Light detection substrate and preparation method thereof, and light detection equipment

A technology for detecting substrates and light, which is applied in the field of photoelectric sensors, can solve the problems of MSM photoelectric characteristics damage, over-engraving, etc., and achieve the effect of improving photoelectric characteristics, avoiding oxidation, and avoiding film thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

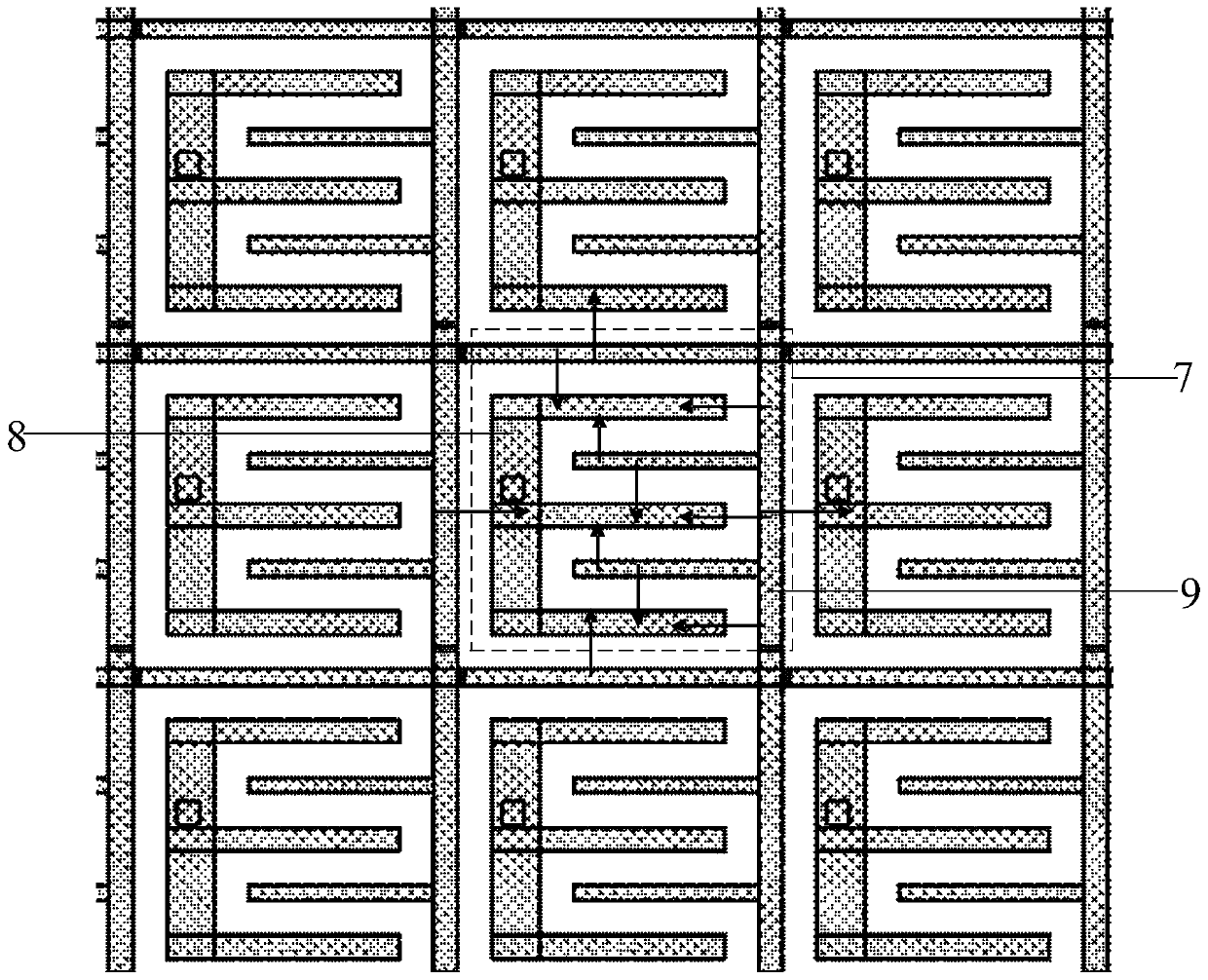

[0037] In order to enable those skilled in the art to better understand the technical solution of the present invention, a light detection substrate, a manufacturing method thereof, and a light detection device of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

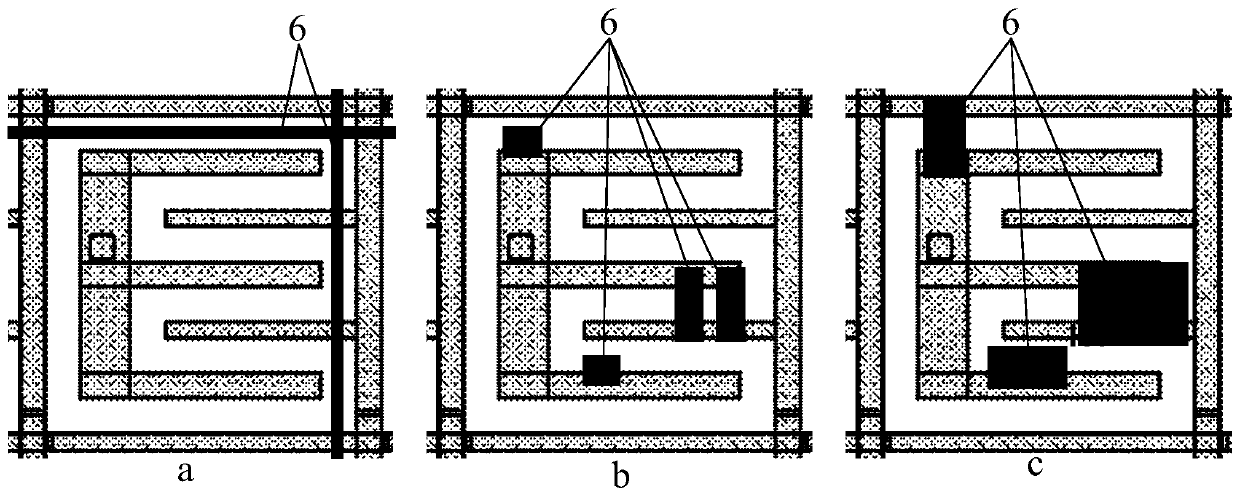

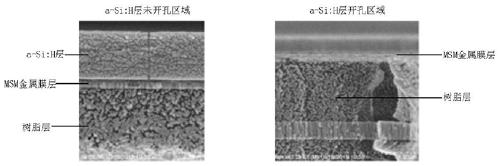

[0038] Metal-semiconductor-metal (Metal-Semiconductor-Metal, MSM) light detection structure has the advantages of fast response, small capacitance, simple process and easy integration, so it is widely used in the field of semiconductor detection, especially with various TFT backplanes Integrated as X-ray (X-ray) flat panel detector. Semiconductors in MSM light detectors usually use hydrogenated amorphous silicon a-Si:H. The active layer of the TFT used to output electrical signals in the TFT backplane usually uses a semiconductor metal oxide, such as IGZO.

[0039]Due to the influence of the a-Si:H (hydrogenated amorphous silicon)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Slope angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com