Method for preparing refractory element high-entropy alloy coating layer through laser cladding forming

A high-entropy alloy and laser cladding technology, which is applied in the coating process and coating of metal materials, can solve the problems of poor protection effect of inert gas and easy oxidation, etc., and achieves strong industrial applicability, reduced consumption and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

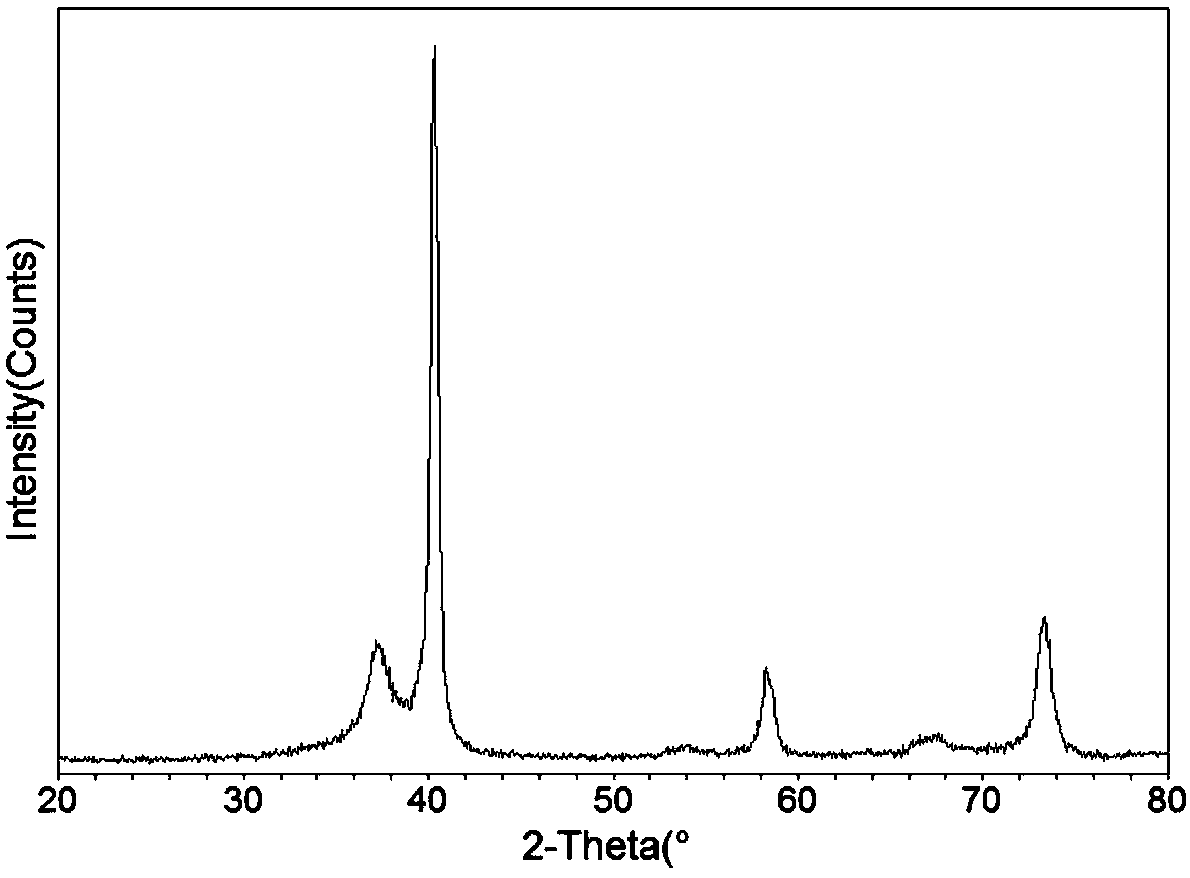

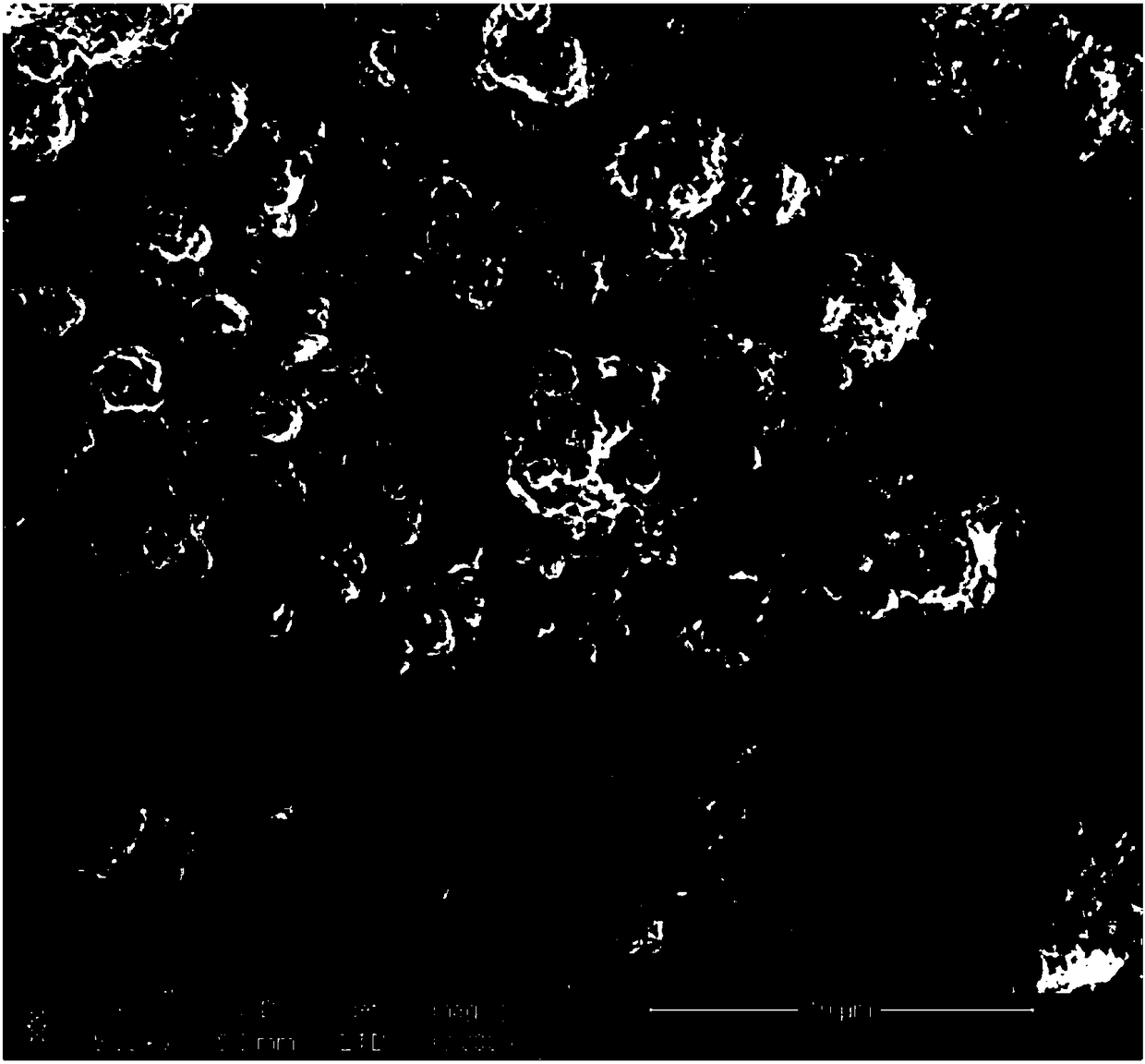

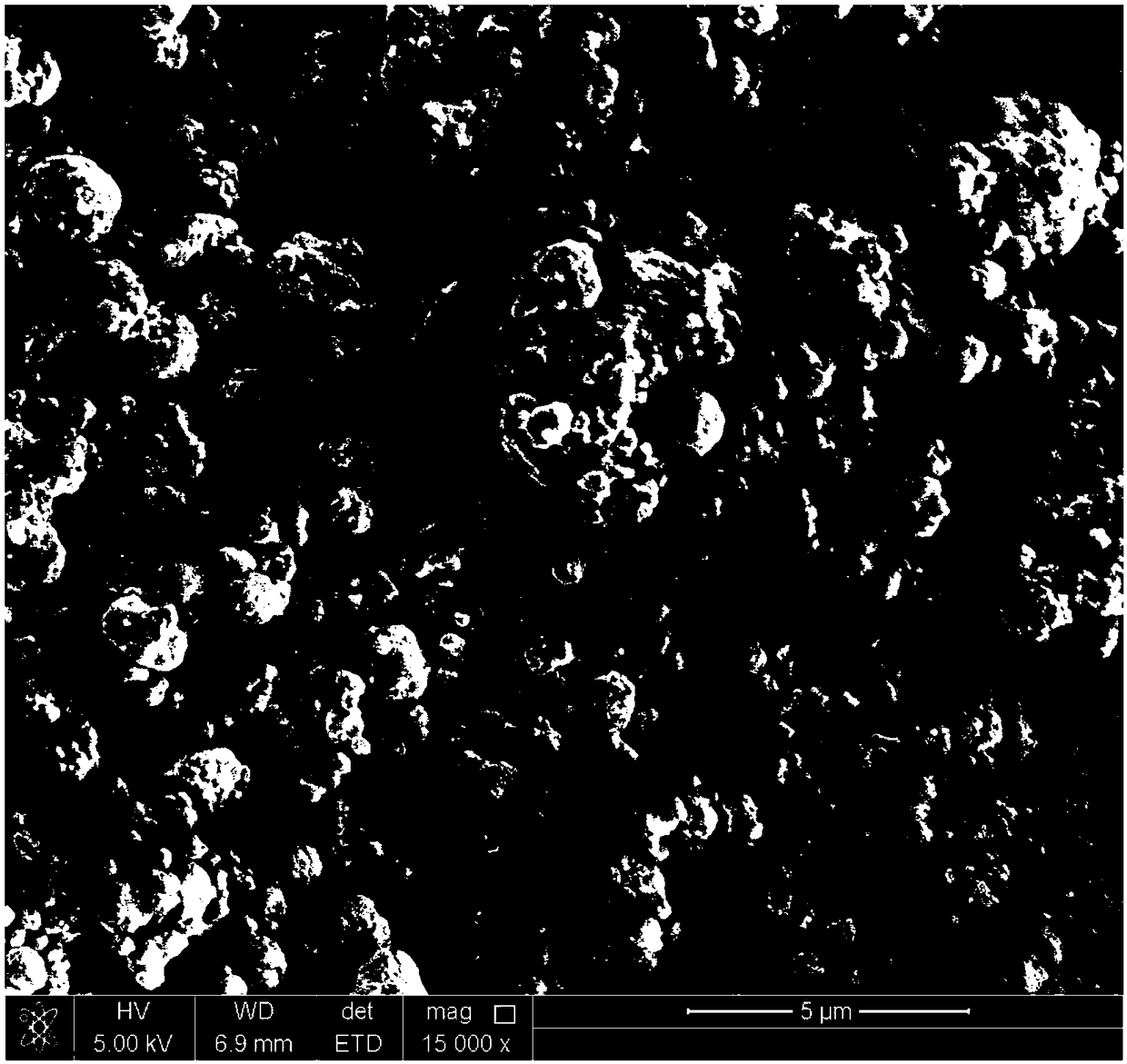

[0049] Example 1 Preparation of an ultrafine spherical MoNbTaW high-entropy alloy powder

[0050] The high-entropy alloy powder is composed of four elements: Mo, Nb, Ta and W, and the molar percentage of alloy elements is Mo:Nb:Ta:W=25:25:25:25.

[0051] Select Mo, Nb, Ta and W powders with a purity higher than 99% and a particle size of 300 meshes, and prepare alloy powders according to the molar percentage of alloy elements Mo:Nb:Ta:W=25:25:25:25. The prepared alloy powder is uniformly mixed in a mixer to obtain unalloyed mechanically mixed powder. Weigh an appropriate amount of the prepared unalloyed mechanically mixed powder according to the ball-to-material ratio of 10:1, put it into a ball mill jar, start vacuuming, and prepare high-entropy alloy powder by high-energy ball milling method in a vacuum environment. The ball milling tank is a vacuum stainless steel tank, and the balls used are stainless steel balls. The ball milling process is a rotating speed of 300 rpm an...

Embodiment 2

[0054] Example 2 Preparation of a superfine spherical high-entropy alloy powder

[0055] The high-entropy alloy powder is composed of four elements: Mo, Nb, Ta and W, and the molar percentage of alloy elements is Nb:Mo:Ta:W=34:34:17:17.

[0056] Select Mo, Nb, Ta and W powders with a purity higher than 99% and particle sizes of 300 meshes, and prepare alloy powders according to the molar percentage of alloy elements Mo:Nb:Ta:W=34:34:17:17. The prepared alloy powder is uniformly mixed in a mixer to obtain unalloyed mechanically mixed powder. Weigh an appropriate amount of the prepared unalloyed mechanically mixed powder according to the ball-to-material ratio of 10:1, put it into a ball mill jar, start vacuuming, and prepare high-entropy alloy powder by high-energy ball milling method in a vacuum environment. The ball milling tank is a vacuum stainless steel tank, and the balls used are stainless steel balls. The ball milling process is a rotating speed of 400 rpm and a ball m...

Embodiment 3

[0063] Embodiment 3 Atmosphere protection device for laser cladding forming technology

[0064] The atmosphere protection device used in laser cladding forming technology, its structure diagram is as follows Figure 5 As shown, the protective gas supply devices 1, 2, and 3 are respectively sealed and connected to the closed casing 11 through two pipelines, and the two pipelines are equipped with valves, 4 is the casing inlet valve, and 12 is the blowing ring inlet valve ; One of the pipes is used to provide protective gas to the shell, and the other pipe is connected to the blowing ring 9 at one end in the shell; the bottom surface of the shell is provided with a liftable sample stage 5; the top surface of the shell is provided with a laser transmission window 10; The vacuum pump 6 and the pressure gauge 7 are connected to the housing 11 respectively, and the housing air release valve 8 is provided on the exhaust pipe outside the housing.

[0065] The air blowing ring (9) is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com