LED encapsulating structure and method thereof

A technology of light-emitting diodes and packaging structures, which is applied in the direction of electrical components, electric solid-state devices, circuits, etc., can solve problems such as uneven lighting, reduced luminous brightness, and poor light spots, so as to achieve uniform light output, no decrease in brightness, and increased uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

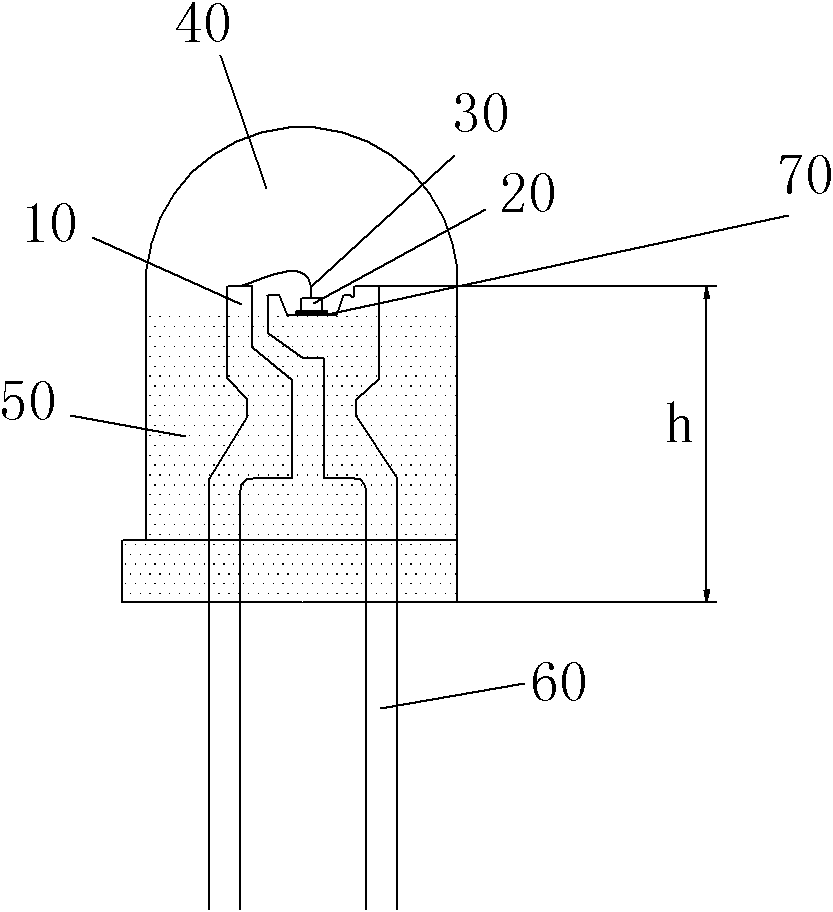

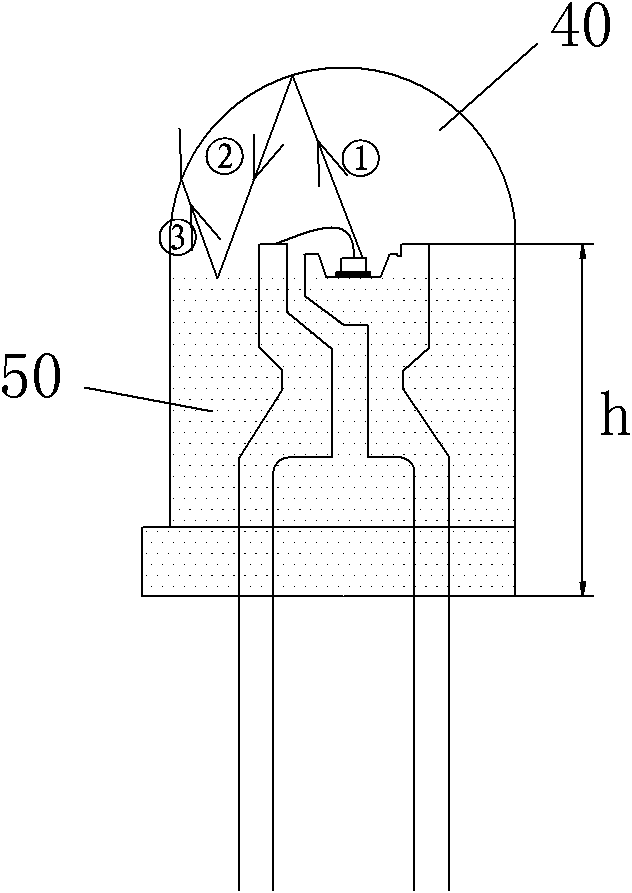

[0024] see figure 2 , embodiments of the light emitting diode packaging structure of the present invention include:

[0025] The bracket 10, the LED chip 20, the wire 30, and the transparent outer sealant 40 connected up and down in layers and the outer sealant 50 added with a diffusing agent;

[0026] The bracket 10 includes two parallel electrodes 60, one end of the electrodes 60 is provided with a groove receiving seat, and the LED chip 20 is fixed on the bottom of the groove receiving seat through a primer 70;

[0027] One end of the wire 30 is connected to the LED chip 20, and the other end is connected to the bracket 10;

[0028] The transparent outer sealant 40 and the outer sealant 50 added with diffusing agent cover the bracket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com