Wire annealing process and device thereof

A wire rod annealing and wire rod technology, used in manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems of fast cooling speed, multiple hidden dangers of quality, and power consumption, avoiding oxidation, reducing energy consumption, and improving performance and quality stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

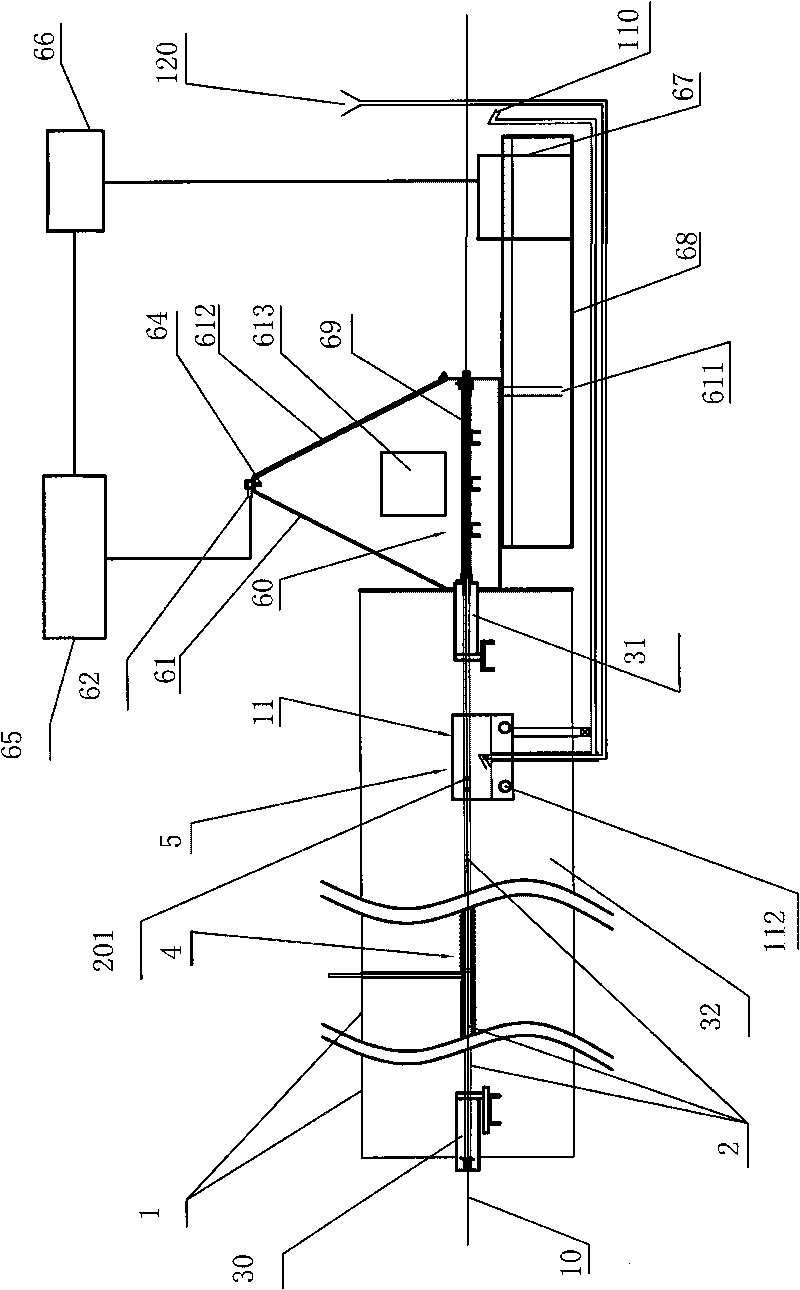

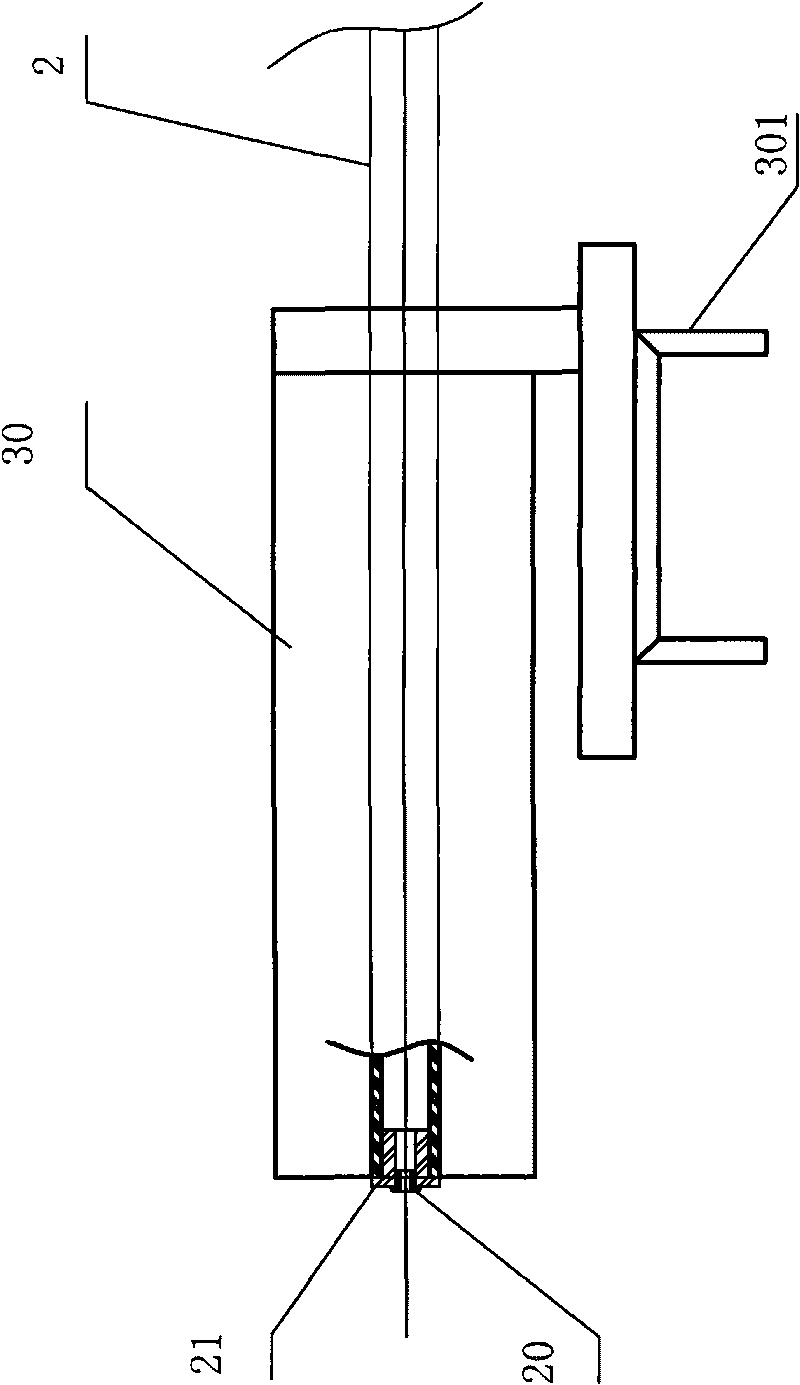

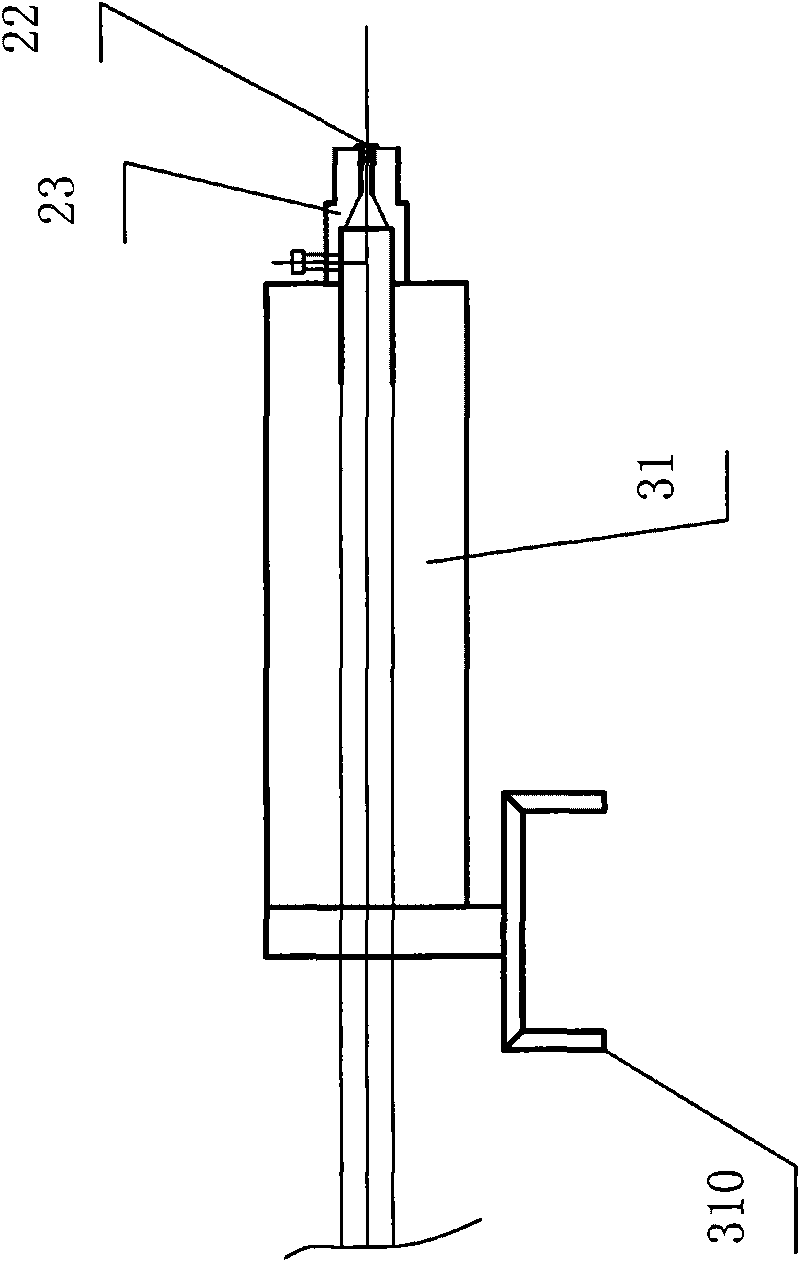

[0046] Below in conjunction with accompanying drawing, the present invention will be further described: Figure 1 to Figure 6 Shown, a kind of wire rod annealing device, it comprises the furnace body 1 of annealing furnace, and furnace body 1 is perforated with several furnace tubes 2 for passing through wire rod 10, and several furnace tubes 2 are arranged side by side at equal intervals to form furnace tube row, and furnace body The middle section of the furnace tube row in 1 is provided with electric heating components to form a high-temperature annealing zone 4. Each furnace tube 2 of the furnace tube row is respectively equipped with a porcelain bead hole sleeve 21 at the inlet pipe mouth, and the porcelain bead hole sleeve 21 is installed with an inlet Porcelain bead holes 20; each furnace tube 2 of the furnace tube row is respectively equipped with an inner outlet guide sleeve 23 with a conical inner hole at the outlet pipe mouth, and the inner outlet guide sleeve 23 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com