Backlight module and light source assembly thereof

A technology of light source components and backlight modules, applied in the field of backlight modules, can solve problems such as unfavorable thin design and thick thickness of backlight modules, and achieve the effects of avoiding bright light sources and shortening light mixing distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

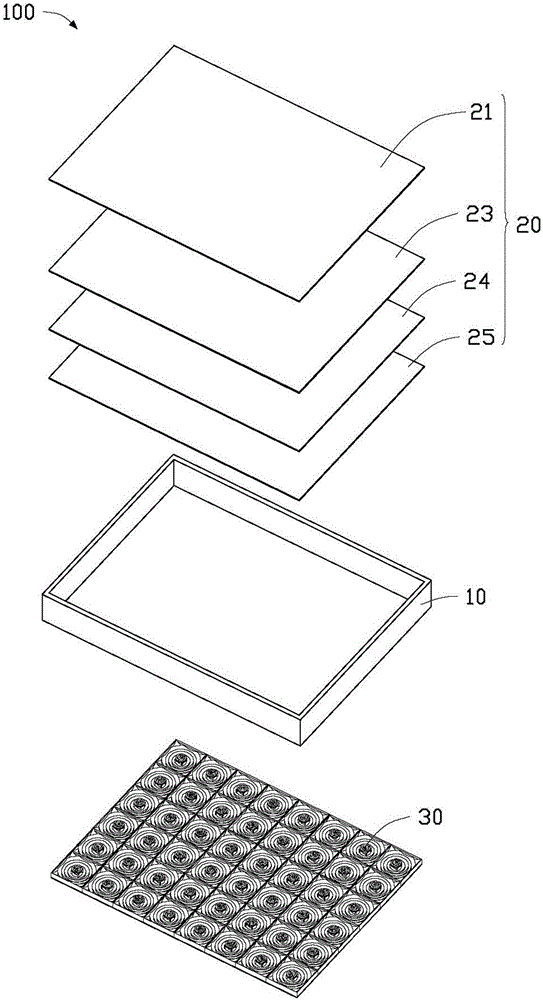

[0016] see figure 1 The backlight module 100 according to the embodiment of the present invention includes a frame body 10 , an optical film set 20 accommodated in the frame body 10 , and a plurality of light source assemblies 30 accommodated in the frame body 10 and located below the optical film set 20 . Multiple light source assemblies 30 are arranged in matrix.

[0017] The frame body 10 is made of metal or plastic with high reflectivity. It can be understood that the frame body 10 can also be made of metal or plastic coated with a high-reflectivity coating.

[0018] The optical film set 20 includes a plurality of optical elements. Preferably, the plurality of optical elements are a diffusion sheet 21 , a prism sheet 23 , a diffusion sheet 24 and a diffusion plate 25 which are stacked.

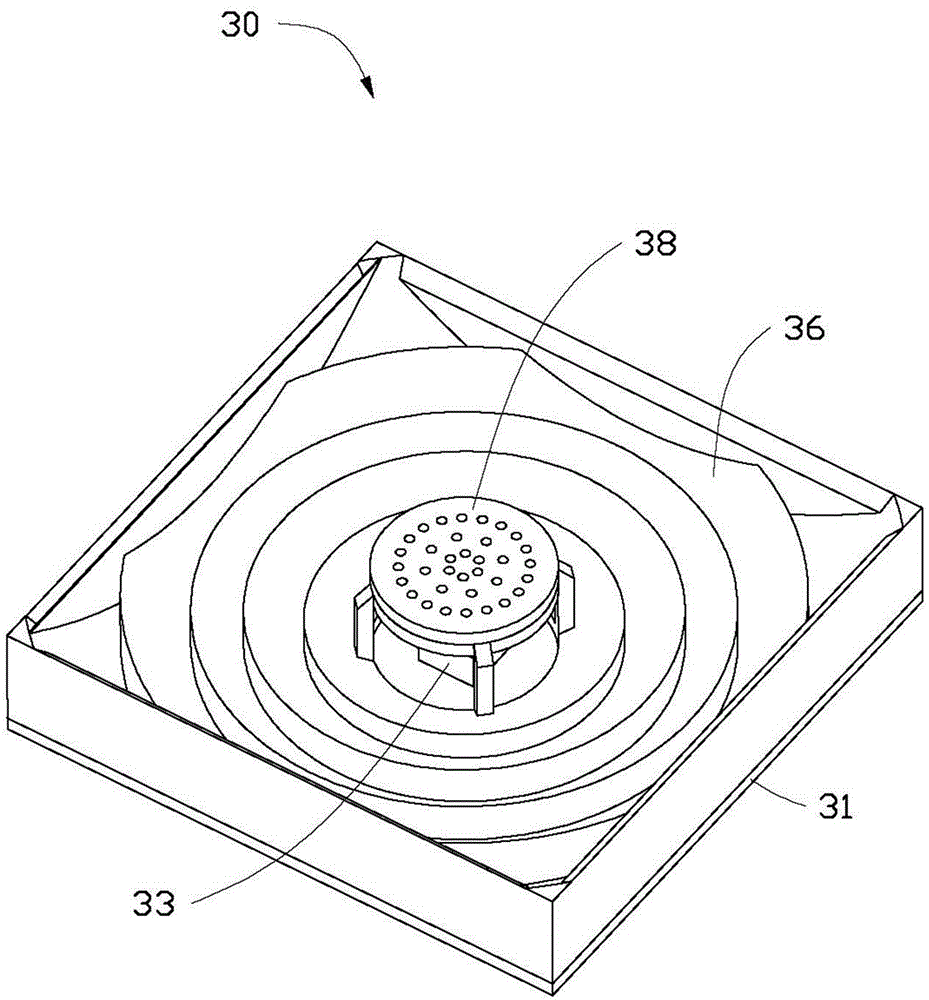

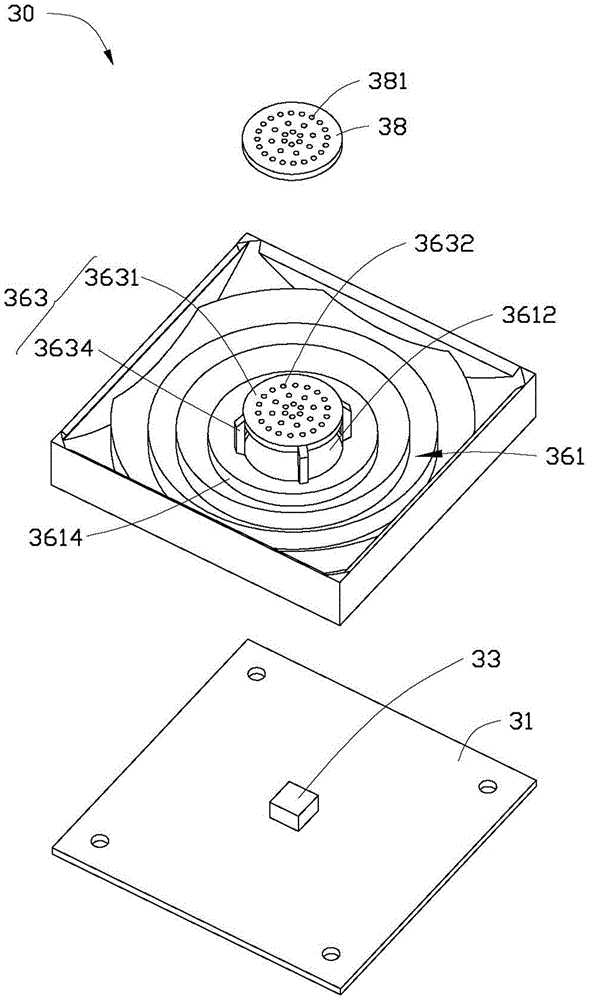

[0019] Please also refer to Figure 2 to Figure 4 . Each light source assembly 30 includes a substrate 31 , an LED light source 33 fixed in the middle of the substrate 31 , a packagin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com