Energy-saving type continuous annealing furnace

A continuous annealing furnace, energy-saving technology, used in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of wasting electric energy, polluted wires, and difficult to ensure whether the steam contains oxygen.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

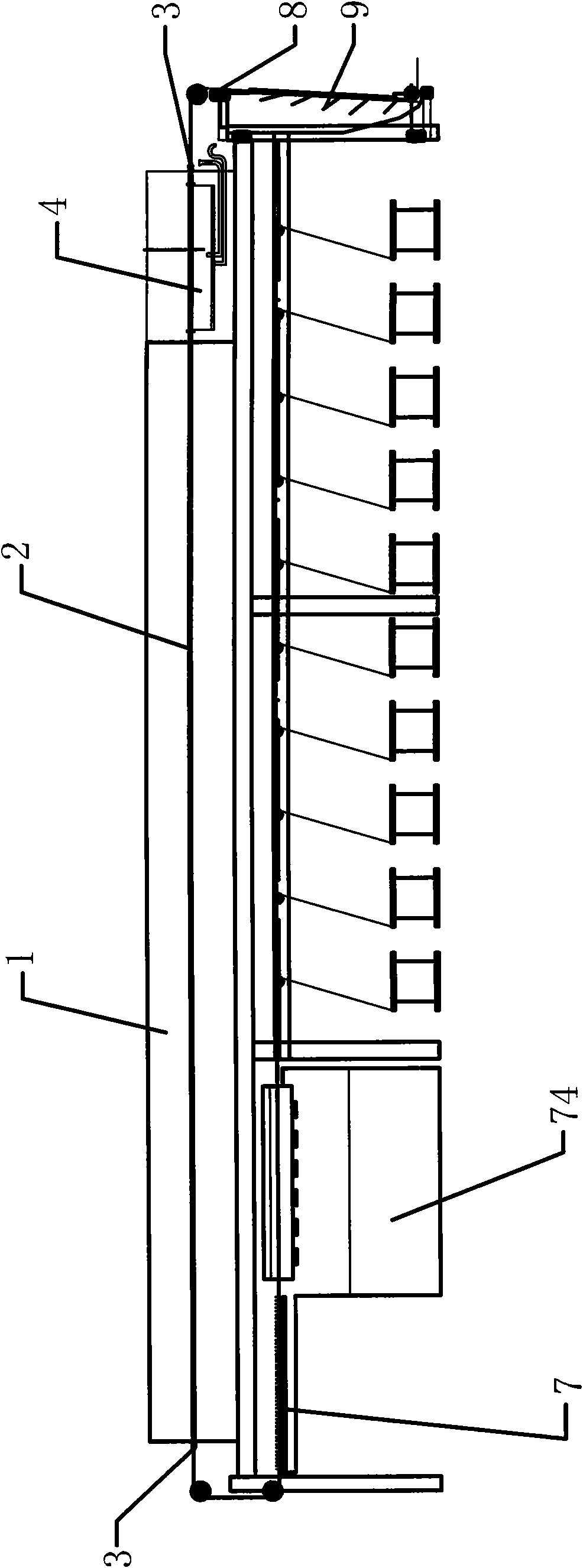

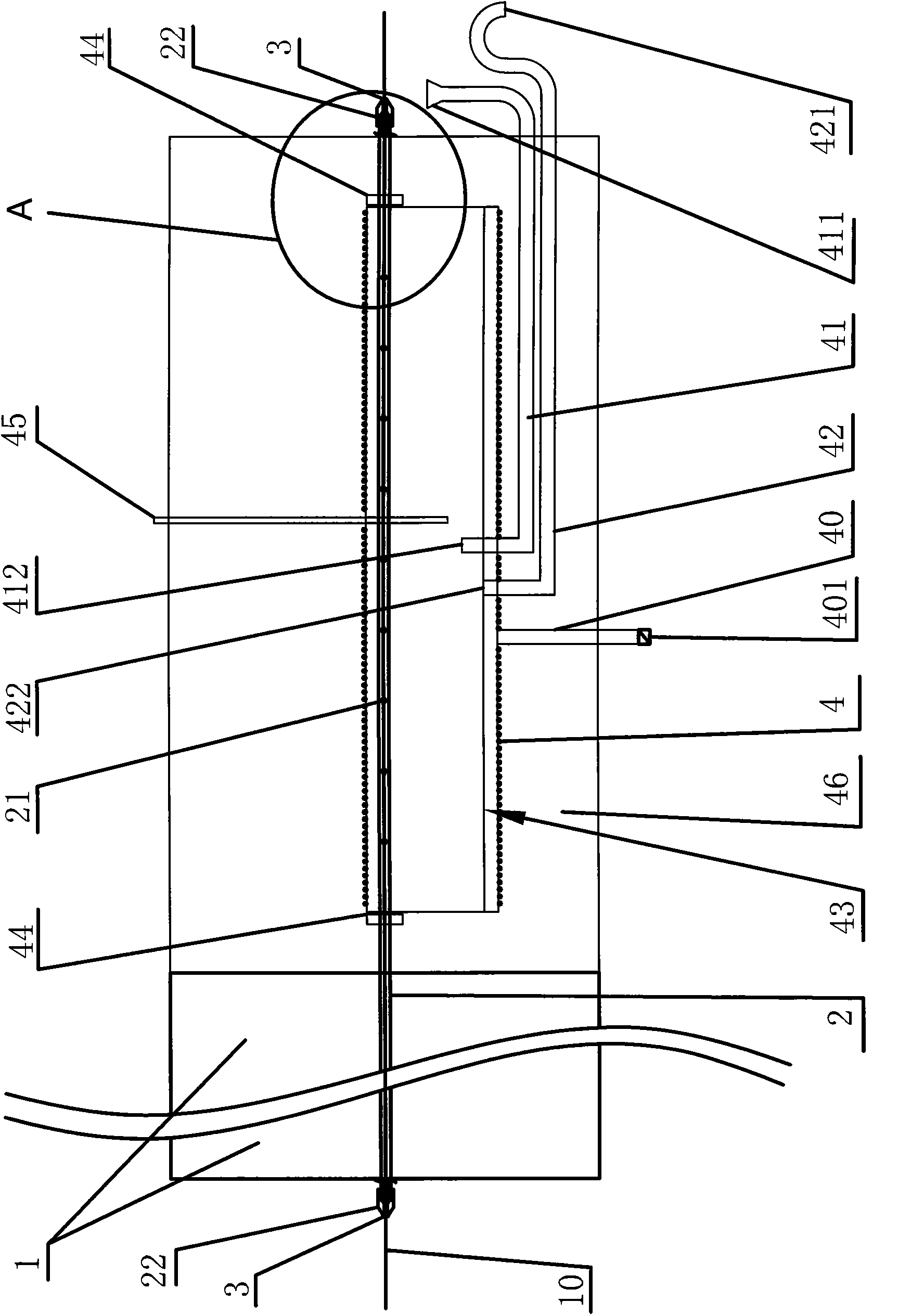

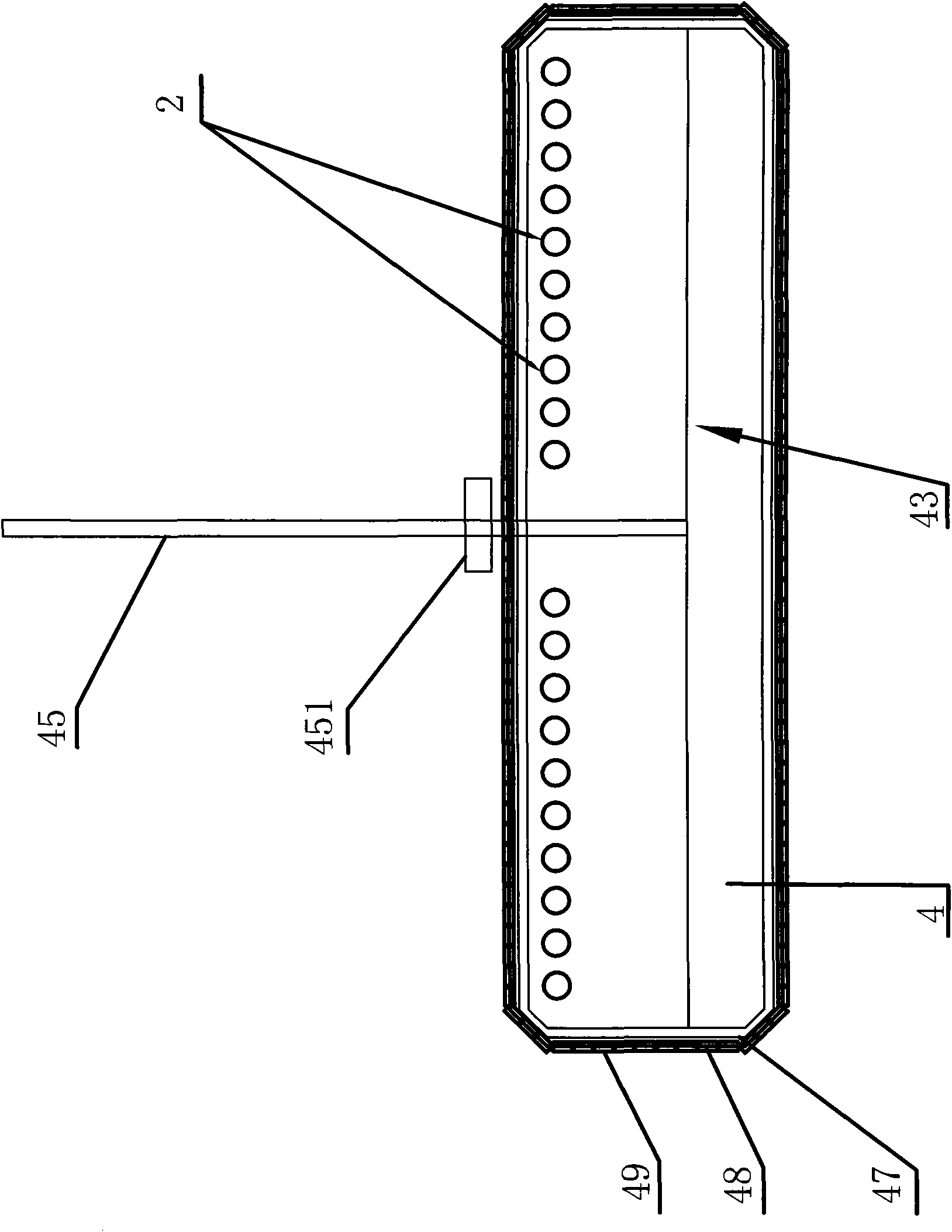

[0031] Embodiment one, such as figure 1 As shown, an energy-saving continuous annealing furnace for wire rods includes a furnace body 1 and several furnace tubes 2 for passing through wire rods 10. The furnace body 1 is placed horizontally, and several furnace tubes 2 are horizontally arranged side by side on the furnace body. 1. A built-in steam generator is installed inside the furnace body 1 close to the outlet of the furnace tube 2; the built-in steam generator includes an inner tank 4, and the furnace tube 2 passes through the inner tank 4 of the built-in steam generator , a number of steam inlets 21 are provided on the wall of the furnace tube 2 inside the liner 4; The tapered guide sleeve 22 of the nozzle and the inlet nozzle is all plugged with a small-diameter ceramic bead hole 3, and the tapered guide sleeve 22 can make the annealed wire 10 pass through the inlet nozzle and the outlet nozzle more conveniently. . The furnace body 1 is placed horizontally and the cer...

Embodiment 2

[0038] Embodiment two, such as Figure 5 to Figure 7 As shown, compared with the first embodiment, the difference of the second embodiment is that a water spray device and a water storage tank 53 are provided, while the built-in steam generator cancels the supplementary bent water pipe 41 . Specifically, the inner tank 4 of the built-in steam generator is provided with a water spray device, which is composed of a spray nozzle 51 connected to the high-pressure water pump 52 outside the furnace body 1; the spray nozzle 51 is inserted into the inner tank 4 and is close to the One end of the furnace tube 2 is provided with a number of water mist inlets 50 on the wall of the furnace tube 2 inside the inner tank 4 and close to the spray nozzle 51, and the water mist inlets 50 are larger than the steam inlet 21; The resistance wire 48 used passes through the furnace tube 2 of the inner container 4 and is close to the top of the inner container 4; The outer water overflow port 421 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com