High power LED bulb

An LED light bulb, high-power technology, applied in the direction of lampshade, cooling/heating device of lighting device, lighting and heating equipment, etc., can solve the problems of low light efficiency, complex production process, and difficulty in comprehensive promotion, and achieve heat dissipation effect. Better, high luminous efficiency, compact and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

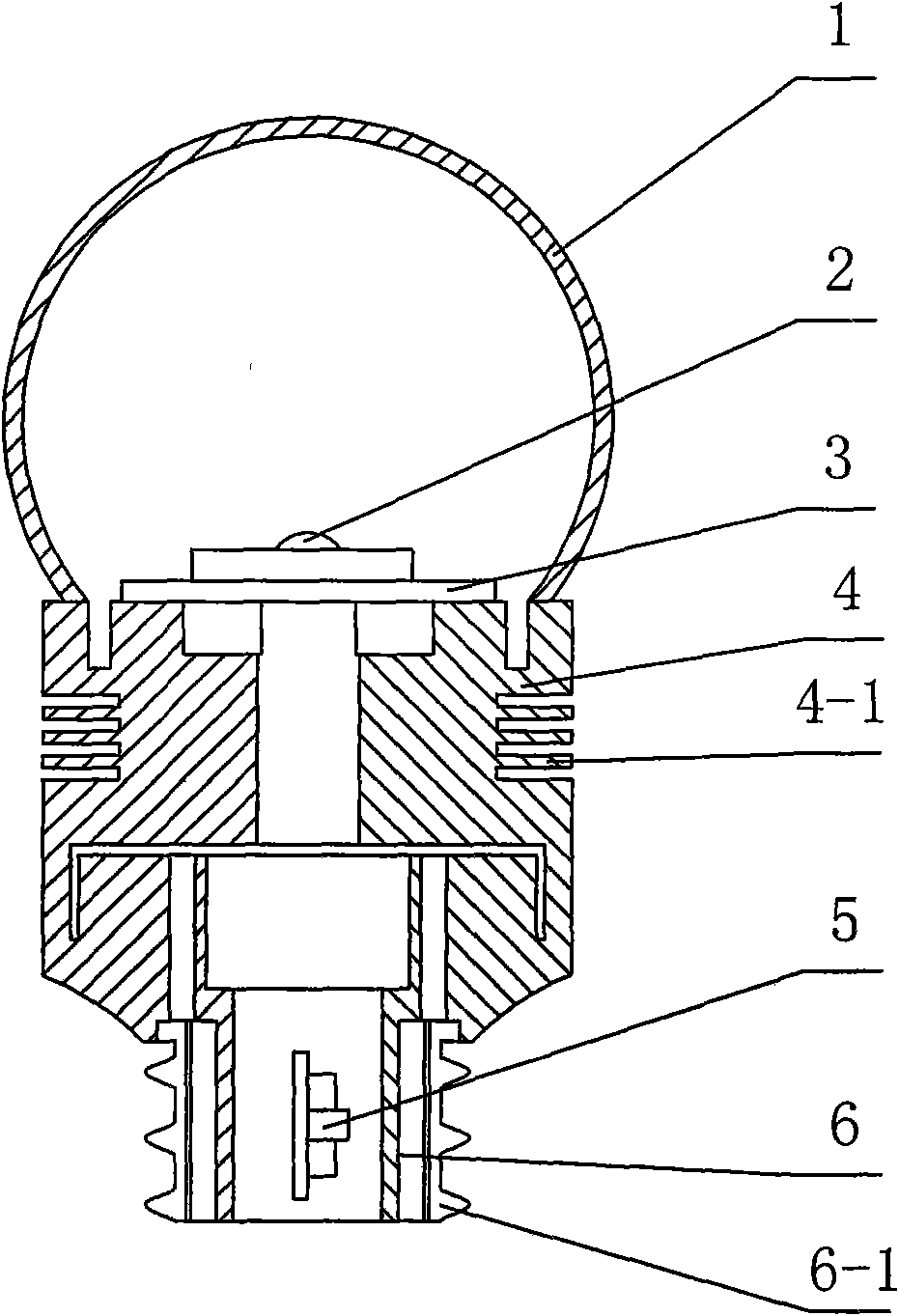

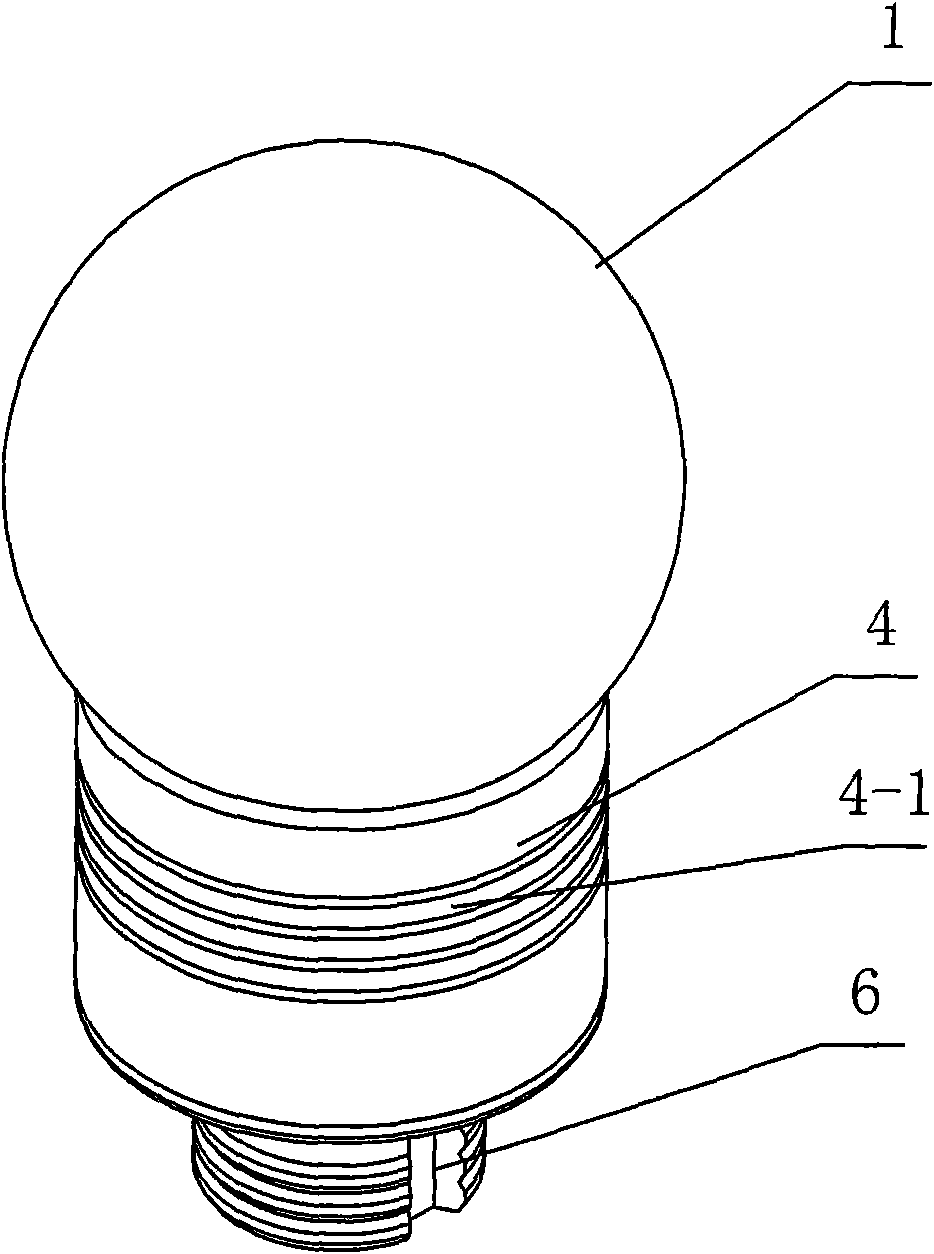

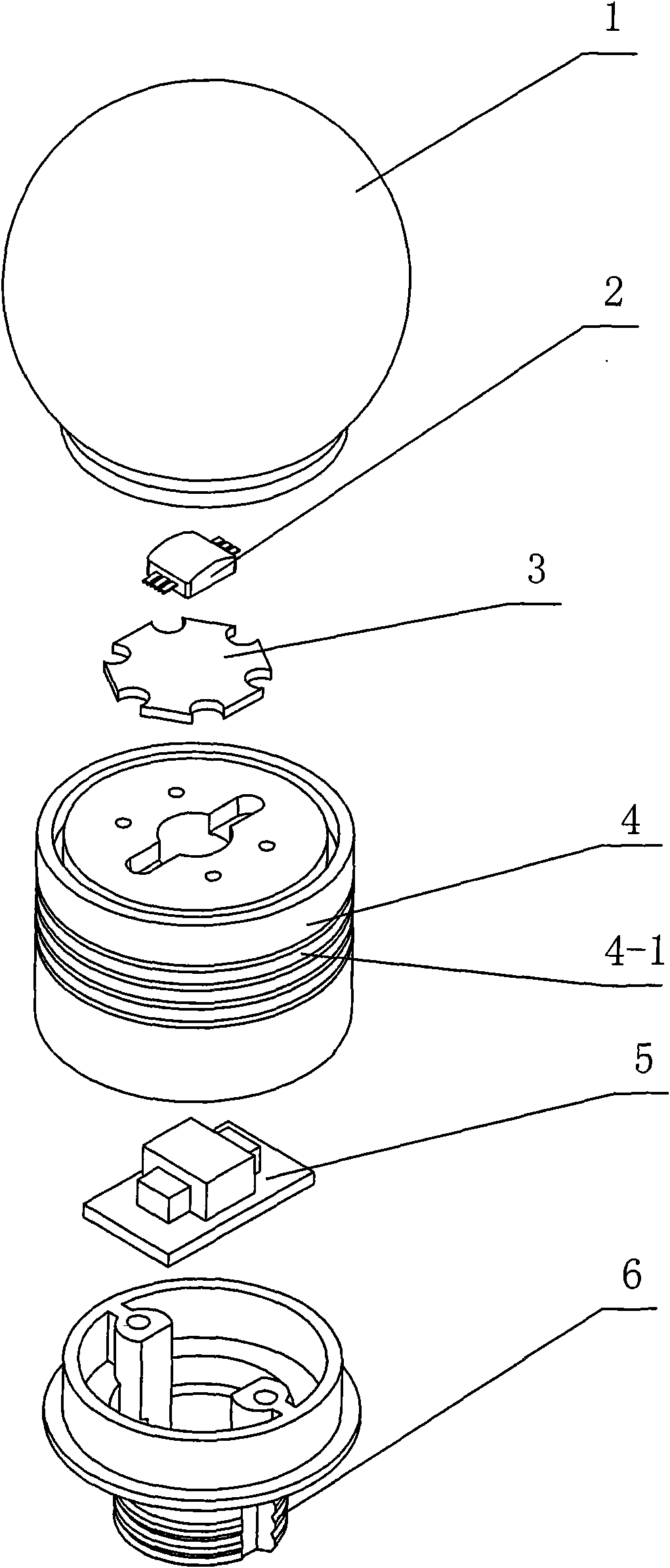

[0017] Such as figure 1 , figure 2 , image 3 , a high-power LED light bulb shown, including a joint 6 for connecting with the lighting fixture interface, an LED constant current drive device 5, a radiator 4, an LED light source 2, a bulb cover 1 and a circuit board 3. The joint 6 has a cavity, and its lower end has a thick thread 6-1, the LED constant current driving device 5 is fixed in the cavity, and can be matched with a conventional lamp interface. The connector 6 is preferably molded at one time by ceramic mold opening, which not only insulates, but also has good heat conduction and heat dissipation effects, and can protect the constant current drive device 5. In addition, materials such as nylon and ABS can also be selected, but the effect is inferior. Radiator 4 is a ceramic radiator with annular fins 4-1, with threading holes inside, and a cavity matching joint 6 at its lower part, which is also used to place constant current drive device 5, the upper part of joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com