Manufacturing process for automobile trunk cover

A manufacturing process and box cover technology, which is applied to vehicle parts, upper structures, and upper structure sub-assemblies, etc., can solve the problems of complex processing technology, low production efficiency, scratches, etc., and achieve simple processing technology and high production efficiency , the effect of preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

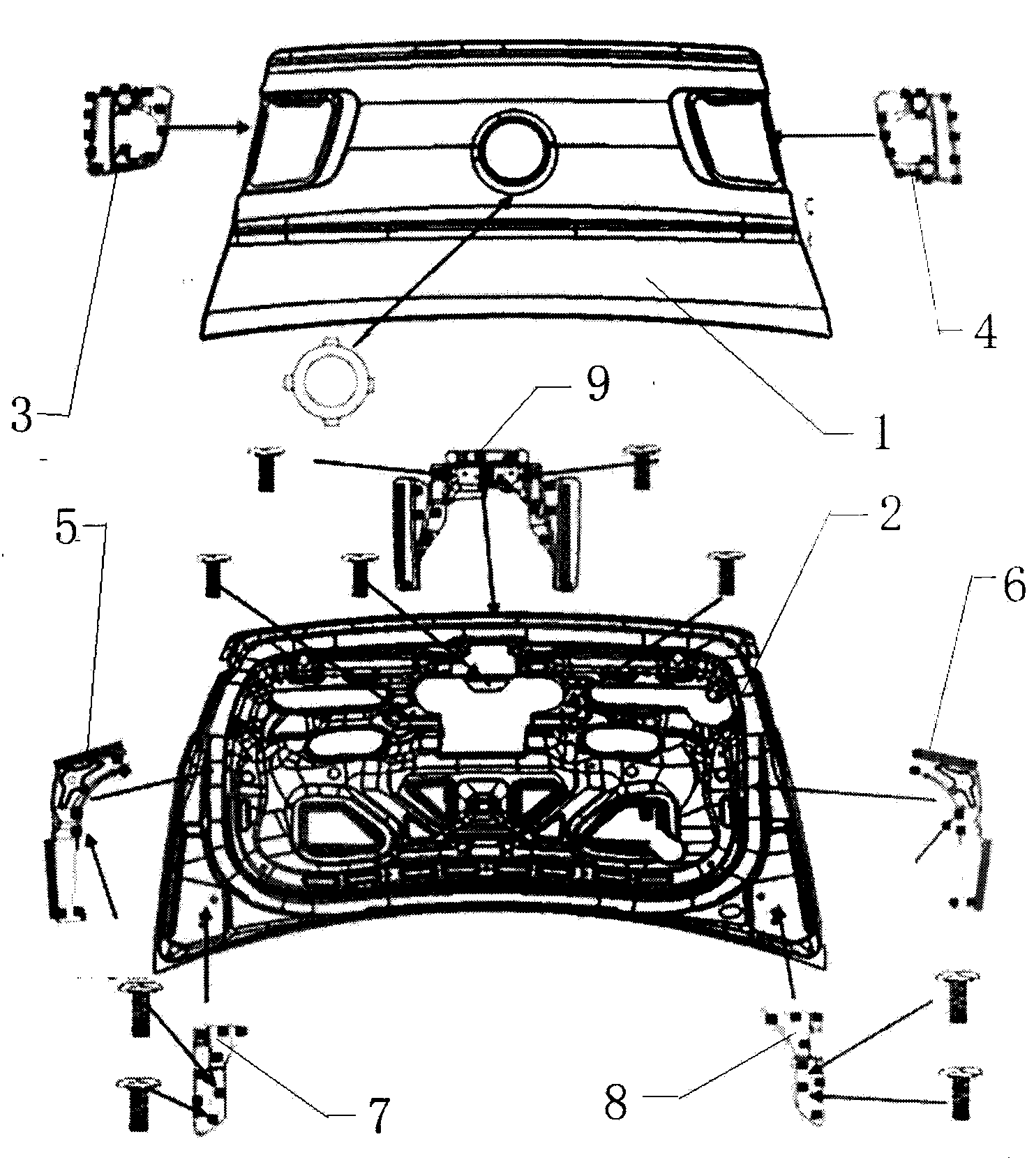

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] The manufacturing process of the automobile trunk lid of the present invention, a kind of manufacturing technique of automobile trunk lid, comprises the following steps:

[0020] Processing process of outer panel 1:

[0021] The first step is flattening and shearing: firstly, select the appropriate cold coil specification, and flatten the cold coil; then, according to the production material specifications, cut the flattened cold coil into iron plates of the corresponding size; Clean the iron filings on the iron plate; in the second step, firstly stretch the iron plate; secondly trim and punch the edge; then fold and punch the edge; finally fold it sideways; the production of the outer plate 1 is completed;

[0022] Processing process of inner panel 2:

[0023] The first step is to repeat the first step in the processing process of the outer plate 1; the second ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com