Improved LED packaging method and packaging structure

A technology of LED encapsulation and encapsulation method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as high cost and complicated operation, and achieve low cost, broad application prospects, and the effect of improving luminous brightness and heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

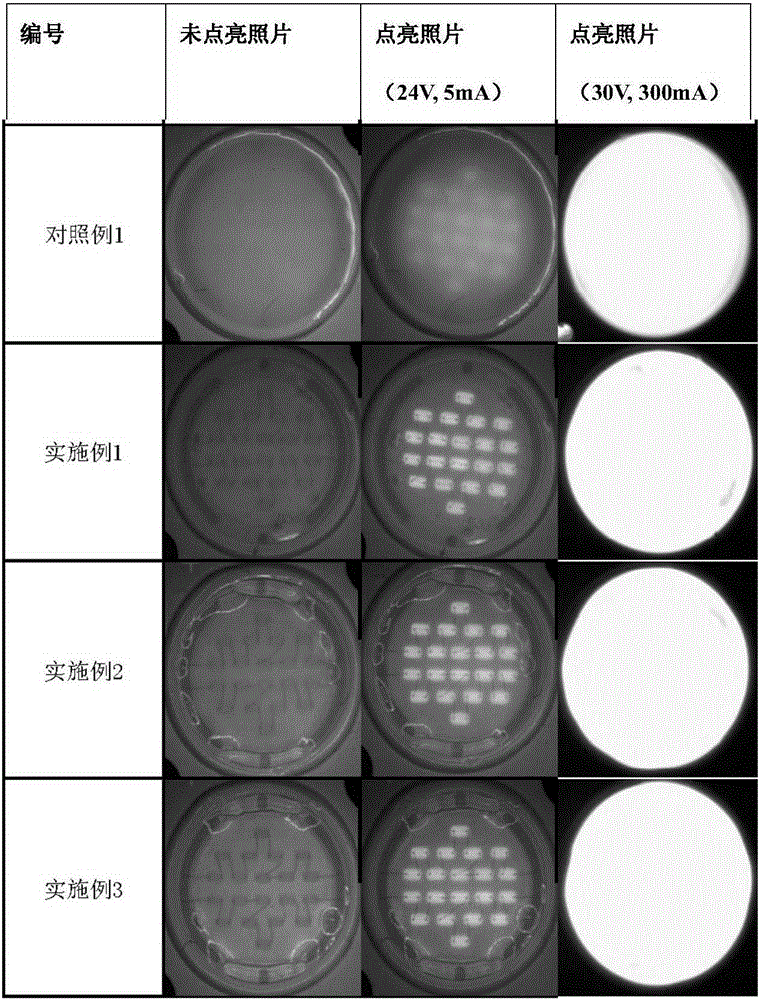

Embodiment 1

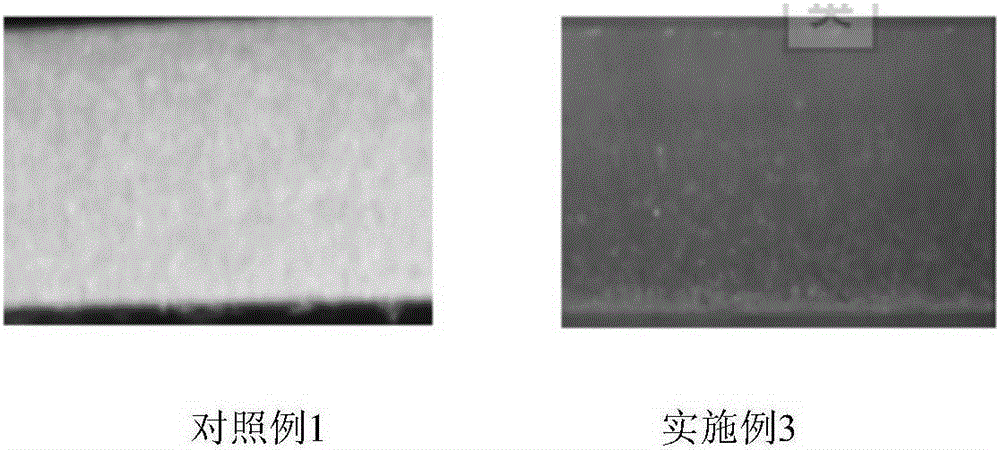

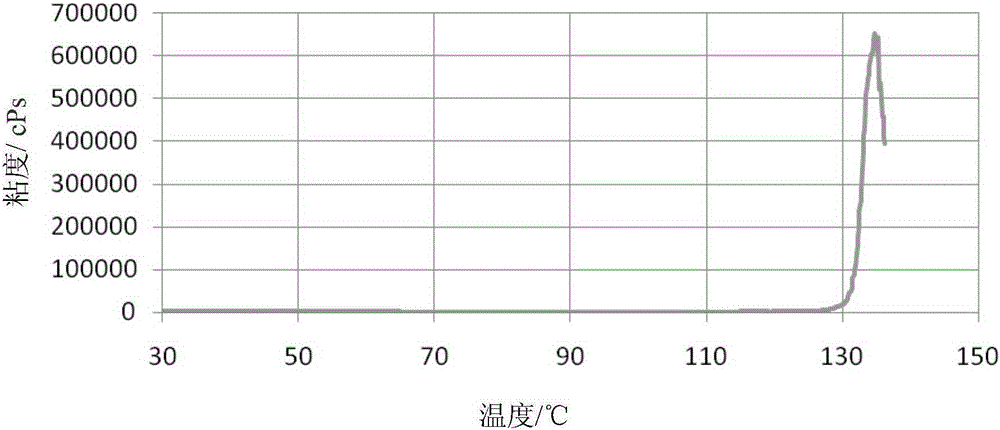

[0084] The LED packaging method of Example 1 includes: injecting the mixture of phosphor powder and organic silica gel into the chip holder that has completed the crystal bonding and gold wire binding by dispensing, completing the phosphor powder coating on the surface of the LED chip, and then heating the LED chip at temperature Stand in an environment of 60°C for 2 hours (this operation can be done on a heating platform), and finally cure at a temperature of 150°C for 4 hours.

[0085] The LED packaging methods of Examples 2 and 3 are basically the same, including: injecting the mixture of phosphor powder and organic silica gel into the chip holder that has completed the crystal bonding and gold wire binding by dispensing, and completing the phosphor powder coating on the surface of the LED chip. Cover, then let it stand for 2 hours in an environment with a temperature of 60°C (this operation can be done on a heating platform), then let it stand for 1 hour in an environment w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com