LED packaging structure and forming method thereof

A technology of LED packaging and LED chips, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of easy oxidation of fluorescent grease, affecting the service life of devices, accelerated aging, etc., to optimize the uniformity of light output and improve the use of Longevity, avoid the effect of easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

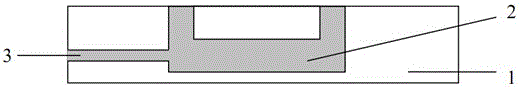

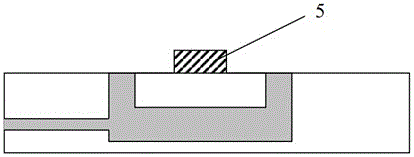

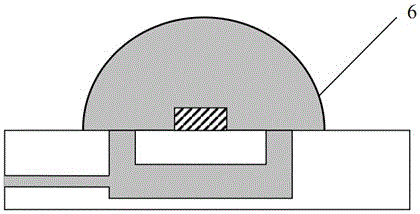

[0028] see Figure 4 , 5 The LED packaging structure of the present invention includes a heat dissipation substrate 1, an LED chip 5 arranged on the heat dissipation substrate 1, and a transparent cover 6 for sealing the LED chip 5, the transparent cover 6 and the heat dissipation substrate 1 The heat dissipation substrate 1 has a heat dissipation channel 2 inside, and the heat dissipation channel 2 communicates with the enclosed space, and the heat dissipation channel 2 and the enclosed space are filled with a fluid 8, and the fluid 8 can It is a colloid in which fluorescent powder is evenly distributed, and the fluid 8 may also be a liquid in which metal particles and / or fluorescent powder are dispersed, and the dispersion medium is oil. Wherein, said transparent cover body 6 can be glass or plastic etc., and its shape is hemispherical (such as Figure 4 shown), ellipsoidal or square (as Figure 6 shown), the heat dissipation channel 2 communicates with the enclosed space...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com