Anti-oxidation device and method for heat treatment of superalloy

A high-temperature alloy and anti-oxidation technology, which is applied in the direction of heat treatment furnace, heat treatment equipment, process efficiency improvement, etc., can solve the problems of low cost, easy peeling, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

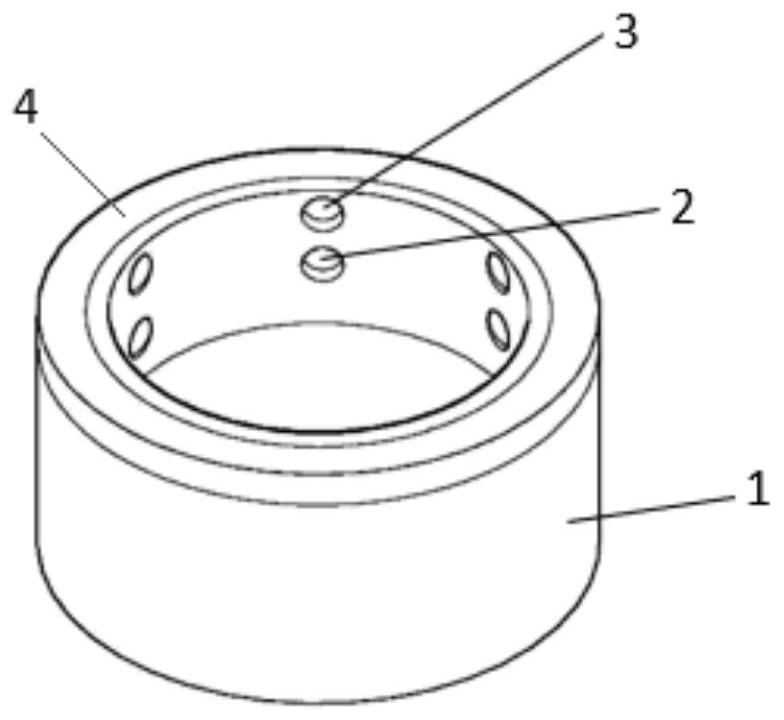

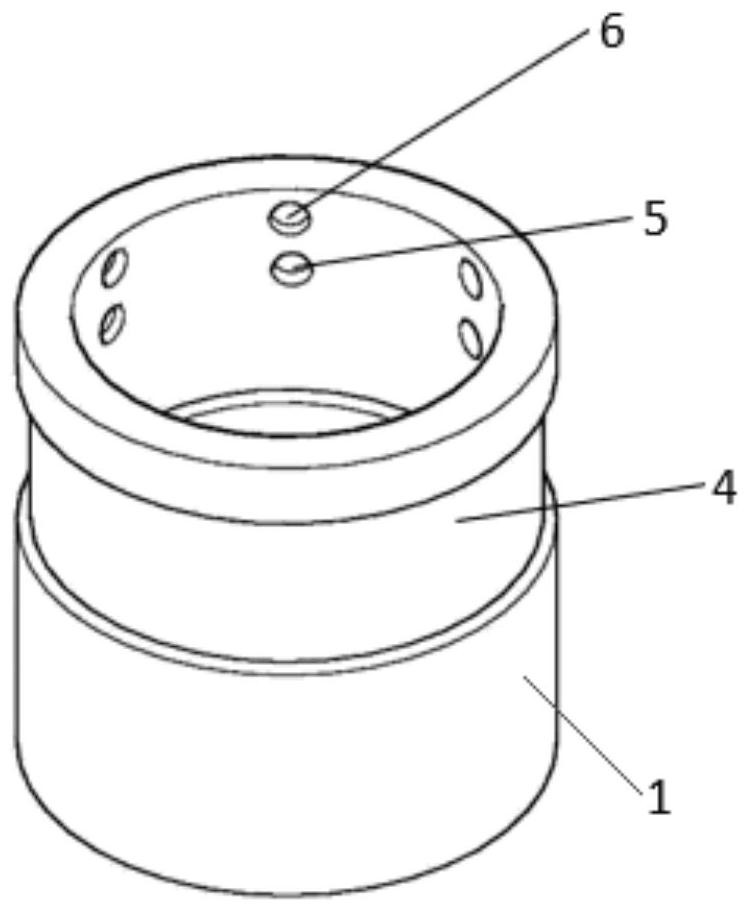

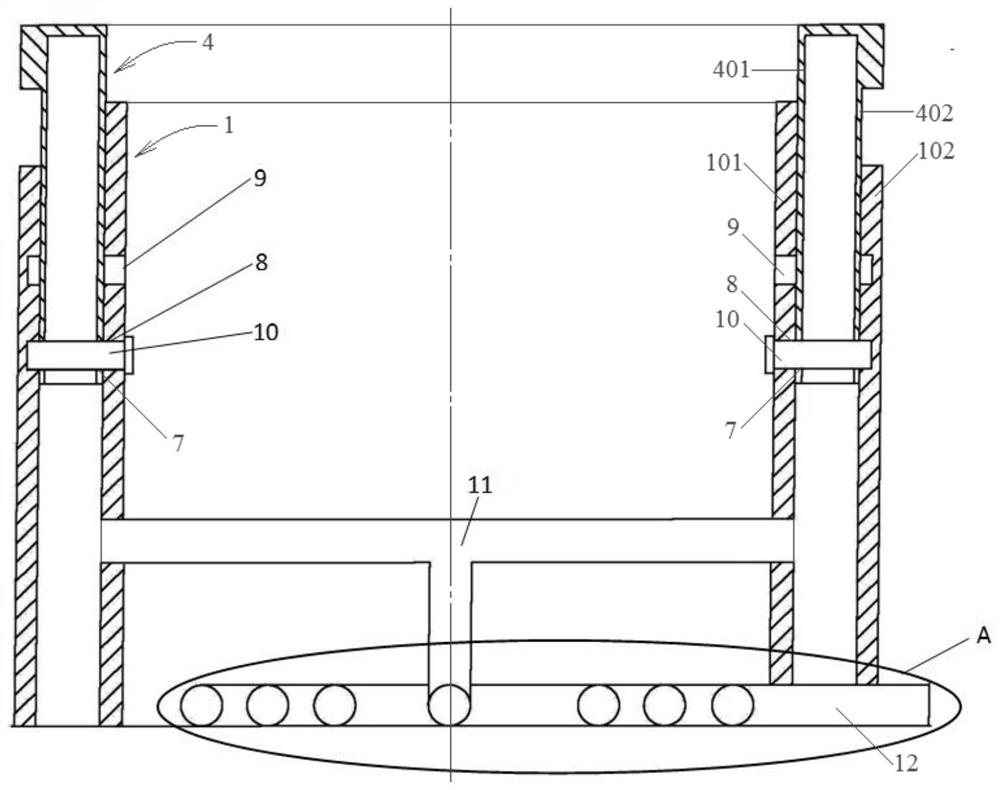

Image

Examples

Embodiment 1

[0042] In the present embodiment, the single crystal nickel-based superalloy DD5 small sample for anti-oxidation solid solution heat treatment, the process steps and parameters are as follows:

[0043] The sample is placed in the center of the stage 11, the heat treatment anti-oxidation device is placed into the heat treatment furnace, the furnace door is closed, the intake pipe 12 is connected to the argon cylinder through the furnace wall hole, the argon cylinder switch is opened, so that the argon output end air pressure is 4kg / cm 2About 5 minutes after ventilation, the heat treatment furnace is heated to a solid solution temperature of 1300 °C, during which argon gas is continuously introduced. After the heat treatment is completed, the heat treatment furnace is closed, and after it has dropped to room temperature, the gas valve is closed, the connection between the intake pipe and the argon bottle is disconnected, and the device is removed with the sample.

Embodiment 2

[0045] In the present embodiment, the sample of the single crystal nickel-based superalloy DD5 is heat treated with an antioxidant solid solution, and the process steps and parameters are as follows:

[0046] The sample is placed in the center of the stage 11, the first fixing hole 7 and the second fixing hole 8 are connected, penetrated into the fixing rod 10 fixed, the heat treatment anti-oxidation device is placed into the heat treatment furnace, the furnace door is closed, the intake pipe 12 is connected to the argon cylinder through the furnace wall hole, the argon cylinder switch is opened, and the argon output end air pressure is 6kg / cm 2 About 5 minutes after ventilation, the heat treatment furnace is heated to a solid solution temperature of 1300 °C, during which argon gas is continuously introduced. After the heat treatment is completed, the heat treatment furnace is closed, and after it has dropped to room temperature, the gas valve is closed, the connection between the...

Embodiment 3

[0048] In the present embodiment, the single crystal nickel-based superalloy DD5 large sample is treated with antioxidant solid solution heat treatment, the process steps and parameters are as follows:

[0049] The sample is placed in the center of the stage 11, the first fixing hole 7 and the third fixing hole 9 are connected, through the fixing rod 10 fixed, the heat treatment anti-oxidation device into the heat treatment furnace, close the furnace door, the intake pipe 12 is connected to the argon cylinder through the furnace wall hole, open the argon cylinder switch, so that the argon output end air pressure at 8kg / cm 2 About 5 minutes after ventilation, the heat treatment furnace is heated to a solid solution temperature of 1300 °C, during which argon gas is continuously introduced. After the heat treatment is completed, the heat treatment furnace is closed, and after it has dropped to room temperature, the gas valve is closed, the connection between the intake pipe and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com