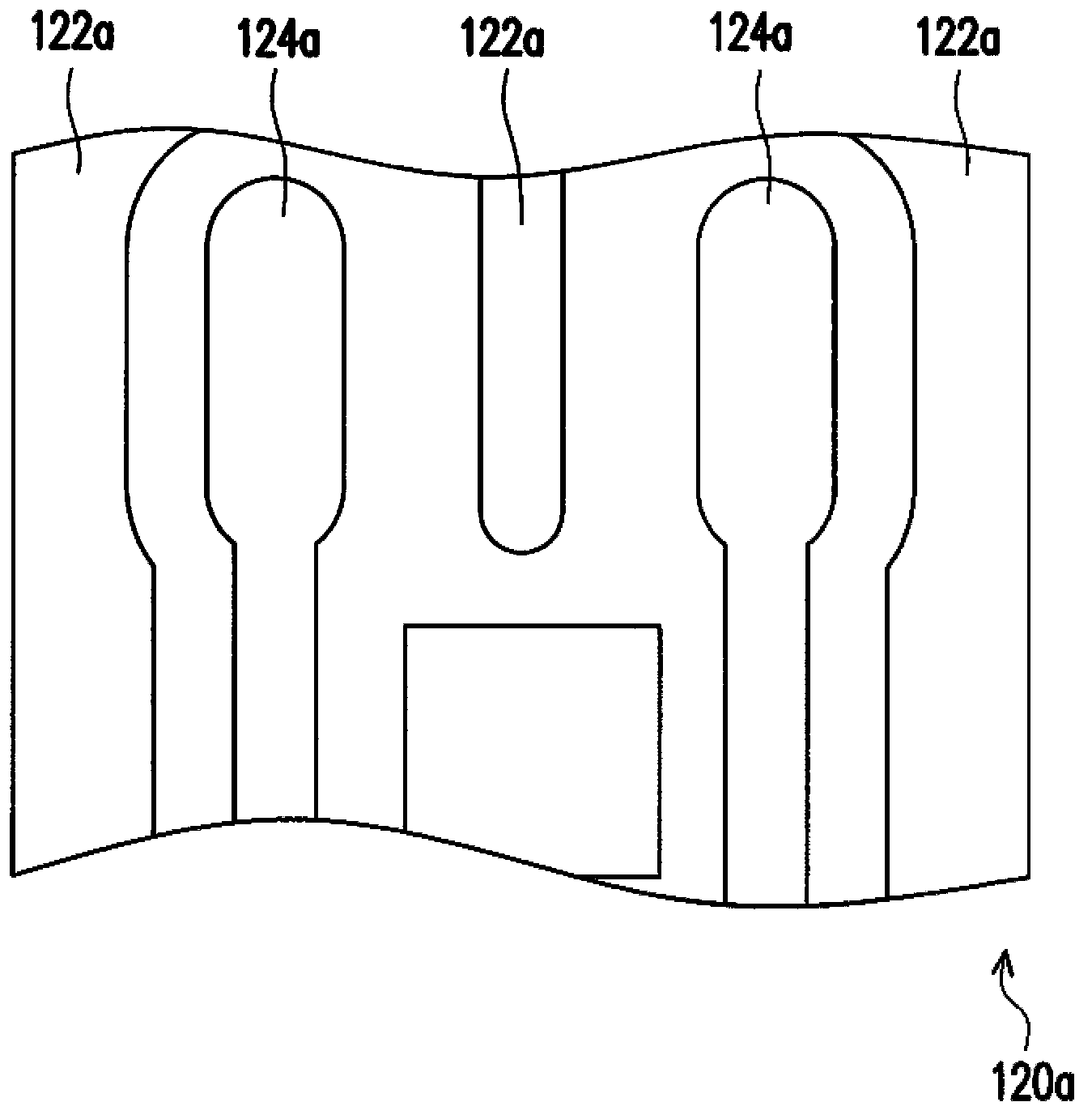

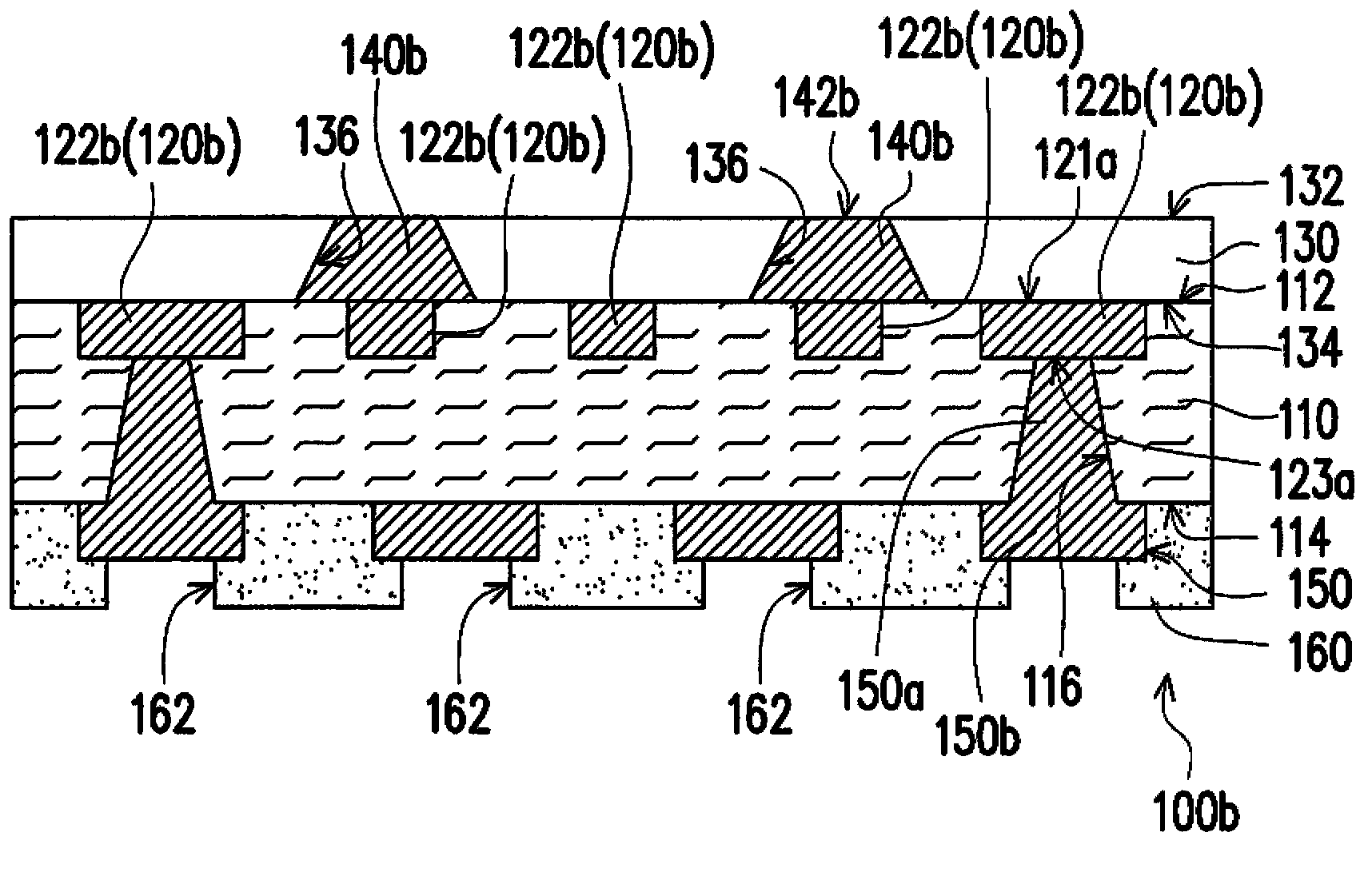

Bearing substrate and manufacturing method thereof

ActiveCN104168706AImprove joint reliabilityAvoid oxidationPrinted circuit assemblingElectrical connection printed elementsElectrical and Electronics engineeringOpen hole

The invention discloses a bearing substrate and a manufacturing method thereof. The bearing substrate comprises a dielectric layer, a first line layer, an insulating layer, a plurality of conductive blocks and a first conductive structure. The dielectric layer has a first surface, a second surface and a plurality of blind holes. The first line layer is internally buried in the first surface, and the blind holes extend to the first line layer from the second surface. The insulating layer is arranged on the first surface and is provided with a third surface, a fourth surface and a plurality of first open holes. The first open holes expose the first line layer, and the diameter of each first open hole increases gradually from the third surface to the fourth surface. The conductive blocks are filled in the conductive blocks and are connected with the first line layer. The first conductive structure comprises a plurality of conductive holes filling to the blind holes and second line layers arranged on a part of the second surface.

Owner:UNIMICRON TECH CORP

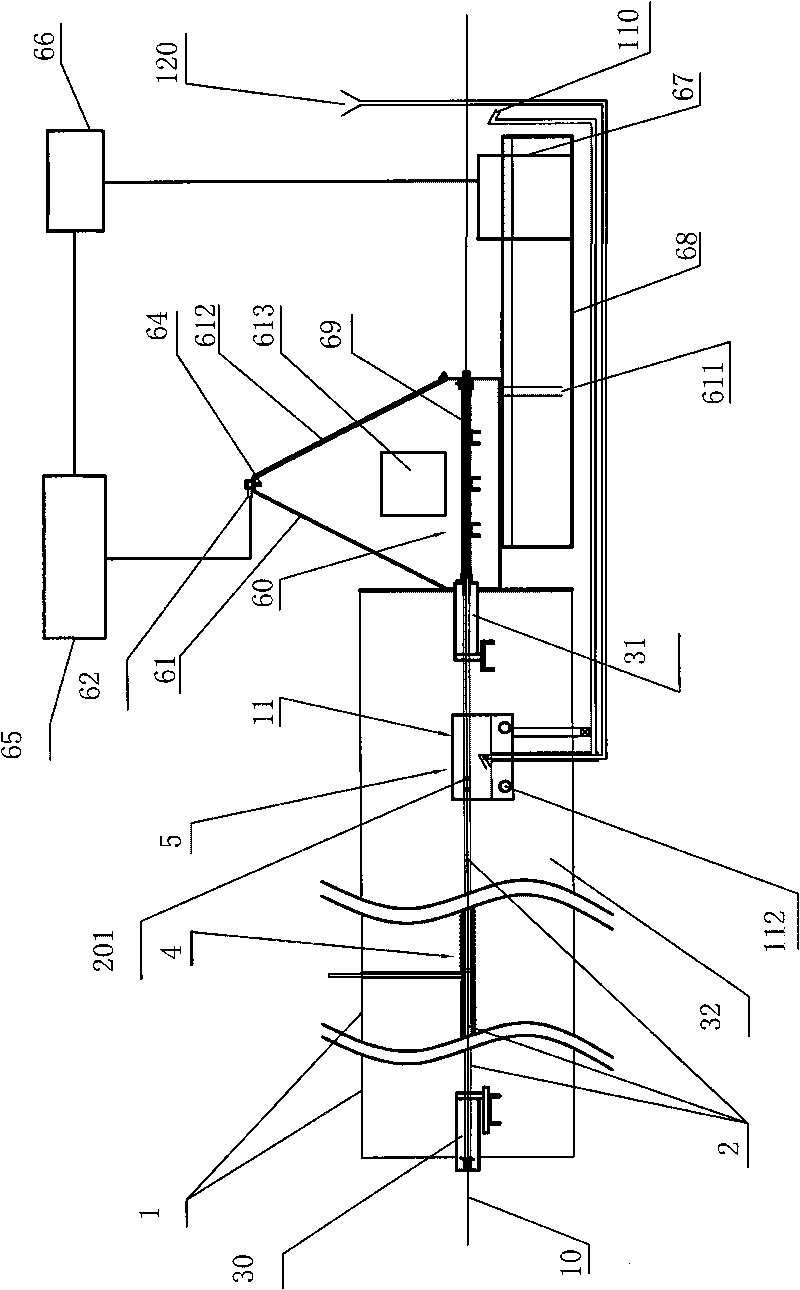

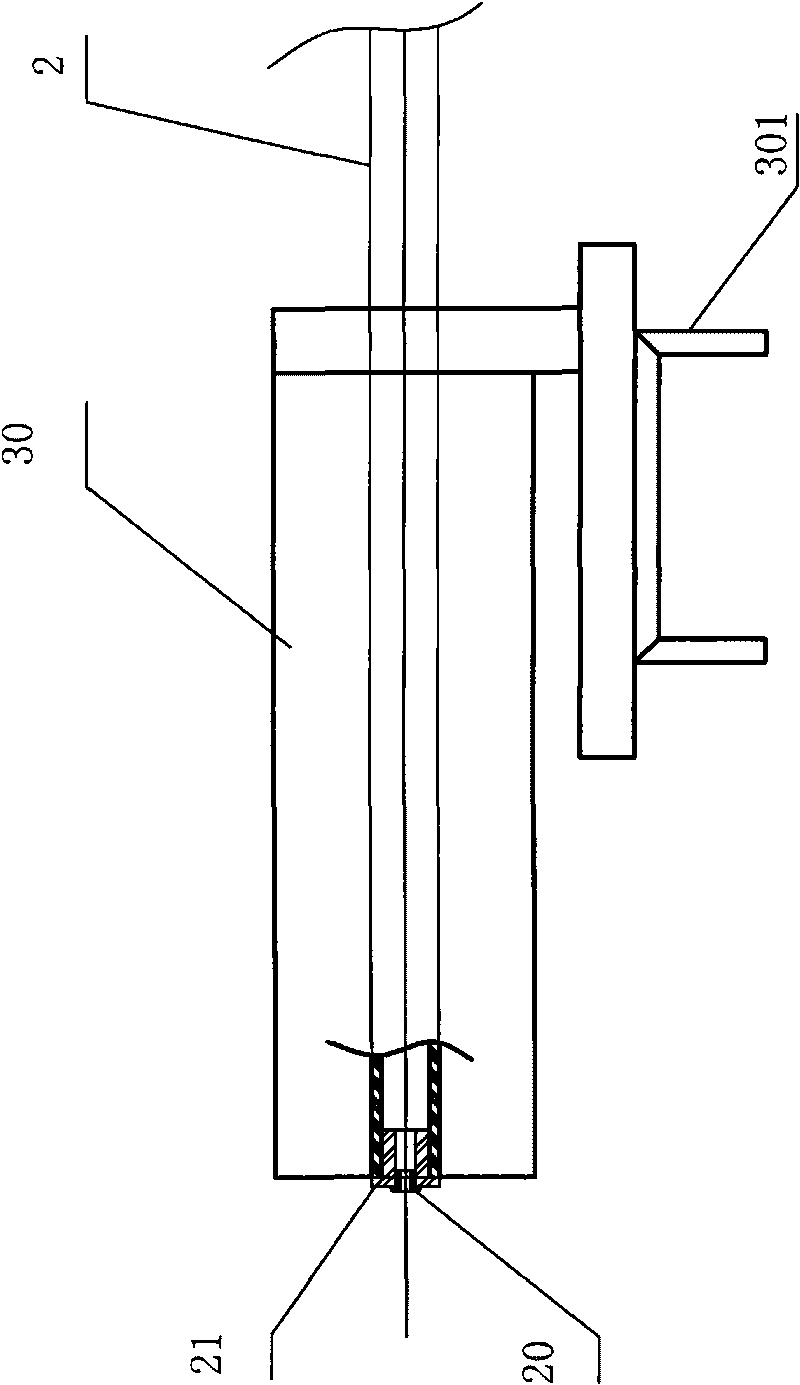

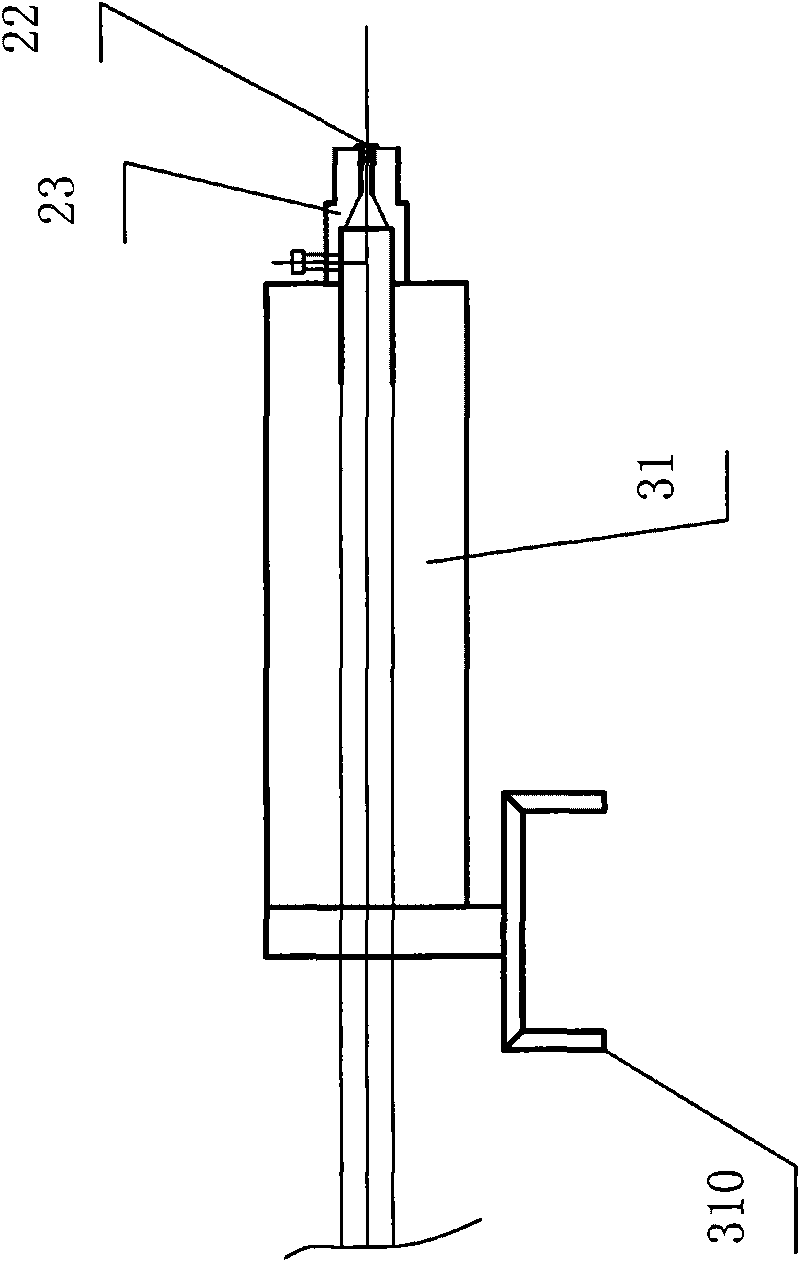

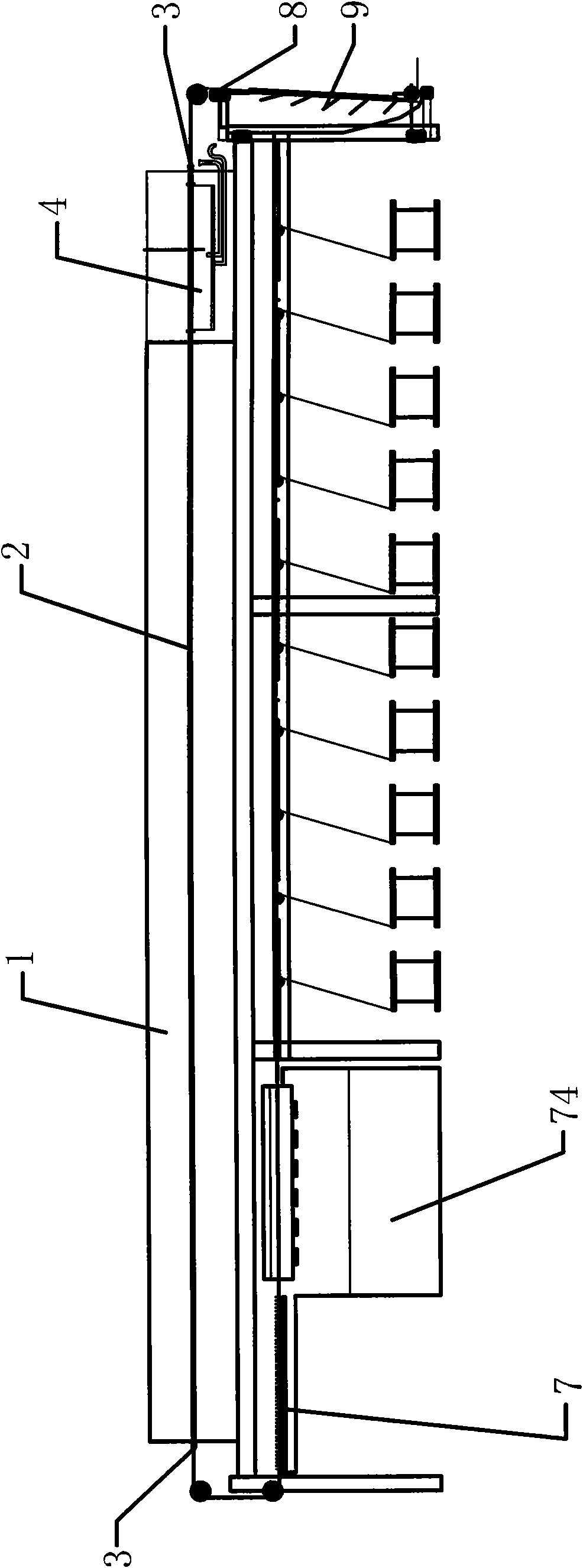

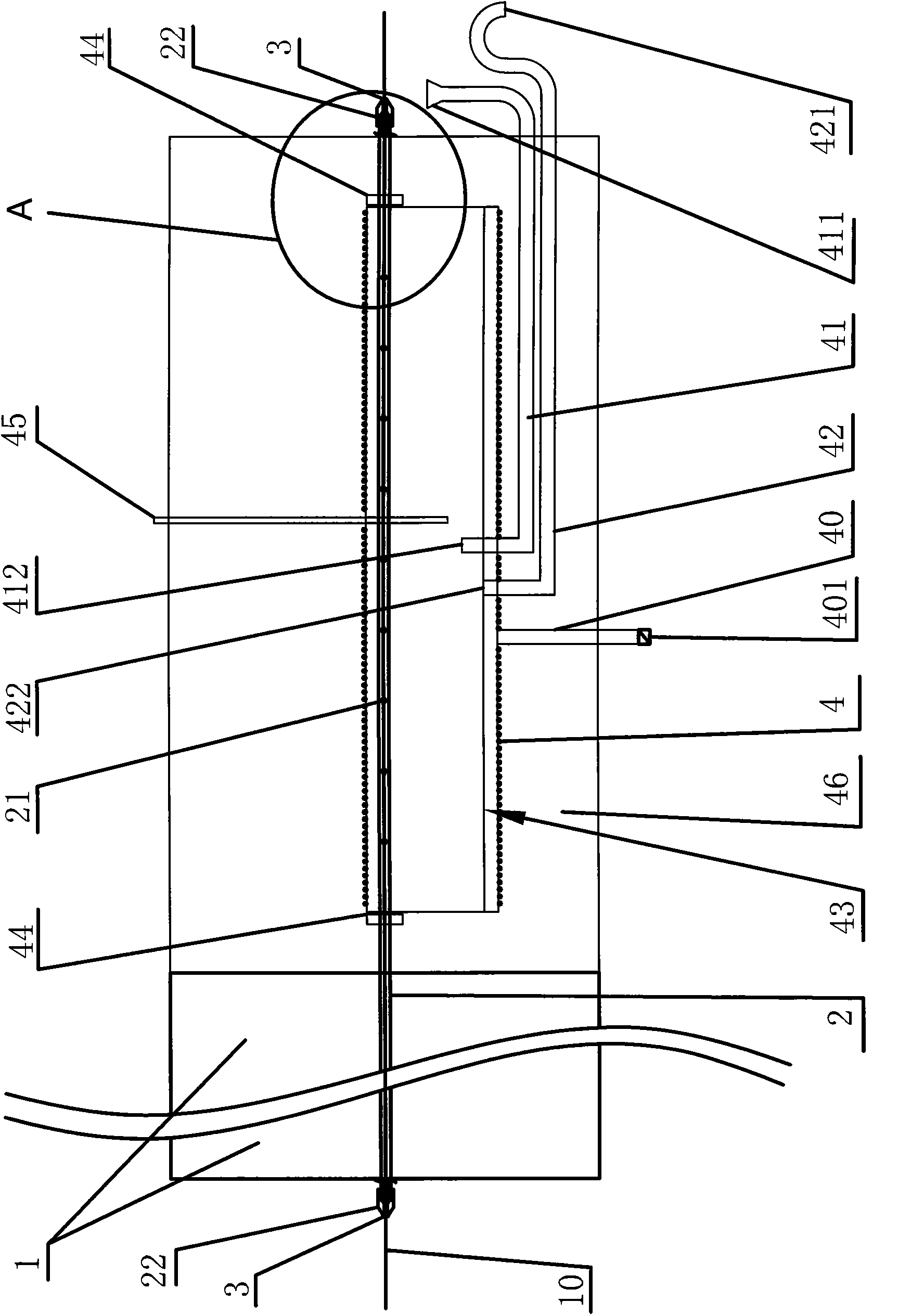

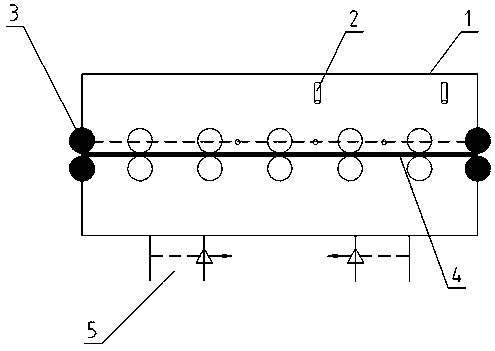

Wire annealing process and device thereof

InactiveCN101736143APrevent oxidationImprove performance and quality stabilityFurnace typesHeat treatment furnacesLiquid waterMetallurgy

The invention relates to the technical field of wire annealing, in particular to a wire annealing process and a device thereof, the wire annealing process mainly comprises three working procedures of heating treatment in a high temperature annealing region, cooling treatment in a steam cooling region and liquid water coating and cooling treatment in a liquid water coating and cooling region, wherein steam in the steam cooling region is low-temperature steam generated by a built-in steam generator, thereby realizing high cooling efficiency, having no problem of condensate and being applied in annealing of a variety of wires; furthermore, due to the working procedure of the liquid water coating and cooling treatment, the wire annealing process can not easily complete the wire cooling, but also better complete the tasks of coating of an antioxidant, coating a booster flux, cleaning the booster flux and the like. Therefore, the wire annealing process and the device thereof can avoid the oxidation of annealed wires, improve the performance and the quality stability of the wires after annealing, further realize the perfect coating of the antioxidant and the pretreatment of tin plating, have good energy-saving effect and be applied in the annealing of a variety of wires.

Owner:东莞市康汇聚线材科技有限公司

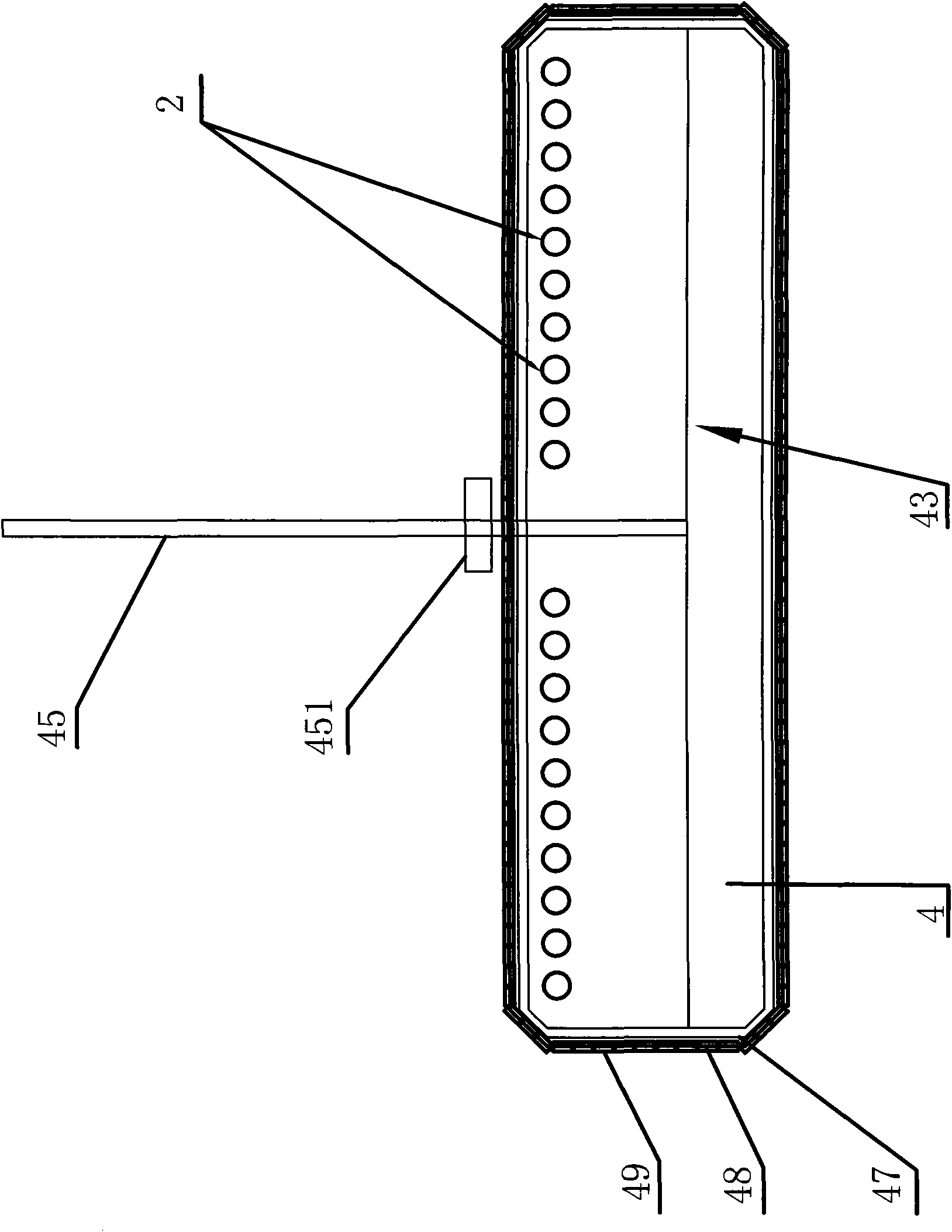

Energy-saving type continuous annealing furnace

InactiveCN101597685AAvoid oxidationReduce lossFurnace typesHeat treatment furnacesWire rodSteam pressure

The invention relates to the technical field of an annealing furnace, particularly relates to an energy-saving type wire rod continuous annealing furnace, comprising a furnace body and a plurality of furnace tubes for the wire rod to pass through, the furnace body is placed horizontally, the plurality of the furnace tubes are horizontally arranged through the furnace body side by side, a built-in steam generator is arranged near the wire outlet pipe orifice of the furnace tube in the furnace body; the built-in steam generator comprises an inner container, the furnace tube passes through the inner container of the built-in steam generator, a plurality of steam inlets are arranged on the tube wall of the furnace tube in the inner container; the steam pressure of the annealing furnace in the invention is easy to control, and has high stability and reliability, and the continuous annealing furnace has good energy-saving effect, can effectively prevent the annealing wire rod from oxidizing.

Owner:周开勇

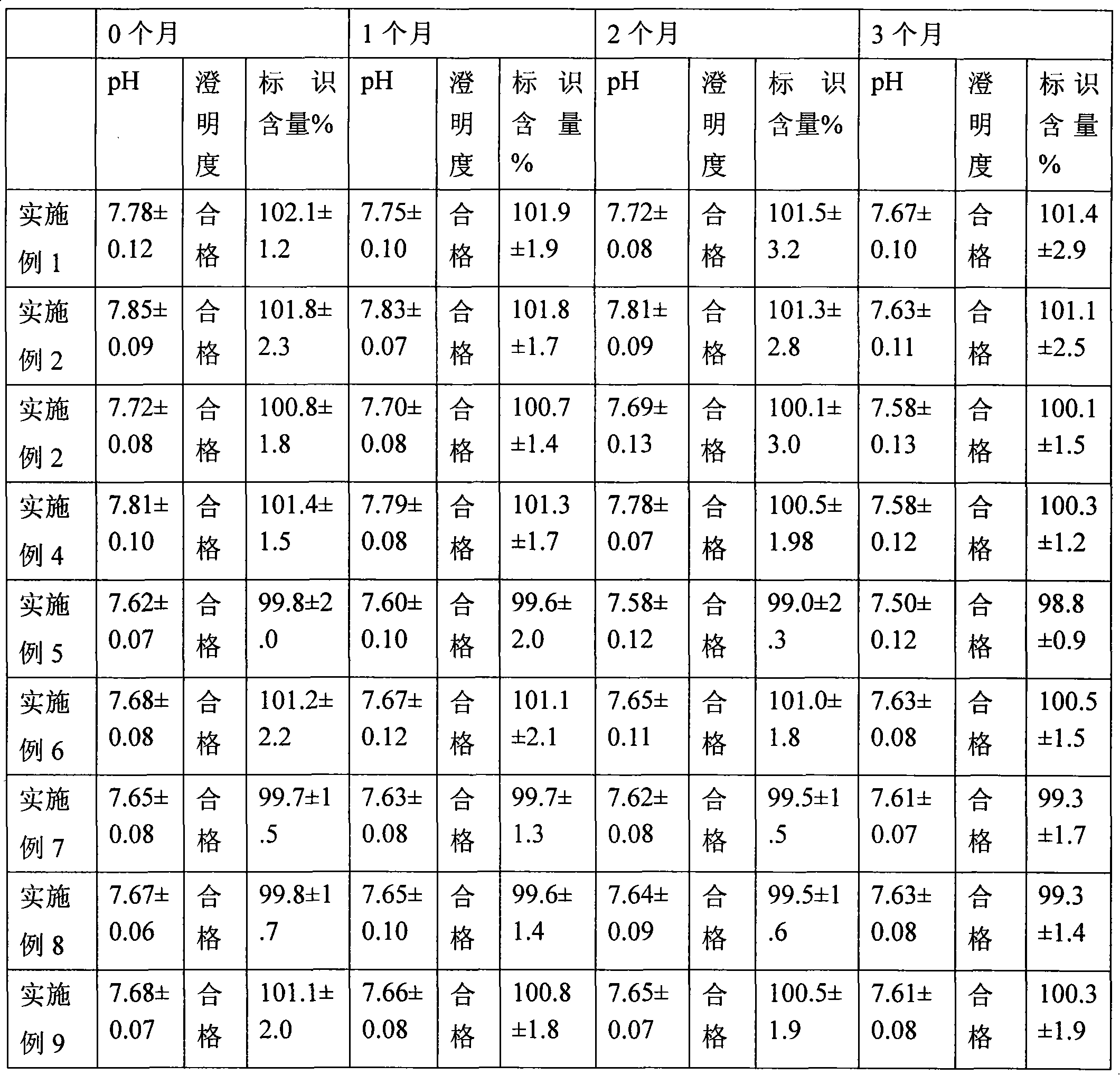

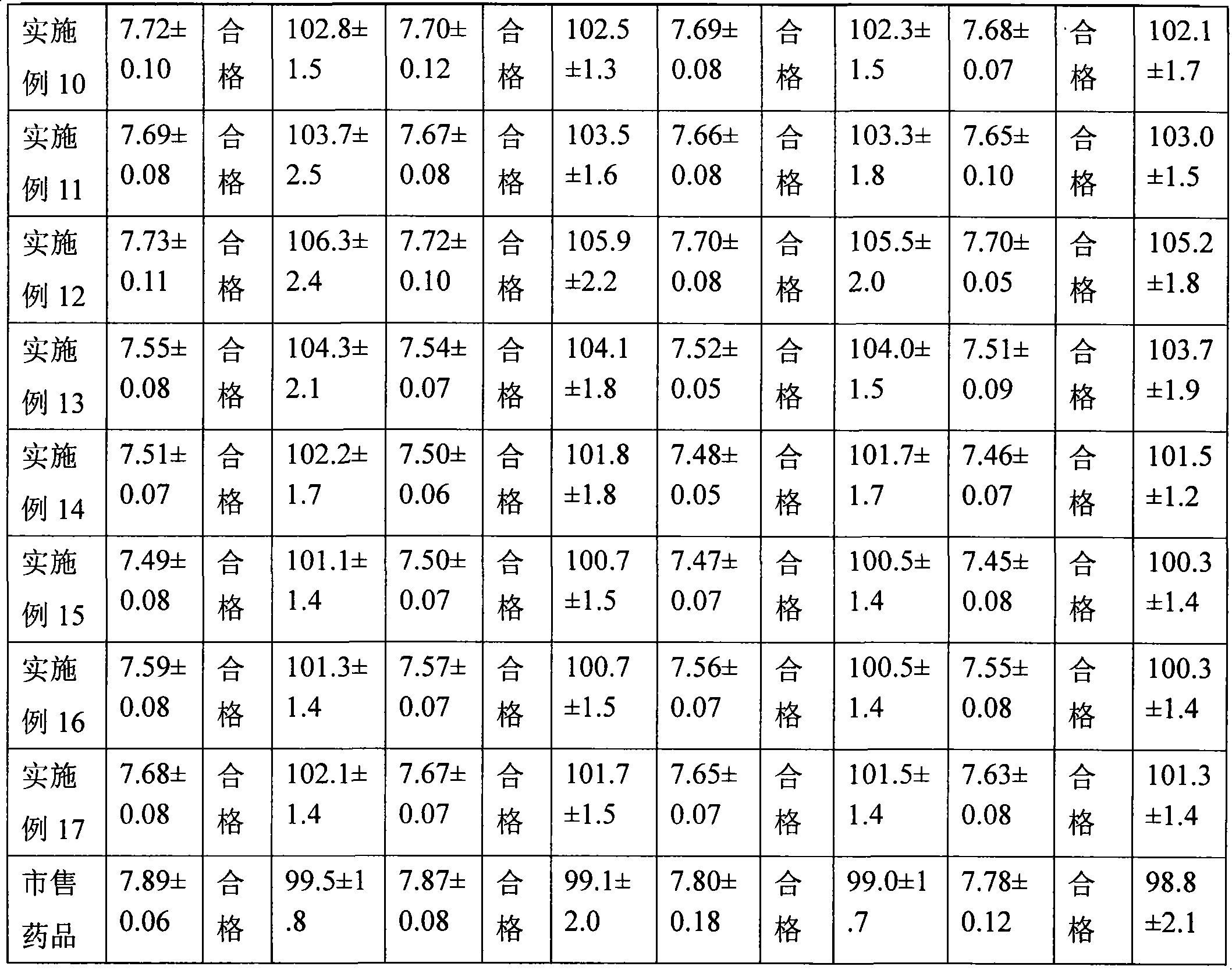

Dexamethasone sodium phosphate injection

The invention provides a dexamethasone sodium phosphate injection, which consists of 0.1 to 1 percent of dexamethasone sodium phosphate, 0 to 2 percent of medicinal propylene glycol, sodium dihydrogen phosphate: disodium hydrogen phosphate=0.01 to 0.1 percent of mixed phosphate buffer according to a ratio of 0-1:10, and the balance of water for injection, wherein the used dexamethasone sodium phosphate bulk medicament preferably selects a spray drying method to produce.

Owner:TIANJIN JINYAO GRP

Lead-free tin-based solder for solar photovoltaic module and preparation method thereof

InactiveCN103801853AImprove wettabilityReduce performance degradationWelding/cutting media/materialsSoldering mediaIndiumSurface oxidation

The invention provides lead-free tin-based solder for a solar photovoltaic module. The lead-free tin-based solder comprises, by mass, stibium 0.05 percent-0.15 percent, silver 0.01 percent-0.05 percent, copper 0.1 percent-0.4 percent, indium 0.01 percent-0.05 percent, bismuth 0.2 percent-0.5 percent, gallium 0.06 percent-0.10 percent, phosphorus 0.02 percent-0.09 percent and the balance tin and inevitable impurities. The invention further provides a manufacturing method of the lead-free tin-based solder. The manufacturing method comprises the step that stibium, silver, copper, indium, bismuth, gallium, tin and phosphorus are placed into a smelting furnace according to the mass percentage and are smelted in an inert atmosphere or a vacuum condition, and the lead-free tin-based solder for the solar photovoltaic module is obtained. According to the lead-free tin-based solder for the solar photovoltaic module, melting temperature is low, surface gloss is good, surface oxidation resistance is high, wetting performance is good, and welding quality is superior. Besides, the lead-free tin-based solder is economical, environmentally friendly and free of threat to human health, thereby being applicable to large-scale industrial production.

Owner:THE NORTHWEST MACHINE

Process for extracting litchi polyphenol from litchi rind

InactiveCN103908514AEffective protectionAvoid oxidationFood preparationPlant ingredientsSolubilityAlcohol

The invention discloses a process for extracting litchi polyphenol from litchi rind. The process comprises the following steps: regulating the pH of an extracting solvent to be less than or equal to 6.0 with acid; extracting and degrading the litchi rind with the pH value-regulated extracting solvent; allowing the extract to pass through a macroporous adsorption resin column; washing the column with water, and then with low-carbon alcohol; tracing and checking with thin layer chromatography, and collecting alcohol eluent containing a target component; and concentrating and drying the alcohol eluent. According to the preparation method, the litchi rind is extracted by adopting the acidity-regulated extracting solvent, on the one hand, the litchi polyphenol is effectively protected, the oxidation degree of polyphenol substances in the extracting process can be furthest avoided, and on the other hand, the whole system is in an acidic condition, so that the polymer in the polyphenol substances can be degraded into small-molecular substances with good water solubility, and the water solubility and bioavailability of the obtained product can be effectively improved. Furthermore, the process is simple and easy to operate, and the product is high in polyphenol content and high in yield.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

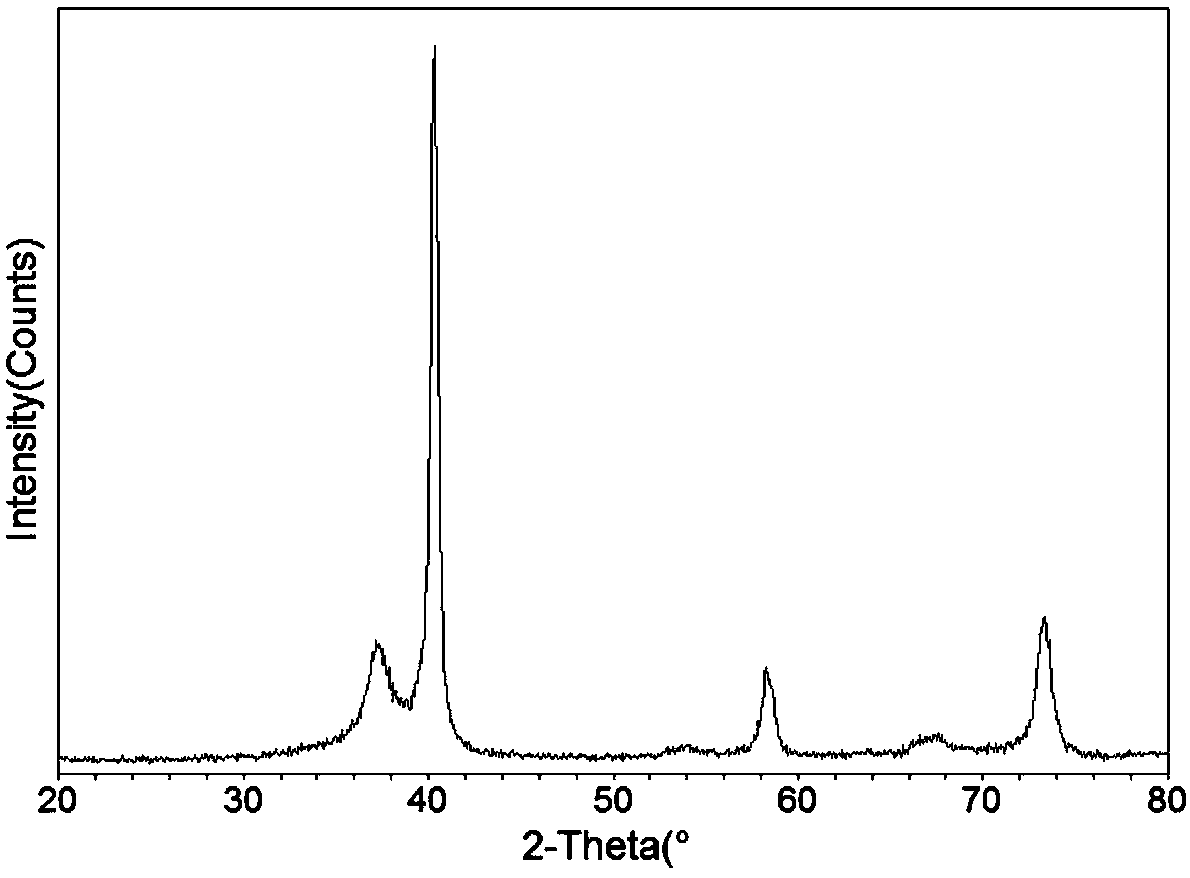

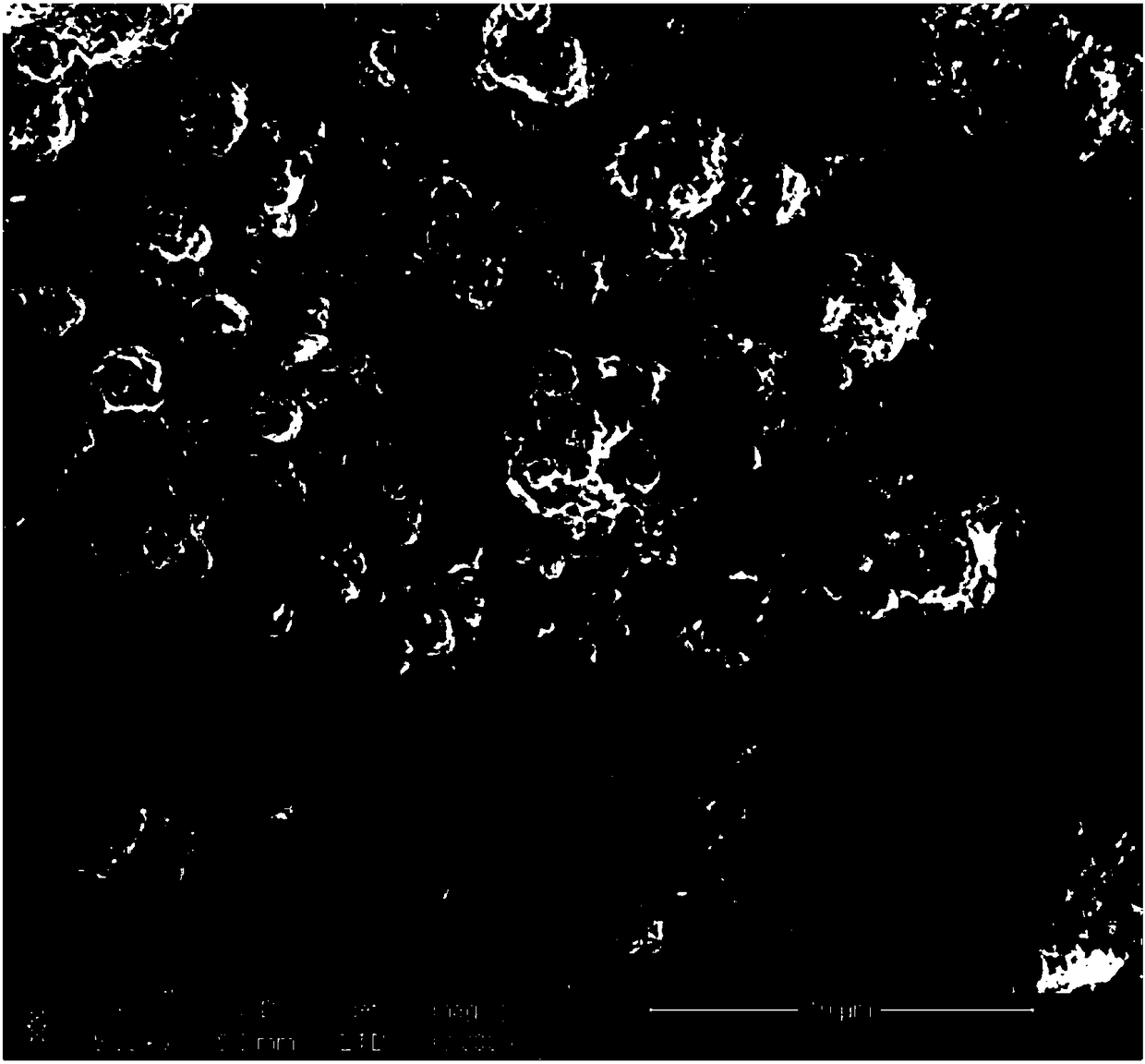

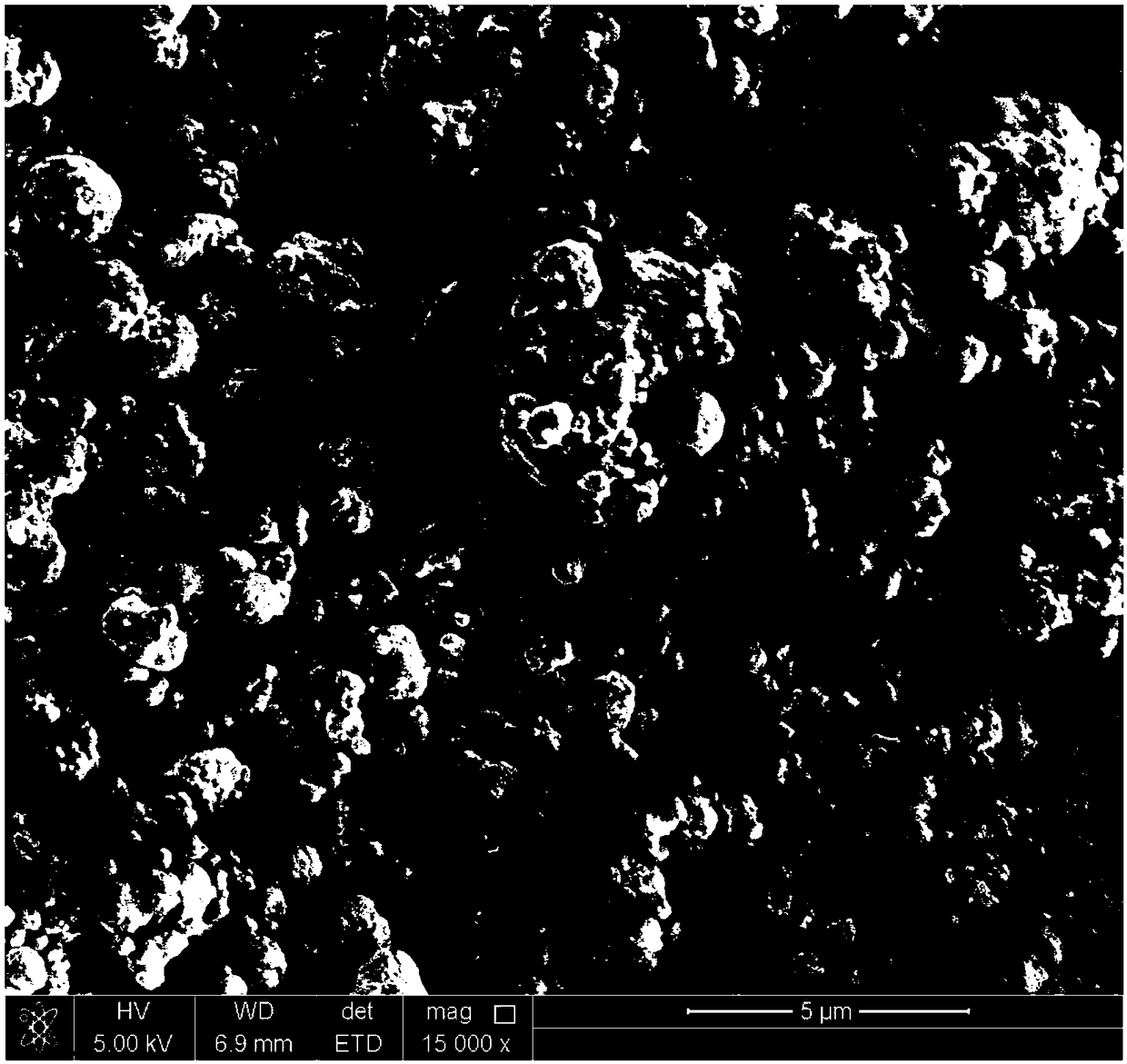

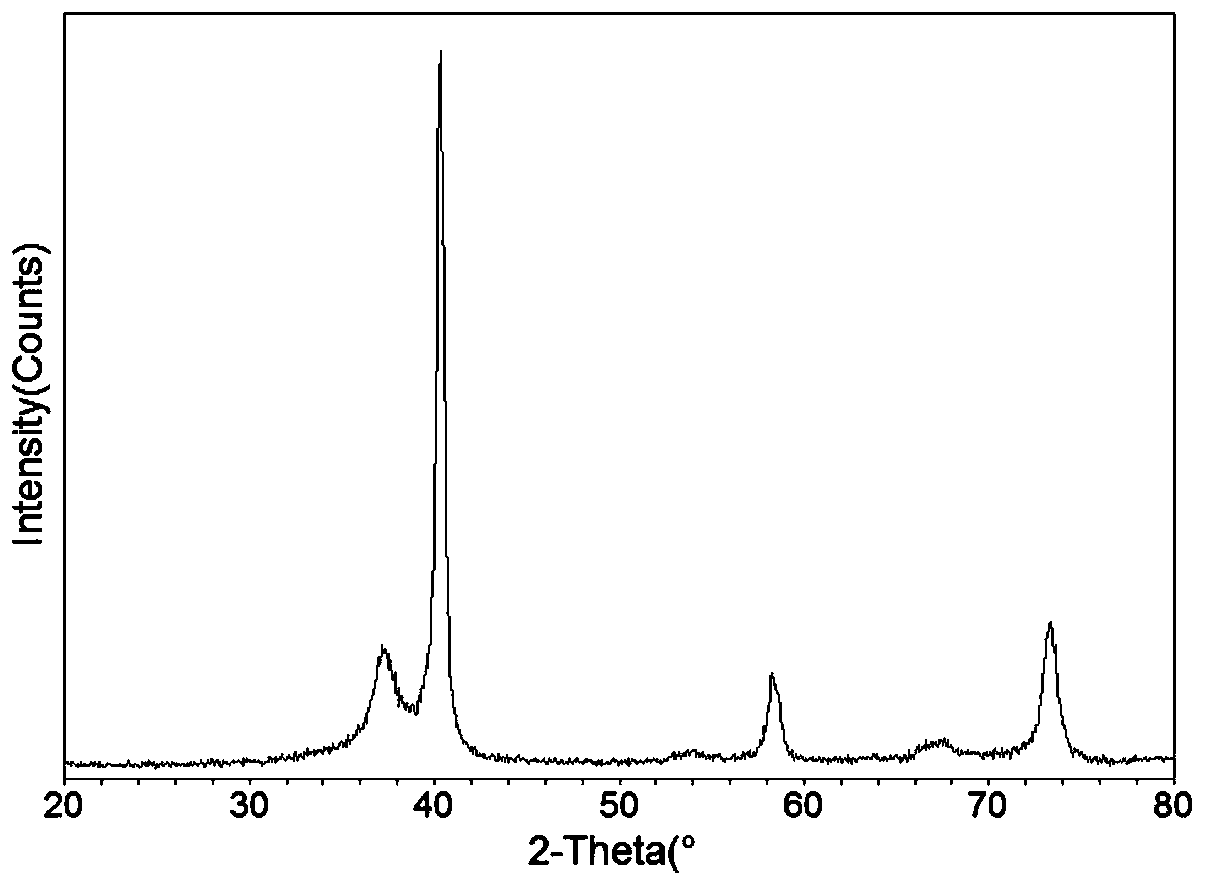

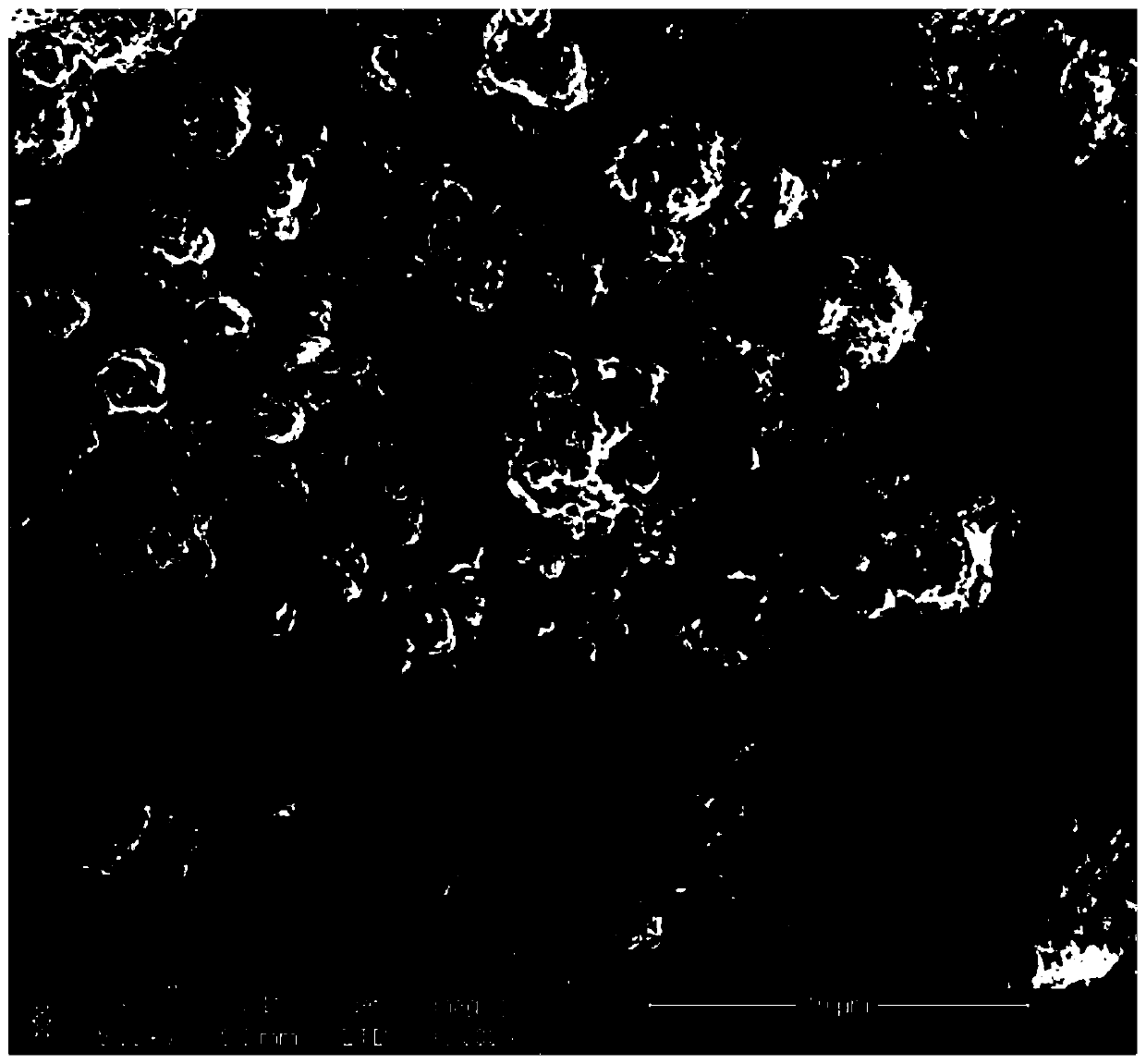

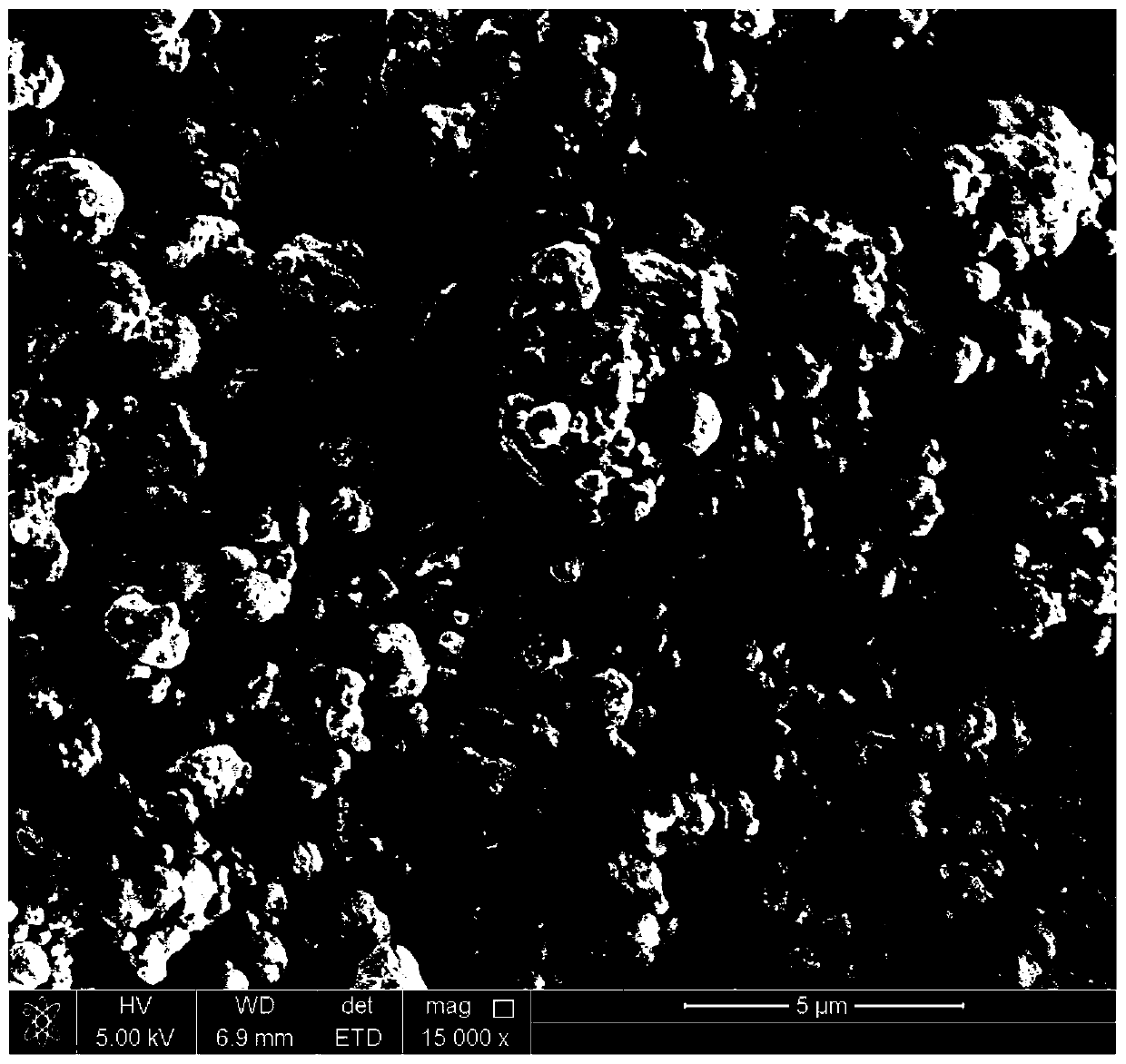

Nanocrystalline Ni-based alloys

InactiveUS6051046AAvoid oxidationReduce grain sizeReversible hydrogen uptakeTransportation and packagingCrystalliteGrain boundary

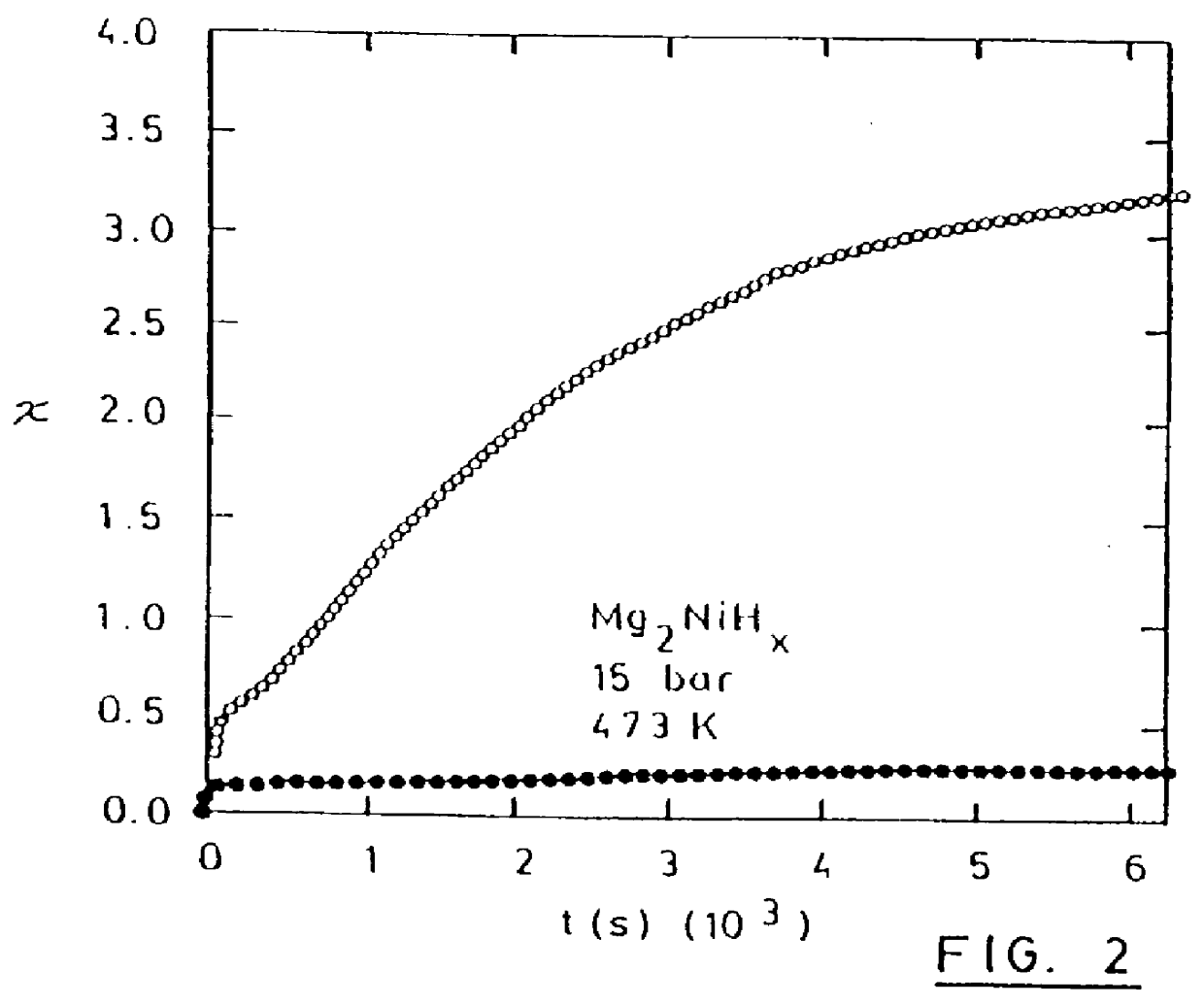

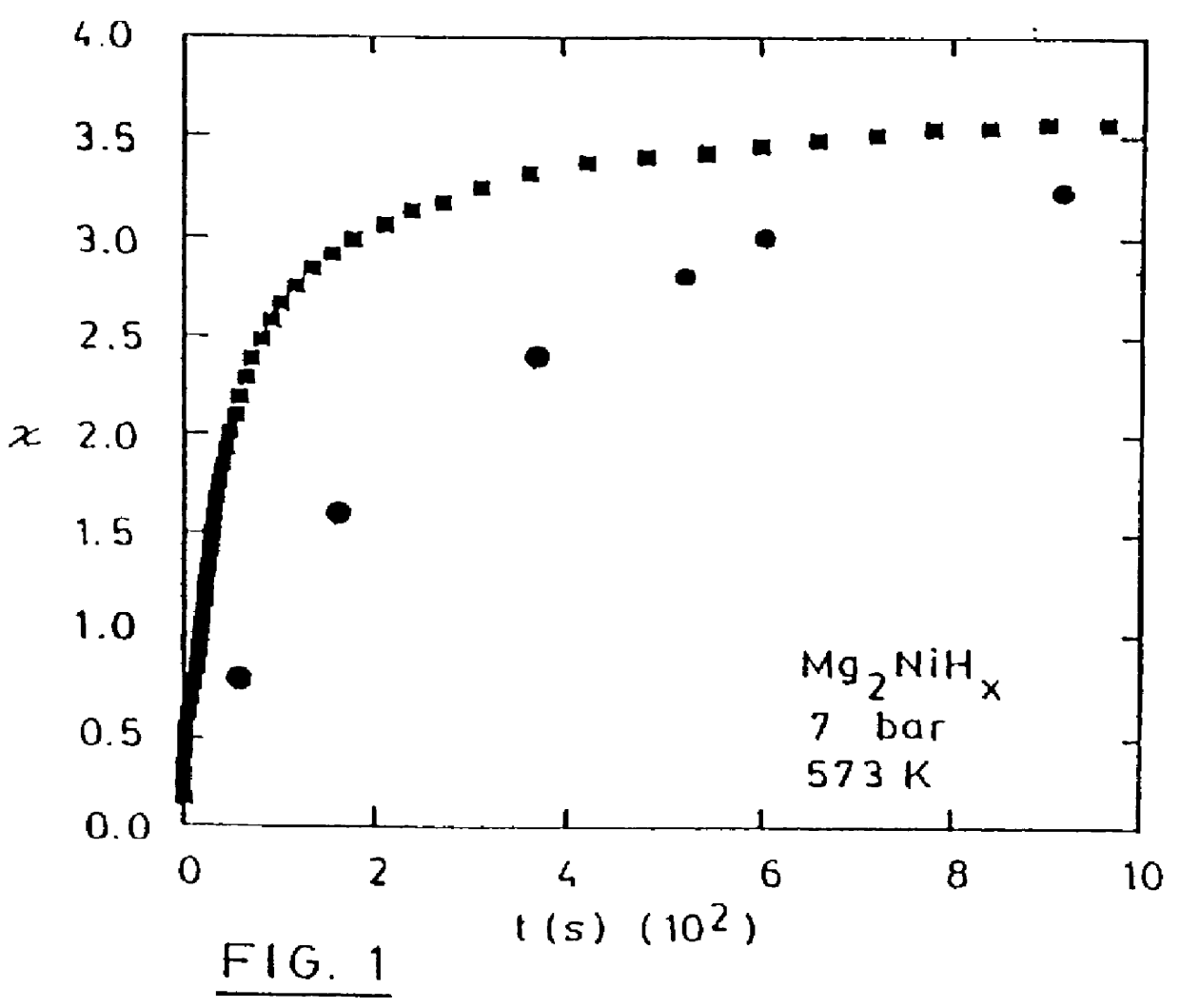

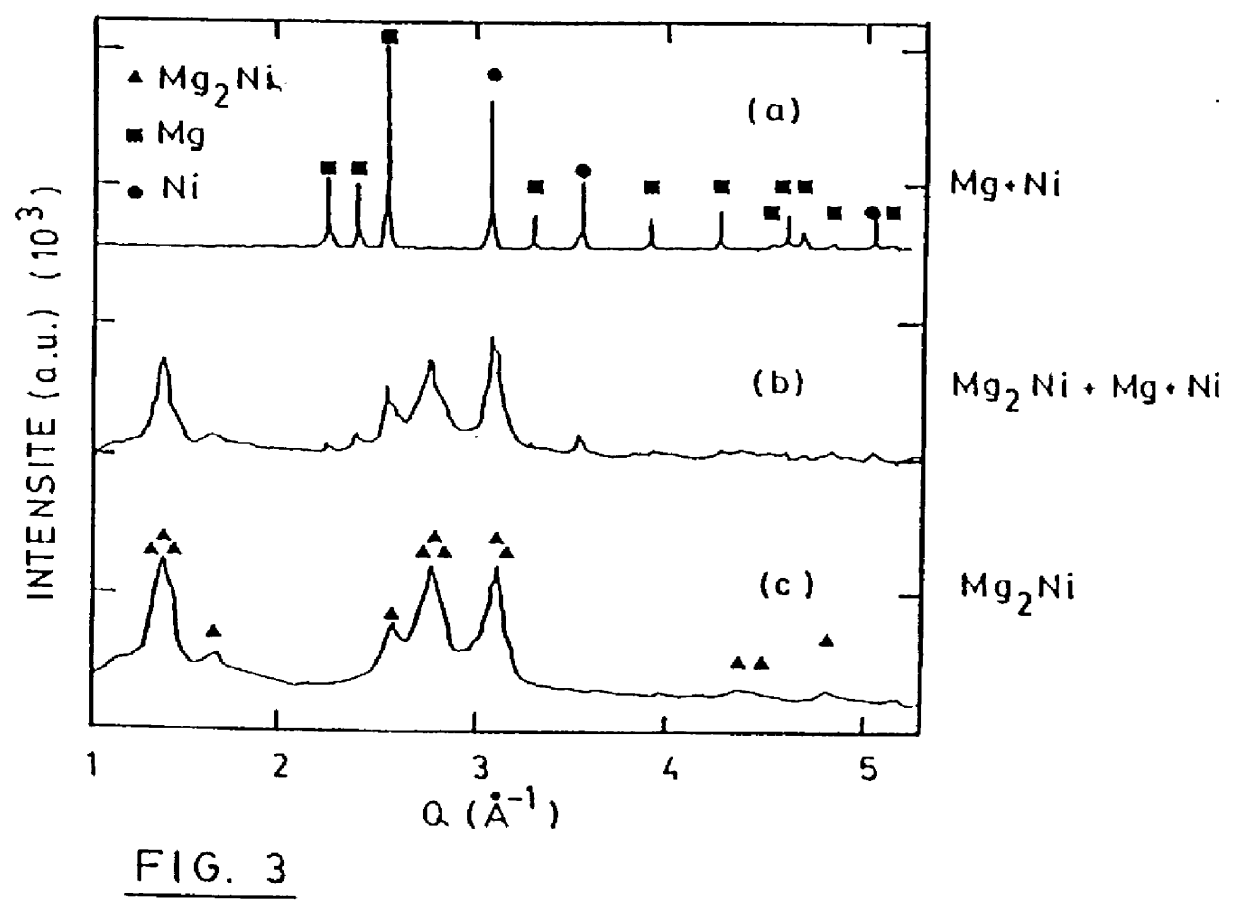

A powder of an alloy of Ni and Mg, La, Be or Li, consisting of crystallites having a grain size lower than 100 nm and a crystalline structure allowing hydrogen absorption. This powder which is preferably obtained by mechanical grinding, may consist of cristallites of Mg2Ni, LaNi5 or of Ni-based alloys of Be or Li having a grain size lower than 100 nm. The powder may also consist of cristallites of formula Mg2-xNi1+x, x ranging from -0.3 to +0.3, which have a grain size lower than 100 nm, and preferably lower than 30 nm. This crystalline powder is particularly useful for storing and transporting hydrogen. Indeed, it has been discovered that such Ni-based nanocrystalline powder requires no or only one single activation treatment at low temperature to absorb hydrogen. It has also been discovered that the kinetic of absorption and diffusion of hydrogen within the powder is much faster. This can be explained by the presence of a large number of grain boundaries.

Owner:HYDRO QUEBEC CORP

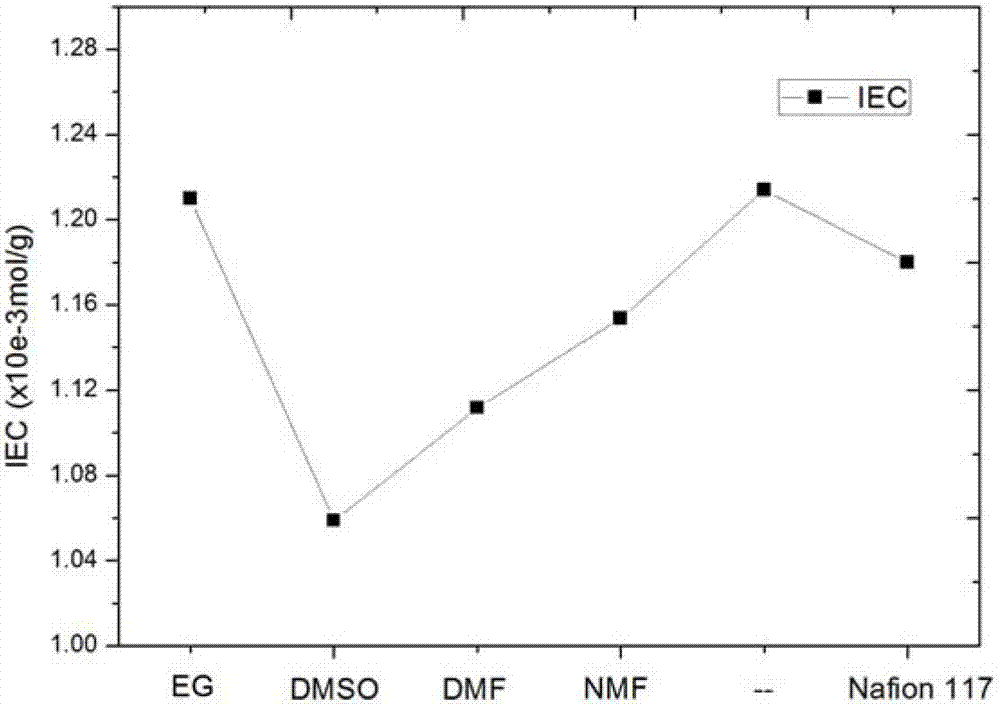

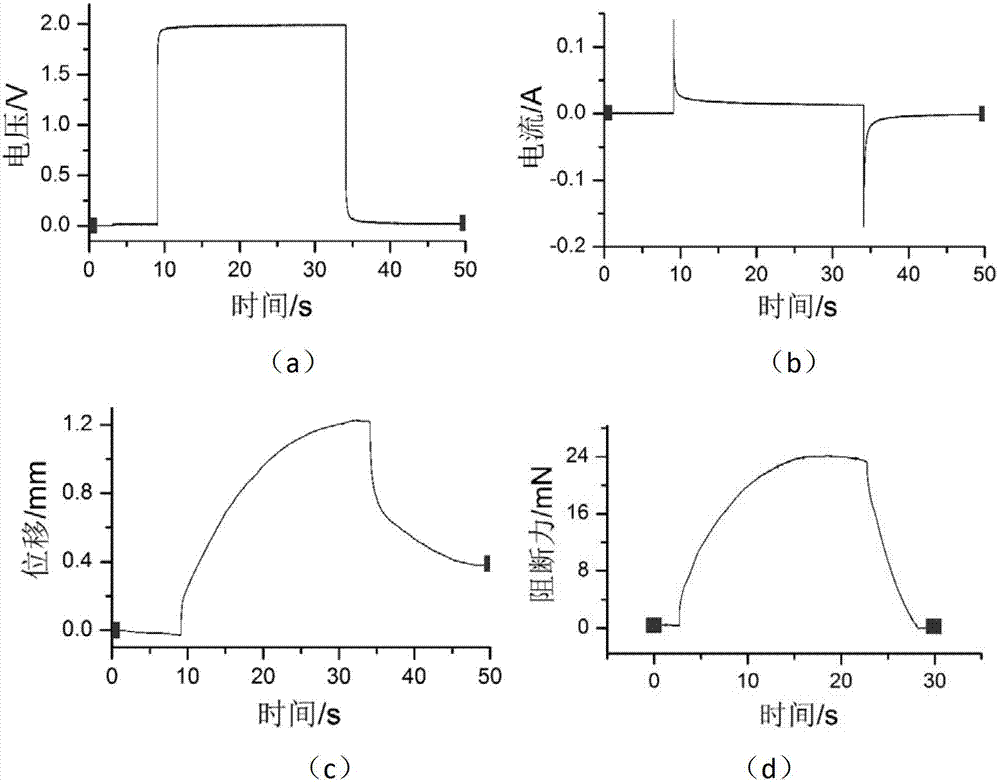

Recovery and recasting technology of Nafion film in IPMC (Ionic Polymer Metal Composite)

The invention discloses a recovery and recasting technology of a Nafion film in an IPMC (Ionic Polymer Metal Composite). The recovery and recasting technology is characterized by comprising the steps as follows: 1) pre-processing the waste IPMC material; 2) recovering the Nafion film; 3) dissolving the recovered film; and 4) casting the Nafion solution. The recovery and recasting technology disclosed by the invention is simple in technical step and operation process, and low in cost of used equipment and medicines, therefore the cost of the obtained high-concentration Nafion solution is low, the obtained casting film has high performance, and the prepared IPMC material has high driving performance and high practicability.

Owner:XI AN JIAOTONG UNIV

Method for preparing refractory element high-entropy alloy coating layer through laser cladding forming

InactiveCN108330484ASimple processEasy to operateMetallic material coating processesMetallurgyHigh entropy alloys

The invention relates to a method for preparing a refractory element high-entropy alloy coating layer through laser cladding forming. The method comprises the following steps that Mo, Nb, Ta and W elements are evenly mixed to prepare high-entropy alloy powder; 2, the high-entropy alloy powder prepared in the step 1 is mixed with an adhesive, the surface of a base material is coated with the mixture, and a cladding prefabricated layer is prepared; 3, the base material treated in the step 2 is placed into an atmosphere protection device, laser cladding forming is carried out, and the base material with the high-entropy alloy coating layer is obtained. The method is easy to operate, the cost is low, refractory elements are effectively prevented from being oxidized at high temperature due to insufficient protection gas, the performance index of the material obtained through laser classing is improved, the consumption of protection gas is reduced, the prepared cladding layer is smooth and compact, the surface is covered with no metal residue, and the method has a wide application prospect in the aspect of high-temperature resistance component preparation.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Method adopting magnetron sputtering to prepare flexible rare earth oxide film

ActiveCN105970171AEasy to process and cutAvoid oxidationVacuum evaporation coatingSputtering coatingOxideVacuum pumping

The invention discloses a method adopting magnetron sputtering to prepare a flexible rare earth oxide film. The method comprises the steps of a, selecting a 4N rare earth metal target material; b, adopting a liquid PDMS precursor as a substrate; c, carrying out vacuum pumping, introducing argon, and cleaning the surface of the target material through pre-sputtering; d, heating a rotating heating table to the temperature required by film deposition, and maintaining the temperature; e, introducing a mixed gas, applying sputtering power, controlling the gas flow, and starting coating the surface of the substrate for 1 h; and f, maintaining a constant temperature for 3 h to obtain the flexible film when the temperature drops to the room temperature. According to the method, the technical problem that a peelable functional film cannot be prepared on a conventional regular rigid substrate is solved, the current situation that a rare earth metal oxide film can only be deposited on a rigid substrate is changed, and the thickness of the rare earth metal oxide film can be accurately controlled.

Owner:扬州君禾薄膜科技有限公司

Method for preparing core-shell flaky aluminum powder-polyacrylic acid composite particles

InactiveCN102516830AAvoid oxidationHigh metallic lusterPigment treatment with macromolecular organic compoundsComposite materialCorrosive substance

The invention discloses a method for preparing core-shell flaky aluminum powder / polyacrylic acid composite particles. The method comprises the following steps of: eluting fatty acid coated on the surface of an aluminum powder pigment by adopting an organic solvent at normal temperature, and performing centrifugal separation to obtain flaky aluminum powder; mixing the flaky aluminum powder, acrylic acid, initiator and dispersant, then transferring the mixture to a preheated reactor, and dripping water step by step in the reaction process; and performing centrifugal separation on the reaction product, and thus obtaining the core-shell flaky aluminum powder-polyacrylic acid composite particles. The core-shell flaky aluminum powder-polyacrylic acid composite particles have excellent acid corrosion resistance based on high metallic luster, are extremely low in hydrogen evolution, and are particularly suitable for water-based coatings.

Owner:SUN YAT SEN UNIV

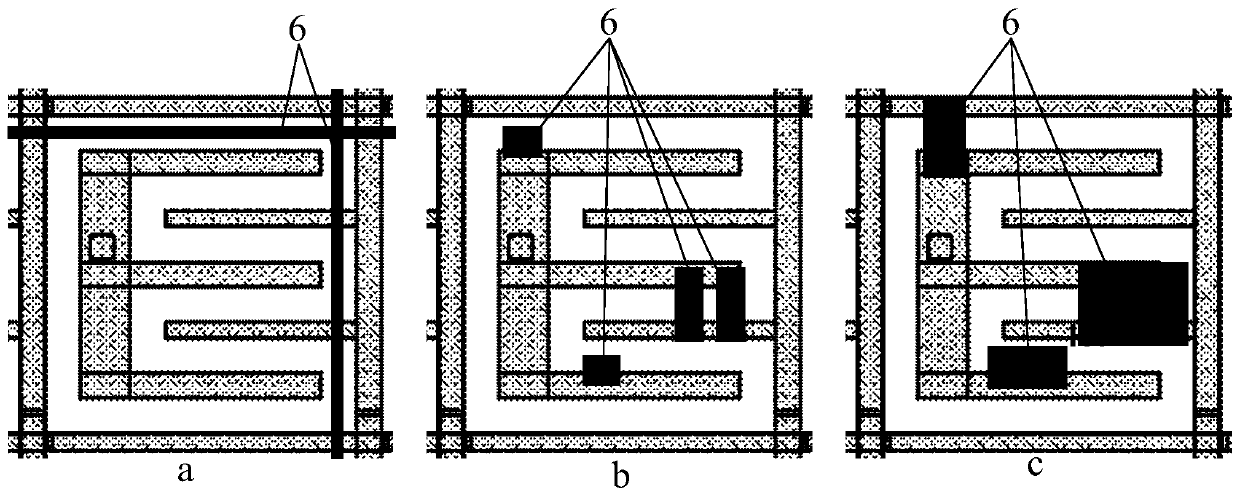

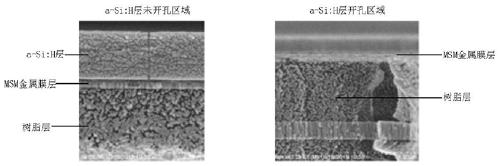

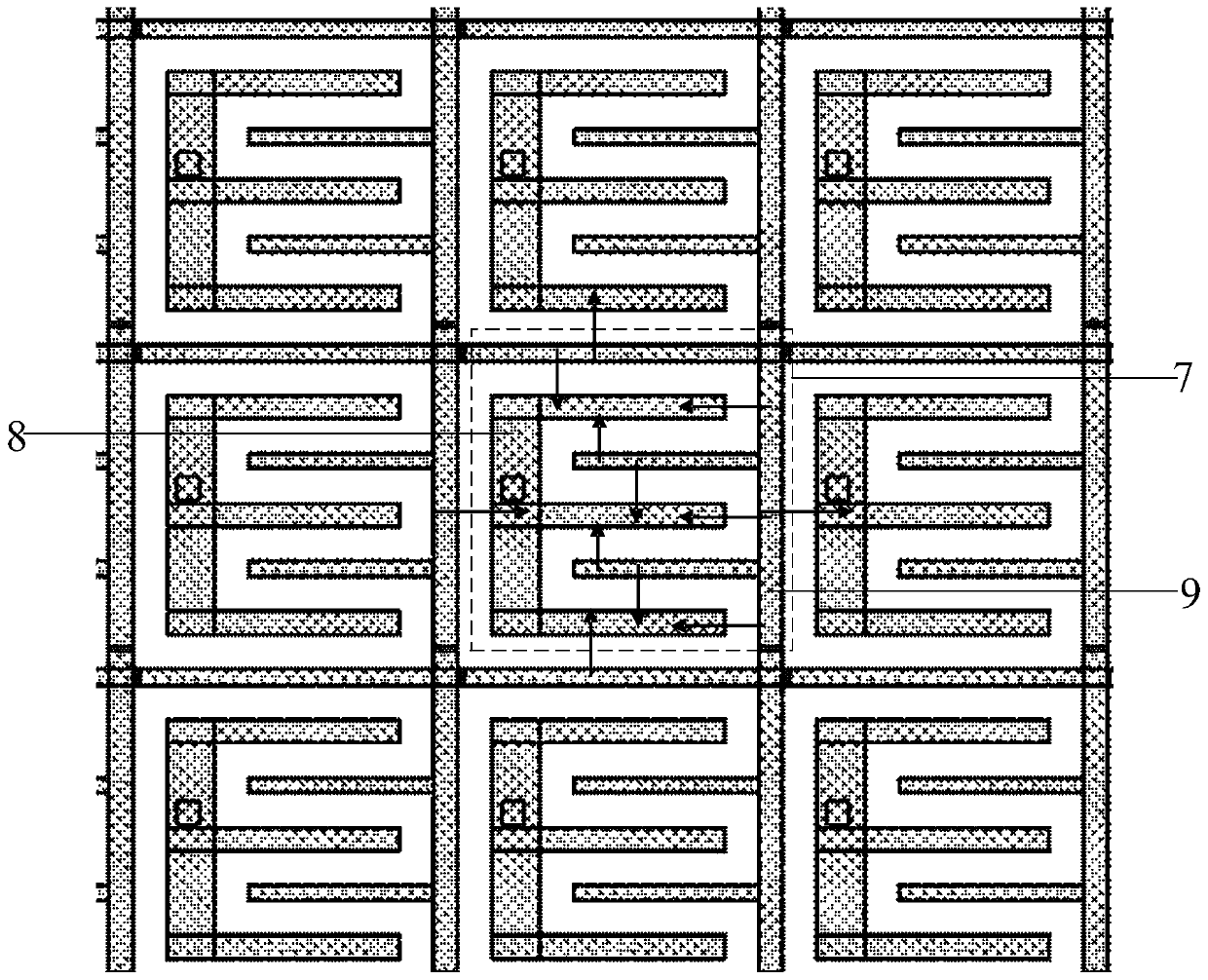

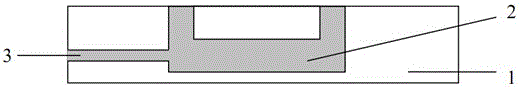

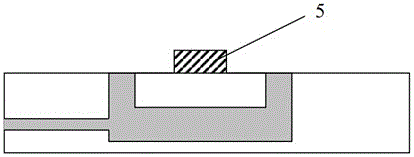

Light detection substrate and preparation method thereof, and light detection equipment

ActiveCN111354756AAvoid film thinningAvoid oxidationTransistorSolid-state devicesChemistryLight detection

The invention provides a light detection substrate and a preparation method thereof, and light detection equipment. The light detection substrate comprises a substrate and a plurality of light detection units arranged on the substrate, and the light detection units are arranged in an array; each light detection unit comprises a first electrode, a second electrode and a photoelectric conversion layer, wherein the photoelectric conversion layer is located on the sides, away from the substrate, of the first electrode and the second electrode, the orthographic projection of the photoelectric conversion layer on the substrate covers the first electrode and the second electrode, a spacing area is formed between the orthographic projections of the first electrode and the second electrode on the substrate, an opening is formed in the photoelectric conversion layer, and the orthographic projection of the opening on the substrate is located in the spacing area. According to the light detection substrate, the orthographic projection of the opening on the substrate is located in the interval area, namely the opening is formed in the non-overlapping area of the photoelectric conversion layer, the first electrode and the second electrode, and it can be ensured that the photoelectric characteristics of the light detection substrate are not damaged when patterns of the photoelectric conversionlayer and the opening are formed through etching.

Owner:BOE TECH GRP CO LTD

Preparation method of graphene composite high speed tool steel

The invention relates to a preparation method of graphene composite high speed tool steel. The reparation method of the graphene composite high speed tool steel comprises the following steps: a mixedsolution is provided, the mixed solution comprises a volatile organic solvent, a graphene powder body, and a high-speed tool steel power body; drying treatment is conducted to the mixed solution so that a mixed power body can be achieved; vacuumizing degassing treatment can be conducted after the mixed power body which is subjected to drying treatment is loaded inside a package sheath and the package sheath is sealed; hot isostatic pressing treatment is conducted to the sealed package sheath which is loaded with the mixed power body, the temperature of the hot isostatic pressing is 950-1300 DEG C, thus the mixed power body forms the graphene composite high speed tool steel; and the graphene composite high speed tool steel is separated from the package sheath.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

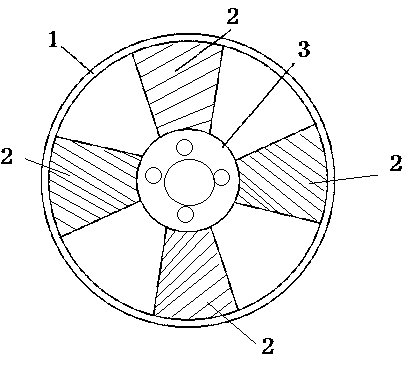

Automobile hub

InactiveCN103738111AAvoid oxidationPlay the effect of wind coolingWheel protectionSpoked wheelsAutomobile safetyCircular section

The invention discloses an automobile hub. The automobile hub is characterized by comprising a rim, multiple spokes and a mounting flange, wherein the mounting flange is fixed with the rim through the spokes; the circular sections of both the spokes and the rim are 31 degrees to 33 degrees; carbon fibers are stuck on one side pointing outwards of the rim, one sides pointing outwards of the spokes and one side pointing outwards of the mounting flange. The automobile hub provided by the invention solves the problem that the existing automobile hub during speed reduction and braking generates a plenty of heat energy and a flat tire is easy to happen to affect safety driving of the automobile, and solves the problems that the quick cool-and-heat alternation anti-oxidation paint is easy to fall off and the oxidation phenomenon is easy to occur.

Owner:SFAM SCI & TECH JIANGSU

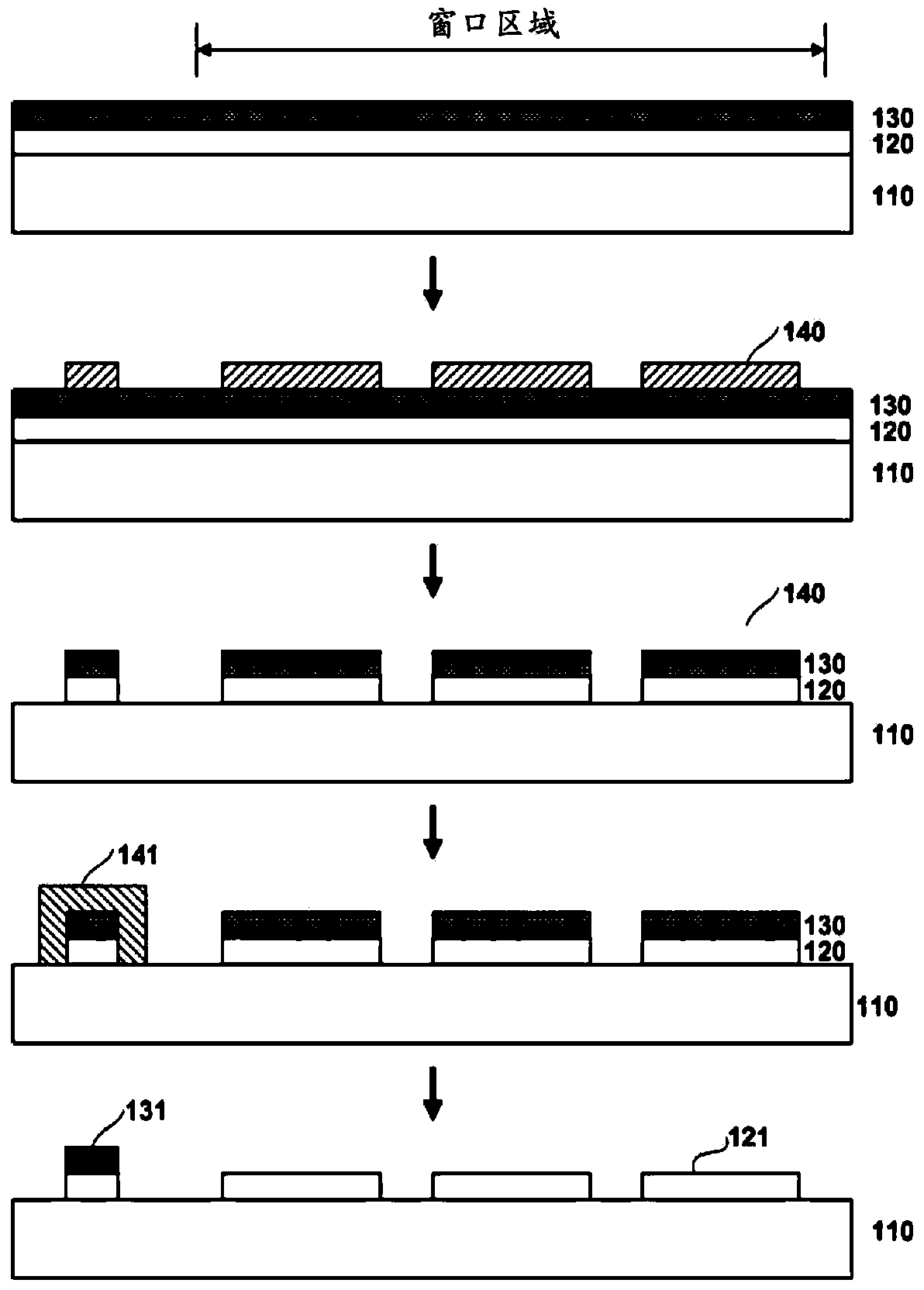

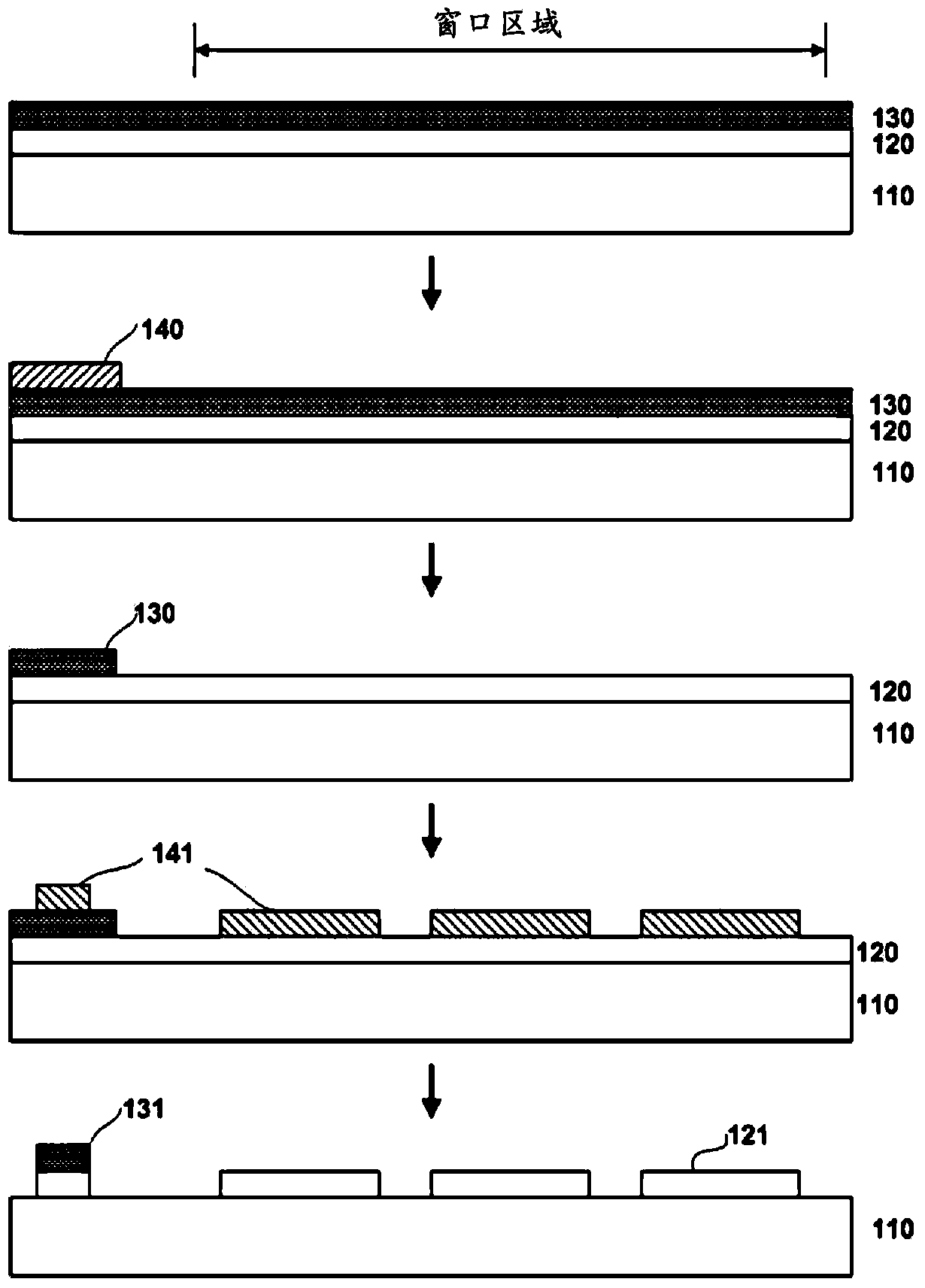

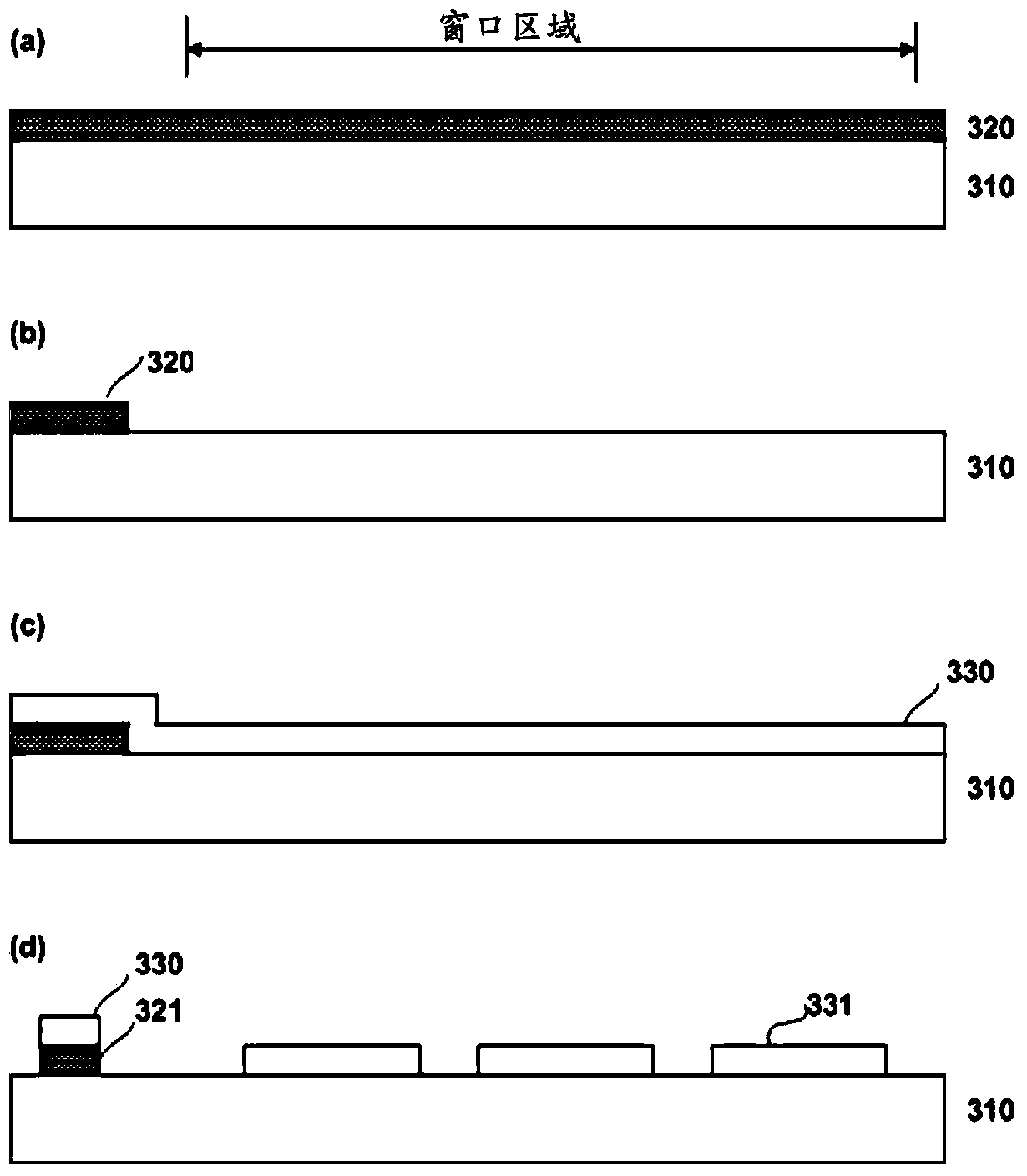

Method for manufacturing pad for touch panel, and pad for touch panel manufactured by method

InactiveCN103430133AAvoid oxidationLower the resistance valueConductive layers on insulating-supportsPrinted circuit manufactureEngineeringTouch panel

PURPOSE: A manufacturing method of a touch panel pad is provided to prevent residue phenomenon due to etching defect of a metal layer. CONSTITUTION: A transparent electrode pattern(331) is formed in a window region of a touch panel on a transparent insulating layer. The transparent electrode pattern is formed in a transparent conductive layer. A line electrode pattern(321) is formed in a region except for a window area of the touch panel on the transparent conductive layer. The line electrode pattern is formed in a metal layer. A transparent conductive layer(330) is formed on the line electrode pattern.

Owner:TMAY +1

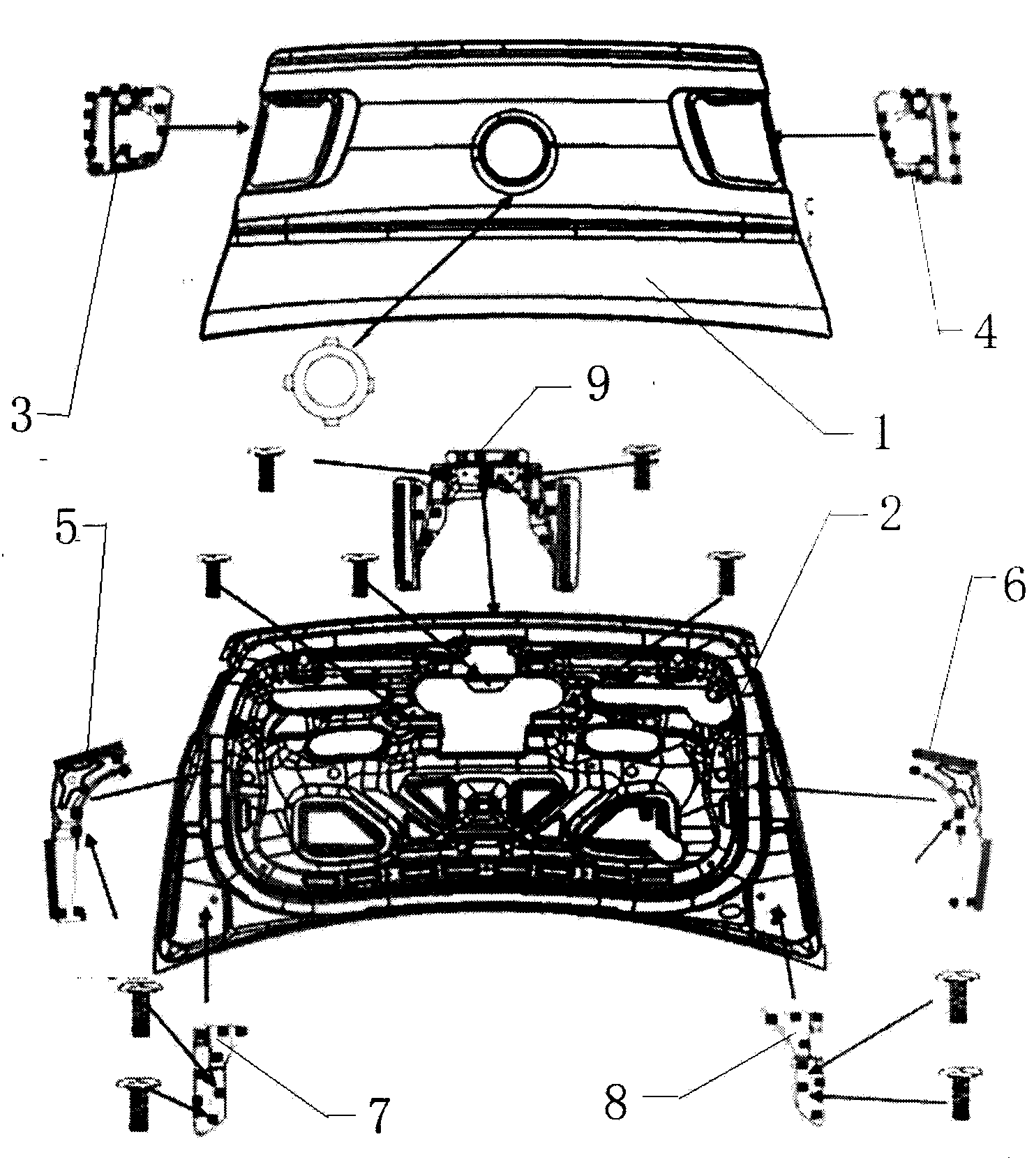

Manufacturing process for automobile trunk cover

The invention discloses a manufacturing process for an automobile trunk cover. The manufacturing process includes the following steps of outer plate machining, inner plate machining and overall combination of an automobile cover. At first, spot welding is carried out on a left annular part and a right annular part, and the left annular part and the right annular part are installed on an outer plate in a welded mode; secondly, a left thin L-shaped workpiece, a right thin L-shaped workpiece, a left thick L-shaped workpiece and a right thick L-shaped workpiece are correspondingly installed on an inner plate in a welded mode, an arched part is correspondingly installed in the middle of the inner plate, and then edge covering and ending are conducted on the inner plate and the outer plate; at last, seal gum is applied to the inner plate and the outer plate after the inner plate and the outer plate are pressed. According to the manufacturing process for the automobile trunk cover, after the outer plate and the inner plate are combined, edge covering and ending are conducted on the outer plate and the inner plate to enable the gap between the outer plate and the inner plate to be small, and air, water and the like are thoroughly isolated from the interior of the trunk cover through the seal gum to prevent oxidation.

Owner:SIMHOONG AUTO PARTS IND ANHUI

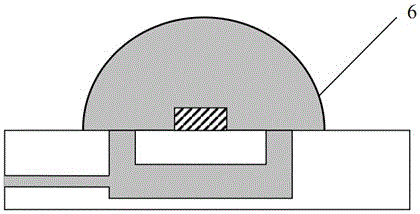

LED packaging structure and forming method thereof

ActiveCN106025041AUniform light outputAvoid oxidationSolid-state devicesSemiconductor devicesLed packagingFluorescence

The invention relates to an LED packaging structure comprising a cooling substrate, an LED chip arranged on the cooling substrate, and a transparent cover sealing the LED chip. A closed space is formed between the transparent cover and the cooling substrate. The LED packaging structure is characterized in that the cooing substrate is internally provided with a cooling channel which is communicated with the closed space, and the cooling channel and the closed space are filled with fluid. A forming method of the LED packaging structure is further disclosed. Oxidation of leads and welding points and aging of fluorescent resin are prevented, the cooling effect of the packaging structure is ensured, and the uniformity of light output is optimized.

Owner:宁波协源光电科技股份有限公司

Stone plastic board and processing method thereof

PendingCN109897302AReduce mutual disengagementImprove surface strengthSynthetic resin layered productsLaminationColor filmLubricant

The invention relates to the technical field of building materials, and specifically relates to a stone plastic board, which comprises a substrate layer, a color film layer, and a UV layer from bottomto top. The substrate layer is prepared from following raw materials in percentage by weight: 52.5 to 72.5% of calcium powder, 20 to 30% of PVC powder, 2.5 to 8.5% of a lubricant, and 5 to 9% of a reinforcing agent. The color film layer is prepared from PVC. The stone plastic board is nontoxic and environmentally friendly, and is harmless to the environment and humans. The substrate layer mainlymade of PVC powder and the color film layer made of PVC can be better combined.

Owner:上海普濡建材科技有限公司

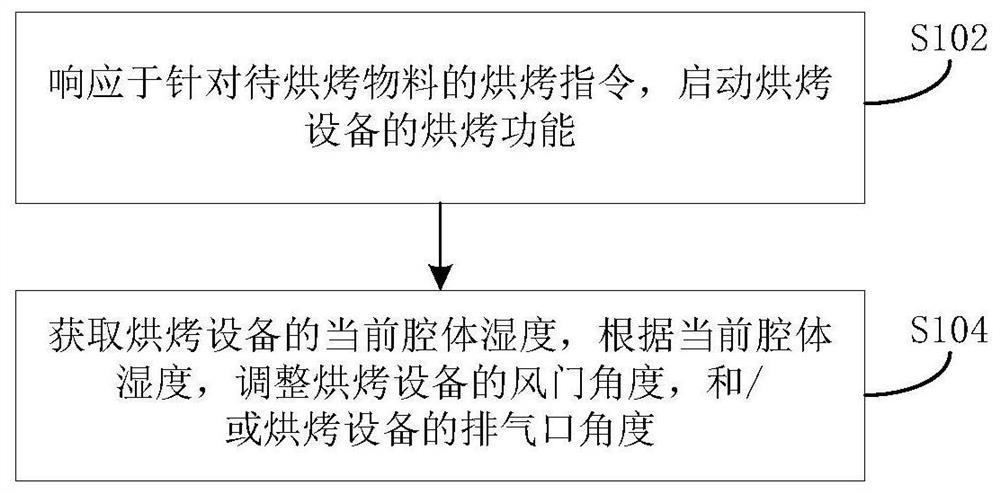

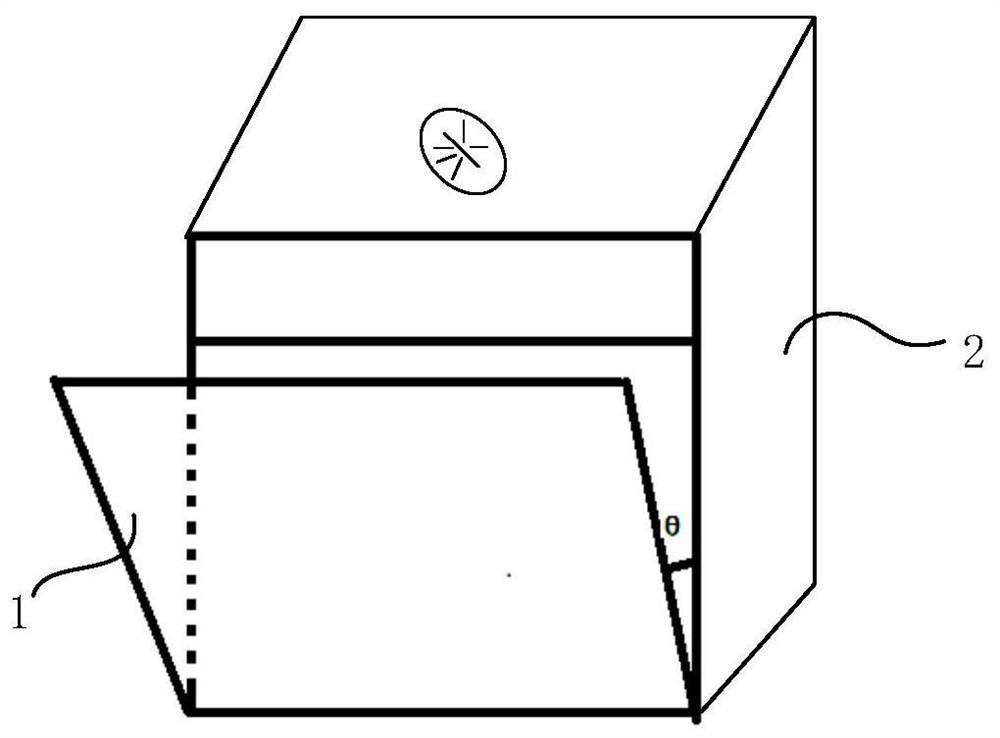

Material baking method and device, baking equipment and computer readable storage medium

The invention provides a material baking method and device, baking equipment and a computer readable storage medium. The method comprises the steps: starting a baking function of the baking equipment in response to a baking instruction for a to-be-baked material; and acquiring the current cavity humidity of the baking equipment, and adjusting the angle of an air door of the baking equipment and / or an exhaust port angle of the baking equipment according to the current cavity humidity. In the mode, the opening angle of the air door and the angle of the exhaust port are adjusted in real time according to the humidity of the cavity, the emission amount and emission speed of water vapor in the cavity of the baking equipment can be adjusted, the humidity of the baking space is reduced, the situation that materials are oxidized is avoided, and meanwhile the baking speed and the baking efficiency are improved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Low-temperature-resistant glass fiber reinforced plastic pultrusion profile and preparation method thereof

PendingCN114015178AImprove low temperature resistanceImprove high temperature resistanceFirming agentPolyester resin

The invention discloses a low-temperature-resistant glass fiber reinforced plastic pultrusion profile and a preparation method thereof, and relates to the technical field of glass fiber reinforced plastic pultrusion profiles. The pultrusion profile comprises the following raw materials: 15-18% of unsaturated polyester resin, 18-20% of polytetrafluoroethylene resin, 6-7% of thermosetting methacrylic resin, 9-10% of epoxy resin, 5-6% of flame-retardant vinyl resin, 4-5% of an anti-ultraviolet agent, 15-16% of a glass fiber mat, 9-10% of basalt fibers, 2.5-3% of an initiator, 3-4% of an epoxy resin curing agent, 3.5-4% of a coloring agent, 2.5-3% of an internal release agent, 1.5-2% of a flame retardant and 3.5-4% of a coupling agent. According to the low-temperature-resistant glass fiber reinforced plastic pultrusion profile and the preparation method thereof, the low-temperature-resistant glass fiber reinforced plastic pultrusion profile has good low-temperature-resistant and high-temperature-resistant effects, and the actual use range is greatly widened; by adding the polytetrafluoroethylene resin, the profile can be used at the low temperature of (-160)-(-200) DEG C, and use in a special environment is met; and the anti-ultraviolet agent is blended, so that the low-temperature-resistant glass fiber reinforced plastic pultrusion profile has a very good anti-oxidation effect.

Owner:江苏澳兰德新材料科技有限公司

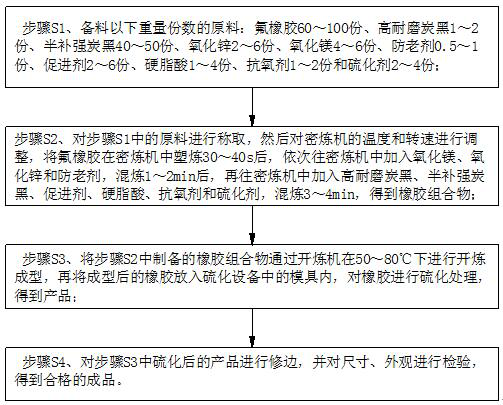

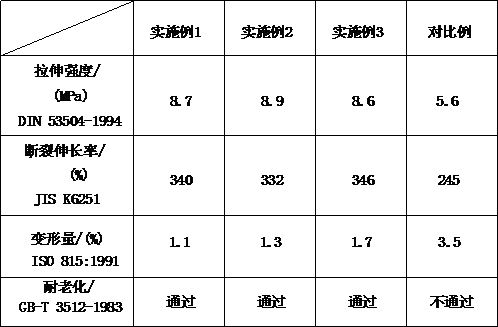

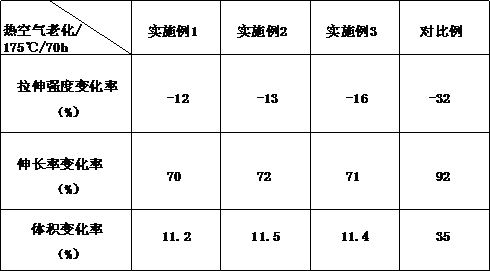

Preparation method of automobile pipeline rubber material

The invention belongs to the technical field of rubber materials, and particularly relates to a preparation method of an automobile pipeline rubber material. The preparation method comprises the steps of S1, preparing the following raw materials in parts by weight: 60-100 parts of fluororubber, 1-2 parts of high wear-resistant carbon black, 40-50 parts of semi-reinforced carbon black, 2-6 parts of zinc oxide, 4-6 parts of magnesium oxide, 0.5-1 part of an anti-aging agent, 2-6 parts of an accelerant, 1-4 parts of stearic acid, 1-2 parts of an antioxidant and 2-4 parts of a vulcanizing agent. Through introduction of fluorine atoms in the fluororubber, the rubber is endowed with excellent heat resistance, oil resistance and corrosion resistance, the wear resistance of the rubber can be enhanced through the high-wear-resistance carbon black, the overall strength of the rubber is guaranteed through the semi-reinforcing carbon black, magnesium oxide and zinc oxide mainly play a role in fluidity and oxidation resistance in the rubber, the tensile strength and the impact resistance of the rubber are improved, the anti-aging agent can improve the thermal oxygen aging resistance of the rubber, and the accelerant can promote the reaction between the rubber and the vulcanizing agent, so that the vulcanization reaction speed is increased.

Owner:扬州尚翔汽车零部件有限公司

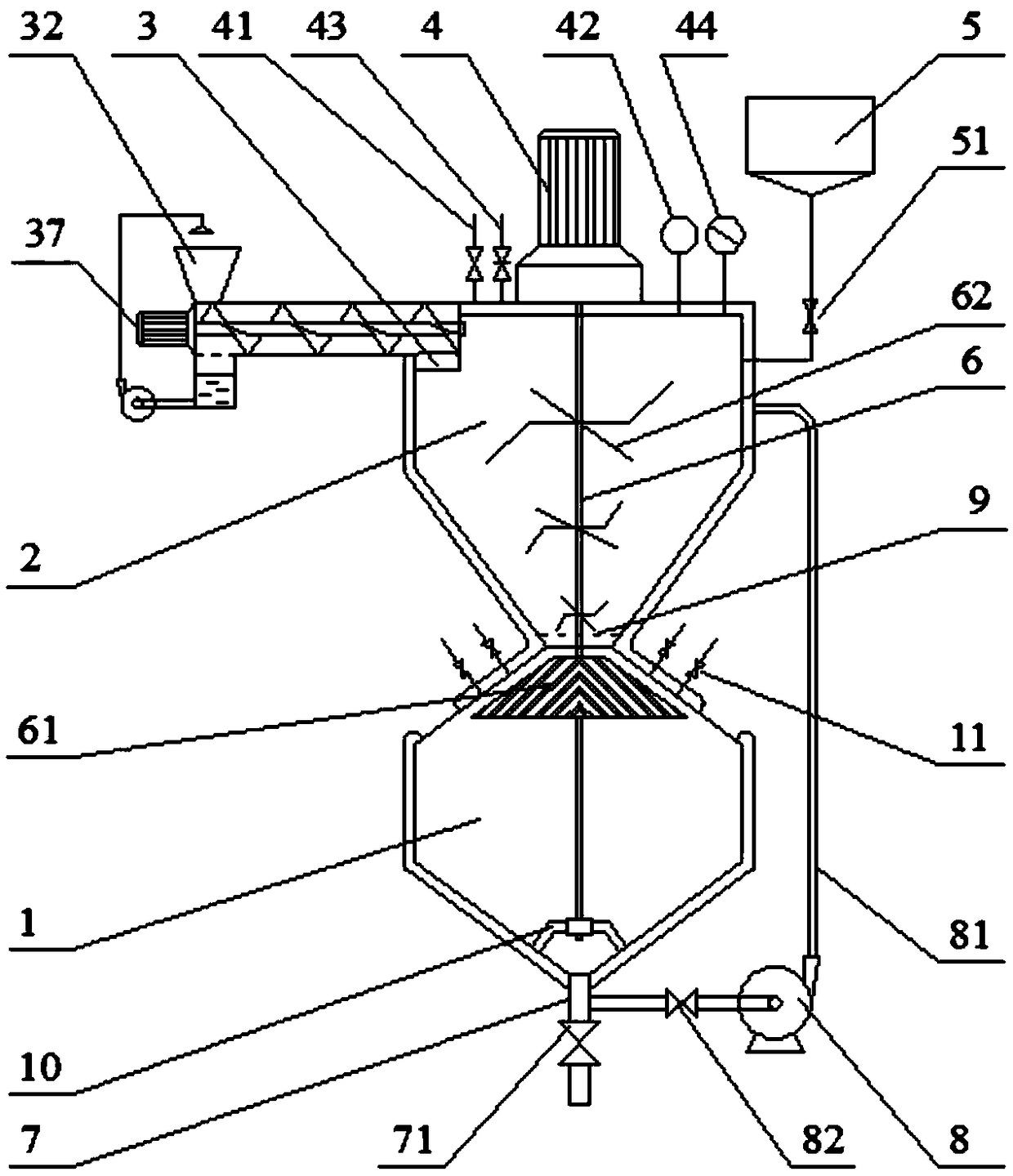

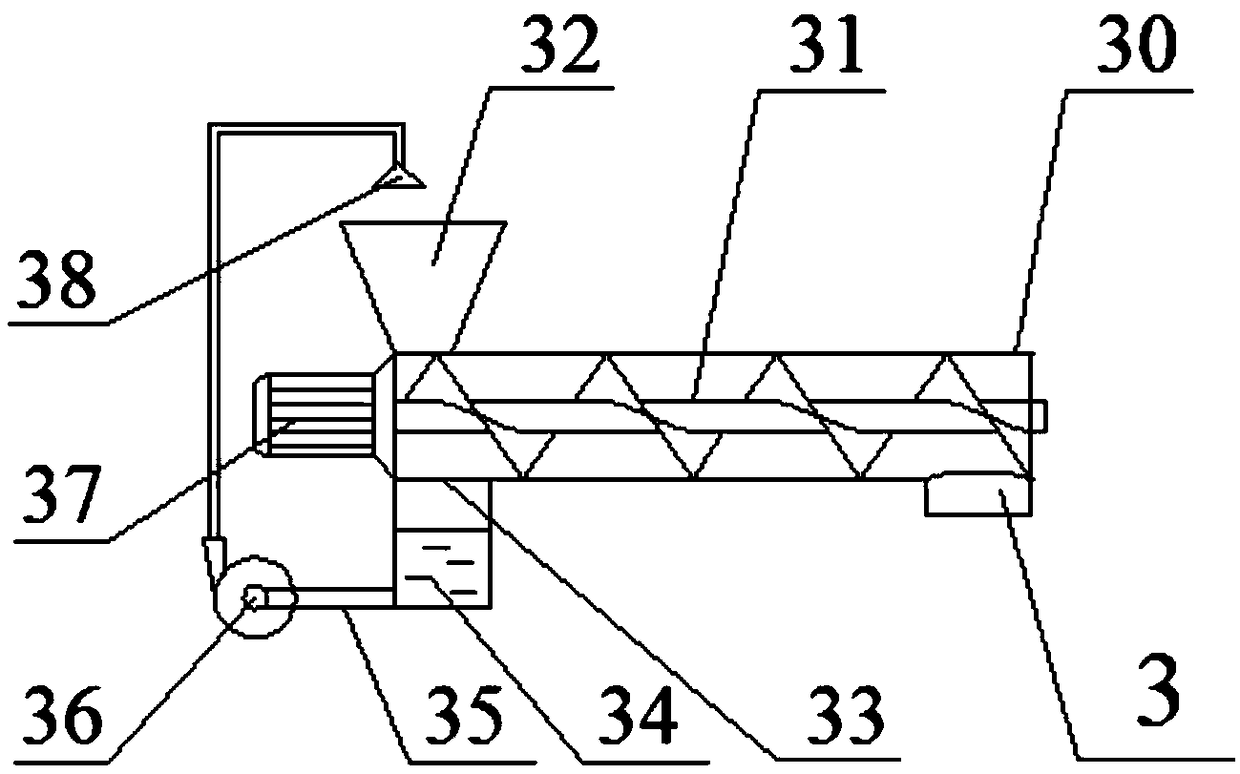

Continuous fruit and vegetable puree making and conditioning device

PendingCN108636536AAvoid oxidationImprove qualityKitchen equipmentGrain treatmentsAgricultural engineeringFruits and vegetables

The invention discloses a continuous fruit and vegetable puree making and conditioning device. The continuous fruit and vegetable puree making and conditioning device comprises a crushing tank. The top of the crushing tank is provided with a crushing motor. The crushing motor is connected with a rotating shaft. The top of the crushing tank is provided with a feed port and a color fixative storagetank. The bottom of the crushing tank is connected with a glue grinding tank. The upper end and the lower end of the glue grinding tank and the bottom of the crushing tank are all in a funnel shape. The bottom of the glue grinding tank is provided with a supporting frame. The bottom of the rotating shaft is connected with the supporting frame. The rotating shaft is provided with a grinding disk and a plurality of crushing cutter sets, the grinding disk is located on the top of the glue grinding tank, the crushing cutter sets are located in the crushing tank, the tail end of the glue grinding tank is connected with a discharging pipe, and the discharging pipe is provided with a discharging valve. The continuous fruit and vegetable puree making and conditioning device is easy and convenientto use, in the whole fruit and vegetable puree making process from the feed port, the contact between raw materials and the air is greatly reduced, and therefore the situation that fruits and vegetables are oxidized after being crushed is avoided, while the using amount of a color fixative is reduced, the color brightness of the fruits and the vegetables is also guaranteed well, and the quality ofthe fruit and vegetable puree is improved.

Owner:SHENYANG AGRI UNIV

Method for measuring ferrous oxide content in iron ore

InactiveCN111257500AAvoid being oxidizedAvoid OxidationChemical analysis using titrationSodium bicarbonateIron(II) oxide

The invention discloses a method for determining the content of ferrous oxide in iron ore. The method comprises steps of a, weighing an iron ore sample, putting the sample into a conical flask, sequentially adding potassium fluoride, sodium bicarbonate and hydrochloric acid, covering with a porcelain cover, putting the flask on an electric furnace, and heating to boiling; b, transferring the diluted solution obtained in the step a into a beaker special for a potentiometric titrator; and c, inserting an indicating electrode and a reference electrode of the potentiometric titrator into the beaker special for the potentiometric titrator in the step b, titrating by adopting potassium dichromate standard solution, starting the potentiometric titrator, and starting titration. The method is advantaged in that problems that reliability of the detection result is easily influenced by indicator end point judgment and subjective judgment of different analysts in the existing measurement, ferrousoxide is extremely easy to oxidize in the decomposition and titration processes, and the analysis result is relatively low can be avoided.

Owner:JIUQUAN IRON & STEEL GRP

A preparation method of laser cladding forming high-entropy alloy coating layer of refractory elements

InactiveCN108330484BSimple processEasy to operateMetallic material coating processesHigh entropy alloysAdhesive

The invention relates to a method for preparing a refractory element high-entropy alloy coating layer through laser cladding forming. The method comprises the following steps that Mo, Nb, Ta and W elements are evenly mixed to prepare high-entropy alloy powder; 2, the high-entropy alloy powder prepared in the step 1 is mixed with an adhesive, the surface of a base material is coated with the mixture, and a cladding prefabricated layer is prepared; 3, the base material treated in the step 2 is placed into an atmosphere protection device, laser cladding forming is carried out, and the base material with the high-entropy alloy coating layer is obtained. The method is easy to operate, the cost is low, refractory elements are effectively prevented from being oxidized at high temperature due to insufficient protection gas, the performance index of the material obtained through laser classing is improved, the consumption of protection gas is reduced, the prepared cladding layer is smooth and compact, the surface is covered with no metal residue, and the method has a wide application prospect in the aspect of high-temperature resistance component preparation.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

Coated iron oxide black pigment and preparation method thereof

InactiveCN112300605AImprove dispersion performanceUniform particle sizePigment treatment with macromolecular organic compoundsPigment physical treatmentIron oxide blackOxide

The invention discloses a coated iron oxide black pigment and a preparation method thereof, and belongs to the technical field of iron oxide black pigment preparation. The method comprises the following steps: (1) adding an iron oxide black filter cake and water into a reaction container, and uniformly stirring; (2) preparing an additive into an aqueous solution, adding the aqueous solution into areaction container, and mechanically ball-milling and dispersing to obtain an iron oxide black dispersion liquid; (3) heating the iron oxide black dispersion liquid, adding a soluble aluminum salt under a nitrogen atmosphere condition, heating, and controlling the temperature for coating; and (4) carrying out centrifugal separation, drying the filter material, and calcining to obtain the iron oxide black pigment coated with the aluminum layer. Air is isolated in the coating process, and black iron oxide is prevented from being oxidized in the coating process; the dispersion performance of theiron oxide black is improved by adopting the additive and a mechanical ball milling mode, and more stable dispersion liquid is obtained. The pigment is uniform in particle size, and the outer layer is coated with a layer of compact aluminum film, so that the pigment cannot be oxidized even at high temperature, and the performance of the pigment is more stable.

Owner:YIXING YUXING IND & TRADE

Surface treatment device for printed circuit board copper foil

InactiveCN103521390AAvoid oxidationAvoid wastingLiquid surface applicatorsCoatingsCopper foilWater pumping

The invention discloses a surface treatment device for a printed circuit board copper foil. The surface treatment device comprises a tank body, water pumping openings and rubber water pouring rollers, wherein two groups of rubber water pouring rollers are arranged on two side walls of the tank body; a circuit board substrate is arranged between the two groups of rubber water pouring rollers; the water pumping openings are formed in the upper part of the tank body; medicinal liquid for surface treatment is contained in the tank body; a water outlet with an adjustment valve is formed in the bottom of the tank body. The surface treatment device has the beneficial effects that the height of the liquid level of the medicinal liquid is controlled by controlling the displacement of the adjustment valve of the water outlet, so that an OSP (antioxidant) film can be uniformly and effectively formed on a copper surface of a product; oxidization of the product is avoided; the cyclic displacement of the OSP medicinal liquid is controlled according to different thicknesses of different products, so that the waste of the OSP medicinal liquid is avoided; therefore, the quality of the product is improved, and the production cost is reduced.

Owner:ZHENJIANG HUAYIN PRINTED CIRCUIT BOARD

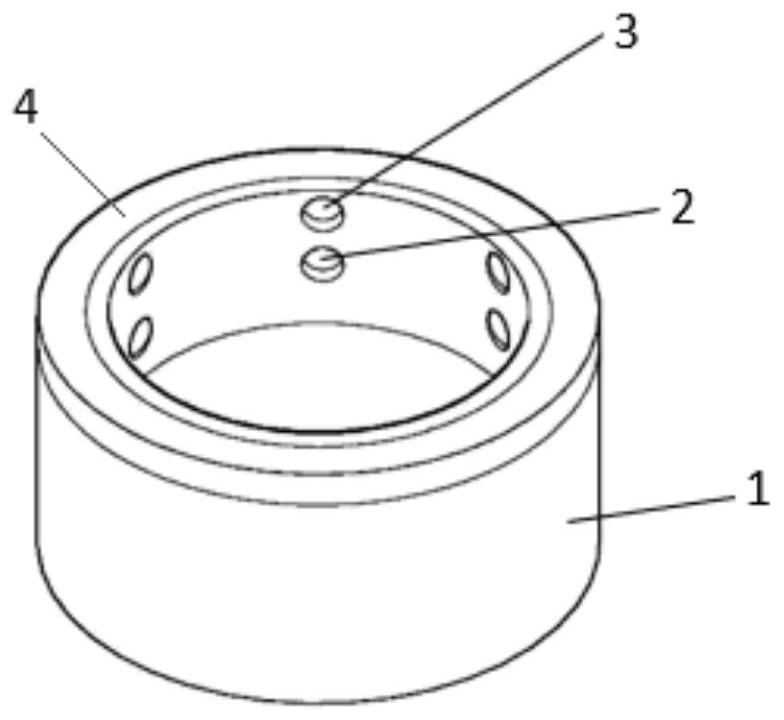

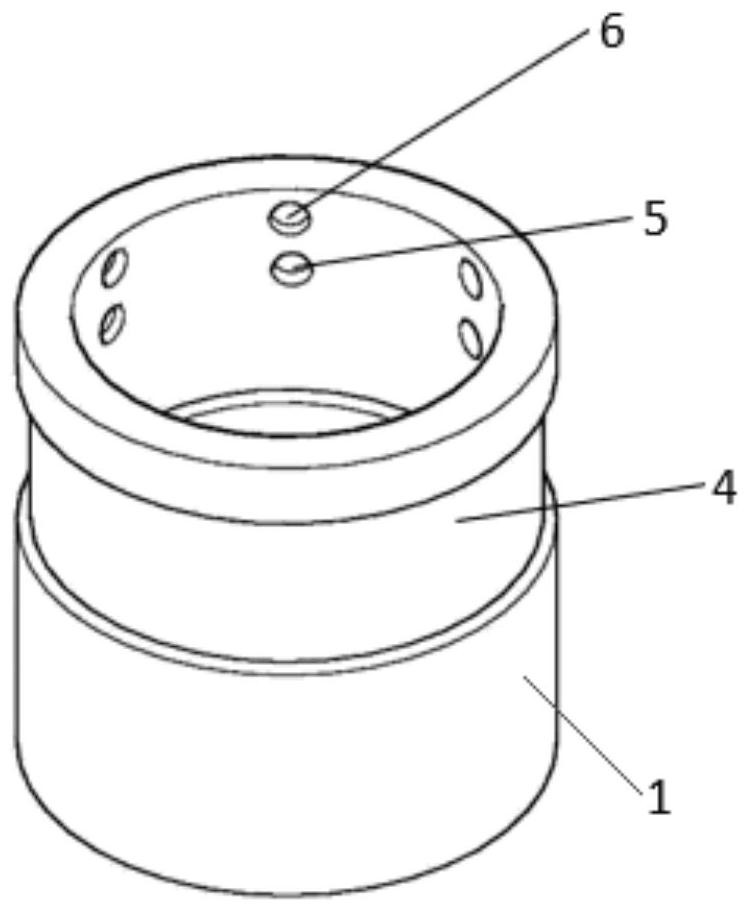

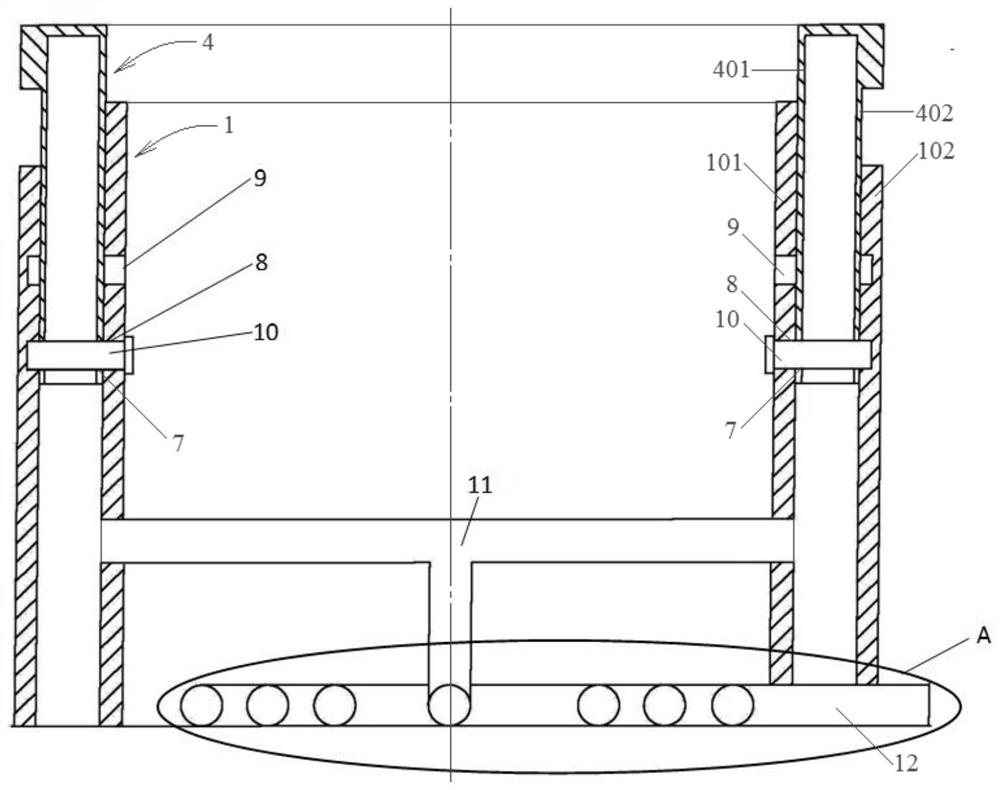

Anti-oxidation device and method for heat treatment of superalloy

ActiveCN112708746BPrevent oxidationProtect samples from oxidationFurnace typesProcess efficiency improvementSuperalloyHeat treating

The invention relates to the technical field of superalloy heat treatment. In particular, it relates to a high-temperature alloy heat treatment anti-oxidation device and method. The device includes an outer exhaust system, an inner exhaust system, a stage and an air intake duct. The outer exhaust system is an annular hollow structure, and the inner exhaust system is an annular hollow structure. The layer exhaust system is plugged and matched, and the cavity of the inner layer exhaust system communicates with the cavity of the outer layer exhaust system; the inner lower part of the first inner ring part of the outer layer exhaust system is provided with a hollow stage. The outer side of the carrier communicates with the cavity of the outer exhaust system, and the bottom of the stage communicates with one end of the intake pipe. The invention continuously blows inert gas into the high-temperature alloy samples in the heat treatment process from different angles, reduces the contact between the samples and the oxidizing environment, and prevents the high-temperature alloys from being oxidized during the high-temperature heat treatment process. The invention can be used for oxidation protection of high-temperature alloy and other materials when they are subjected to high-temperature heat treatment in an atmospheric environment.

Owner:辽宁红银金属有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com